Home>Renovation & DIY>Tools & Equipment>What Kind Of Sandpaper For Metal

Tools & Equipment

What Kind Of Sandpaper For Metal

Published: December 20, 2023

Looking for the right sandpaper for metal? Discover essential tools and equipment for your metalworking projects.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to our comprehensive guide on choosing the right sandpaper for metal surfaces. When it comes to metalworking, sanding is a crucial step in achieving the desired finish. Whether you are working on a DIY project or a professional metal fabrication job, using the correct sandpaper can make all the difference.

Sanding metal involves the removal of imperfections, scratches, and rust, as well as the smoothing of surfaces to ensure a clean and polished look. However, with a wide variety of sandpaper options available in the market, it can be overwhelming to know which type and grit to choose for your specific metalwork needs.

In this guide, we will break down everything you need to know about sandpaper for metal, including the different types available, how to choose the right grit, and the best sandpaper for various metals. We will also explore various sanding techniques and important safety precautions to follow to ensure a successful and safe metal sanding experience.

So, if you’re ready to elevate your metalworking projects and achieve professional-level results, let’s dive into the world of sandpaper for metal!

Key Takeaways:

- Choose the right sandpaper type and grit for metalworking to achieve smooth, polished results. Consider the metal type and surface condition when selecting the best sandpaper for your project.

- Prioritize safety while sanding metal surfaces by wearing protective gear, securing workpieces, and maintaining proper ventilation. Follow effective sanding techniques to achieve professional-level results.

Read more: What Grit Sandpaper To Polish Metal

Understanding Metal Sanding

Metal sanding is a process that involves using abrasive material, such as sandpaper, to remove imperfections from metal surfaces. It is an essential step in metalworking, as it helps prepare the surface for further treatment, such as painting, coating, or polishing.

There are various reasons why you might need to sand metal surfaces. For instance, if you are working with a piece of metal that has rough edges, scratches, or rust, sanding can help smooth out these imperfections. Sanding also provides a level surface for better adhesion of paints or coatings, ensuring a more durable and aesthetically pleasing finish.

When sanding metal, it is important to understand the different types of sandpaper available. Sandpaper consists of an abrasive material bonded to a backing material. The abrasive material can be made of various substances, including aluminum oxide, silicon carbide, or diamond, each with its own level of hardness and aggressiveness.

The backing material can be made of paper, cloth, or a combination of both. Paper-backed sandpaper is more common and is suitable for most metal sanding applications. However, cloth-backed sandpaper is more durable and can be ideal for heavy-duty metal removal or shaping tasks.

Understanding the grit rating of sandpaper is also crucial for metal sanding. Grit refers to the size of the abrasive particles on the sandpaper. The higher the grit number, the finer the particles and the smoother the sandpaper. Lower grit numbers, on the other hand, indicate coarser particles, which are more suitable for aggressive material removal.

Now that we have a basic understanding of metal sanding, let’s explore the different types of sandpaper available and how to choose the right grit for your specific metalworking needs.

Different Types of Sandpaper

When it comes to sandpaper for metal, there are different types available, each designed to cater to specific metalworking requirements. Understanding the differences between these types can help you choose the most suitable option for your project.

- Aluminum Oxide Sandpaper: This is the most common type of sandpaper for general metal sanding. It is versatile, durable, and offers excellent cutting power. Aluminum oxide sandpaper is suitable for removing rust, smoothing surfaces, and preparing metal for painting or coating.

- Silicon Carbide Sandpaper: Known for its aggressive cutting action, silicon carbide sandpaper is ideal for heavy-duty metal removal tasks. It is commonly used for sanding harder metals like stainless steel or titanium and can effectively tackle rough surfaces, welds, or sharp edges.

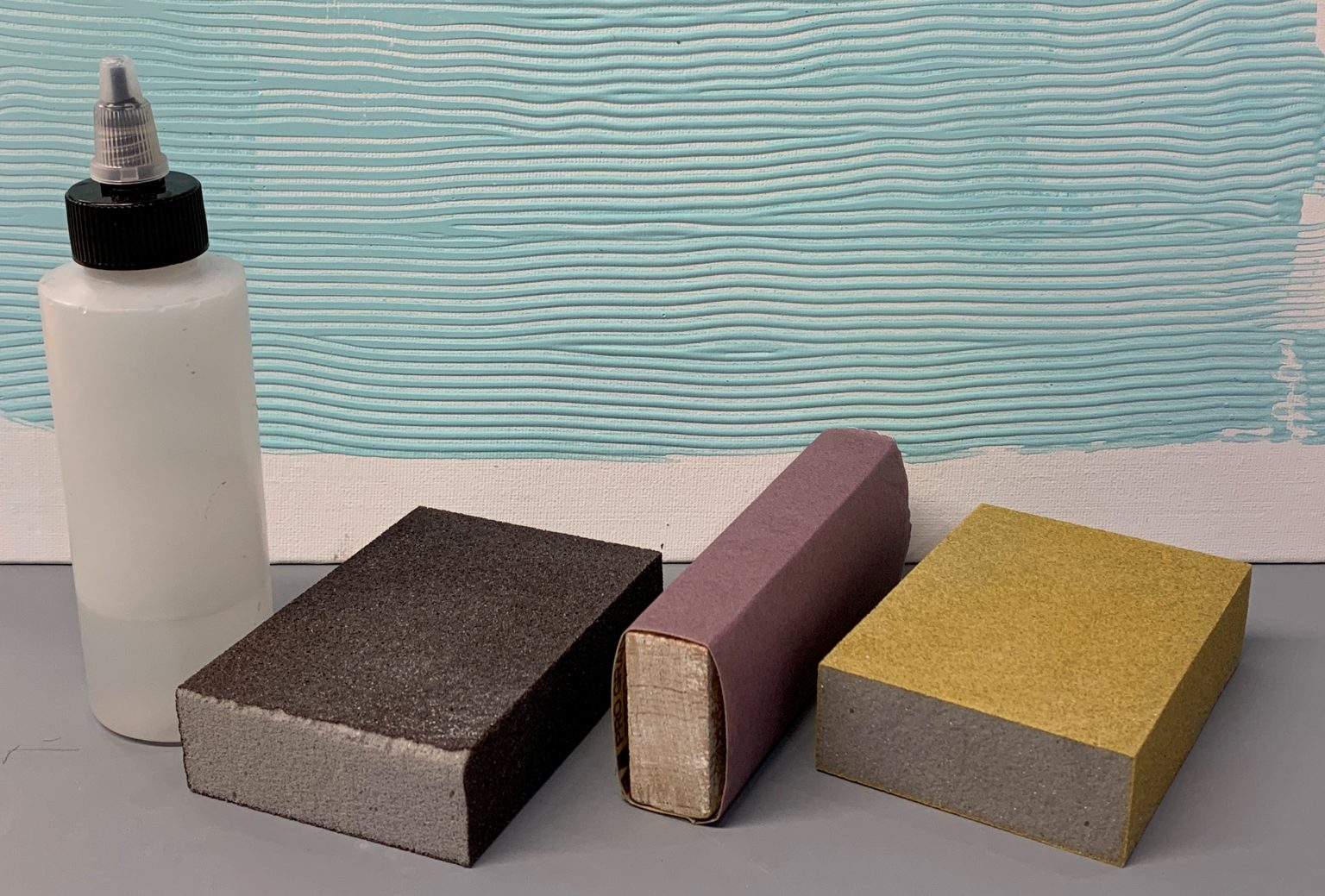

- Emery Cloth: Emery cloth is a type of sandpaper that uses emery minerals as the abrasive material. It is often used for hand sanding and is suitable for polishing and finishing metal surfaces. Emery cloth is known for its flexibility and is commonly used for metalworking projects that require precision and a high-quality finish.

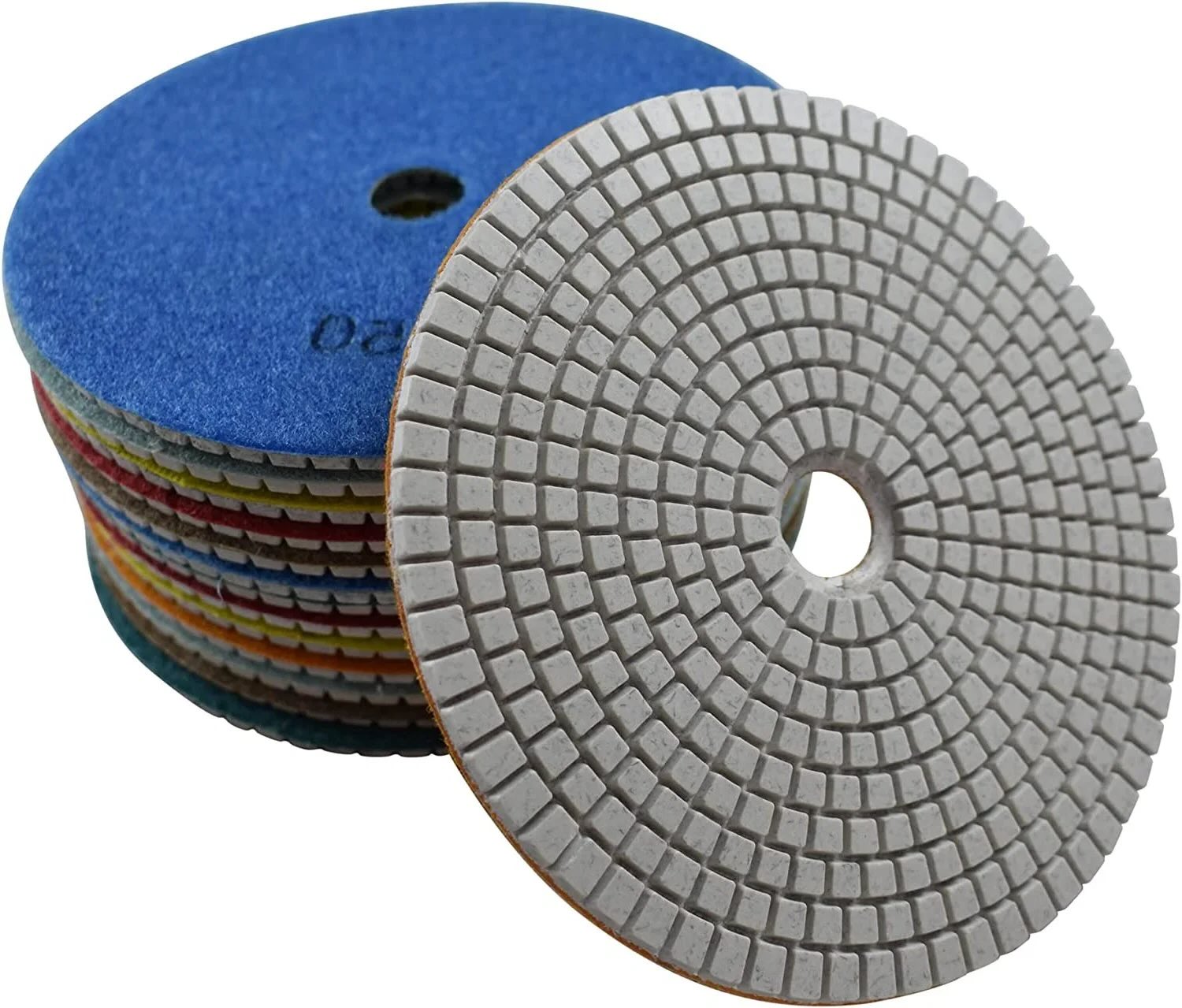

- Wet and Dry Sandpaper: As the name suggests, wet and dry sandpaper can be used for both dry and wet sanding applications. It is waterproof and can be used with water or other lubricants to reduce friction and prevent clogging. Wet and dry sandpaper is commonly used for automotive metalwork or applications where a high-quality, smooth finish is desired.

- Flap Discs: Flap discs are abrasive discs made of overlapping flaps of sandpaper. They are attached to a backing plate and are usually used with a grinder or angle grinder. Flap discs are efficient for fast material removal and can be ideal for shaping, grinding, and smoothing metal surfaces.

It’s important to note that when choosing sandpaper for metal, the backing material is equally important. While most sandpaper comes with a paper backing, cloth-backed sandpaper offers increased durability, especially for heavy-duty metal sanding tasks.

Now that we know about the different types of sandpaper available for metalworking, it’s time to learn how to choose the right grit for your specific needs.

Choosing the Right Grit

Selecting the appropriate grit is crucial for achieving the desired results when sanding metal surfaces. The grit of sandpaper determines its level of coarseness or fineness, depending on the size of the abrasive particles. The right grit selection depends on the condition of the metal surface and the desired outcome.

Coarser grits, such as 40 to 80, are suitable for heavy material removal and for smoothing rough or uneven surfaces. They are ideal for removing paint, rust, or surface imperfections. However, be aware that using a coarse grit can leave noticeable scratches or marks on the metal.

Middle grits, ranging from 100 to 180, are often used for intermediate sanding. They can smooth out scratches left by coarser grits and prepare the surface for finer sanding. These grits are widely used for general-purpose metal sanding, refining surfaces, and preparing them for painting or coating.

Finer grits, such as 220 to 400, are used for the final sanding stages. They help achieve a smooth and polished finish on metal surfaces. These grits are commonly used before painting, clear-coating, or applying a protective finish to the metal. They are also suitable for smoothing out any remaining imperfections or scratches left by coarser grits.

It is important to keep in mind that the ideal grit selection may vary depending on the type of metal you are working with. Softer metals, like aluminum or brass, may require finer grits to avoid excessive material removal, while harder metals, like stainless steel or titanium, can withstand coarser grits for efficient material removal.

When starting a sanding project on metal surfaces, it is recommended to begin with a coarser grit and gradually work your way up to finer grits. This progressive sanding process helps maintain control over the surface and ensures a smoother transition from the previous grit.

Remember to always consider the condition of the metal surface, the level of imperfections you need to address, and the desired outcome when choosing the right grit for your project.

Now that we understand how to select the right grit, let’s explore the best sandpaper options for specific metals.

When sanding metal, use aluminum oxide sandpaper for the best results. It is durable and can effectively smooth and polish metal surfaces.

Best Sandpaper for Various Metals

Choosing the best sandpaper for specific metals can greatly impact the efficiency and effectiveness of your metal sanding projects. Different metals have unique characteristics and require different levels of abrasiveness and grit to achieve optimal results. Here are some recommendations for the best sandpaper options for various metals:

- Steel: For sanding steel surfaces, aluminum oxide sandpaper with grits ranging from 80 to 180 is commonly used. Coarser grits are ideal for heavy material removal or rust removal, while finer grits will help achieve a smooth and polished finish.

- Stainless Steel: Stainless steel is a harder metal and requires sandpaper with higher abrasiveness. Silicon carbide sandpaper with grits ranging from 120 to 220 is recommended for initial metal removal, followed by aluminum oxide sandpaper with finer grits, such as 320 to 400, for smoothing and polishing.

- Aluminum: Aluminum is a softer metal, and using sandpaper with a coarse grit can cause excessive material removal and scratches. It is best to start with finer grits, such as 120 or 180, to remove imperfections and then move on to finer grits, like 220 to 400, for a smooth finish.

- Brass: Brass is a softer alloy and can easily be scratched. Therefore, it is recommended to use sandpaper with finer grits, ranging from 220 to 400, to achieve a polished finish without causing damage to the metal.

- Copper: Copper is a relatively soft metal that can rapidly develop a patina. To maintain its bright finish, it is best to use sandpaper with finer grits, such as 320 to 400, to gently remove any tarnish or imperfections and restore its shine.

Remember, these are general recommendations, and other factors, such as the condition of the metal surface and the specific project requirements, may impact the sandpaper selection. Always ensure you have a variety of grits available to suit different stages of your metal sanding process.

Now that we know which sandpapers are suitable for different metals, let’s move on to learning some effective sanding techniques for metal surfaces.

Read more: What Is Sandpaper Used For

Sanding Techniques for Metal Surfaces

Mastering the proper sanding techniques for metal surfaces is key to achieving smooth, polished, and professional-looking results. Here are some effective sanding techniques to help you achieve optimal outcomes:

1. Prepare the Surface: Before you begin sanding, ensure that the metal surface is clean and free from any dirt, grease, or debris. This will prevent contaminants from scratching or damaging the surface during the sanding process.

2. Secure the Workpiece: It’s important to securely hold down the metal workpiece to prevent it from shifting or moving while you sand. This can be done using clamps, a vice, or other suitable methods to provide stability as you work.

3. Start with Coarse Grit: If you are working with a metal surface that needs significant material removal, begin with a coarse grit sandpaper. Apply even pressure and sand in a steady back-and-forth motion, following the grain of the metal.

4. Gradually Progress to Finer Grits: As you remove imperfections and achieve a smoother surface, switch to finer grit sandpaper. Gradually work your way up to achieve the desired level of smoothness and remove any scratches left by the previous grit.

5. Keep the Surface Wet (For Wet Sanding): When wet sanding metal surfaces, it’s essential to keep the sandpaper and the surface area wet. Use a spray bottle or immerse the sandpaper in water to create a slurry, which helps reduce friction and prevents the sandpaper from clogging.

6. Use Circular or Figure-Eight Motion: When sanding metal, it is often effective to use circular or figure-eight motions. This ensures even coverage and helps prevent creating linear scratches on the surface.

7. Be Mindful of Overheating: Metal surfaces can generate heat when sanded for extended periods. Be cautious not to overheat the metal, as it can cause damage or change its properties. Take breaks during the sanding process and use cooling methods like spraying water if necessary.

8. Check Your Progress: Regularly inspect your work as you sand to ensure you are achieving the desired results. Look for any remaining imperfections, scratches, or unevenness. If needed, repeat the sanding process with the appropriate grit to achieve a flawless finish.

9. Clean the Surface: Once you have completed the sanding process, use a clean cloth or tack cloth to remove any dust or debris left on the surface. This will ensure a clean base for further treatment or finishing, such as painting or coating.

Remember to always work in a well-ventilated area and wear appropriate safety gear, including goggles and a dust mask, to protect yourself from airborne particles.

By following these sanding techniques, you can achieve professional-level results and transform your metal surfaces into flawless masterpieces.

Now, let’s move on to discussing important safety precautions to keep in mind while sanding metal.

Safety Precautions while Sanding Metal

While sanding metal surfaces can be a rewarding process, it is essential to prioritize safety to avoid any accidents or injuries. Here are some important safety precautions to keep in mind when sanding metal:

- Protective Gear: Always wear appropriate protective gear, including safety goggles or glasses, a dust mask, and gloves. These will protect your eyes, respiratory system, and hands from flying debris, dust, and potential chemical irritants from paint or coatings.

- Work Area Ventilation: Ensure you are working in a well-ventilated area to prevent the build-up of dust particles and fumes. If necessary, use a fan or open windows and doors to improve air circulation.

- Secure the Workpiece: Securely fasten the metal workpiece using clamps or a vice to prevent it from moving or slipping during the sanding process. This will ensure stability and reduce the risk of accidents or injuries.

- Avoid Excessive Pressure: Apply consistent and moderate pressure while sanding metal surfaces. Excessive pressure can not only cause fatigue but may also damage the sandpaper or result in uneven sanding. Let the sandpaper do the work and maintain a steady motion.

- Electrical Safety: If using power tools for sanding, ensure they are in good condition and have proper grounding. Follow all safety guidelines and precautions while operating powered sanding equipment to prevent electrical accidents.

- Heat and Fire Hazards: Be cautious of heat generation during the sanding process, especially with power tools. Metal surfaces can heat up, potentially causing burns or starting a fire. Take breaks if needed and use cooling techniques to avoid overheating.

- Protect Nearby Surfaces: Cover or protect nearby surfaces, objects, or equipment that you do not want to be accidentally damaged or scratched during the sanding process. Use drop cloths or masking tape to prevent any unintended accidents.

- Cleanliness: Regularly clean your work area to minimize the accumulation of dust and debris. This will help maintain visibility, prevent accidents caused by slipping on loose debris, and reduce the risk of respiratory issues.

- Proper Disposal: Dispose of used sandpaper and any waste material properly. Check local regulations for guidelines on the safe disposal of abrasive materials, such as sandpaper or dust generated from sanding.

Remember, following these safety precautions will help ensure a safe and injury-free sanding experience while working with metal surfaces.

Now that we have covered important safety measures, let’s wrap up this guide on sandpaper for metal.

Conclusion

Congratulations! You have now gained a comprehensive understanding of sandpaper for metal and the essential factors to consider when choosing the right sandpaper for your metalworking projects. By utilizing the appropriate sandpaper, you can achieve smooth, polished, and professional-looking results on various metals.

We discussed the different types of sandpaper available, such as aluminum oxide, silicon carbide, emery cloth, wet and dry sandpaper, and flap discs. Each type serves specific purposes, providing a range of options to cater to different metalworking needs.

Choosing the right grit is crucial to achieving the desired outcome. Coarser grits are suitable for material removal, while finer grits are used for smoothing and polishing. Remember to consider the type of metal you are working with, as different metals may require different levels of abrasiveness.

We also explored the best sandpaper options for various metals, including steel, stainless steel, aluminum, brass, and copper. Each metal has its own unique characteristics, and selecting the appropriate sandpaper ensures efficient and effective results.

In addition, we discussed important sanding techniques, such as preparing the surface, progressing from coarse to fine grits, using circular or figure-eight motions, and checking your progress along the way. These techniques will help you achieve professional-level results and transform your metal surfaces into flawless masterpieces.

Lastly, we emphasized the importance of safety precautions during the sanding process. Wearing the proper protective gear, working in a well-ventilated area, securing the workpiece, and following electrical and fire safety measures are essential to prevent accidents and injuries.

Now that you have the knowledge and understanding of sandpaper for metal, it’s time to put it into practice. Explore your metalworking projects with confidence, knowing that you have the right tools and techniques to achieve outstanding results. Happy sanding!

Frequently Asked Questions about What Kind Of Sandpaper For Metal

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Kind Of Sandpaper For Metal”