Home>Renovation & DIY>Tools & Equipment>How Does Sandpaper Grit Work

Tools & Equipment

How Does Sandpaper Grit Work

Modified: January 4, 2024

Discover how sandpaper grit works and its importance in achieving smooth and polished surfaces. Learn how to choose the right grit for your tools and equipment.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of woodworking and DIY projects, where the art of sanding plays a crucial role in achieving a smooth and polished finish. Whether you’re refinishing a vintage piece of furniture, smoothing out rough edges on a woodworking project, or preparing surfaces for painting, sandpaper is an indispensable tool in your arsenal. But have you ever wondered how sandpaper actually works its magic? In this article, we’ll delve into the fascinating realm of sandpaper grit, exploring its composition, the impact of grit size on sanding, and the role of backing material. By the end, you’ll have a deeper understanding of this humble yet essential tool, empowering you to elevate the quality of your sanding endeavors.

Key Takeaways:

- Sandpaper grit determines the smoothness of your project. Coarse grit removes material, medium grit smooths surfaces, and fine grit polishes for a flawless finish.

- The backing material of sandpaper affects its durability and suitability for different tasks. Paper is versatile, cloth is durable, and film is waterproof for specialized applications.

Read more: What Does Grit Mean In Sandpaper

What is Sandpaper Grit?

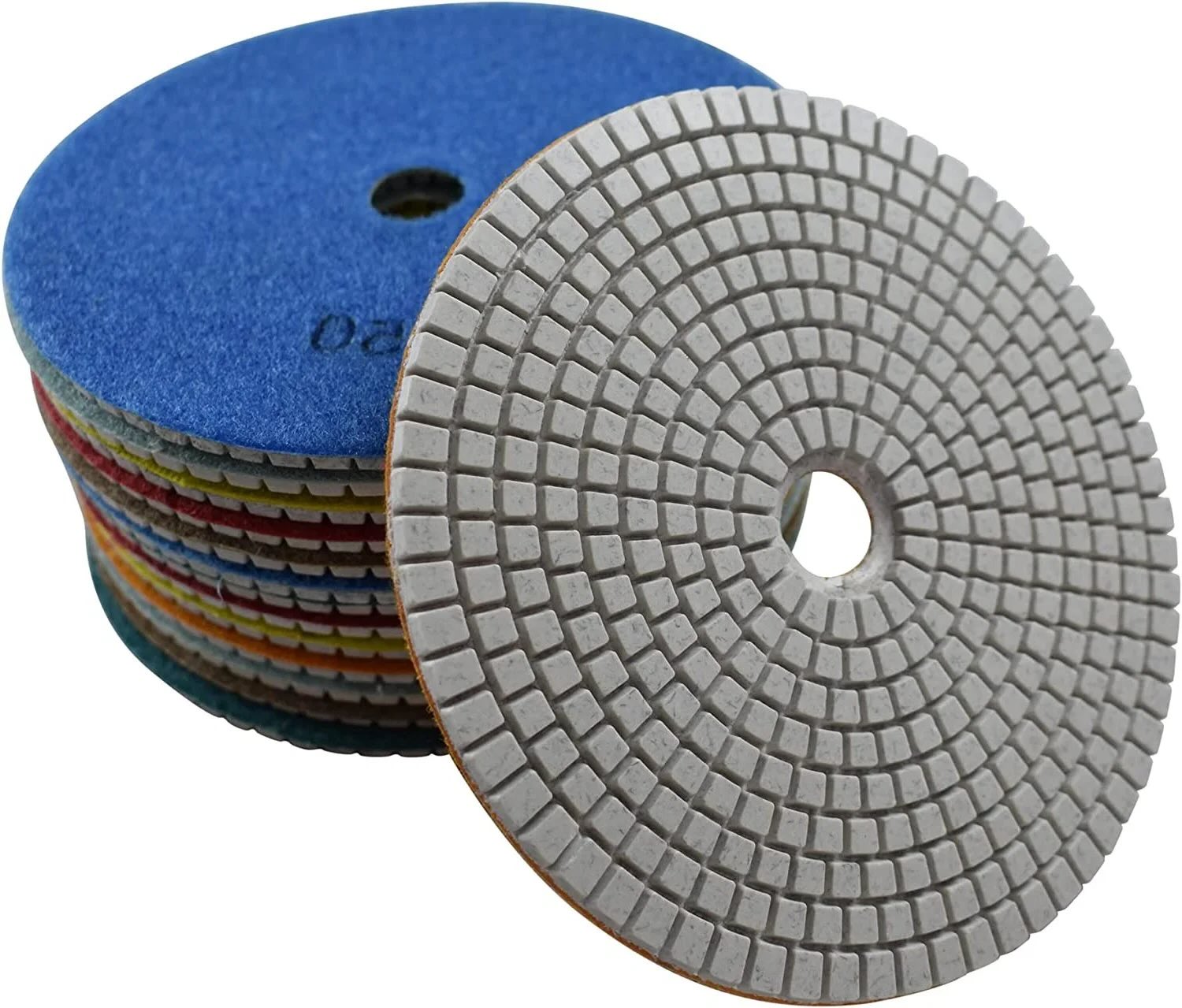

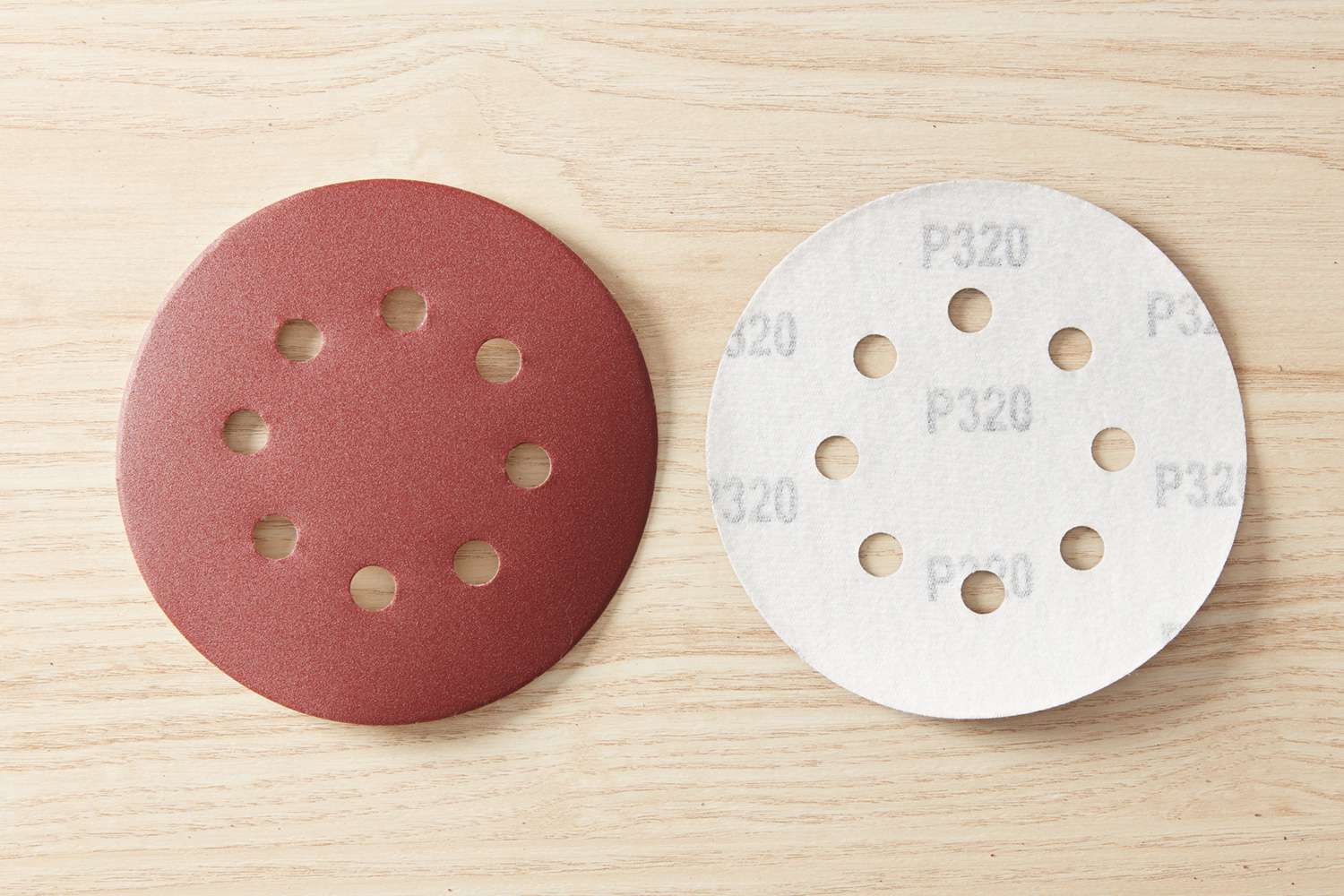

Sandpaper, a staple in any workshop or toolbox, is a versatile abrasive material used to smooth surfaces, remove material, and prepare surfaces for finishing. At the heart of sandpaper’s effectiveness lies its grit – a measure of the size of the abrasive particles embedded in the paper or cloth backing. These abrasive particles, often made of aluminum oxide, silicon carbide, or garnet, come in varying sizes and are distributed across the sandpaper’s surface at specific densities.

The grit size, typically denoted by a number, refers to the number of abrasive particles per square inch of the sandpaper. Lower grit numbers indicate larger, coarser particles, which are ideal for heavy material removal and shaping tasks. On the other hand, higher grit numbers represent smaller, finer particles, suited for achieving smooth, polished finishes and preparing surfaces for painting or staining.

For instance, sandpaper with a grit size of 40 to 60 is considered coarse and is best suited for rough sanding and shaping tasks, such as removing paint or smoothing out uneven surfaces. In contrast, sandpaper with grit sizes ranging from 150 to 180 is categorized as medium grit, suitable for general sanding and preparing surfaces for finishing. Finally, fine grit sandpaper, typically ranging from 240 to 600, is designed for achieving a smooth, polished surface, often used in between coats of finish or for delicate woodworking projects.

Understanding the role of grit size is essential for selecting the right sandpaper for your specific task, ensuring efficient material removal and achieving the desired surface texture. As we delve deeper into the impact of grit size on sanding, you’ll gain valuable insights into harnessing the power of sandpaper grit to elevate the quality of your woodworking and DIY projects.

How Grit Size Affects Sanding

The grit size of sandpaper plays a pivotal role in determining the efficiency and outcome of the sanding process. Understanding the impact of grit size empowers craftsmen and DIY enthusiasts to make informed decisions when selecting sandpaper for their projects.

Coarse grit sandpaper, characterized by lower grit numbers such as 40 to 60, is designed for aggressive material removal. Its larger abrasive particles excel at leveling uneven surfaces, removing old finishes, and shaping wood or metal. When tackling rough surfaces or stubborn imperfections, coarse grit sandpaper is the go-to choice, swiftly transforming rugged textures into smooth, workable surfaces.

Medium grit sandpaper, with grit sizes ranging from 80 to 120, strikes a balance between material removal and surface refinement. It is ideal for smoothing out rough surfaces, removing scratches, and preparing wood, metal, or other materials for further finishing. This versatile grit range is commonly employed in woodworking, carpentry, and metalworking to achieve a uniform and workable surface texture.

As we ascend to the realm of fine grit sandpaper, typically ranging from 150 to 600, the focus shifts to surface refinement and achieving a polished finish. Fine grit sandpaper excels at smoothing out imperfections, refining surfaces between coats of finish, and preparing materials for painting, staining, or varnishing. Its smaller abrasive particles delicately finesse the surface, resulting in a lustrous and flawless appearance.

It’s important to note that the progression from coarse to fine grit sandpaper is often a multi-step process, especially when striving for a professional-grade finish. Starting with a coarse grit to remove imperfections and shape the surface, craftsmen then transition to medium grit to refine the texture before culminating with fine grit for a smooth and pristine finish.

By understanding the nuanced impact of grit size on sanding, craftsmen and DIY enthusiasts can optimize their sanding techniques, maximize efficiency, and achieve impeccable results across a diverse range of projects. The next section will shed light on the pivotal role of backing material in the realm of sandpaper, further enriching your understanding of this essential tool.

The higher the number on sandpaper grit, the finer the abrasive particles, resulting in a smoother finish. Lower grit numbers are coarser and remove material faster.

The Role of Backing Material

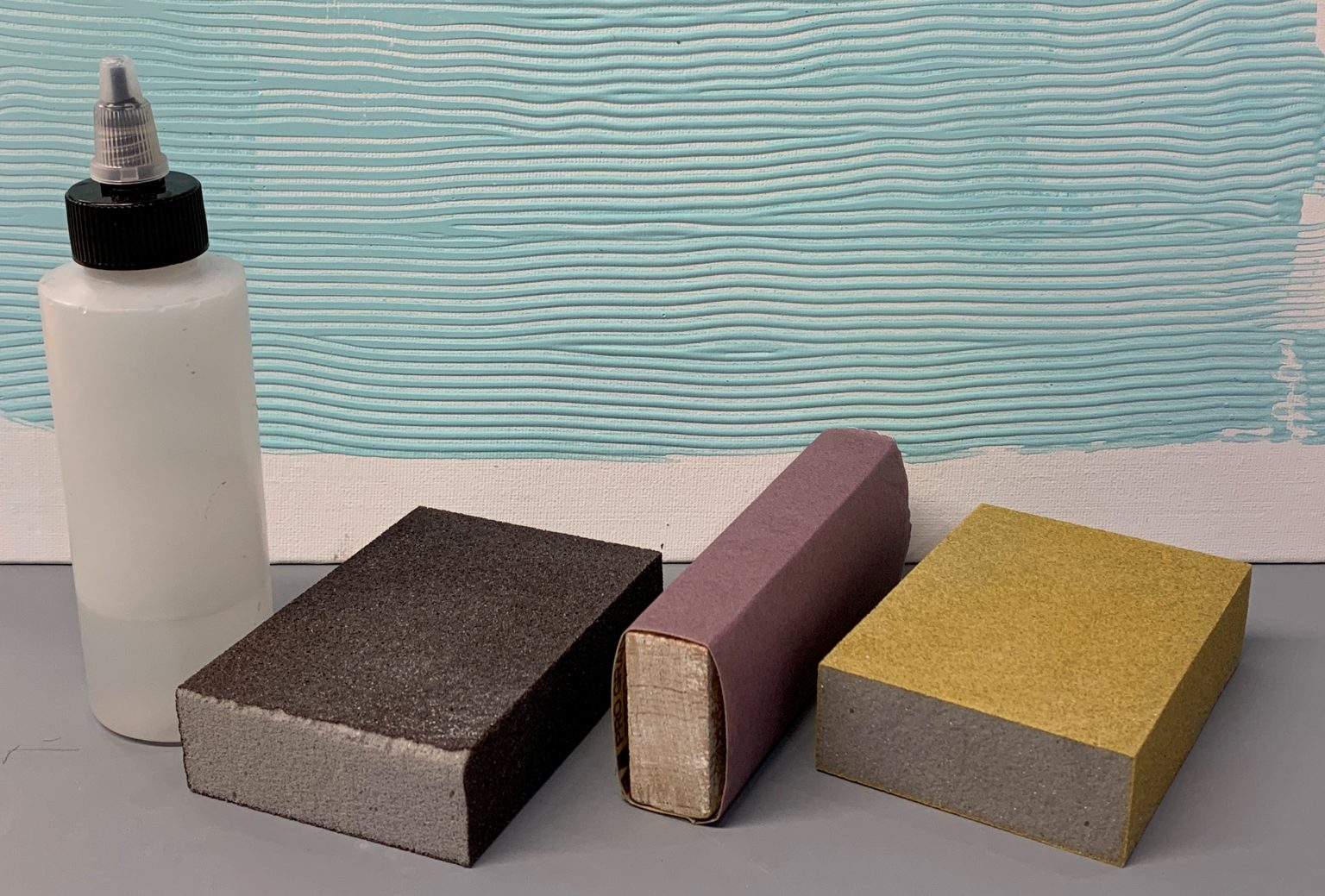

While the grit of sandpaper rightfully receives much attention, the backing material is equally significant in determining the overall performance and durability of the abrasive tool. The backing material provides the necessary support for the abrasive particles, ensuring that they remain securely bonded and effectively engage with the workpiece during the sanding process.

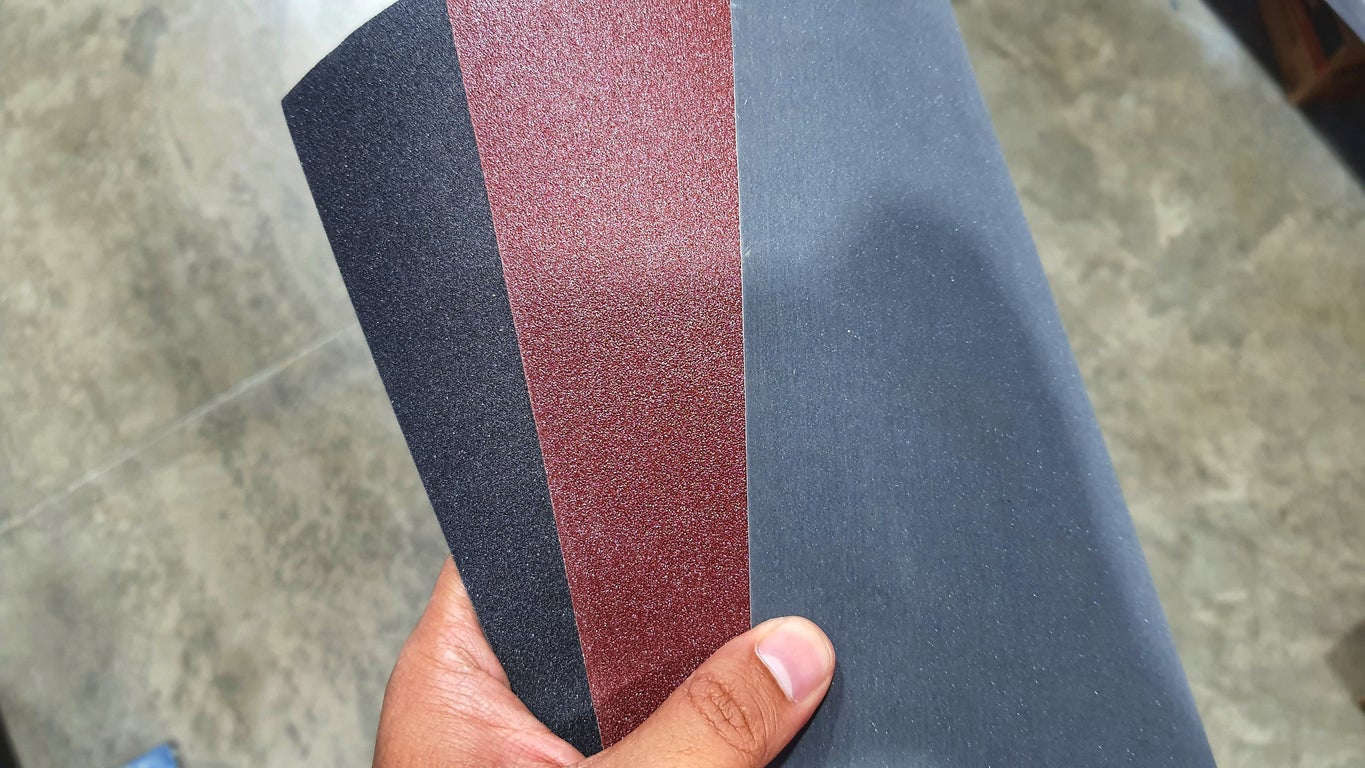

Sandpaper backing materials come in various forms, with the most common being paper, cloth, and film. Each backing material offers distinct advantages and is tailored to specific applications, catering to the diverse needs of craftsmen and DIY enthusiasts.

- Paper Backing: Traditional and cost-effective, paper-backed sandpaper is widely used in woodworking and general sanding applications. Its flexibility and ability to conform to irregular surfaces make it a versatile choice for tasks ranging from wood sanding to paint removal. However, paper-backed sandpaper may have limitations in wet sanding applications due to its susceptibility to moisture damage.

- Cloth Backing: Known for its exceptional durability and tear resistance, cloth-backed sandpaper is favored in heavy-duty sanding tasks, metalworking, and applications where longevity is paramount. The sturdy backing material enables craftsmen to tackle demanding projects with confidence, withstanding the rigors of aggressive sanding without compromising performance.

- Film Backing: Film-backed sandpaper, often made from polyester or a combination of polyester and nylon, offers exceptional tear resistance and waterproof properties. This makes it well-suited for wet sanding applications and tasks requiring a high degree of flexibility and durability. Film-backed sandpaper is particularly valued in automotive refinishing, woodworking, and other specialized applications.

Additionally, the quality of the bonding between the abrasive particles and the backing material significantly influences the sandpaper’s longevity and performance. A strong and resilient bond ensures that the abrasive particles remain securely attached, preventing premature wear and ensuring consistent sanding results throughout the tool’s lifespan.

By understanding the role of backing material and its suitability for specific applications, craftsmen and DIY enthusiasts can make informed choices when selecting sandpaper, optimizing their sanding experience and achieving superior results across a myriad of projects. As we conclude our exploration of sandpaper grit and backing material, you now possess a deeper appreciation for the intricacies of this indispensable tool, empowering you to elevate the quality of your woodworking and DIY endeavors.

Conclusion

As we conclude our journey into the realm of sandpaper grit and backing material, you have gained valuable insights into the pivotal role of these components in the art of sanding. The nuanced interplay between grit size and backing material forms the foundation of sandpaper’s effectiveness, influencing its performance across diverse applications and projects.

Understanding the significance of grit size empowers craftsmen and DIY enthusiasts to select the most suitable sandpaper for their specific tasks, whether it involves aggressive material removal, surface refinement, or achieving a polished finish. By harnessing the power of coarse, medium, and fine grit sandpaper, you can optimize your sanding techniques and elevate the quality of your woodworking, carpentry, metalworking, and DIY projects.

Furthermore, recognizing the distinct characteristics and advantages of paper, cloth, and film backing materials enables informed decision-making when choosing sandpaper tailored to the demands of your projects. Whether you require flexibility, tear resistance, or waterproof properties, the backing material plays a crucial role in ensuring the durability and performance of the abrasive tool.

Armed with this newfound understanding, you are equipped to embark on your sanding endeavors with confidence, knowing that the selection of sandpaper grit and backing material is a deliberate and informed decision. As you refine surfaces, remove imperfections, and prepare materials for finishing, the synergy between grit size and backing material will be your guiding force, driving the attainment of impeccable results.

So, the next time you reach for a sheet of sandpaper to breathe new life into a worn piece of furniture, refine the surface of a woodworking masterpiece, or prepare a metalwork project for painting, remember the intricate dance between grit and backing material. Embrace the art of sanding with a deeper appreciation for the role of sandpaper grit and backing material, and let your projects shine with a level of craftsmanship that reflects your newfound expertise.

Frequently Asked Questions about How Does Sandpaper Grit Work

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Does Sandpaper Grit Work”