Articles

What Kind Of Tubing For Kegerator

Modified: February 27, 2024

Looking for articles about different types of tubing for kegerators? Get all the information you need to choose the right tubing for your kegerator setup.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

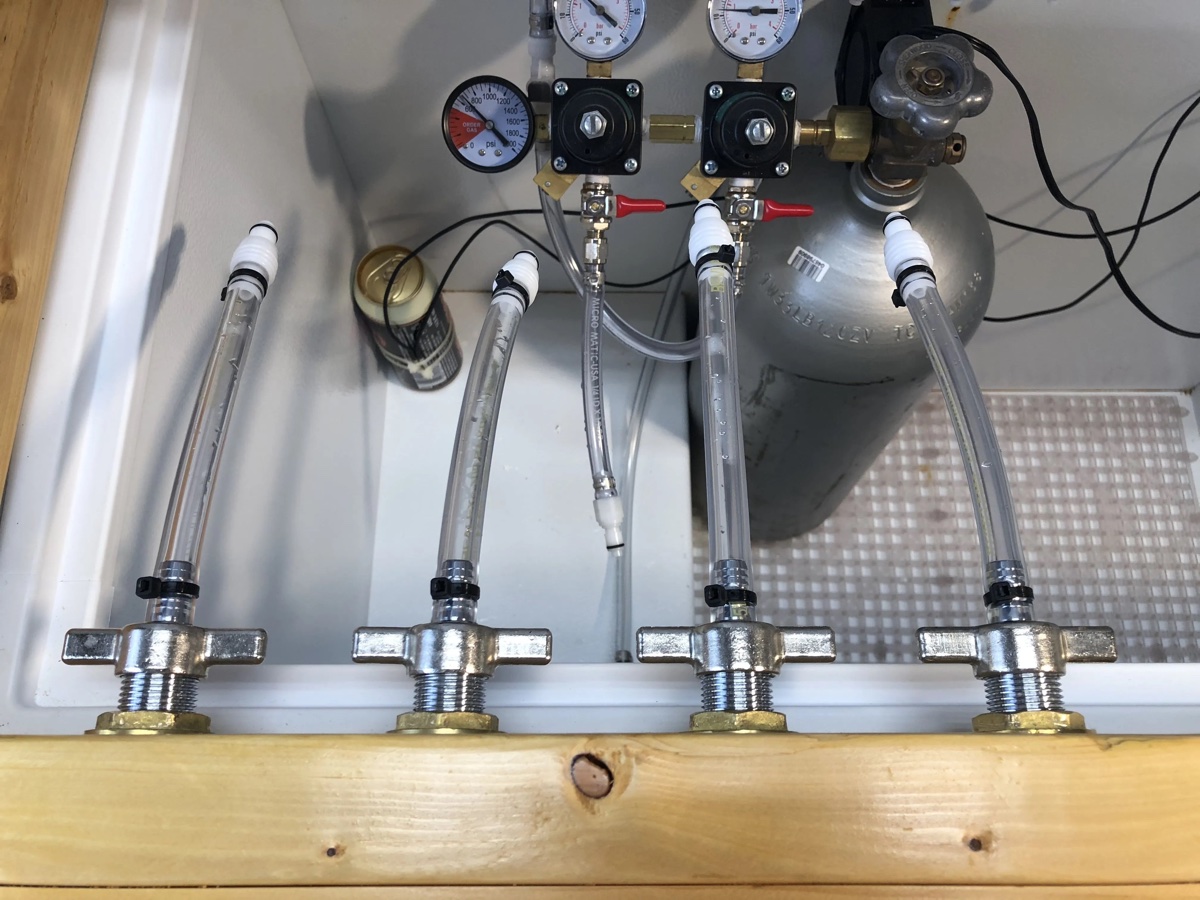

A kegerator is a popular appliance for beer enthusiasts and homebrewers alike. It allows you to store and dispense your favorite brews straight from a keg, providing a convenient and efficient way to enjoy a cold draft beer at home. However, the kegerator is not complete without the right tubing.

Tubing plays a crucial role in the functionality of a kegerator. It connects the keg to the tap, allowing the beer to flow smoothly from the keg to your glass. But with so many options available, what kind of tubing should you use for your kegerator?

In this article, we will explore the different types of tubing commonly used in kegerators, their benefits, and factors to consider when choosing the right tubing for your setup. Whether you are a beer aficionado or a homebrewer, understanding the different types of tubing available for kegerators will help you make an informed decision and enhance your overall beer-drinking experience.

Key Takeaways:

- Choose the right tubing for your kegerator based on your specific needs and preferences, whether it’s affordability, durability, temperature resistance, or professional-grade performance. Proper installation and maintenance ensure optimal beer flow and taste preservation.

- Understanding the benefits and considerations of vinyl, PVC, silicone, and stainless steel tubing will help you make an informed decision for an enhanced beer-drinking experience. Select the tubing that suits your kegerator setup and enjoy perfectly poured draft beer at home.

Read more: What Size Tubing For Kegerator

Benefits of Using Tubing in a Kegerator

Tubing is an essential component of a kegerator, serving several important purposes. Here are some key benefits of using tubing in your kegerator:

- Smooth Beer Flow: The primary function of tubing in a kegerator is to provide a smooth flow of beer from the keg to the tap. The tubing helps maintain a consistent pressure and prevents any obstructions or air bubbles that can affect the beer’s flow and quality.

- Hygienic Dispensing: Using tubing in your kegerator ensures that the beer is dispensed in a hygienic manner. The tubing provides a clean and sealed pathway for the beer, preventing any contamination from outside sources and ensuring that the beer remains fresh and untainted.

- Temperature Control: Tubing can play a role in temperature control within the kegerator. Insulated tubing, such as silicone tubing, can help maintain the desired temperature of the beer from the keg to the tap. This is especially important for sensitive beer styles that require specific temperature ranges to preserve their flavors.

- Flexibility and Mobility: Tubing allows for flexibility and mobility when it comes to kegerator setup. You can easily route the tubing to accommodate your desired tap location, whether it’s on top of the kegerator or through a wall-mounted draft tower. This flexibility allows for customized configurations that suit your specific needs and preferences.

- Durability and Longevity: High-quality tubing is designed to be durable and long-lasting. It can withstand frequent use, temperature fluctuations, and the rigors of operating in a kegerator environment. Investing in good quality tubing ensures that you can enjoy your kegerator for years to come without worrying about constant replacements.

Overall, using tubing in a kegerator not only enhances the functionality and performance of the system but also ensures the proper dispensing and enjoyment of your favorite beers. Now that we’ve discussed the benefits, let’s dive into the factors you should consider when choosing the right tubing for your kegerator setup.

Factors to Consider When Choosing Tubing for a Kegerator

When selecting tubing for your kegerator, there are a few key factors to consider to ensure optimal performance and compatibility with your setup. Here are some important factors to keep in mind:

- Material: The material of the tubing is crucial as it affects the durability, flexibility, and taste of the beer. Common materials used for kegerator tubing include vinyl, PVC, silicone, and stainless steel. Each material has its own advantages and considerations, which we will dive into later in this article.

- Inner Diameter: The inner diameter of the tubing determines the flow rate and level of resistance experienced by the beer. Larger inner diameters allow for faster beer flow but may result in increased foaming, while smaller inner diameters can restrict flow. Consider the requirements of your specific beer and kegerator setup when selecting the appropriate inner diameter for your tubing.

- Length: The length of tubing you need will depend on the distance between the keg and the tap. Ensure that you measure the required length accurately to avoid any issues with installation or dispensing.

- Temperature Resistance: Consider the temperature range at which your kegerator operates and choose tubing that can withstand those temperatures without affecting the quality of the beer. Temperature-resistant tubing helps maintain the desired temperature of the beer from keg to tap.

- Wear and Tear: Take into account the wear and tear that your tubing may experience. Factors such as frequent use, exposure to sunlight, and contact with cleaning agents can impact the longevity of the tubing. Opt for tubing that is durable and resistant to abrasion and deterioration.

- Compatibility: Ensure that the tubing you choose is compatible with the fittings and connections in your kegerator system. Consider the types of connectors and fittings you have, such as barbed or push-to-connect fittings, and select tubing that fits securely without any leakage.

By considering these factors, you can make an informed decision and choose the most suitable tubing for your kegerator setup. In the next section, we will explore the different types of tubing commonly used in kegerators and discuss their features and benefits.

Different Types of Tubing for Kegerators

There are several types of tubing commonly used in kegerators, each with its own unique properties and suitability for specific applications. Let’s explore the different types of tubing:

1. Vinyl Tubing: Vinyl tubing is one of the most popular choices for kegerators. It is affordable, easy to work with, and readily available. Vinyl tubing is flexible, making it ideal for navigating tight spaces in your kegerator setup. However, it is not as temperature-resistant as other options and can impart a plastic-like taste to the beer if not properly maintained and cleaned.

2. PVC Tubing: PVC tubing, also known as polyvinyl chloride, is a durable and economical choice for kegerators. It is resistant to impact and abrasion, making it suitable for heavy-duty applications. PVC tubing is available in various sizes and thicknesses, allowing for customization based on your specific needs. However, it is important to note that PVC tubing is not recommended for use with hot liquids or for applications where it may come into contact with food.

3. Silicone Tubing: Silicone tubing is a premium choice for kegerators, known for its temperature resistance and flexibility. It can withstand both high and low temperatures, making it suitable for kegerators that require precise temperature control. Silicone tubing is also highly resistant to cracking, UV light, and oxidation. It is non-toxic and doesn’t impart any flavors or odors to the beer, ensuring a clean and pure taste.

4. Stainless Steel Tubing: Stainless steel tubing is a top-of-the-line option for kegerators, prized for its durability and sanitary qualities. It is corrosion-resistant, easy to clean, and maintains its shape under pressure. Stainless steel tubing is a common choice for commercial kegerator setups or homebrewers who prefer a professional-grade system. However, it is important to note that stainless steel tubing can be more expensive than other options and may require specialized tools for installation.

Consider the specific requirements of your kegerator setup, such as temperature control, taste considerations, and budget, when choosing the type of tubing for your kegerator. Now that we have explored the different types of tubing, let’s move on to installation and maintenance tips to ensure the optimal performance of your kegerator tubing.

Vinyl Tubing

Vinyl tubing is one of the most commonly used types of tubing in kegerators. It is affordable, readily available, and easy to work with. Vinyl tubing is made from a synthetic plastic material called polyvinyl chloride (PVC).

Here are some key features and considerations regarding vinyl tubing:

- Flexibility: Vinyl tubing is highly flexible, allowing for easy routing and installation in your kegerator setup. It can be easily maneuvered around corners, through tight spaces, and around obstacles without compromising the beer flow.

- Affordability: Vinyl tubing is a cost-effective option for kegerators. It is widely available at various lengths and diameters, making it accessible for all budgets.

- Maintenance: Proper maintenance is crucial for vinyl tubing to ensure the best performance and prevent off-flavors in your beer. It is recommended to clean vinyl tubing regularly using brewery-approved cleaning solutions to remove any residues and prevent bacterial growth.

- Taste Considerations: Vinyl tubing can potentially impart a plastic-like taste to the beer if not properly maintained or if exposed to high temperatures. It is important to ensure that the tubing remains clean and free from any contaminants that can impact the taste of the beer.

- Temperature Limitations: Vinyl tubing is not as temperature-resistant as some other options. It is best suited for kegerators that operate within standard temperature ranges. If you require precise temperature control or plan to serve beers that require specific temperature ranges, you might want to consider other tubing options.

Vinyl tubing is a popular choice for those who are just starting their kegerator journey or have budget constraints. It is readily available, easy to find, and offers flexibility in installation. However, for those seeking enhanced taste preservation or precise temperature control, alternative tubing options like silicone or stainless steel might be more suitable.

When using vinyl tubing, it is important to regularly monitor and inspect the tubing for any signs of wear, cracks, or degradation. Replacing the tubing at the first sign of wear can prevent any potential issues with beer quality or dispensing. Always ensure that the vinyl tubing is securely and properly connected to the fittings and that there are no leaks.

Now that we’ve discussed vinyl tubing, let’s move on to explore another popular option: PVC tubing.

Read more: What Kind Of Keg For Kegerator?

PVC Tubing

PVC tubing, also known as polyvinyl chloride tubing, is another commonly used option for kegerators. It is a durable and economical choice that offers several advantages. PVC tubing is made from a synthetic plastic material called polyvinyl chloride.

Here are some key features and considerations regarding PVC tubing:

- Durability: PVC tubing is highly durable and resistant to impact and abrasion, making it suitable for heavy-duty applications. It can withstand the rigors of a kegerator environment and is less likely to incur damage.

- Customization: PVC tubing is available in various sizes and thicknesses, allowing for customization based on your specific needs. You can easily find PVC tubing that fits your kegerator setup and requirements.

- Cost-Effective: PVC tubing is an affordable option for kegerators. It is readily available at hardware stores or online retailers, making it a cost-effective choice for those on a budget.

- Temperature Limitations: It is important to note that PVC tubing is not recommended for use with hot liquids or in applications where it may come into contact with food. PVC can release toxic chemicals when exposed to high temperatures, which can contaminate the beer. Therefore, PVC tubing is best suited for traditional kegerator setups that maintain standard serving temperatures.

- Maintenance: Proper maintenance is vital to ensure the longevity of PVC tubing. Regular cleaning with brewery-approved cleaning solutions is recommended to prevent bacterial growth and maintain the cleanliness of the tubing.

- Compatibility: PVC tubing is compatible with various fittings and connectors commonly used in kegerators. Whether you have barbed or push-to-connect fittings, PVC tubing can be easily attached securely, ensuring a leak-free connection.

PVC tubing is a popular choice due to its durability, affordability, and ease of customization. It is suitable for kegerator setups that operate within standard temperature ranges and where exposure to hot liquids is not a concern. However, it is important to take precautions and avoid using PVC tubing in applications where it may come into contact with hot liquids or food. For those looking for more temperature resistance or higher-quality taste preservation, alternative tubing options like silicone or stainless steel may be more appropriate.

When using PVC tubing, it is important to regularly inspect and replace any tubing that shows signs of wear, cracking, or deterioration. Proper installation and secure connections are crucial to prevent leaks and maintain proper beer flow. Ensure that the PVC tubing is properly cleaned and maintained to avoid any potential off-flavors in your beer.

Now that we’ve covered PVC tubing, let’s move on to explore another popular option: silicone tubing.

When choosing tubing for your kegerator, make sure to use food-grade vinyl or polyethylene tubing. These materials are safe for use with beverages and will not affect the taste of your beer.

Silicone Tubing

Silicone tubing is a premium choice for kegerators, known for its temperature resistance, flexibility, and superior taste preservation. It is made from a synthetic polymer material called silicone, which offers several advantages for kegerator applications.

Here are some key features and considerations regarding silicone tubing:

- Temperature Resistance: Silicone tubing is highly temperature-resistant, making it suitable for kegerators that require precise temperature control. It can withstand both high and low temperatures without affecting the quality of the beer. This makes it ideal for serving beers that have specific temperature requirements.

- Flexibility: Silicone tubing is highly flexible, allowing for effortless routing and installation in your kegerator setup. It can easily navigate tight spaces and bends without compromising the beer flow. The flexibility of silicone tubing also makes it easy to remove and clean.

- Taste Preservation: Silicone tubing is non-toxic and does not impart any flavors or odors to the beer. It ensures a clean and pure taste, making it a popular choice for those who want to fully enjoy the flavors of their favorite brews without any interference from the tubing material.

- Longevity: Silicone tubing is known for its durability and longevity. It is resistant to cracking, UV light, and oxidation, ensuring that it maintains its performance over an extended period. Investing in silicone tubing can provide peace of mind, knowing that your kegerator tubing will withstand the rigors of regular use.

- Maintenance: Silicone tubing is easy to clean and maintain. It can be easily cleaned using brewery-approved cleaning solutions to ensure the removal of any residues or contaminants that might affect the quality of the beer. Regular cleaning and proper maintenance will help keep the silicone tubing in top condition.

Silicone tubing is a top-of-the-line choice for kegerators that prioritize temperature control, taste preservation, and durability. It is commonly used in commercial kegerator setups or by homebrewers who want a professional-grade system. However, it is important to note that silicone tubing tends to be pricier than other options due to its premium features.

When using silicone tubing, it is important to regularly inspect and clean it to maintain its performance and hygiene. Check for any signs of wear or damage and replace the tubing if necessary. Ensure secure connections and proper installation to prevent leaks and maintain optimal beer flow.

Now that we’ve covered silicone tubing, let’s move on to explore another popular option: stainless steel tubing.

Stainless Steel Tubing

Stainless steel tubing is a high-quality option for kegerators, known for its durability, sanitary properties, and professional-grade performance. It is made from a corrosion-resistant alloy of steel containing a minimum of 10.5% chromium.

Here are some key features and considerations regarding stainless steel tubing:

- Durability: Stainless steel tubing is highly durable and resistant to corrosion, making it a long-lasting choice for kegerators. It can withstand frequent use, temperature fluctuations, and the rigors of operating in a kegerator environment.

- Sanitary Properties: Stainless steel is a non-porous material that is easy to clean and sanitize. It does not harbor bacteria, making it a hygienic choice for kegerator applications. Stainless steel tubing is commonly used in commercial settings or by homebrewers who prioritize cleanliness.

- Professional-grade Performance: Stainless steel tubing provides a professional-grade performance, ensuring optimal beer flow and minimal flavor interference. It maintains its shape under pressure, allowing for consistent and smooth dispensing of your favorite brews.

- Compatibility: Stainless steel tubing is compatible with a wide range of kegerator fittings and connectors. Whether you have barbed or push-to-connect fittings, stainless steel tubing can be easily attached securely, ensuring a leak-free connection.

- Maintenance: Stainless steel tubing is relatively easy to maintain. It can be cleaned using brewery-approved cleaning solutions to ensure the removal of any residues or contaminants that might affect the beer quality. Regular cleaning and proper maintenance will help keep the stainless steel tubing in optimum condition.

Stainless steel tubing is an excellent choice for those who value durability, hygiene, and professional-grade performance in their kegerator setup. However, it is important to note that stainless steel tubing can be more expensive than other options. It is commonly used in commercial kegerator systems or by homebrewers who want to elevate their brewing experience.

When using stainless steel tubing, ensure secure connections and properly installed fittings to prevent leaks. Regularly monitor the tubing for any signs of wear or damage and replace if necessary. By properly cleaning and maintaining stainless steel tubing, you can enjoy its benefits for many years to come.

Now that we have explored the different types of tubing commonly used in kegerators, let’s move on to the next section, where we will discuss installation and maintenance tips to ensure the optimal performance of your kegerator tubing.

Installation and Maintenance Tips for Tubing in a Kegerator

Proper installation and maintenance of tubing in your kegerator are essential for ensuring optimal performance and longevity. Here are some helpful tips to consider:

Read more: Where To Buy Tubing For Kegerator

Installation Tips:

- Measure Twice, Cut Once: Before cutting the tubing to the desired length, make sure to measure the distance accurately. This will help avoid any wastage or the need for additional tubing.

- Choose the Right Tubing Size: Consider the inner diameter of the tubing when selecting the size. Larger inner diameters allow for faster beer flow but may result in increased foaming, while smaller inner diameters can restrict flow. Choose the tubing size that best suits your kegerator setup and beer requirements.

- Secure Connections: Ensure that all connections between the tubing and fittings are secure and tight. Loose connections can lead to leaks and affect the beer flow. Use appropriate clamps or connectors to secure the tubing in place.

- Proper Routing: Carefully plan and route the tubing in your kegerator to avoid kinks, twists, or sharp bends. Smooth and straight tubing routing ensures optimal beer flow and minimal resistance.

- Avoid Excessive Pressure: Be mindful of the pressure applied to the tubing during installation. Excessive force or pressure can cause damage to the tubing or fittings, leading to leaks or performance issues.

Maintenance Tips:

- Regular Cleaning: Clean the tubing regularly using brewery-approved cleaning solutions. This helps remove any residues or contaminants that may affect the taste and quality of the beer. Follow the manufacturer’s guidelines for cleaning frequency and procedures.

- Inspect for Wear and Tear: Regularly inspect the tubing for any signs of wear, cracks, or deterioration. Replace any tubing that shows signs of damage to prevent potential issues with beer quality or flow.

- Sanitize when Needed: Consider sanitizing the tubing when changing kegs or if you suspect any bacterial growth. Sanitizing the tubing helps maintain a hygienic environment and ensures the freshness of the beer.

- Prevent Exposure to Sunlight: Avoid exposing the tubing to direct sunlight or excessive heat, as it can degrade the tubing material over time. Protect the tubing by routing it away from any heat sources or direct sunlight.

- Store Properly: When not in use, make sure to store the tubing in a clean and dry environment. Properly coiling or hanging the tubing prevents tangling and helps maintain its shape for future use.

By following these installation and maintenance tips, you can ensure the optimal performance and longevity of the tubing in your kegerator. Regular inspection, cleaning, and proper installation will help you enjoy fresh and flavorful beer every time you pour.

Now that we have covered installation and maintenance tips, let’s wrap up the article.

Conclusion

Choosing the right tubing for your kegerator is crucial for optimal beer flow, taste preservation, and overall performance. Each type of tubing, whether it’s vinyl, PVC, silicone, or stainless steel, has its own unique features and considerations. Understanding these options will help you make an informed decision based on your specific needs and preferences.

Vinyl tubing offers affordability and flexibility, making it a popular choice for entry-level kegerator setups. On the other hand, PVC tubing provides durability and customization options, suitable for those looking for a cost-effective and long-lasting solution. Silicone tubing offers temperature resistance and superior taste preservation, making it the go-to choice for those who prioritize precise temperature control and the purest beer flavors. Lastly, stainless steel tubing delivers durability, sanitary properties, and professional-grade performance, ideal for commercial kegerator setups or homebrewers seeking a high-quality system.

During installation, it is important to properly measure, choose the right size, secure connections, and route the tubing appropriately to ensure smooth beer flow and minimal resistance. Regular maintenance, including proper cleaning, inspection for wear and tear, and sanitization when needed, will help keep the tubing in optimal condition and preserve the quality of your beer.

Whether you are a beer enthusiast or a homebrewer, understanding the different types of tubing available for kegerators is essential for an enhanced beer-drinking experience. Consider your specific requirements, such as temperature control, taste preservation, and budget, when selecting the tubing for your kegerator.

Investing in the right tubing will not only improve the functionality and performance of your kegerator but also ensure the optimal dispensing and enjoyment of your favorite beers. So, choose wisely, install properly, maintain regularly, and raise your glass to a perfectly poured draft beer from your kegerator.

Frequently Asked Questions about What Kind Of Tubing For Kegerator

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Kind Of Tubing For Kegerator”