Home>Renovation & DIY>Tools & Equipment>Which Grit Sandpaper Is The Roughest

Tools & Equipment

Which Grit Sandpaper Is The Roughest

Published: December 20, 2023

Find out which grit sandpaper is the roughest for your tools and equipment. Discover the perfect choice for a smooth finish.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of sandpaper! If you’ve ever been involved in a DIY project or tackled woodworking tasks, you’ve likely come across the term “grit sandpaper.” But have you ever wondered what exactly it means and why it matters?

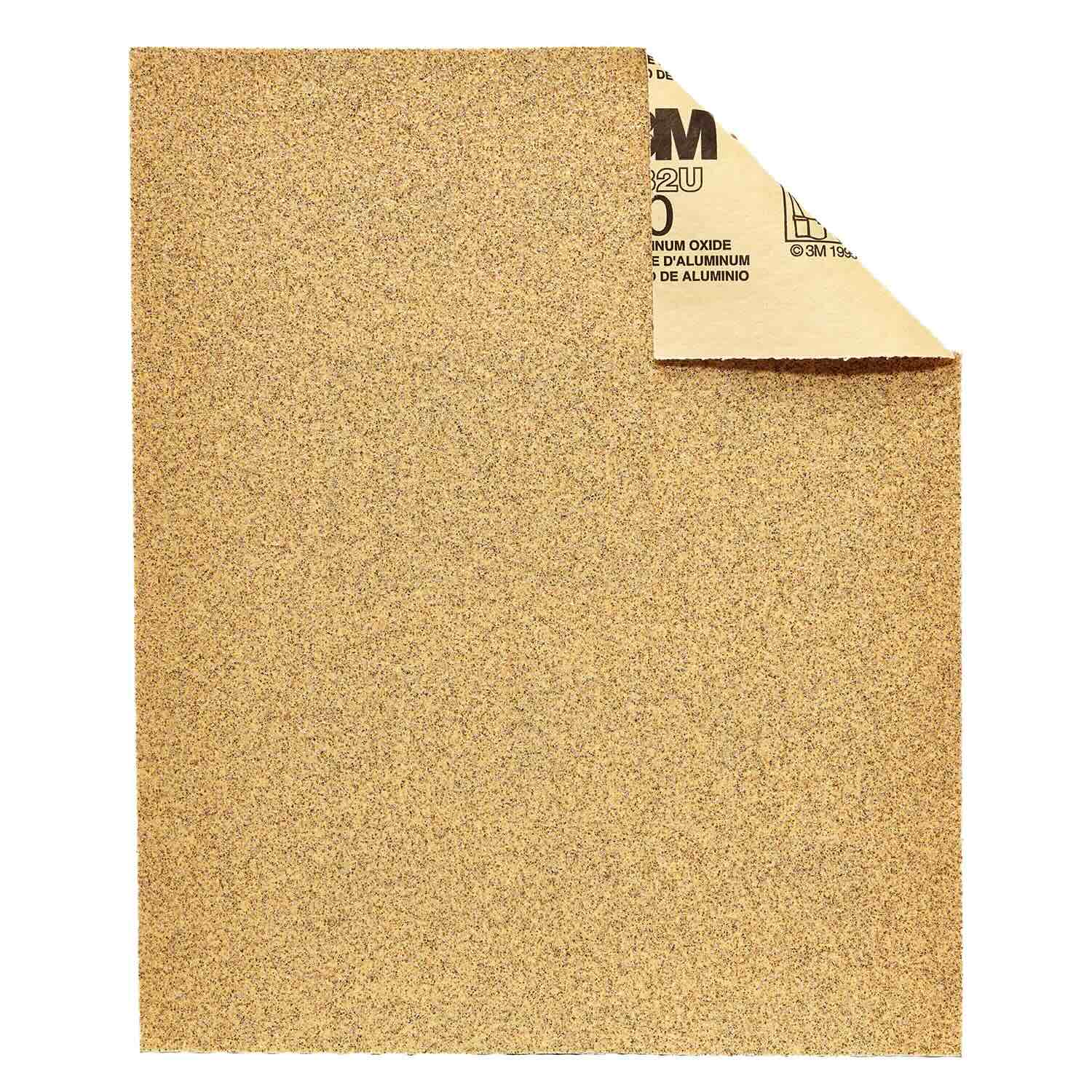

Grit sandpaper is an essential tool for smoothing and shaping various materials. It consists of an abrasive surface attached to a backing material, such as paper or cloth. The abrasive particles on the sandpaper are measured in grit, which determines the coarseness or roughness of the surface it can achieve.

In this article, we will explore the intricacies of grit sandpaper and delve into the significance of using the right grit level. To help you fully understand the topic, we will also compare different grit levels and discuss the factors that affect sandpaper roughness.

So, whether you are a woodworking enthusiast, a DIY hobbyist, or simply curious about the world of sanding, sit back, relax, and let’s dive into the fascinating world of grit sandpaper!

Key Takeaways:

- Choose the right grit sandpaper for efficient material removal, optimal surface preparation, and achieving the desired finish. It saves time, money, and ensures professional-quality results in your projects.

- Understanding factors like grit size, material being sanded, pressure applied, and sanding technique helps achieve the desired surface texture and finish. Experiment and find the right combination for optimal results.

Read more: Which Sandpaper Grit To Use For Wood

Understanding Grit Sandpaper

Grit sandpaper plays a crucial role in achieving a smooth and polished finish on a variety of surfaces. To grasp the concept better, let’s break it down:

1. What is Grit? – Grit refers to the particle size of the abrasive material on the sandpaper. It is measured in units known as “grains per square inch” or “grit.” The higher the grit number, the finer and smoother the surface is and vice versa.

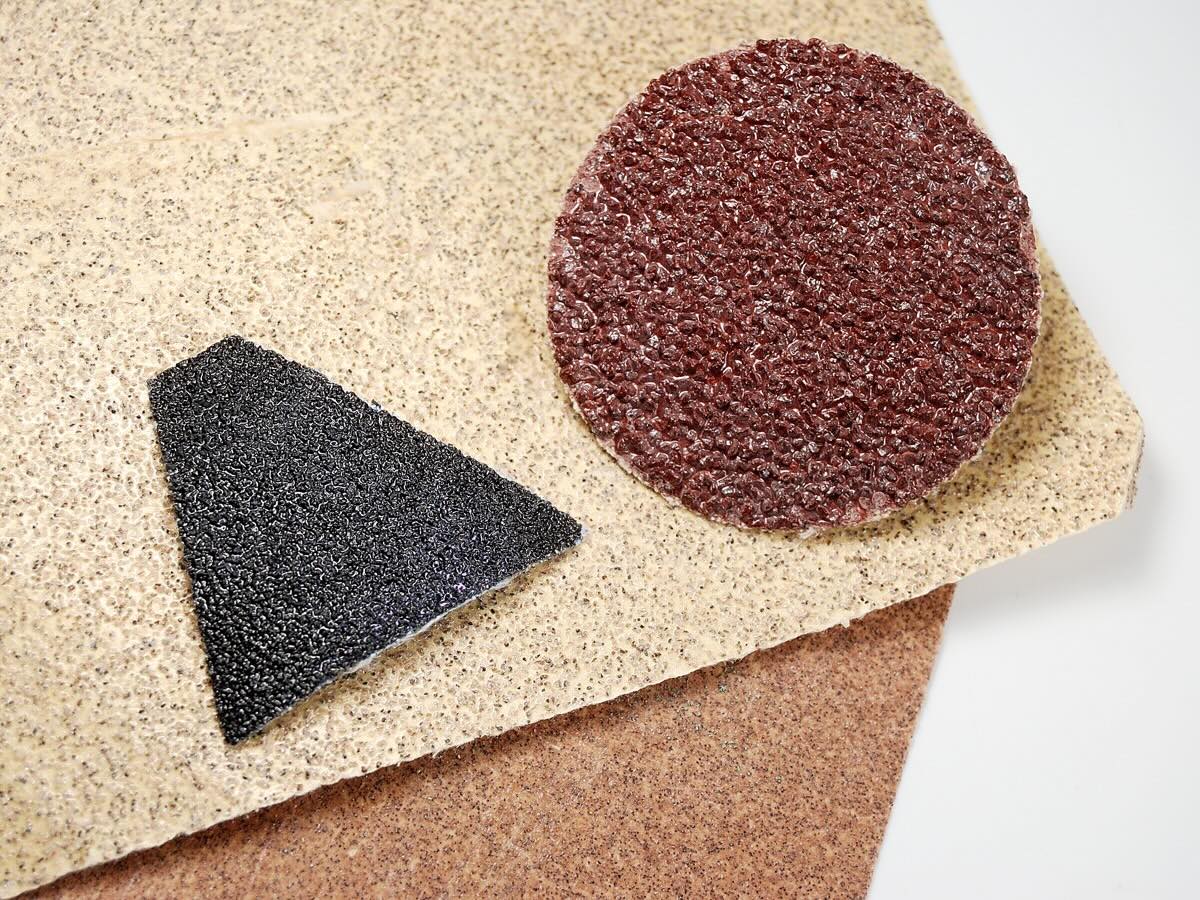

2. Grit Classification – Grit sandpaper is classified into different categories based on its coarseness or fineness. The most common types are coarse, medium, fine, and extra fine. Each grit level serves a specific purpose and is suitable for different stages of sanding.

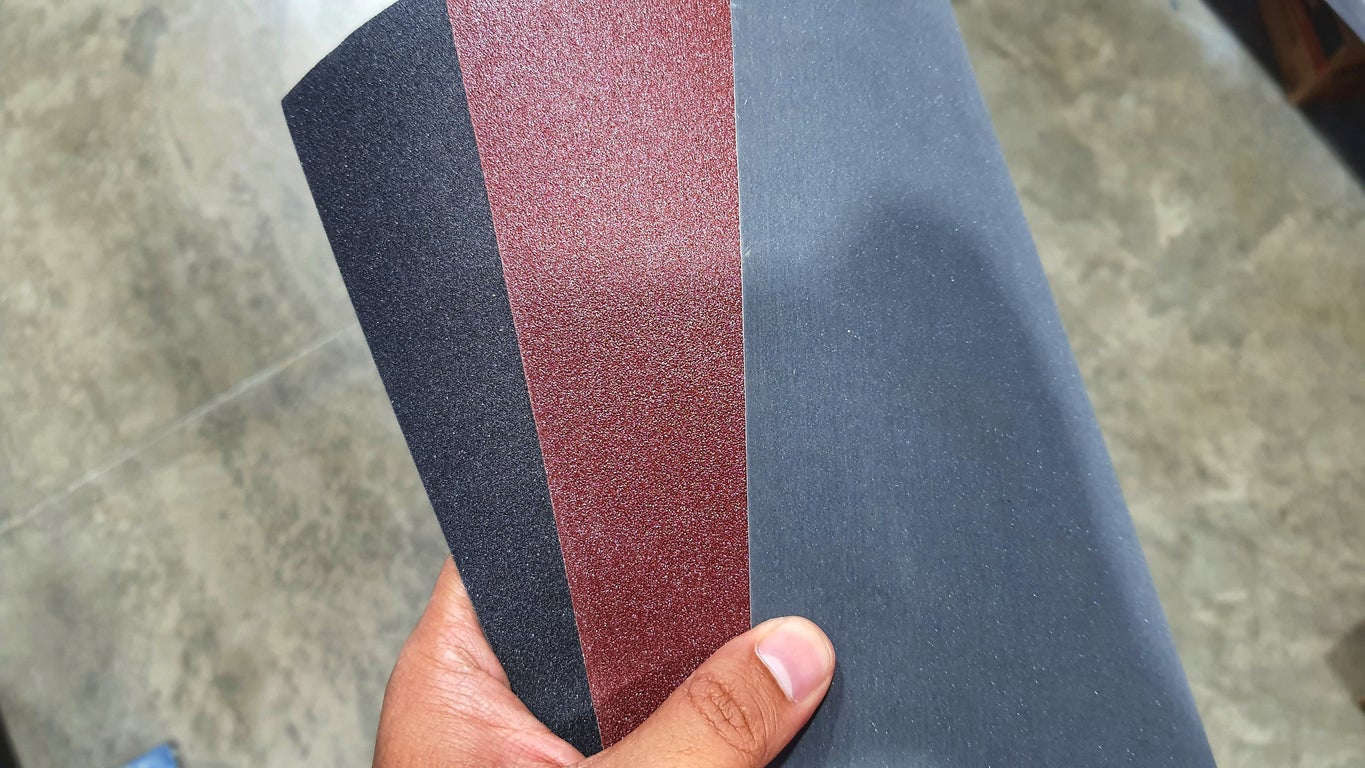

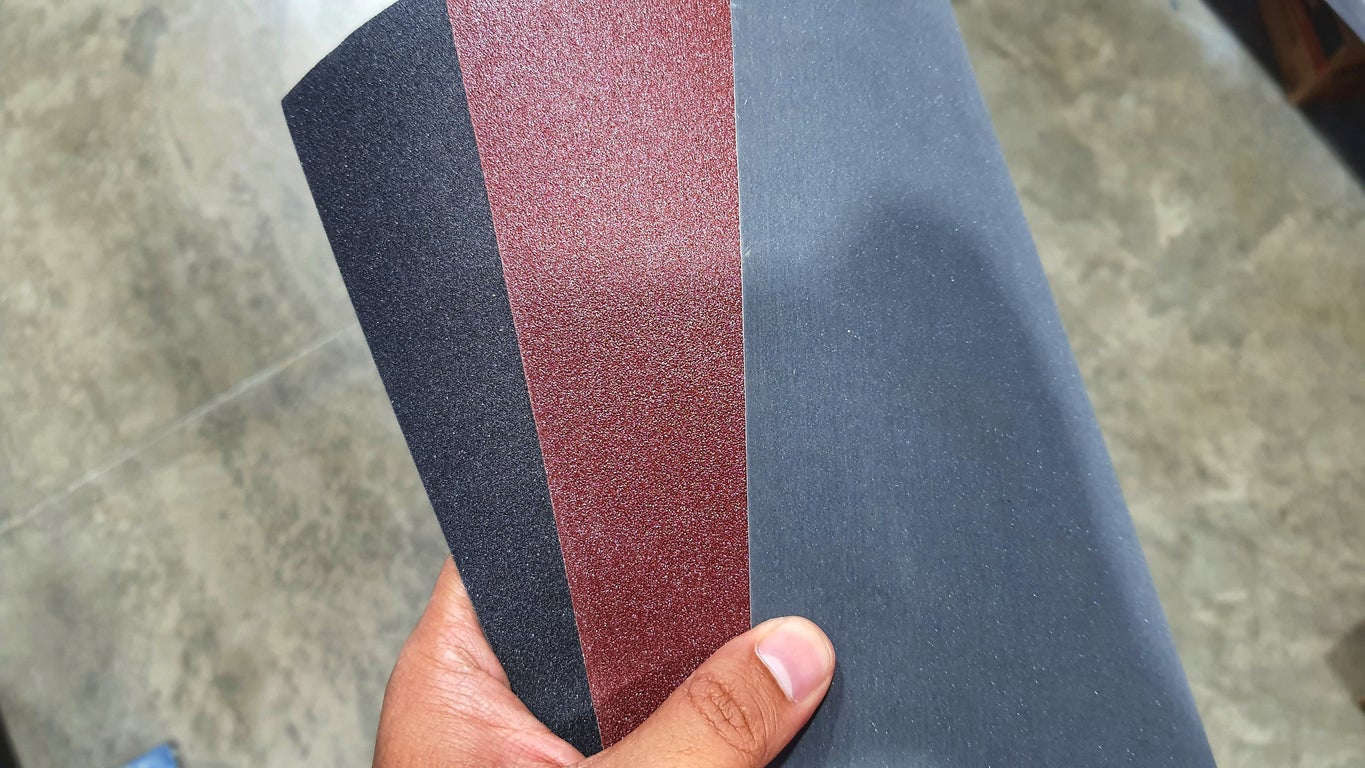

- Coarse Grit: Coarse grit sandpaper (typically between 40 and 80 grit) is the roughest and is used for heavy material removal. It is ideal for initial sanding of rough surfaces, such as removing old paint or smoothing out imperfections.

- Medium Grit: Medium grit sandpaper (around 100 to 150 grit) is the go-to option for general sanding tasks. It strikes a balance between stock removal and surface refinements, making it suitable for smoothing surfaces and preparing them for further finishing.

- Fine Grit: Fine grit sandpaper (between 180 and 220 grit) is designed for achieving a smooth finish on surfaces without causing excessive abrasion. It is often used for sanding between coats of paint or varnish to ensure a flawless final result.

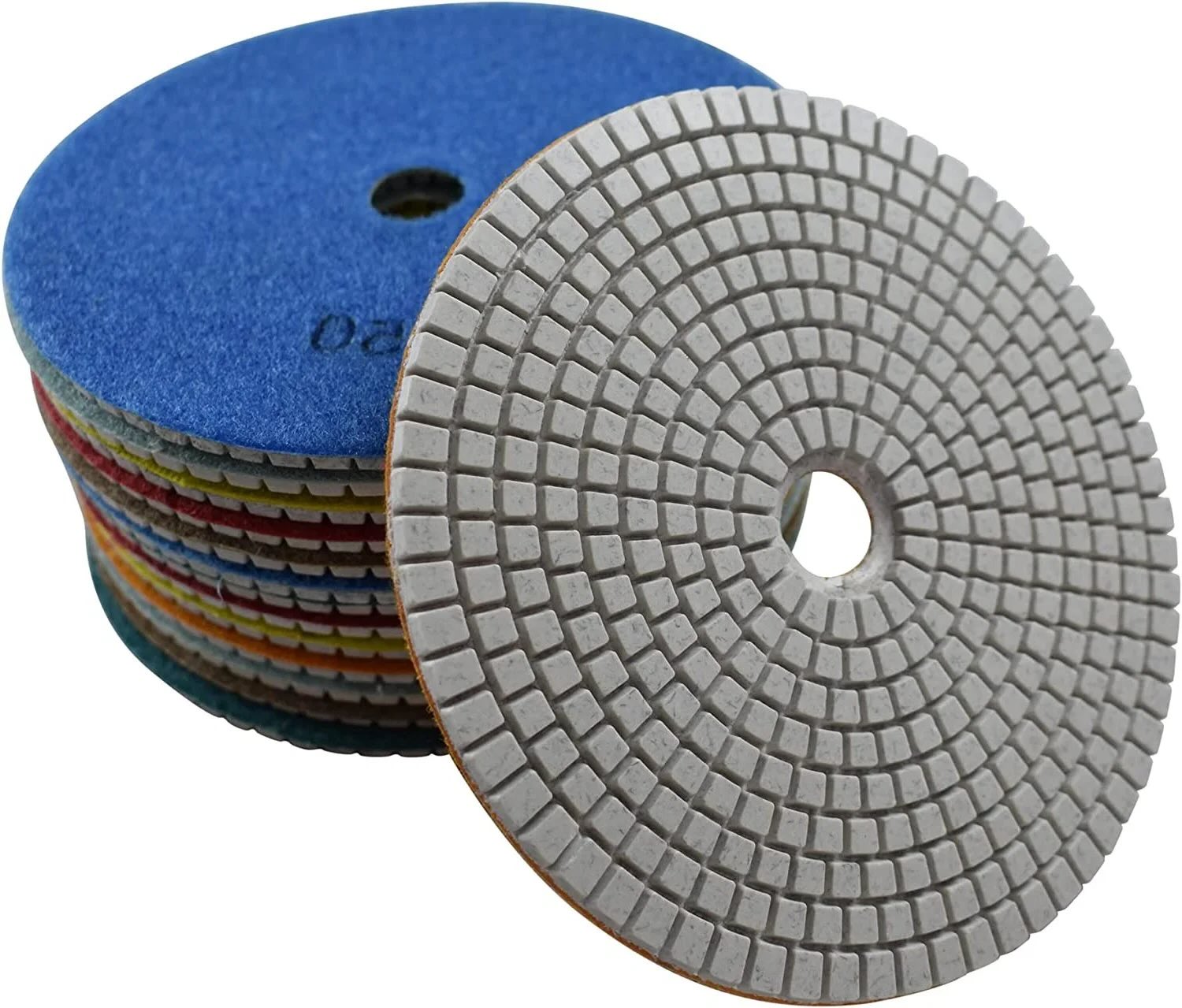

- Extra Fine Grit: Extra fine grit sandpaper (typically above 240 grit) is the finest type available. It is crucial for achieving a polished finish and for delicate sanding tasks, such as removing scratches from glass or polishing metal surfaces.

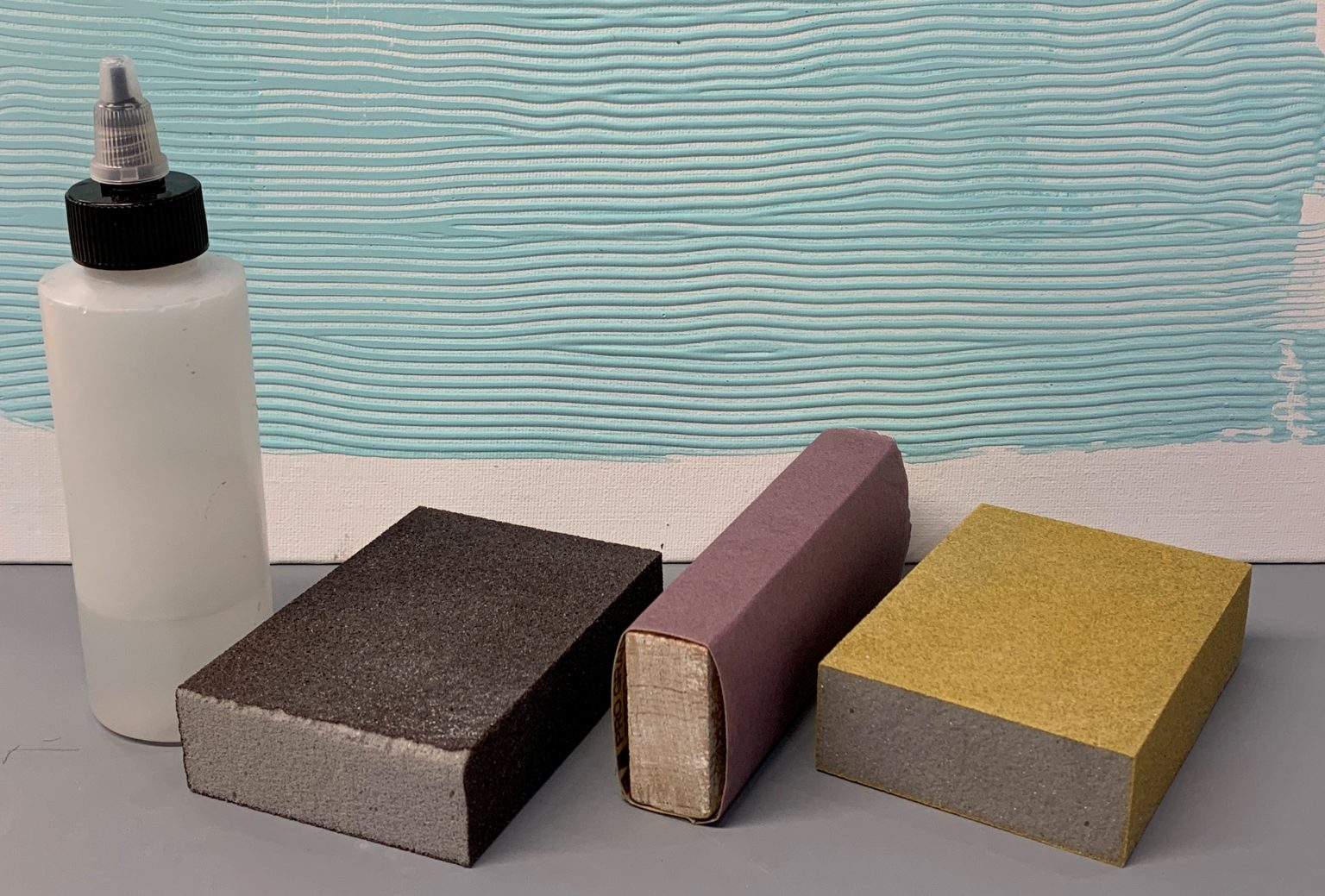

3. Backing Material – The abrasive particles on grit sandpaper are attached to a backing material, which can be paper or cloth. Paper-backed sandpaper is more affordable and suitable for most applications. Cloth-backed sandpaper, on the other hand, is more durable and is commonly used for heavy-duty tasks or in professional settings.

By understanding the different grit levels and their applications, you can determine the right sandpaper grit for your specific project. This knowledge will save you time, effort, and ensure a high-quality end result.

Importance of Using the Right Grit Sandpaper

Using the right grit sandpaper is vital for achieving the desired results in your sanding projects. Here are some key reasons why it is important:

1. Effective Material Removal: Different grit levels are designed to remove specific amounts of material. Using a coarse grit sandpaper when you need to remove a significant amount of material ensures efficient and timely results. Conversely, using a finer grit sandpaper for material removal can prolong the process and lead to frustration.

2. Optimal Surface Preparation: Properly preparing the surface is essential for achieving a smooth and even finish. Choosing the right grit sandpaper allows you to prepare the surface appropriately by smoothing out imperfections, removing old finishes, and creating an ideal surface for subsequent coats of paint, varnish, or sealant.

3. Avoiding Surface Damage: Using an incorrect grit sandpaper can potentially damage the surface you are working on. If you use a grit that is too coarse for delicate materials like wood or paint, it can cause gouging or scratches. On the other hand, using too fine a grit on a rough surface may not effectively smooth it out, resulting in an uneven finish.

4. Time and Cost Efficiency: Selecting the appropriate grit sandpaper saves you time and money in the long run. Using the right grit level ensures efficient material removal and reduces the need for excessive sanding or rework. By avoiding unnecessary sanding steps, you save both time and money on sandpaper and potentially costly repairs.

5. Achieving Desired Finish: The right grit contributes to the quality of the final finish. Finer grit sandpapers remove smaller imperfections and provide a smooth surface. If you want a high-gloss, professional-looking finish, using an appropriate grit sandpaper will help you accomplish that goal.

6. Safety Considerations: Working with the wrong grit sandpaper can lead to safety hazards. For instance, using a coarse grit on metal without caution can cause sparks or damage. It is crucial to consider the material, its hardness, and the appropriate grit level for a safe and successful sanding process.

By understanding the importance of using the right grit sandpaper, you can make informed decisions while selecting sandpaper for your projects. Choosing the appropriate grit level ensures efficient material removal, optimal surface preparation, and helps you achieve the desired finish with precision and safety.

Comparing Different Grit Levels

Let’s take a closer look at the different grit levels available and understand their specific applications:

Coarse Grit (40-80 Grit): Coarse grit sandpaper is the roughest type available. It is designed for heavy material removal and rough surface preparation. Use coarse grit sandpaper when you need to strip old paint or varnish, remove deep scratches, or shape and smooth rough surfaces.

Medium Grit (100-150 Grit): Medium grit sandpaper strikes a balance between material removal and surface refinement. It is ideal for general sanding tasks, including leveling uneven surfaces, removing moderate scratches, and preparing surfaces for paint or stain applications.

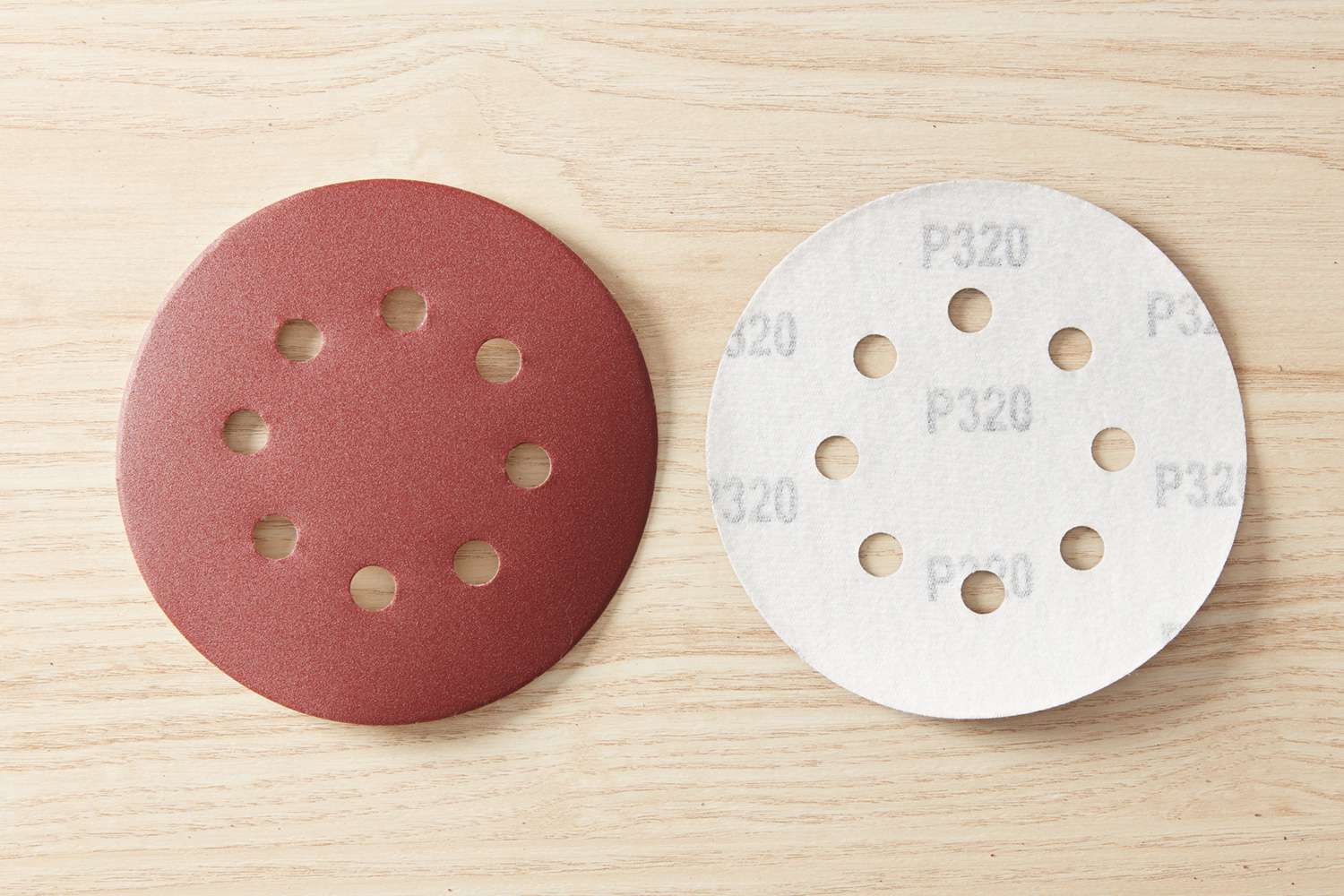

Fine Grit (180-220 Grit): Fine grit sandpaper is used for achieving a smooth surface and preparing it for the final finish. It is commonly used for sanding between coats of paint or varnish to achieve a flawless finish. Fine grit sandpaper also helps to remove light scratches and imperfections.

Extra Fine Grit (240+ Grit): Extra fine grit sandpaper is the finest available, perfect for achieving a polished and refined finish. It is commonly used for delicate sanding tasks, such as removing scratches from glass, polishing metal surfaces, or preparing surfaces for a high-gloss finish.

When comparing the different grit levels, it’s important to keep in mind that the coarseness or fineness of the sandpaper corresponds to the size of the abrasive material on its surface. Lower grit numbers indicate rougher sandpaper, while higher numbers indicate finer sandpaper.

It’s worth noting that when working on a project, it’s often necessary to use sandpaper with progressively finer grits. Starting with a coarse grit to remove significant imperfections, gradually transitioning to finer grits allows for smoother and more refined results.

Remember, the specific grit levels required for a project may vary depending on the material, the desired finish, and the level of preparation needed. It’s always important to evaluate the surface condition and choose the appropriate grit sandpaper accordingly.

By understanding the differences between various grit levels and their intended purposes, you can confidently select the right sandpaper for your specific project and achieve the desired results effectively and efficiently.

The higher the grit number, the finer the sandpaper. For rough sanding, use a lower grit (e.g. 60-100). For smoother finishes, use a higher grit (e.g. 150-220).

Determining the Roughest Grit Sandpaper

When it comes to determining the roughest grit sandpaper, it’s important to consider the range of grit levels available and their intended applications.

Typically, coarse grit sandpaper is considered the roughest. These sandpapers have lower grit numbers, typically ranging from 40 to 80. Coarse grit sandpaper is designed for heavy material removal and rough surface preparation. It is ideal for tasks such as stripping old paint or varnish, removing deep scratches, or shaping and smoothing rough surfaces.

Coarse grit sandpaper offers a higher level of aggressiveness due to the larger abrasive particles on its surface. These larger particles are capable of removing material quickly and efficiently, making it the go-to option when tackling tough, stubborn surfaces.

However, it’s important to note that the assessment of sandpaper roughness is relative. While coarse grit sandpaper may be considered rough in comparison to finer grits, it’s relatively smoother when compared to other abrasive materials like grinding wheels or metal files.

Another factor to consider in determining the roughest grit sandpaper is the material being sanded. Softer materials like wood may respond differently to the same grit sandpaper than harder materials like metal or concrete. The density, hardness, and texture of the material can influence the perceived roughness of the sandpaper.

It’s also worth mentioning that a rougher grit sandpaper may not always be the appropriate choice for every application. Using an excessively rough grit on delicate surfaces or for fine finishing work can lead to damage or an undesired result.

Ultimately, the choice of grit sandpaper should be based on the specific task at hand, considering factors such as the material being sanded, the level of material removal required, and the desired finish. Starting with a rougher grit for heavy material removal and gradually progressing to finer grits allows for a more controlled and refined sanding process.

Remember, the roughest grit sandpaper is subjective and dependent on the context of the project. It’s essential to assess the surface, consider the material being worked on, and choose the appropriate grit that balances efficiency with the desired outcome.

By understanding the range of grit levels and their intended applications, you can make informed decisions to achieve your desired results effectively and efficiently.

Read more: What Is Fine Sandpaper Grit

Factors Affecting Sandpaper Roughness

The roughness of sandpaper can be influenced by several factors. Understanding these factors can help you choose the right sandpaper for your specific needs. Here are the key factors that affect sandpaper roughness:

1. Grit Size: The grit size of the sandpaper is the primary determinant of its roughness. Lower grit numbers indicate coarser sandpaper, while higher numbers indicate finer sandpaper. Coarser grits have larger abrasive particles, resulting in a rougher surface finish. Finer grits, on the other hand, have smaller abrasive particles, which produce a smoother finish.

2. Material Being Sanded: The type of material being sanded plays a significant role in the perceived roughness of sandpaper. Softer materials like wood will tend to feel rougher when sanded with the same grit sandpaper compared to harder materials like metal or concrete. The density and texture of the material can affect how the abrasive particles interact with the surface, resulting in variations in perceived roughness.

3. Pressure Applied: The amount of pressure applied when sanding can influence the roughness of the sandpaper. Applying more pressure can result in increased abrasion and a rougher surface. Conversely, using a lighter touch can yield a smoother finish. It’s important to find the right balance of pressure to achieve the desired surface texture without causing damage or unnecessary roughness.

4. Sanding Technique: The technique used while sanding can affect the roughness of the sandpaper. Sanding in a consistent, uniform motion with even pressure can result in a more even and smooth surface. In contrast, uneven or erratic sanding can lead to uneven or rough areas. It’s important to maintain a steady technique to achieve the desired level of roughness.

5. Sandpaper Quality: The quality of the sandpaper can also impact its roughness. Higher-quality sandpaper tends to have more consistent grit sizes and better adhesion of abrasive particles to the backing material. Lower-quality sandpapers may have uneven distribution of particles or wear out quickly, leading to an inconsistent sanding experience and potentially rougher results.

6. Previous Sanding Stages: The previous stages of sanding can affect the roughness of the final surface. Using progressively finer grits and properly sanding between each stage helps to achieve a smoother finish. Neglecting to sand with finer grits after using coarser grits can leave visible scratches or roughness on the surface.

By considering these factors and understanding how they impact sandpaper roughness, you can make informed decisions about the appropriate sandpaper grit for your specific application. It’s important to experiment and find the right combination of factors to achieve the desired surface texture and finish.

Remember, sandpaper roughness is subjective and dependent on the specific project and desired outcome. By taking these factors into account, you can achieve optimal results and create a smooth, polished finish on your projects.

Conclusion

Grit sandpaper is an indispensable tool for achieving smooth and polished surfaces in various projects. Understanding the different grit levels and their specific applications is crucial for selecting the right sandpaper for each task. The roughness of sandpaper depends on factors such as the grit size, material being sanded, pressure applied, sanding technique, sandpaper quality, and previous sanding stages.

Using the right grit sandpaper is vital for effective material removal, optimal surface preparation, and achieving the desired finish. Selecting a sandpaper with the appropriate grit level ensures efficient results, saves time, and prevents surface damage. It also contributes to a more cost-effective and safer sanding process. By choosing the right sandpaper, you can achieve professional-quality results that meet your expectations.

Remember to consider the specific needs of your project and the characteristics of the material being worked on. Assess the level of material removal required and the desired finish. Use progressively finer grits to achieve a smooth surface and an even, polished result. Take into account the pressure applied and the sanding technique to achieve consistent and desired roughness levels.

In conclusion, by understanding and utilizing the appropriate grit sandpaper, you can elevate the quality of your woodworking, DIY, or other projects. Take the time to select the right sandpaper for each stage of your project, and you will be rewarded with impressive results. So go ahead, grab your sandpaper, and make your surfaces shine!

Frequently Asked Questions about Which Grit Sandpaper Is The Roughest

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “Which Grit Sandpaper Is The Roughest”