Home>Renovation & DIY>Tools & Equipment>How Is Grit Measured In Sandpaper

Tools & Equipment

How Is Grit Measured In Sandpaper

Modified: October 20, 2024

Discover how grit is measured in sandpaper and its importance in choosing the right tools and equipment for your projects. Explore the different grit sizes and their applications.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When it comes to sandpaper, the term “grit” holds significant importance. Grit refers to the coarseness or fineness of the abrasive particles embedded in the sandpaper. Understanding how grit is measured in sandpaper is crucial for achieving desired results in various sanding applications. Whether you’re a seasoned woodworker, a DIY enthusiast, or simply someone looking to touch up a few surfaces, comprehending the intricacies of grit measurement can make a world of difference in your projects.

Let’s delve into the fascinating world of sandpaper grit, exploring the various aspects of its measurement and its impact on the sanding process. By the end of this article, you’ll have a deeper understanding of how grit is quantified, the different measurement methods employed, and the implications of grit size on the sanding experience.

Key Takeaways:

- Sandpaper grit is measured by the coarseness or fineness of abrasive particles, impacting sanding efficiency and surface quality. Understanding grit size helps achieve desired results in various sanding applications.

- The grit numbering system, measurement methods like sieve analysis and laser diffraction, and the type of abrasive material used are crucial in determining the effectiveness of sandpaper for specific sanding tasks.

Read more: Which Grit Sandpaper Is The Roughest

Abrasive Grit Size

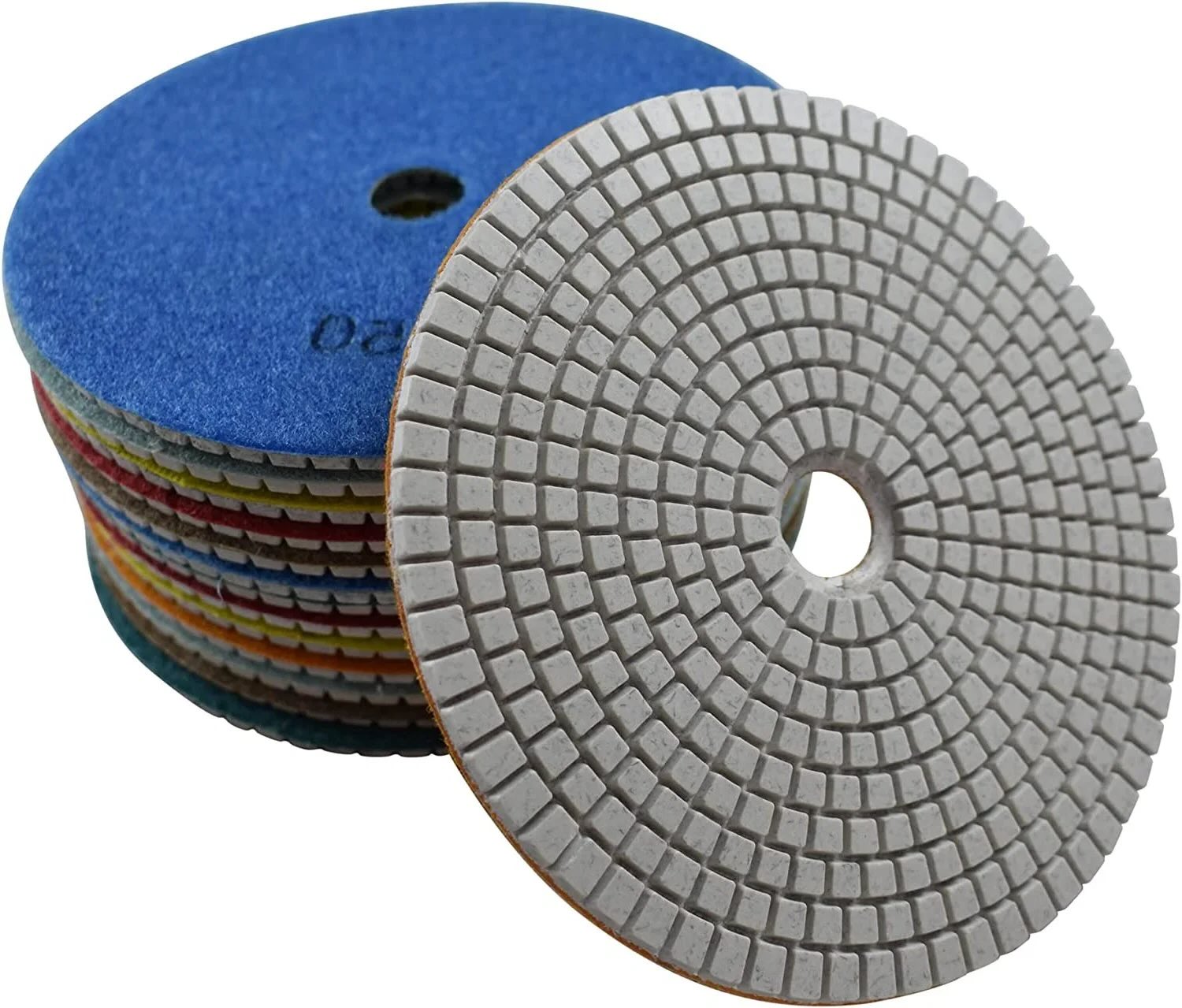

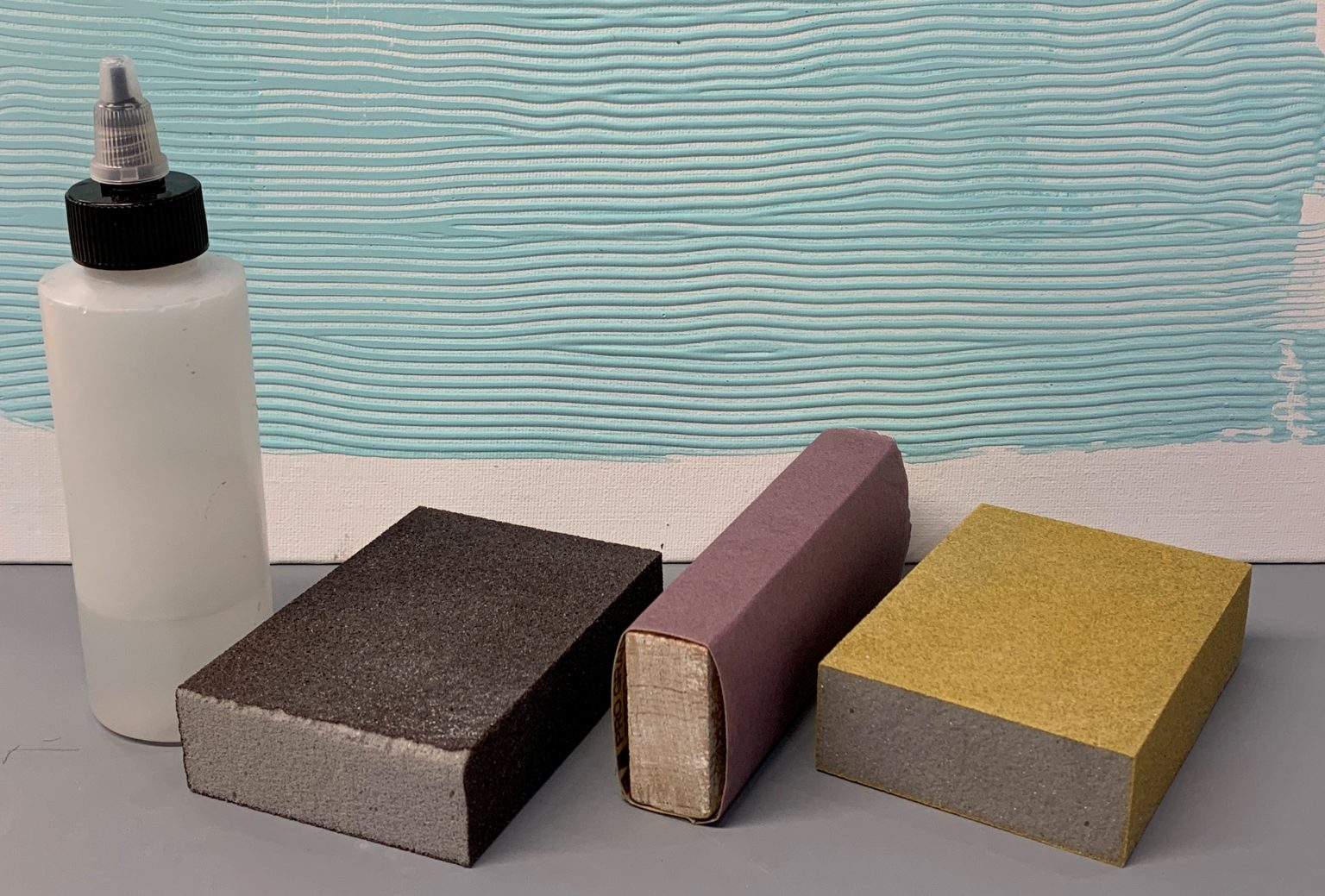

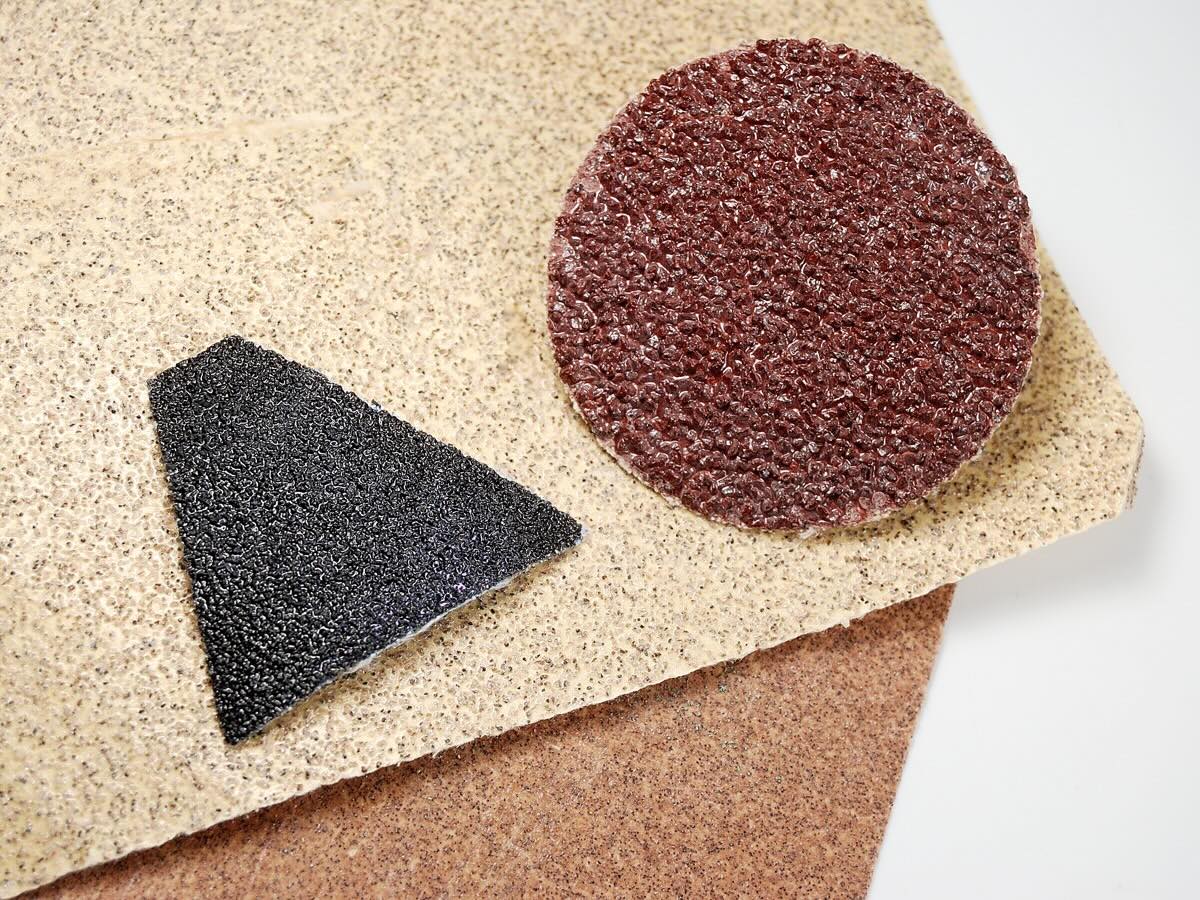

The abrasive grit size refers to the dimensions of the abrasive particles used in sandpaper. These particles are typically made from materials like aluminum oxide, silicon carbide, or garnet, and they come in various sizes to cater to different sanding requirements. The grit size directly impacts the aggressiveness and smoothness of the sanding action. Coarser grits are more abrasive and are suitable for removing material quickly, while finer grits produce smoother finishes and are ideal for final sanding and polishing.

Understanding abrasive grit size involves familiarizing oneself with the concept of mesh size. This measurement system quantifies the number of abrasive particles per square inch of sandpaper. For instance, a 100-grit sandpaper contains 100 abrasive particles per square inch. The higher the grit number, the finer the particles and the smoother the sandpaper. Conversely, lower grit numbers indicate coarser particles, resulting in more aggressive sanding.

It’s important to note that the abrasive grit size is not the sole determinant of a sandpaper’s effectiveness. The type of abrasive material used also plays a crucial role in the sanding process. Different materials exhibit varying hardness, sharpness, and durability, influencing the overall performance of the sandpaper.

Grit Numbering System

The grit numbering system is a standardized method used to categorize the coarseness or fineness of abrasive particles in sandpaper. This system provides a clear and consistent way to identify the abrasive grit size, enabling users to select the most suitable sandpaper for their specific applications.

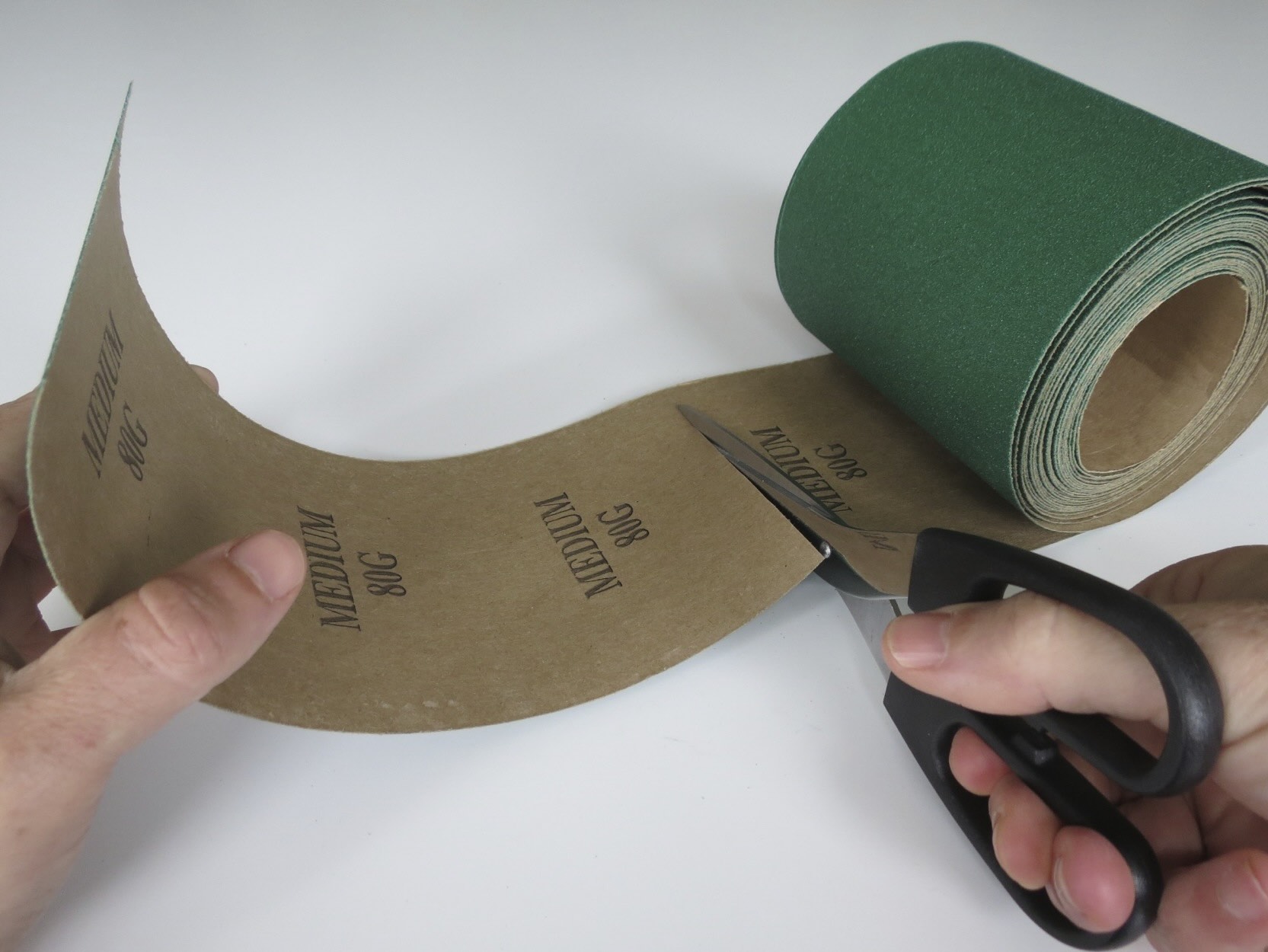

In the United States, the most widely adopted grit numbering system for sandpaper is the CAMI (Coated Abrasives Manufacturers Institute) system. This system assigns a numerical value to each grit size, with lower numbers representing coarser grits and higher numbers denoting finer grits. For instance, 40-grit sandpaper is coarser and more aggressive, while 400-grit sandpaper is finer and produces smoother finishes.

Conversely, the European standard, known as the FEPA (Federation of European Producers of Abrasives) system, utilizes a P-scale to designate grit sizes. The P-scale is accompanied by a number, such as P40 or P400, indicating the coarseness or fineness of the abrasive particles. This system is widely recognized in European countries and provides a comparable method for identifying grit sizes across different regions.

It’s essential for users to familiarize themselves with the grit numbering system to make informed decisions when selecting sandpaper. By understanding the implications of different grit sizes, individuals can effectively tailor their sanding approach to achieve the desired surface texture and finish.

Grit in sandpaper is measured by the number of abrasive particles per square inch. The higher the number, the finer the grit. For example, 80-grit sandpaper has coarser particles than 120-grit.

Measurement Methods

Several methods are employed to measure the grit of sandpaper, each offering unique insights into the coarseness or fineness of the abrasive particles. These measurement techniques are instrumental in ensuring the accuracy and consistency of grit classification across various sandpaper products.

One common method used to determine grit size is the sieve analysis. In this approach, the sandpaper particles are sieved through a series of mesh screens with progressively finer openings. The particles that pass through each screen are collected and analyzed to ascertain the distribution of particle sizes. This method provides valuable data on the range of particle sizes present in the sandpaper, aiding in the precise classification of grit.

Another widely utilized measurement method is the laser diffraction technique. This advanced method employs laser technology to analyze the scattering of light by the abrasive particles, enabling the calculation of particle size distribution. The laser diffraction method offers high precision and is capable of capturing a broad range of particle sizes, making it an invaluable tool for assessing the grit characteristics of sandpaper.

Furthermore, microscopic analysis is utilized to examine the individual abrasive particles present in the sandpaper. By magnifying the particles under a microscope, their size and shape can be meticulously studied, contributing to a comprehensive understanding of the grit composition. This method allows for detailed observations of the abrasive particles, facilitating accurate grit classification and quality assessment.

Overall, the measurement methods employed for evaluating sandpaper grit play a pivotal role in ensuring the consistency and reliability of grit classification. By leveraging these techniques, manufacturers can uphold stringent quality standards, while consumers can make well-informed decisions when selecting sandpaper for their specific sanding needs.

Conclusion

Understanding how grit is measured in sandpaper is essential for anyone seeking to achieve optimal results in their sanding endeavors. The abrasive grit size, characterized by the coarseness or fineness of the abrasive particles, directly influences the efficiency and quality of the sanding process. By comprehending the nuances of grit measurement, individuals can make informed choices when selecting sandpaper for various applications, ensuring that the chosen grit aligns with the desired surface texture and finish.

The grit numbering system, encompassing standards such as CAMI and FEPA, provides a universal framework for classifying grit sizes, enabling users to navigate the diverse range of sandpaper options with clarity and confidence. This standardized approach simplifies the selection process, empowering individuals to identify the most suitable sandpaper for their specific sanding tasks.

Moreover, the meticulous measurement methods employed to assess sandpaper grit, including sieve analysis, laser diffraction, and microscopic analysis, underscore the commitment to precision and quality in the manufacturing and evaluation of sandpaper products. These techniques ensure that grit classification is accurate and consistent, fostering trust and reliability in the performance of sandpaper across various applications.

Ultimately, the measurement of grit in sandpaper is not merely a technical aspect but an integral component that shapes the entire sanding experience. It empowers individuals to tailor their approach, achieve desired outcomes, and elevate the quality of their craftsmanship. Whether it’s refining a woodworking project, restoring a piece of furniture, or tackling a DIY home improvement task, a nuanced understanding of grit measurement equips enthusiasts and professionals alike to embark on their sanding endeavors with precision and proficiency.

Frequently Asked Questions about How Is Grit Measured In Sandpaper

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Is Grit Measured In Sandpaper”