Home>Renovation & DIY>Tools & Equipment>What Grit Sandpaper To Polish Aluminum

Tools & Equipment

What Grit Sandpaper To Polish Aluminum

Modified: January 4, 2024

Discover the best grit sandpaper for polishing aluminum with our comprehensive guide. Find the right tools and equipment for your project.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

**

Introduction

**

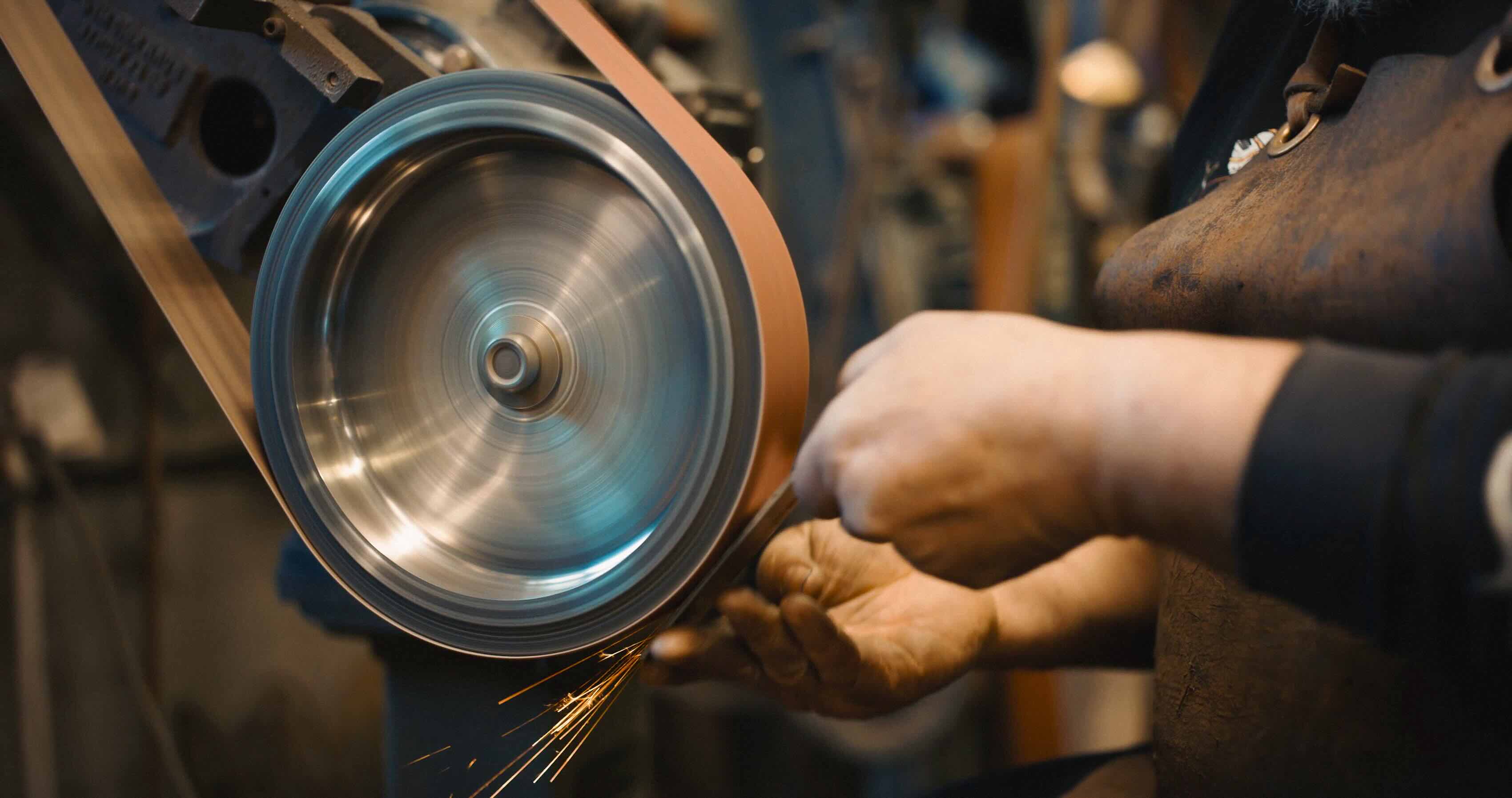

Polishing aluminum can transform dull, tarnished surfaces into gleaming, reflective finishes. Whether you're restoring vintage aluminum fixtures, refining car parts, or simply aiming to revitalize household items, understanding the nuances of grit sandpaper selection is crucial for achieving optimal results. By delving into the world of grit sizes and mastering the art of aluminum polishing, you can elevate the aesthetic appeal of various items while simultaneously honing your DIY skills.

Aluminum, renowned for its malleability and corrosion-resistant properties, is a versatile material used in diverse applications, including automotive components, household appliances, and decorative pieces. However, over time, aluminum surfaces can succumb to oxidation, scratches, and general wear and tear, resulting in a lackluster appearance. This is where the transformative power of polishing comes into play.

To embark on an aluminum polishing endeavor, it's essential to comprehend the significance of grit sizes, as they directly influence the sanding and polishing process. From coarse abrasives capable of smoothing out imperfections to fine-grit sandpapers that impart a lustrous sheen, the world of grit sizes is a pivotal aspect of aluminum polishing. By navigating this terrain with confidence, you can effectively restore the brilliance of aluminum surfaces, breathing new life into weathered or lackluster items.

In the subsequent sections, we'll delve into the intricacies of grit sizes, explore the art of choosing the right grit sandpaper for aluminum polishing, and uncover valuable tips for achieving impeccable results. By the end of this journey, you'll be equipped with the knowledge and insights needed to embark on your aluminum polishing endeavors with poise and precision. Let's embark on this enlightening exploration of aluminum polishing and the pivotal role of grit sandpaper in this transformative process.

Key Takeaways:

- Choose the right sandpaper grit for aluminum polishing based on the surface condition. Start with coarse grit for imperfections and gradually transition to finer grits for a lustrous finish.

- Follow tips like consistent motion, mindful pressure, and directional sanding for effective aluminum polishing with sandpaper. Prepare the surface, maintain cleanliness, and finish with a metal polish for enduring brilliance.

Read more: What Grit Sandpaper To Polish Headlights

Understanding Grit Sizes

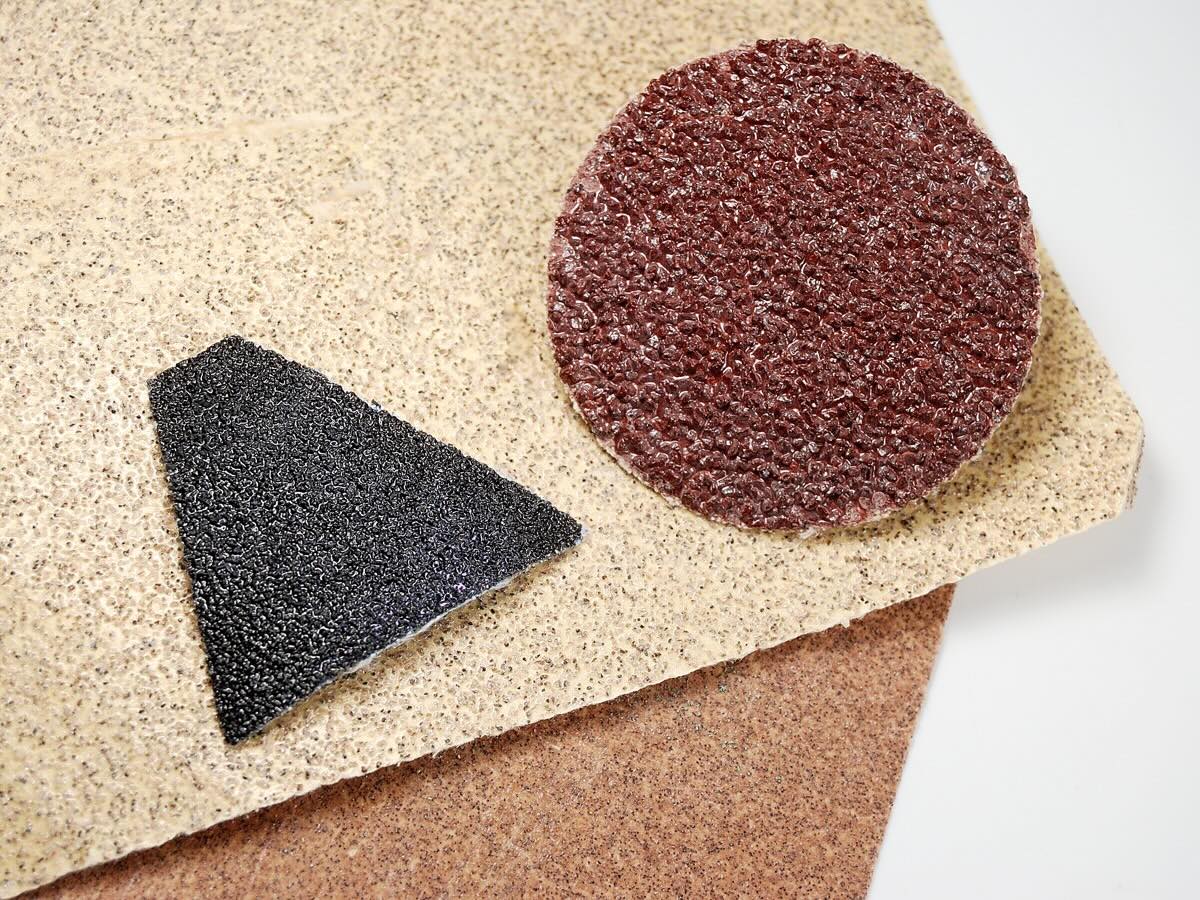

Before delving into the intricacies of aluminum polishing, it’s crucial to grasp the concept of grit sizes and their impact on the sanding and polishing process. Grit size refers to the measure of abrasive particles per square inch of sandpaper, determining the coarseness or fineness of the abrasive material. Understanding grit sizes is akin to unraveling the language of abrasives, enabling you to navigate the diverse array of sandpapers with confidence and precision.

Grit sizes are denoted by numbers, with lower numbers signifying coarser abrasives and higher numbers indicating finer particles. Coarse grit sandpapers, typically ranging from 40 to 100 grit, are adept at swiftly removing imperfections, corrosion, and stubborn blemishes from aluminum surfaces. As the grit size increases, the abrasives become finer, facilitating the gradual refinement and smoothing of the metal’s texture.

When selecting sandpaper for aluminum polishing, it’s essential to consider the specific requirements of the project. For instance, if the aluminum surface exhibits deep scratches, corrosion, or rough patches, commencing the polishing process with a coarse grit sandpaper, such as 40 or 60 grit, is recommended. This coarse abrasive swiftly levels imperfections, preparing the surface for subsequent refinement with finer grits.

Conversely, when the aluminum surface is relatively smooth and requires minor polishing or the removal of superficial blemishes, transitioning to medium or fine grit sandpapers, such as 180 or 240 grit, is advantageous. These finer abrasives facilitate the gradual enhancement of the metal’s luster, culminating in a polished finish that exudes brilliance.

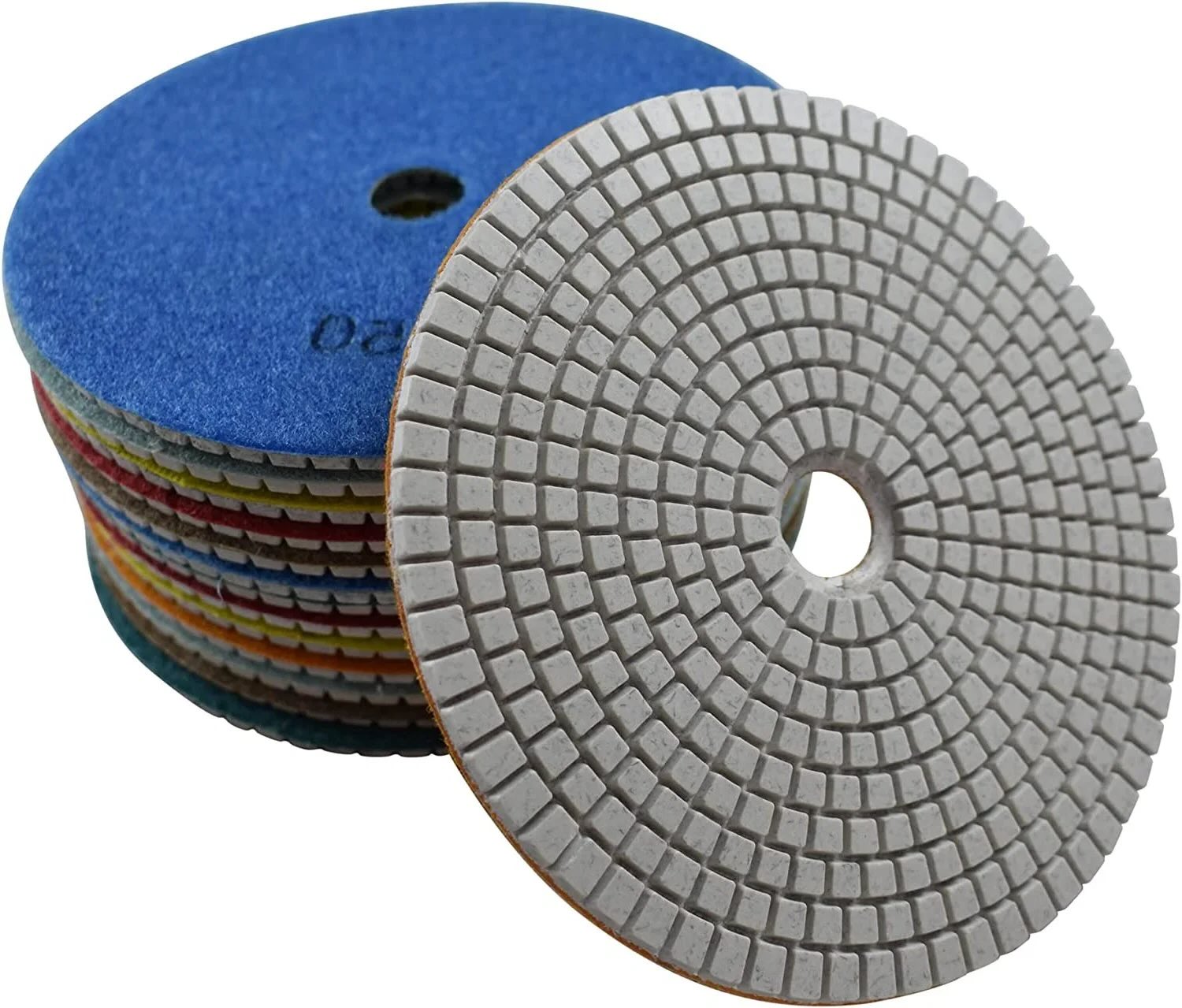

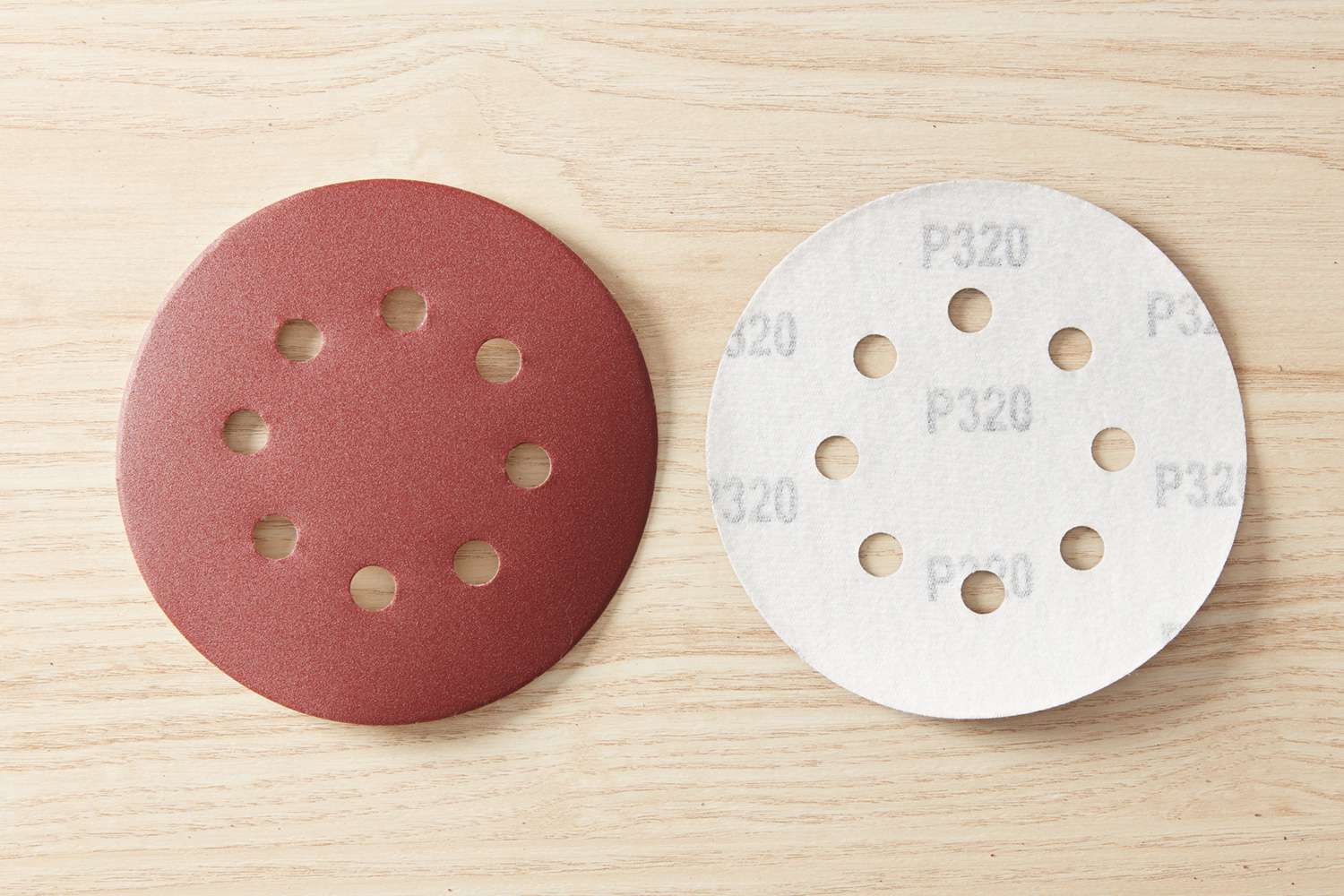

Furthermore, ultra-fine grit sandpapers, ranging from 600 to 1500 grit, are instrumental in refining aluminum surfaces to a mirror-like sheen. These exceptionally fine abrasives meticulously smooth the metal, eradicating minute imperfections and bestowing a dazzling, reflective quality to the polished aluminum.

By comprehending the nuances of grit sizes, you can discern the ideal sandpaper for each stage of the aluminum polishing process, ensuring a methodical and effective approach to revitalizing aluminum surfaces. The next step in this enlightening journey involves deciphering the art of choosing the right grit sandpaper for aluminum polishing, a pivotal aspect that significantly influences the outcome of your polishing endeavors.

Choosing the Right Grit Sandpaper for Aluminum Polishing

Embarking on an aluminum polishing venture necessitates a discerning approach to selecting the appropriate grit sandpaper for each stage of the process. By aligning the grit sizes with the specific requirements of the aluminum surface, you can orchestrate a seamless progression from abrasion to refinement, culminating in a resplendent, mirror-like finish. Let’s unravel the art of choosing the right grit sandpaper for aluminum polishing, a pivotal step in the transformative journey of restoring aluminum surfaces to their former glory.

When initiating the aluminum polishing process, particularly if the surface exhibits noticeable imperfections, corrosion, or rough patches, commencing with a coarse grit sandpaper is imperative. Coarse abrasives, such as 40 or 60 grit, possess the potency to swiftly level the surface, effectively eradicating stubborn blemishes and preparing the aluminum for subsequent refinement. This initial stage sets the foundation for the subsequent phases of polishing, laying the groundwork for the gradual enhancement of the metal’s luster.

As the aluminum surface evolves from a coarser texture to a smoother state, transitioning to medium grit sandpapers, typically ranging from 80 to 180 grit, is advantageous. These abrasives facilitate the progressive refinement of the metal, smoothing out imperfections and bestowing a burgeoning sheen upon the surface. The meticulous use of medium grit sandpapers paves the way for the subsequent stage of polishing, bringing the aluminum one step closer to its radiant transformation.

Upon reaching a relatively smooth texture, the utilization of fine grit sandpapers, such as 220 to 400 grit, becomes instrumental in further enhancing the luster of the aluminum. These finer abrasives meticulously refine the surface, diminishing minor blemishes and imperfections while fostering a burgeoning brilliance that heralds the impending transformation of the metal.

Finally, the culmination of the aluminum polishing journey involves the application of ultra-fine grit sandpapers, ranging from 600 to 1500 grit, to achieve a mirror-like, reflective finish. These exceptionally fine abrasives meticulously smooth the metal, eradicating minute imperfections and imparting a dazzling, lustrous quality to the polished aluminum, elevating it to a state of resplendence.

By judiciously selecting the right grit sandpaper for each phase of the aluminum polishing process, you can orchestrate a methodical and effective approach, ensuring that each stage seamlessly transitions into the next, ultimately yielding a polished aluminum surface that exudes timeless allure.

Use 400-600 grit sandpaper to polish aluminum. Start with a coarser grit to remove imperfections, then switch to a finer grit for a smooth finish. Always sand in the direction of the grain for best results.

Tips for Polishing Aluminum with Sandpaper

Embarking on the journey of polishing aluminum with sandpaper entails a meticulous approach and a keen understanding of the nuances involved in the process. By integrating these insightful tips into your aluminum polishing endeavors, you can navigate the intricacies of the sanding and polishing process with finesse, ultimately achieving impeccable results that breathe new life into weathered aluminum surfaces.

-

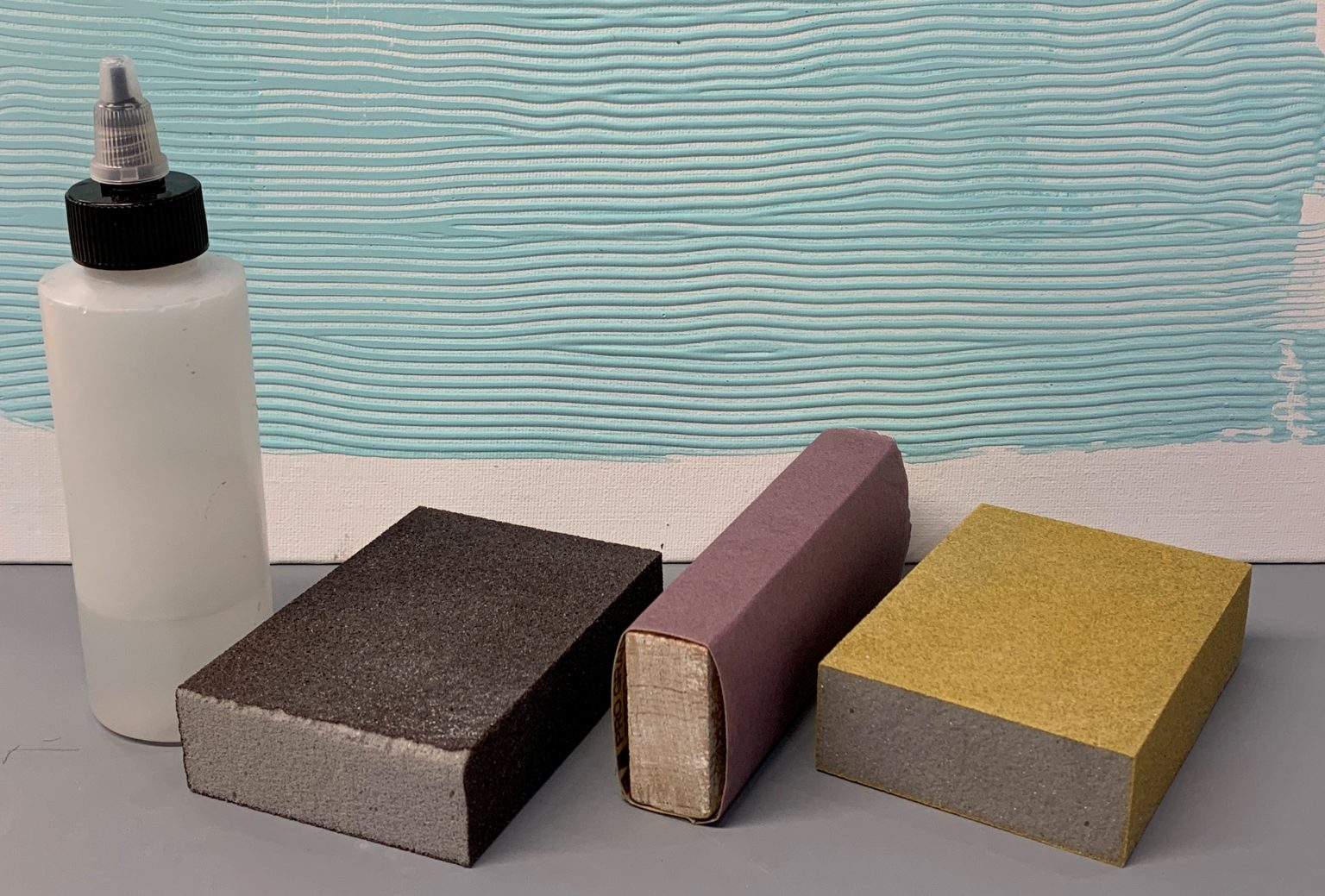

Surface Preparation: Before commencing the polishing process, ensure that the aluminum surface is clean and free of any debris or contaminants. This preparatory step lays the foundation for seamless sanding and polishing, allowing the abrasive action of the sandpaper to exert its transformative prowess on the metal.

-

Progressive Grit Transition: Embrace a systematic approach to grit progression, commencing with coarse grit sandpaper to address imperfections and gradually transitioning to finer grits for refinement. This methodical progression ensures a seamless transformation of the aluminum surface, culminating in a lustrous, mirror-like finish.

-

Consistent Motion: When sanding the aluminum surface, maintain a consistent and even motion to facilitate uniform abrasion. This approach minimizes the risk of uneven texture and ensures a harmonious progression towards a polished finish.

-

Mindful Pressure: Apply gentle yet deliberate pressure when sanding the aluminum, allowing the sandpaper to efficaciously smooth the metal without causing undue abrasion. Balancing the pressure ensures controlled refinement, yielding a polished surface that exudes elegance.

-

Directional Sanding: Adhere to a consistent sanding direction, such as linear strokes, to promote uniformity and precision in the abrasion process. This deliberate approach fosters a cohesive texture and minimizes the likelihood of irregularities in the polished surface.

-

Intermittent Inspection: Periodically inspect the aluminum surface during the polishing process to gauge the progress and identify areas that may require additional attention. This vigilant approach empowers you to address specific areas effectively, ensuring comprehensive refinement throughout the polishing journey.

-

Cleanliness Maintenance: Regularly clean the sandpaper and the aluminum surface during the polishing process to prevent the accumulation of debris and maintain optimal abrasion efficacy. This practice safeguards against potential abrasion irregularities and facilitates a seamless polishing experience.

-

Finishing Flourish: Upon completing the sanding process, consider employing a metal polish or aluminum-specific buffing compound to further enhance the luster and protective qualities of the polished surface. This finishing touch elevates the aluminum to a state of enduring brilliance, accentuating the transformative impact of the polishing endeavor.

By integrating these tips into your aluminum polishing pursuits, you can navigate the intricacies of the sanding and polishing process with finesse, ultimately achieving impeccable results that breathe new life into weathered aluminum surfaces. The judicious application of these insights will empower you to orchestrate a seamless and transformative aluminum polishing experience, culminating in resplendent, mirror-like finishes that exude timeless allure.

Conclusion

Embarking on the transformative journey of aluminum polishing unveils a realm of creative expression and meticulous craftsmanship, where the interplay of grit sandpaper and diligent technique yields resplendent, mirror-like finishes that breathe new life into weathered surfaces. By immersing oneself in the art of aluminum polishing, one can harness the transformative potential of grit sandpaper, revitalizing tarnished aluminum with precision and finesse.

Throughout this enlightening exploration, we’ve delved into the significance of grit sizes, unraveled the art of choosing the right sandpaper for aluminum polishing, and gleaned invaluable tips for navigating the intricacies of the sanding and polishing process. From understanding the language of abrasives to orchestrating a methodical progression from abrasion to refinement, the journey of aluminum polishing encapsulates a harmonious fusion of artistry and technique.

The nuances of grit sizes, ranging from coarse abrasives that swiftly level imperfections to ultra-fine grits that bestow a mirror-like sheen, underscore the pivotal role of sandpaper in the transformative process of aluminum polishing. By judiciously selecting the appropriate grit sandpaper for each phase of the polishing journey, one can orchestrate a seamless progression towards resplendent, polished surfaces that exude timeless allure.

Furthermore, the insightful tips for polishing aluminum with sandpaper, encompassing meticulous surface preparation, progressive grit transition, and mindful technique, equip enthusiasts with the knowledge and finesse needed to navigate the intricacies of the polishing process. By integrating these tips into their aluminum polishing pursuits, individuals can elevate their craftsmanship and achieve impeccable results that breathe new life into weathered aluminum surfaces.

As we conclude this enriching odyssey through the realm of aluminum polishing, it’s evident that the transformative potential of grit sandpaper transcends mere abrasion, evolving into a catalyst for revitalization and restoration. Whether it’s reviving vintage aluminum fixtures, refining car parts, or imbuing household items with a newfound radiance, the art of aluminum polishing, intertwined with the mastery of grit sandpaper, empowers enthusiasts to embark on transformative journeys that culminate in resplendent, mirror-like finishes.

Armed with the insights garnered from this exploration, enthusiasts are poised to embark on their aluminum polishing endeavors with confidence and finesse, harnessing the transformative potential of grit sandpaper to breathe new life into aluminum surfaces and unveil their timeless allure.

Frequently Asked Questions about What Grit Sandpaper To Polish Aluminum

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Grit Sandpaper To Polish Aluminum”