Home>Home Maintenance>How Long Does It Take To Replace An Air Conditioner

Home Maintenance

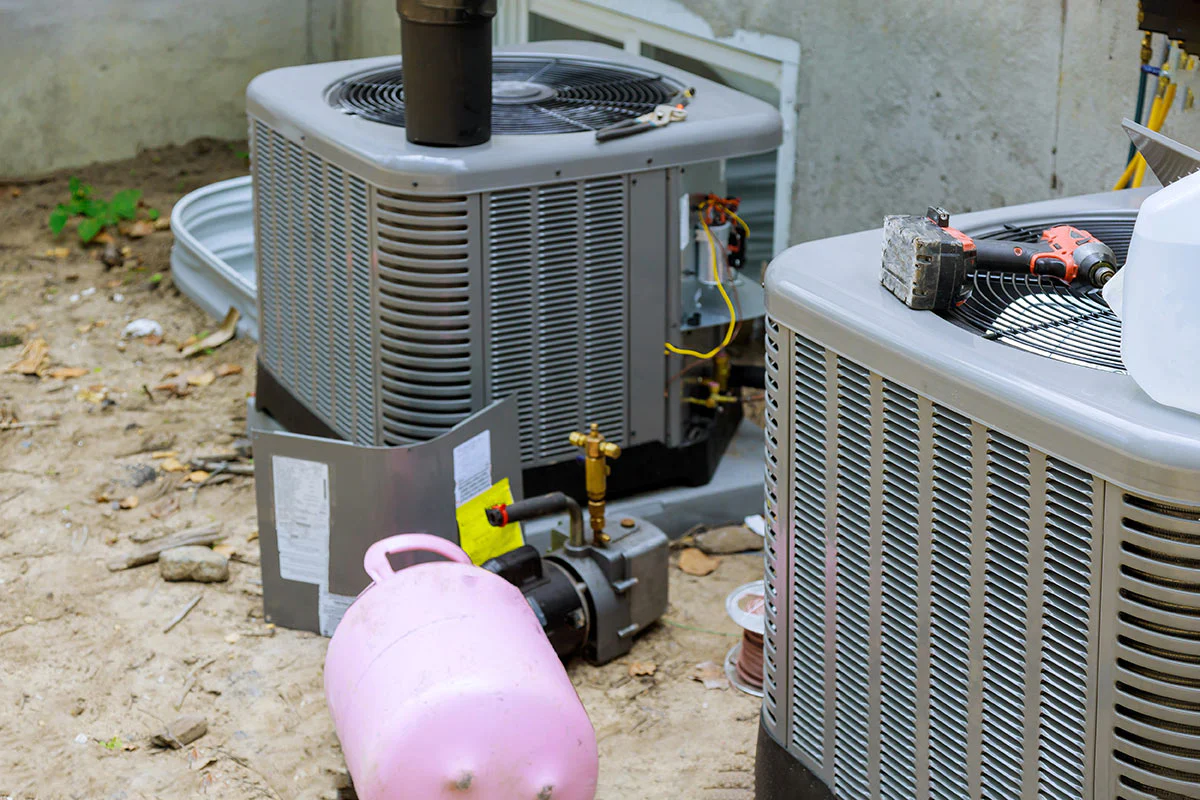

How Long Does It Take To Replace An Air Conditioner

Modified: October 19, 2024

Looking to replace your air conditioner? Find out how long it takes and get expert tips on home maintenance for a smoother process.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Replacing an air conditioner is a common home maintenance task that may become necessary due to age, inefficiency, or system failure. When it comes to replacing an air conditioner, one question that often comes to mind is, “How long will it take?” The time required for this process can vary depending on various factors. In this article, we will explore the factors that can affect the time needed to replace an air conditioner, from the removal of the old unit to the installation of the new one.

It’s essential to consider these factors as homeowners often want to know the timeline to plan their schedules and understand the scope of the project. While it’s difficult to provide an exact timeframe without assessing individual circumstances, having a general idea can help set expectations.

So, let’s delve into the factors that can impact the time it takes to replace an air conditioner:

Key Takeaways:

- Replacing an air conditioner can take varying amounts of time due to factors like system size, accessibility, and necessary repairs. Consulting a professional can provide a more accurate timeline for your specific situation.

- The process involves removing the old unit, installing the new one, and conducting necessary electrical and plumbing work. Thorough testing and inspection ensure proper functionality and compliance with safety standards.

Factors Affecting the Time Required to Replace an Air Conditioner

Several factors can affect the time required to replace an air conditioner. Understanding these factors will give you a better idea of what to expect during the replacement process. Here are the key factors to consider:

- Size and complexity of the system: The size and complexity of the air conditioning system can greatly impact the time required for replacement. Larger and more intricate systems may take longer to remove and install compared to smaller, simpler ones.

- Accessibility: The accessibility of the air conditioning unit plays a significant role in the time it takes to replace it. If the unit is located in an easily accessible area with ample space, the replacement process will likely be quicker. However, if the unit is in a confined space or requires special equipment to access, it may take additional time.

- Condition of existing ductwork: The condition of the existing ductwork can also affect the timeline for replacing an air conditioner. If the ductwork is in good condition and compatible with the new unit, the replacement process will be smoother and faster. However, if the ductwork needs repairs or modifications, it will add extra time to the overall project.

- Additional repairs: Sometimes, when replacing an air conditioner, additional repairs or upgrades may be required. These could include electrical work, plumbing adjustments, or structural modifications. The extent of these additional repairs will impact the overall time required for the replacement.

- Permits and inspections: Depending on your local regulations, permits and inspections may be necessary for replacing an air conditioner. The time required for obtaining permits and scheduling inspections should be factored into the overall timeline.

It’s important to keep in mind that each home and air conditioning system is unique, so the time required for replacement can vary. It’s advisable to consult with a professional HVAC contractor who can assess your specific situation and provide a more accurate estimate.

Now that we’ve explored the factors that can affect the time required to replace an air conditioner, let’s move on to the specific steps involved in the replacement process.

Removal of Old Air Conditioner

The first step in replacing an air conditioner is the removal of the old unit. This process involves several key steps:

- Shutting off power: Before any work can begin, it is crucial to shut off the power supply to the air conditioner. This ensures safety during the removal process.

- Disconnecting electrical and plumbing connections: The next step is to disconnect all electrical and plumbing connections to the old unit. This includes disconnecting power cables, wiring, and refrigerant lines.

- Removing the air conditioner: Once all connections are disconnected, the air conditioner can be removed. This may require assistance, as air conditioning units can be heavy and cumbersome.

- Proper disposal: Proper disposal of the old air conditioner is important. Many areas have guidelines and regulations regarding the disposal of old HVAC equipment. It is advisable to consult with local authorities or a professional service to ensure proper disposal.

The time required for the removal of the old air conditioner can vary based on factors such as accessibility, size, and the complexity of the system. Additionally, any unforeseen issues or complications that arise during the removal process can also affect the timeline.

Once the old air conditioner has been successfully removed, it’s time to move on to the next step: the installation of the new unit.

Installation of New Air Conditioner

After the old air conditioner has been removed, the next step in replacing an air conditioner is the installation of the new unit. This process involves several important steps:

- Placement and positioning: The first task is to determine the optimal placement and positioning of the new air conditioner. Factors such as airflow, accessibility, and space requirements need to be taken into consideration.

- Mounting the unit: Once the placement has been determined, the new unit is mounted in its designated location. This may involve using brackets or other mounting hardware.

- Connecting ductwork: The next step is to connect the ductwork to the new air conditioner. This ensures proper distribution of conditioned air throughout the home. Existing ductwork may need to be modified or adjusted to fit the new unit.

- Electrical and plumbing connections: After the ductwork is connected, the electrical and plumbing connections are made. This includes wiring the new unit to the power supply and connecting the refrigerant lines.

- Insulating and sealing: To ensure energy efficiency and proper operation, all connections and joints are insulated and sealed. This helps prevent air leaks and improves system performance.

The installation process requires careful attention to detail and may involve working with electrical components and refrigerant. It is highly recommended to hire a licensed HVAC professional to handle the installation to ensure safety and proper functionality of your new air conditioner.

The time required for the installation of a new air conditioner can vary depending on factors such as the complexity of the system, the extent of modifications required, and any unforeseen challenges that may arise during the process.

Now that the new air conditioner is installed, further electrical and plumbing work may be necessary to ensure the system is fully operational.

When replacing an air conditioner, the time it takes can vary depending on factors like the size of the unit, the complexity of the installation, and any necessary ductwork modifications. On average, it can take anywhere from 4 to 8 hours for a professional to complete the replacement.

Necessary Electrical and Plumbing Work

Once the new air conditioner has been installed, there may be additional electrical and plumbing work required to ensure the system functions properly. These tasks involve:

- Electrical connections: The new air conditioner will need to be properly connected to the electrical system of the home. This includes wiring the unit to the electrical panel and ensuring it is safely grounded. It is crucial to follow local electrical codes and regulations during this process to maintain safety and prevent any electrical hazards.

- Testing electrical components: After the electrical connections are made, a thorough testing of the electrical components is necessary. This includes checking voltage levels, circuit connections, and ensuring that the electrical system is properly synchronized with the new air conditioner.

- Refrigerant line connections: The refrigerant lines need to be properly connected to the new air conditioner. This involves using the appropriate fittings and ensuring a tight seal to prevent any leakage. The refrigerant levels also need to be accurately measured and adjusted to ensure optimal cooling performance.

- Insulation and sealing: Any exposed electrical wiring or refrigerant lines should be properly insulated and sealed. This helps prevent any energy losses, protects the system from external elements, and improves overall efficiency.

- Pressure and leak testing: Once all the connections are made, it is essential to perform a pressure and leak test to identify any potential issues. This ensures that the system is airtight and operating at the desired pressure levels. If any leaks or abnormalities are detected, they can be addressed promptly to avoid further complications.

The necessary electrical and plumbing work may vary depending on the specific requirements of your new air conditioner and the existing infrastructure of your home. It is highly recommended to hire a licensed professional with expertise in HVAC systems to handle these tasks safely and effectively.

Once the electrical and plumbing work is completed, the system is ready for testing and inspection.

Testing and Inspection

After the installation, electrical and plumbing work, it is crucial to conduct thorough testing and inspection to ensure the new air conditioner is functioning properly and meets safety regulations. This step involves the following:

- Power-up and initial startup: Once all the connections are in place, the new air conditioner is powered up and started. This allows for an initial assessment of its functionality.

- Testing the cooling performance: The cooling performance of the air conditioner is tested to ensure it provides adequate cooling throughout the designated areas. The temperature and airflow are measured and adjusted if necessary.

- Checking for air leaks: A careful inspection is conducted to identify any air leaks in the ductwork or connections. Any leaks found are sealed to prevent energy waste and maintain optimal performance.

- Verifying proper refrigerant levels: The refrigerant levels are checked to ensure they are within the recommended range. If any adjustments are needed, they are made to optimize the system’s cooling efficiency.

- Inspecting safety controls and features: The safety controls and features of the new air conditioner are thoroughly checked to ensure they are functioning correctly. This includes checking the thermostat, sensors, and emergency shutoff switches.

- Testing the overall system performance: A comprehensive test is conducted to assess the overall performance of the air conditioning system. This includes checking for proper functioning of the fan, compressor, and other key components.

- Obtaining necessary permits and inspections: Depending on local regulations, obtaining permits and scheduling inspections may be required to ensure the proper installation and compliance with safety codes.

Testing and inspection are essential to confirm that the new air conditioner is operating efficiently, providing effective cooling, and meeting all safety standards. It is recommended to hire a qualified HVAC professional to perform these tasks to ensure accuracy and compliance.

Once the system has passed all necessary tests and inspections, you can enjoy the comfort of your newly replaced air conditioner.

Conclusion

Replacing an air conditioner is a significant home maintenance task that requires careful planning and execution. The time required for the entire process can vary depending on several factors, including the removal of the old unit, the installation of the new one, necessary electrical and plumbing work, and testing and inspection.

Factors such as the size and complexity of the system, accessibility, condition of existing ductwork, additional repairs, and permits and inspections can all impact the timeline for air conditioner replacement. It is essential to consider these factors to set realistic expectations and ensure a smooth process.

Properly removing the old air conditioner involves shutting off power, disconnecting electrical and plumbing connections, and ensuring proper disposal. The installation of the new air conditioner includes placing and positioning the unit, connecting ductwork, electrical and plumbing connections, as well as insulating and sealing the system.

Necessary electrical and plumbing work may be required to ensure proper functionality, involving electrical connections, testing, refrigerant line connections, insulation, and sealing. Afterward, thorough testing and inspection are conducted to verify cooling performance, check for leaks, verify refrigerant levels, and ensure safety controls are functioning correctly.

It is crucial to consult with a licensed HVAC professional to handle the replacement process and ensure compliance with safety regulations. Their expertise and experience will ensure a smooth and efficient replacement, minimizing any potential issues or complications.

By considering these factors and working with a professional, you can expect a successful air conditioner replacement that will provide you with reliable cooling and comfort in your home for years to come.

Frequently Asked Questions about How Long Does It Take To Replace An Air Conditioner

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.