Home>Renovation & DIY>Tools & Equipment>What Does Grit Mean In Sandpaper

Tools & Equipment

What Does Grit Mean In Sandpaper

Published: December 20, 2023

Discover the significance of grit in sandpaper and its impact on tools and equipment. Learn how different grit levels affect the sanding process.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

What Does Grit Mean in Sandpaper?

Introduction

When it comes to sanding wood, metal, or any other surface, the term "grit" plays a crucial role in achieving the desired results. Imagine trying to smooth out a rough wooden surface without the right level of grit – it would be like attempting to write with a broken pencil. Understanding the concept of grit in sandpaper is essential for anyone looking to tackle a sanding project effectively. In this article, we will delve into the world of sandpaper grit, exploring its meaning, its impact on sanding, and how to choose the right grit for various projects.

Sandpaper is more than just a sheet of abrasive material – it is a tool with different levels of coarseness, known as grit. This coarseness is measured using a grading system, and understanding the significance of these grades can make a world of difference in the outcome of your sanding endeavors. Let's embark on a journey to uncover the mysteries of grit in sandpaper and how it influences the sanding process.

Key Takeaways:

- Grit in sandpaper refers to the coarseness of the abrasive particles, impacting material removal and surface smoothness. Choosing the right grit is crucial for achieving a flawless finish in sanding projects.

- Coarser grits are for heavy material removal, while finer grits are for refining surfaces. Progressing from lower to higher grits ensures a smooth and polished result, making grit selection a key factor in successful sanding.

Read more: What Grit Sandpaper For Plastic

What is Grit in Sandpaper?

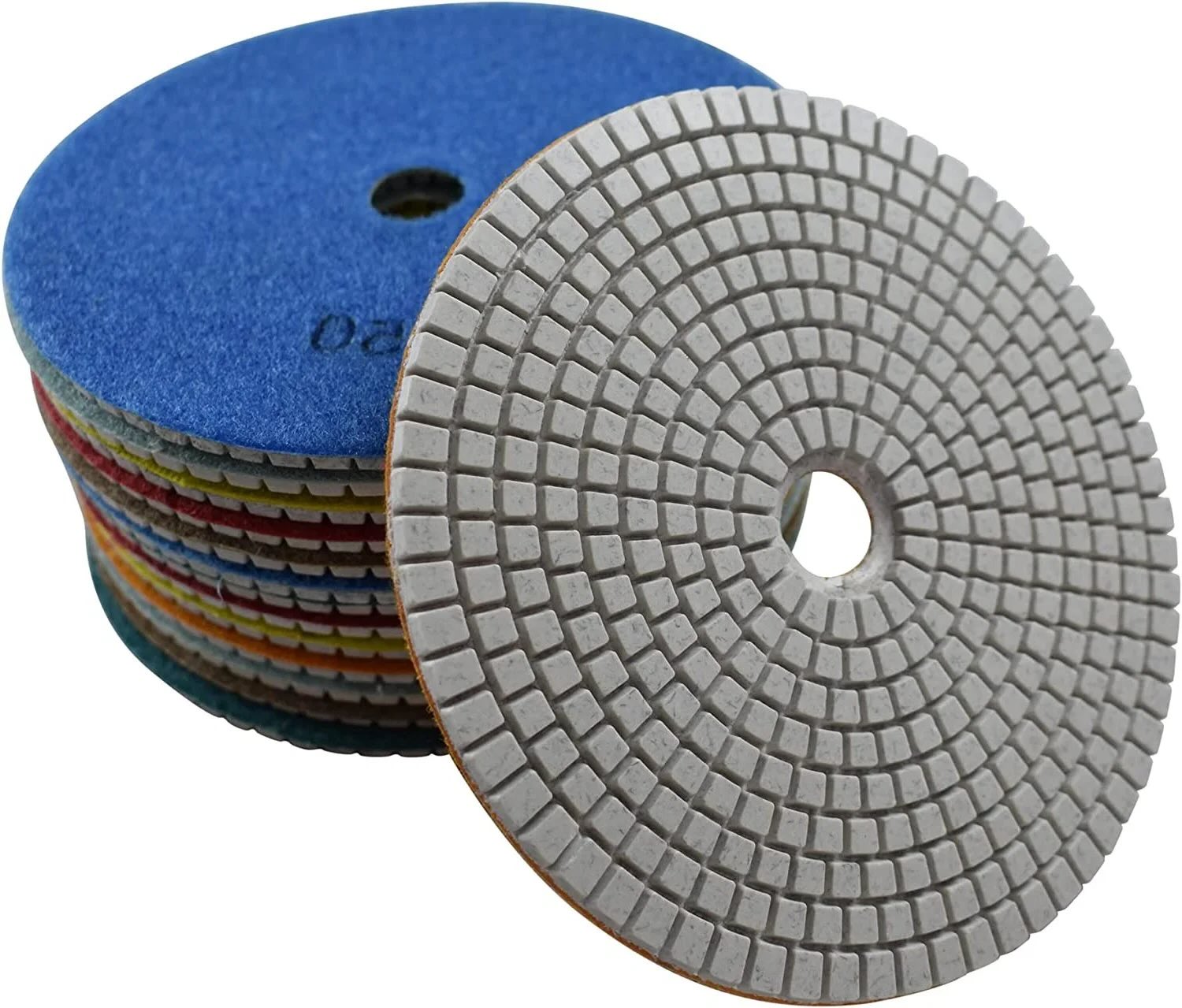

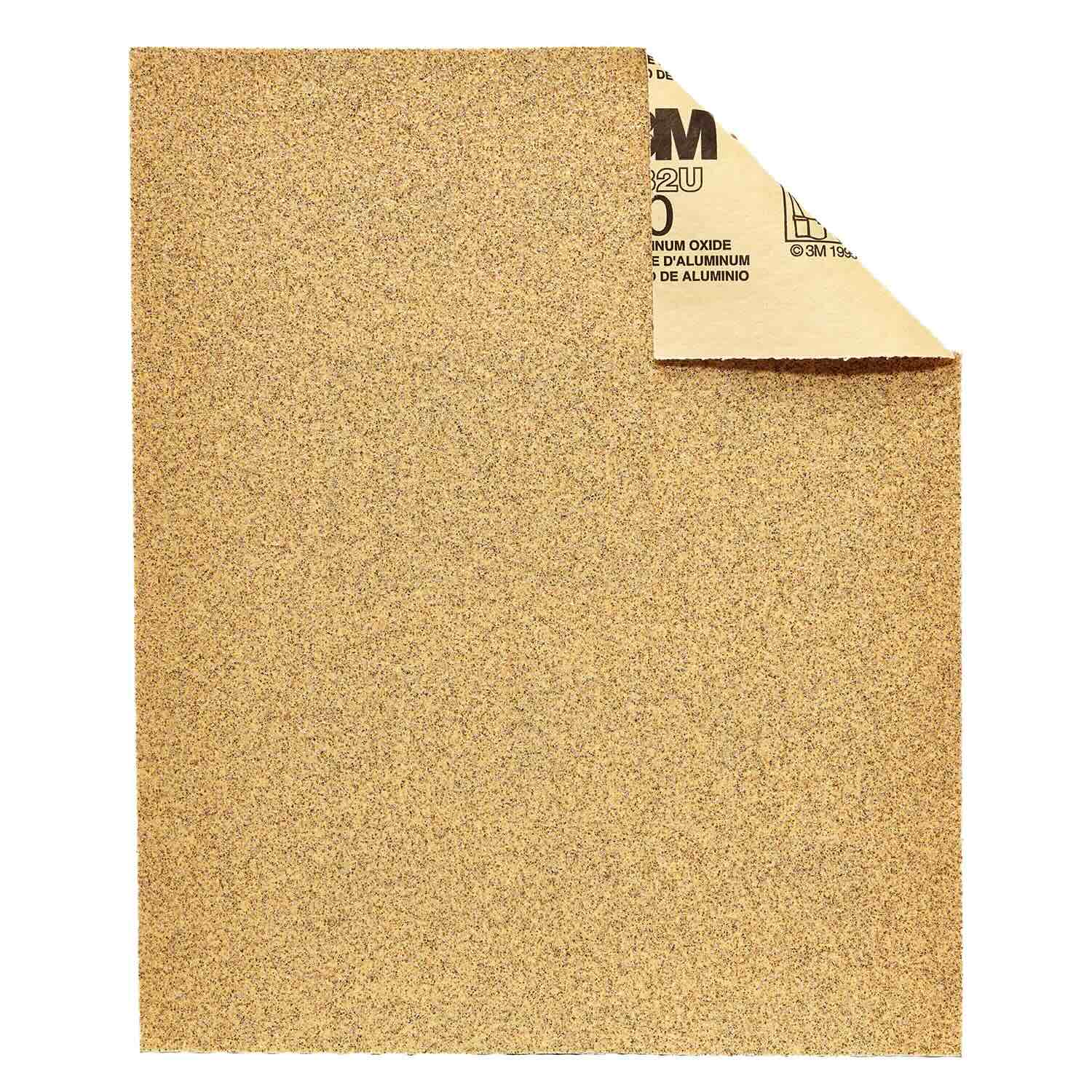

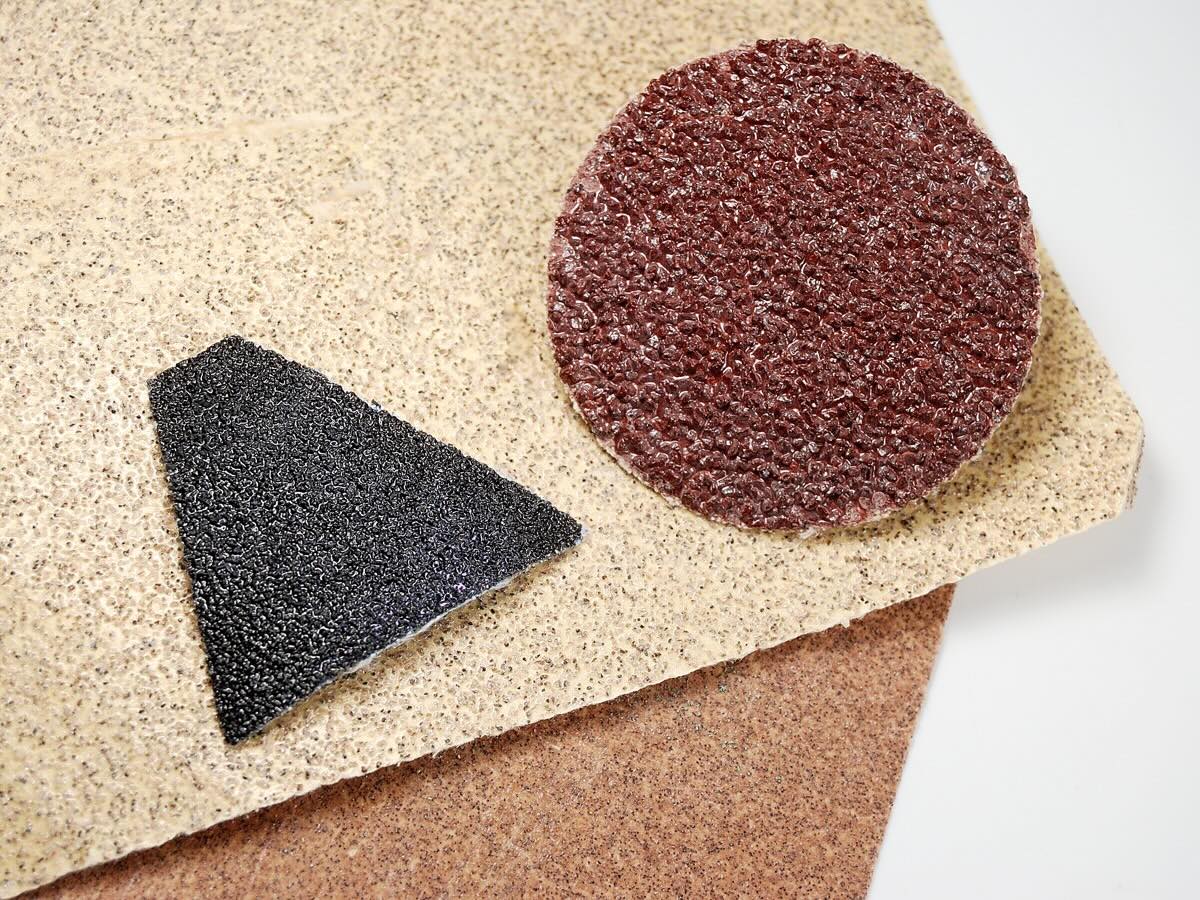

Simply put, the "grit" in sandpaper refers to the number of abrasive particles per square inch of the paper. These abrasive particles, often made of materials like aluminum oxide, silicon carbide, or garnet, are distributed across the sandpaper to create a rough surface capable of smoothing and shaping various materials.

The grit number on sandpaper indicates the coarseness or fineness of the abrasive particles. Lower grit numbers signify coarser sandpaper, with larger abrasive particles that are suitable for heavy material removal and rough shaping. On the other hand, higher grit numbers denote finer sandpaper, featuring smaller abrasive particles ideal for smoothing surfaces and preparing them for finishing touches.

For instance, sandpaper with a grit rating of 40 to 60 is considered coarse and is commonly used for initial sanding of rough surfaces or for heavy material removal, such as leveling uneven wooden planks. In contrast, sandpaper with a grit rating of 180 to 220 is categorized as fine and is typically employed for smoothing surfaces and preparing them for painting, staining, or varnishing.

Understanding the concept of grit in sandpaper is akin to knowing the various brush sizes and bristle types for a painter – it enables you to select the right tool for the specific task at hand. Whether you are aiming to remove layers of old paint, smooth out imperfections in wood, or prepare metal surfaces for refinishing, the grit of the sandpaper will significantly influence the efficiency and quality of your sanding efforts.

How Grit Affects Sanding

The grit of sandpaper has a profound impact on the sanding process, influencing the speed of material removal, the smoothness of the surface, and the overall efficiency of the task. Coarser grits, characterized by lower grit numbers, are designed for aggressive material removal. When using coarse-grit sandpaper, such as 40 or 60 grit, the abrasive particles are larger and more widely spaced, making them highly effective for leveling uneven surfaces, removing old finishes, and shaping wood or metal.

On the other hand, finer grits, denoted by higher grit numbers, are tailored for refining surfaces and achieving a smooth, polished result. Sandpaper with grit ratings of 180 and above excels in preparing surfaces for painting, staining, or varnishing. The smaller, densely packed abrasive particles of fine-grit sandpaper facilitate the removal of imperfections, blemishes, and fine layers of material, resulting in a silky-smooth finish.

Furthermore, the progression from lower to higher grits plays a pivotal role in the sanding process. It is common practice to start with a coarser grit to address major imperfections or rough surfaces, gradually moving to finer grits to refine the surface and achieve the desired level of smoothness. This systematic approach ensures that each successive grit removes the scratches and marks left by the previous grit, leading to a progressively smoother surface.

Understanding how grit affects sanding empowers craftsmen and DIY enthusiasts to make informed decisions when selecting sandpaper for their projects. By recognizing the relationship between grit and sanding outcomes, individuals can optimize their sanding techniques, minimize unnecessary effort, and achieve superior results, whether they are restoring furniture, refinishing floors, or crafting intricate woodwork.

When choosing sandpaper, the grit number indicates the coarseness or fineness of the abrasive particles. The higher the grit number, the finer the sandpaper and the smoother the finish it will produce.

Choosing the Right Grit for the Job

When embarking on a sanding project, selecting the appropriate grit of sandpaper is paramount to achieving the desired outcome. The ideal grit for a specific job depends on the material being sanded, the condition of the surface, and the goal of the sanding process. Understanding how to choose the right grit for the job is akin to selecting the perfect tool for a particular task – it can make the difference between a satisfactory result and a flawless finish.

For tasks involving heavy material removal, such as leveling uneven wooden surfaces or eliminating layers of old paint or varnish, coarse-grit sandpaper is the go-to choice. Grits ranging from 40 to 80 are well-suited for these demanding tasks, as they efficiently tackle rough surfaces and expedite the material removal process.

When aiming to smooth out imperfections, refine surfaces, or prepare them for finishing, finer grits are indispensable. Grits in the range of 120 to 220 are ideal for achieving a smooth, polished surface, making them suitable for tasks like preparing wood for staining, smoothing drywall compound, or prepping metal for painting.

It’s important to note that some projects may require a progression through multiple grits to achieve the desired result. For example, refinishing a wooden tabletop may involve starting with a coarse-grit sandpaper, such as 80 or 100, to remove the old finish and level the surface. Subsequently, transitioning to finer grits, such as 150 and 220, can refine the surface and prepare it for staining or varnishing.

Additionally, when working with delicate materials or intricate details, it’s crucial to consider the potential impact of the grit on the surface. Using excessively coarse grit on delicate woodwork or intricate designs can result in irreversible damage, underscoring the importance of matching the grit to the specific requirements of the project.

By understanding the nuances of grit selection, individuals can approach sanding projects with confidence, armed with the knowledge to choose the right grit for the job at hand. This informed decision-making process ensures that the sanding process is efficient, effective, and tailored to the unique characteristics of the material being worked on.

Conclusion

The concept of grit in sandpaper is far more than a mere technicality – it is the cornerstone of successful sanding endeavors. Understanding the nuances of grit, from its impact on material removal to its role in achieving a smooth, refined finish, empowers craftsmen, artisans, and DIY enthusiasts to elevate the quality of their work.

As we’ve explored the significance of grit in sandpaper, it becomes evident that selecting the right grit for a specific task is akin to wielding a precision instrument. Whether it’s reviving weathered wooden furniture, refinishing hardwood floors, or crafting intricate woodwork, the choice of grit profoundly influences the outcome of the sanding process.

By recognizing the relationship between grit and sanding outcomes, individuals can refine their approach to sanding, ensuring that each stroke of the sandpaper contributes to the gradual transformation of the surface, from rough and uneven to smooth and flawless. This meticulous progression through various grits exemplifies the artistry of sanding, where each level of coarseness or fineness serves a purpose in achieving the desired result.

Ultimately, the journey through the world of sandpaper grit unveils a realm of possibilities, where the right grit becomes a companion in the quest for perfection. It is not merely a number on a sheet of sandpaper, but a guide that navigates the hands of craftsmen toward the realization of their vision.

So, the next time you embark on a sanding project, remember that behind each stroke of sandpaper lies the wisdom of grit – the silent architect of smooth surfaces and impeccable finishes.

Embrace the artistry of grit, and let it sculpt your creations with finesse and precision.

Frequently Asked Questions about What Does Grit Mean In Sandpaper

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Does Grit Mean In Sandpaper”