Home>Articles>What Is The Difference Between Electric Motor And Generator

Articles

What Is The Difference Between Electric Motor And Generator

Modified: October 20, 2024

Discover the key distinctions between electric motors and generators in this insightful article. Explore the inner workings and functions of these essential devices.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Electric motors and generators are two essential devices used in various industries and applications. These devices are often mentioned in discussions about electricity and power generation. While they may seem similar because of their reliance on electromagnetism, electric motors and generators actually serve different purposes in the world of electrical engineering.

In this article, we will delve into the intricacies of electric motors and generators, exploring their differences, functionalities, and applications. Understanding these key distinctions will provide you with a comprehensive knowledge of these devices and their crucial roles in powering the modern world.

So, let’s embark on a journey to unravel the differences between electric motors and generators, and gain insights into their inner workings.

Key Takeaways:

- Electric motors convert electrical energy into mechanical energy, powering machinery, appliances, and transportation. Generators, on the other hand, convert mechanical energy into electrical energy, crucial for power generation and backup solutions.

- Understanding the differences between electric motors and generators is essential, as they play vital roles in powering our modern world. From driving machinery to generating electricity, these devices drive progress and improve our quality of life.

Basic Principles

To understand the differences between electric motors and generators, let’s start by examining their basic principles of operation.

An electric motor is a device that converts electrical energy into mechanical energy. It operates on the principle of electromagnetic induction, where a current-carrying conductor placed in a magnetic field experiences a force that causes it to move. This movement is harnessed to produce mechanical work, such as rotating a shaft or driving a mechanism.

On the other hand, a generator functions in the opposite way. It converts mechanical energy into electrical energy. Generators operate on the principle of electromagnetic induction as well, but in reverse. When a conductor moves through a magnetic field, or a magnetic field moves around a conductor, it induces an electric current in the conductor. This current can be used to power electrical devices or be stored for later use.

Both electric motors and generators rely on the interaction between magnetic fields and electrical currents to function. However, the direction in which energy is converted determines whether a device operates as a motor or a generator.

In summary, electric motors convert electrical energy into mechanical energy, while generators convert mechanical energy into electrical energy. This fundamental distinction sets them apart and determines their respective roles in electrical systems.

Construction and Components

Electric motors and generators have similar construction and share some common components, but certain variations exist to fulfill their specific functions. Let’s explore the construction and key components of both devices.

An electric motor typically consists of several main components, including a stator, rotor, and commutator or brushes. The stator is a stationary part of the motor and comprises coils or windings wound around an iron core. These coils generate a magnetic field when an electric current passes through them.

The rotor, on the other hand, is the rotating part of the motor. It consists of a shaft and a set of armature coils or permanent magnets. The magnetic field produced by the stator interacts with the magnetic field of the rotor, causing the rotor to rotate.

In some electric motors, a commutator is used to control the direction of the current flow in the rotor. The commutator consists of conductive segments that are connected to the armature coils. Brushes, typically made of carbon or graphite, make contact with the segments and allow the current to flow in the appropriate direction, thus enabling continuous rotation of the rotor.

On the other hand, generators have similar construction but with some key differences. A generator comprises a rotor, stator, and brushes. The rotor, also known as the armature, includes coils or permanent magnets and is responsible for generating the magnetic field.

The stator, in contrast, is the stationary part of the generator. It consists of a set of coils or windings that surround the rotor. When the rotor rotates, it induces a current in the stator windings using the principle of electromagnetic induction.

To collect the generated electrical energy, generators use brushes and slip rings instead of a commutator. The brushes press against the slip rings, which are electrical conductors connected to the rotor coils or magnets, allowing the current to be extracted and used for external purposes.

In summary, both electric motors and generators consist of stators and rotors, but motor rotors rotate due to the interaction with the stator’s magnetic field, while generator rotors produce the magnetic field to induce current in the stator windings. The presence of a commutator or slip rings also differs, depending on the device’s function.

Flow of Energy

Understanding the flow of energy is crucial in discerning the differences between electric motors and generators. Let’s delve into how energy flows through these devices.

In an electric motor, the flow of energy is unidirectional. Electrical energy is supplied to the motor, which is then converted into mechanical energy. The electrical current flows through the motor’s coils, creating a magnetic field that interacts with the rotor’s magnetic field. This interaction generates a torque that causes the rotor to rotate, thereby converting electrical energy into mechanical energy.

On the other hand, in a generator, the flow of energy is bidirectional. Mechanical energy is applied to the generator, which is then converted into electrical energy. The prime mover, such as a steam turbine or a water turbine, rotates the generator’s rotor. As the rotor spins, it induces a current in the stator coils through electromagnetic induction, resulting in the generation of electrical energy.

It is important to note that the flow of energy in a motor is from electrical to mechanical, while the flow of energy in a generator is from mechanical to electrical. This distinction arises from the fundamental purpose of each device.

In summary, electric motors convert electrical energy into mechanical energy, while generators convert mechanical energy into electrical energy. The flow of energy in a motor is unidirectional, whereas in a generator, it is bidirectional, depending on the supplied input.

Direction of Current

The direction of current is an essential factor that distinguishes electric motors from generators. Let’s explore how the direction of current differs in these devices.

In an electric motor, the direction of current flow remains constant. The electrical energy is supplied to the motor, and the current flows through the coils, creating a magnetic field that interacts with the rotor. This interaction causes the rotor to rotate in a specific direction, resulting in the desired mechanical output.

On the other hand, in a generator, the direction of current flow depends on the motion of the rotor in relation to the stator’s magnetic field. When the rotor rotates in one direction, the induced current flows in one direction. However, if the rotor rotates in the opposite direction, the induced current also changes direction.

This phenomenon is known as the “Lenz’s Law” which states that the direction of the induced current will always oppose the change that caused it. As a result, the directional change of the induced current in a generator is a direct consequence of the rotation of the rotor.

It is important to note that the direction of current flow in a motor remains constant as long as the electrical input is maintained. However, in a generator, the direction of current flow changes depending on the rotation of the rotor.

In summary, electric motors have a constant direction of current flow, while generators have a variable direction of current flow based on the motion of the rotor. This distinction highlights the differences in the operating principles between these two devices.

An electric motor converts electrical energy into mechanical energy to produce motion, while a generator converts mechanical energy into electrical energy. Remember, motors move, generators generate.

Functionality

The functionality of electric motors and generators is one of the key factors that differentiate them. Let’s explore how these devices operate and what purposes they serve.

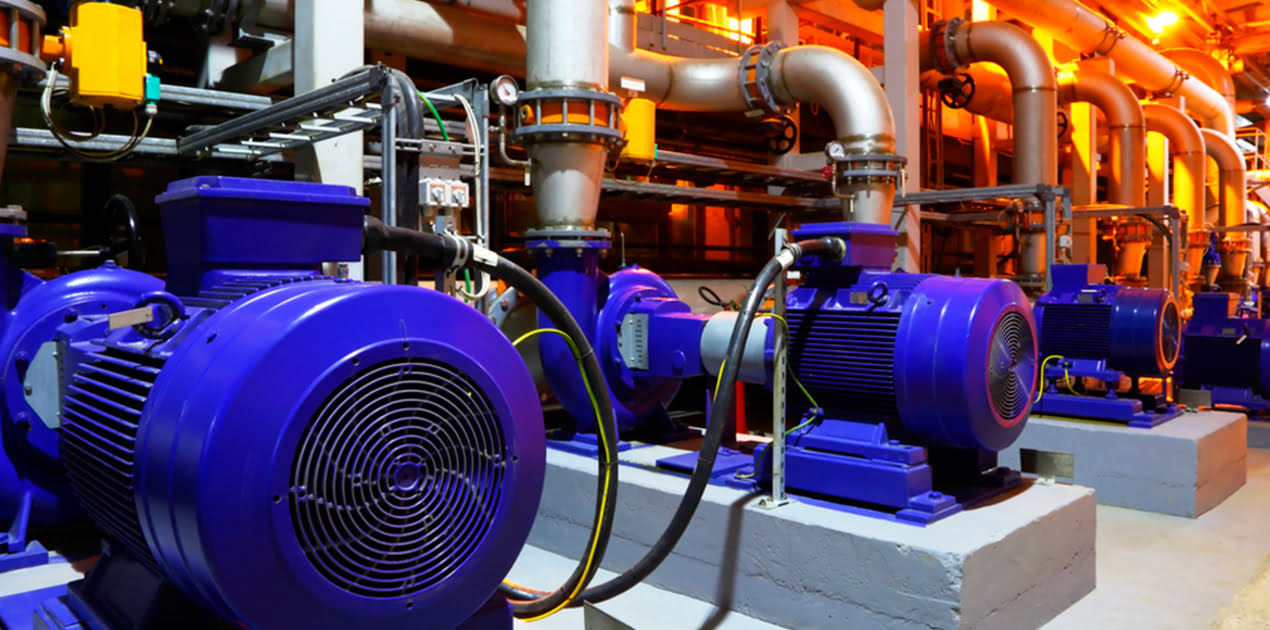

An electric motor is primarily designed to convert electrical energy into mechanical energy. It serves as a power source for various applications, such as driving machinery, operating pumps, rotating fans, and powering vehicles. Electric motors are widely used in industries, homes, and transportation sectors to provide mechanical motion and power in a controlled manner.

Electric motors come in different types, including AC motors and DC motors. AC motors are commonly found in household appliances and industrial equipment, while DC motors are often used in battery-powered devices and automotive applications.

Conversely, a generator functions to convert mechanical energy into electrical energy. It is utilized in power generation systems to produce electricity on a large scale. Generators are crucial in power plants, where they are driven by steam, water, or gas turbines to convert mechanical energy into electricity. They can also be used as backup power sources during blackouts or in remote areas without access to the electrical grid.

Generators can be classified into different types based on their design and application, such as diesel generators, gas generators, wind turbines, and hydroelectric generators. Each type has its advantages and is chosen based on factors like fuel availability, environmental considerations, and power requirements.

In summary, electric motors are primarily used to convert electrical energy into mechanical energy, while generators are utilized to convert mechanical energy into electrical energy for power generation purposes. The functionality of these devices depends on the direction of energy flow, making them integral components in various industries and applications.

Output

The output of electric motors and generators is another important aspect that sets them apart. Let’s explore how the output of these devices differs.

An electric motor produces mechanical output, which can be in the form of rotational motion or linear motion, depending on the design and application. The rotational motion output is commonly used in machinery and equipment to drive pumps, compressors, conveyors, and other mechanical systems. Linear motion output, on the other hand, is utilized in applications such as lifts, elevators, and actuators.

The power output of an electric motor is measured in terms of torque and rotational speed. Torque refers to the rotational force exerted by the motor, while rotational speed indicates the rate at which the motor rotates. The power output of a motor is the product of torque and rotational speed and is usually expressed in terms of kilowatts or horsepower.

On the flip side, a generator produces electrical output. The electrical energy generated by the generator can be in the form of alternating current (AC) or direct current (DC), depending on the design and configuration. The power output of a generator is typically measured in terms of kilowatts or megawatts.

The voltage and frequency of the electrical output from a generator depend on the specific requirements of the application. In power plants, generators produce high-voltage AC electricity that is then stepped up through transformers for efficient transmission over long distances. In residential and commercial settings, the output voltage is stepped down for utilization by electrical appliances and devices.

In summary, electric motors produce mechanical output in the form of rotational or linear motion, while generators produce electrical output in the form of AC or DC electricity. The output characteristics of these devices are tailored to meet the specific requirements of different applications, making them vital components in numerous industries and power generation systems.

Efficiency

The efficiency of electric motors and generators is a crucial aspect that determines their performance and energy consumption. Let’s delve into how efficiency is measured and how it differs between these devices.

Electric motors have a relatively high efficiency, typically ranging from 80% to 95%. Efficiency is the ratio of the useful work output by the motor to the electrical energy input. In other words, it measures how effectively the motor converts electrical energy into mechanical energy without significant losses.

The efficiency of an electric motor is influenced by factors such as the design, size, and quality of its components, as well as the operating conditions. High-quality motors with optimized designs and low-friction components tend to have higher efficiency, resulting in reduced energy consumption and cost savings.

On the other hand, the efficiency of generators can vary depending on the type and size of the generator. Large-scale power generation systems, such as those found in power plants, typically have high efficiency, often exceeding 95%. This is because these systems are designed with advanced technologies and optimized to maximize the conversion of mechanical energy into electrical energy.

However, smaller generators, such as portable gasoline or diesel generators, have lower efficiency, typically ranging from 70% to 90%. The efficiency of these generators can be influenced by factors such as engine design, fuel quality, and maintenance. It is important to note that efficiency can decrease at lower loads, as generators operate less efficiently when not operating near their rated capacity.

Overall, the efficiency of both electric motors and generators is an important consideration as it directly impacts energy consumption and operating costs. Choosing high-efficiency devices can lead to significant energy savings and environmental benefits.

In summary, electric motors are known for their high efficiency in converting electrical energy into mechanical energy, while the efficiency of generators can vary depending on their size and type. The efficiency of these devices is influenced by various factors, such as design, component quality, and operating conditions, making it essential to consider efficiency when selecting motors and generators for specific applications.

Applications

Electric motors and generators find applications in a wide range of industries and fields. Let’s explore the diverse uses of these devices in different sectors.

Electric motors are ubiquitous in our daily lives, powering numerous appliances and machinery. They are extensively used in industrial settings for driving pumps, compressors, conveyor belts, and manufacturing equipment. Electric motors are also found in household appliances such as refrigerators, washing machines, fans, air conditioners, and power tools.

In the transportation sector, electric motors play a vital role in electric vehicles, powering their propulsion systems. From electric cars to trains and even aircraft, the use of electric motors is steadily increasing to reduce emissions and improve energy efficiency.

Generators, on the other hand, are widely used in power generation systems. They play a central role in traditional fossil fuel power plants, hydroelectric power plants, and nuclear power plants. These generators convert mechanical energy from turbines driven by steam, water, or gas into electrical energy to meet the growing demand for electricity.

Generators are also essential in renewable energy systems. Wind turbines utilize generators to convert the rotational motion of the turbine blades driven by wind into electricity. Similarly, hydroelectric power plants rely on generators to convert the energy from flowing or falling water into electrical power.

Portable generators, often powered by gasoline or diesel engines, provide a convenient source of backup power during power outages or in remote locations where access to the electrical grid is limited. They are commonly used in construction sites, outdoor events, camping, and recreational activities.

The applications of electric motors and generators continue to expand as new technologies and advancements take place. From robotics to medical equipment, renewable energy systems to industrial automation, these devices are integral components that drive innovation and power essential operations across various sectors.

In summary, electric motors find applications in industrial machinery, household appliances, and transportation systems, while generators are crucial in power plants, renewable energy systems, and portable backup power solutions. The versatility of these devices enables them to play vital roles in powering our modern world.

Conclusion

In conclusion, electric motors and generators are two distinct devices with unique functionalities and operating principles, even though they both rely on electromagnetism. Electric motors convert electrical energy into mechanical energy, making them essential for driving machinery, appliances, and transportation systems. On the other hand, generators convert mechanical energy into electrical energy, serving as critical components in power generation systems and backup power solutions.

Electric motors and generators differ in terms of their construction, components, flow of energy, direction of current, functionality, output, efficiency, and applications. Electric motors consist of a stator, rotor, and commutator/brushes, while generators have a rotor, stator, and brushes/slip rings. Electric motors have a unidirectional flow of energy, whereas generators have a bidirectional flow determined by the rotation of the rotor. Electric motors produce mechanical output in the form of rotational or linear motion, while generators generate electrical output in the form of AC or DC electricity. Electric motors usually have higher efficiency, ranging from 80% to 95%, whereas generator efficiency can vary based on their size and type.

Electric motors and generators have diverse applications across industries and fields. Electric motors are used in industrial machinery, household appliances, and electric vehicles. Generators play crucial roles in power generation systems, renewable energy systems, and portable backup power solutions.

Understanding the differences between electric motors and generators allows us to appreciate the vital roles they play in our modern world. From powering our homes and industries to enabling sustainable energy generation, these devices drive progress and improve our quality of life. As technology advances and energy efficiency becomes increasingly important, the development of highly efficient motors and generators will continue to be a focus of research and innovation.

Ultimately, electric motors and generators are the driving force behind the functionality, productivity, and power of our interconnected world.

Frequently Asked Questions about What Is The Difference Between Electric Motor And Generator

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is The Difference Between Electric Motor And Generator”