Home>Technology>Smart Home Devices>How To Put Sublimation Paper In Printer

Smart Home Devices

How To Put Sublimation Paper In Printer

Modified: August 27, 2024

Learn how to properly load sublimation paper into your printer for flawless printing results. Discover the best techniques for smart home devices.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

**

Introduction

**

Welcome to the exciting world of sublimation printing, where creativity knows no bounds and vibrant, long-lasting designs come to life. Whether you're a seasoned crafter, a small business owner, or an enthusiast exploring the endless possibilities of sublimation printing, understanding how to effectively utilize sublimation paper in your printer is crucial for achieving professional results.

In this comprehensive guide, we'll delve into the intricate process of using sublimation paper in your printer to transfer stunning designs onto various substrates. From understanding the unique properties of sublimation paper to seamlessly loading it into your printer and optimizing settings for impeccable prints, we've got you covered. By the end of this journey, you'll be well-equipped to harness the full potential of sublimation paper and elevate your printing endeavors to new heights.

So, let's embark on this enlightening exploration of sublimation paper and unravel the secrets to unlocking its transformative capabilities within your printer. Whether you're aiming to personalize apparel, create bespoke home decor, or embark on a myriad of other creative projects, mastering the art of using sublimation paper will undoubtedly set the stage for unparalleled artistic expression and innovation.

**

Key Takeaways:

- Sublimation paper is essential for transferring vibrant designs onto various substrates using a printer. Understanding its unique properties and preparing the printer are crucial for achieving exceptional print quality.

- Loading and adjusting printer settings for sublimation paper require precision and attention to detail. This ensures seamless integration and optimal results, setting the stage for vibrant and enduring prints.

Read more: How To Convert A Printer To Sublimation

Understanding Sublimation Paper

**

Before delving into the intricacies of using sublimation paper in your printer, it’s essential to grasp the fundamental characteristics and functionalities of this specialized printing medium. Sublimation paper serves as the vessel for transferring vibrant designs from the paper to a diverse range of substrates, including garments, mugs, and other items coated with a polyester or polymer surface.

At its core, sublimation paper is engineered to accommodate the sublimation process, wherein heat and pressure are applied to facilitate the transformation of solid dye particles into a gaseous state without transitioning through the liquid phase. This unique sublimation process enables the dye particles to permeate the polymer coating of the substrate, resulting in exceptionally durable and vivid prints that resist fading, cracking, and peeling.

One of the defining attributes of sublimation paper is its specialized coating, which plays a pivotal role in ensuring optimal transfer of designs. This coating is designed to retain the dye particles during the sublimation process, allowing for precise and high-fidelity reproduction of intricate designs with remarkable color accuracy and clarity.

Furthermore, the weight and thickness of sublimation paper are meticulously calibrated to facilitate seamless feeding and passage through your printer, minimizing the risk of jams and ensuring consistent print quality. It’s important to select sublimation paper that aligns with the specifications of your printer, as compatibility is integral to achieving optimal results.

By comprehending the composition and functionality of sublimation paper, you’ll be better equipped to harness its potential and elevate your printing endeavors with confidence. With this foundational knowledge in mind, let’s proceed to the next crucial step: preparing your printer to accommodate the sublimation paper and unleash its transformative capabilities.

**

Preparing the Printer

**

Before embarking on the exhilarating journey of using sublimation paper in your printer, it’s imperative to ensure that your printer is suitably prepared to accommodate this specialized medium. The preparation process encompasses several crucial steps that are instrumental in optimizing the performance and output quality of your printer when utilizing sublimation paper.

First and foremost, it’s essential to verify the compatibility of your printer with sublimation paper. Not all printers are inherently equipped to handle sublimation printing, and as such, it’s imperative to ascertain whether your printer supports this specialized printing technique. Printers specifically designed for sublimation printing are engineered to withstand the elevated temperatures and precise pressure required for the sublimation process, thereby yielding superior results.

Once you’ve confirmed the compatibility of your printer, the next step involves conducting a thorough cleaning and maintenance routine to ensure that the printer is free from any residual ink, debris, or obstructions that could compromise the quality of the prints. Regular maintenance not only optimizes the functionality of the printer but also mitigates the risk of potential issues arising during the printing process.

Furthermore, it’s advisable to install a dedicated set of sublimation ink cartridges in your printer to facilitate seamless integration with the sublimation paper. Sublimation inks are formulated to transition into a gaseous state under controlled heat and bind with the polymer coating of the substrate, resulting in vivid and enduring prints. By utilizing sublimation-specific ink, you can harness the full potential of the sublimation paper and achieve exceptional color vibrancy and longevity.

Additionally, calibrating the printer settings to align with the properties of sublimation paper is paramount for achieving optimal results. This entails adjusting the print head position, ink density, and other relevant parameters to ensure compatibility with the unique characteristics of sublimation paper, thereby enhancing the precision and fidelity of the printed designs.

By meticulously preparing your printer to accommodate sublimation paper, you’re laying the groundwork for seamless integration and exceptional print quality. With the printer primed and ready, the next step entails loading the sublimation paper to commence the exhilarating process of bringing your designs to life.

**

Loading Sublimation Paper

**

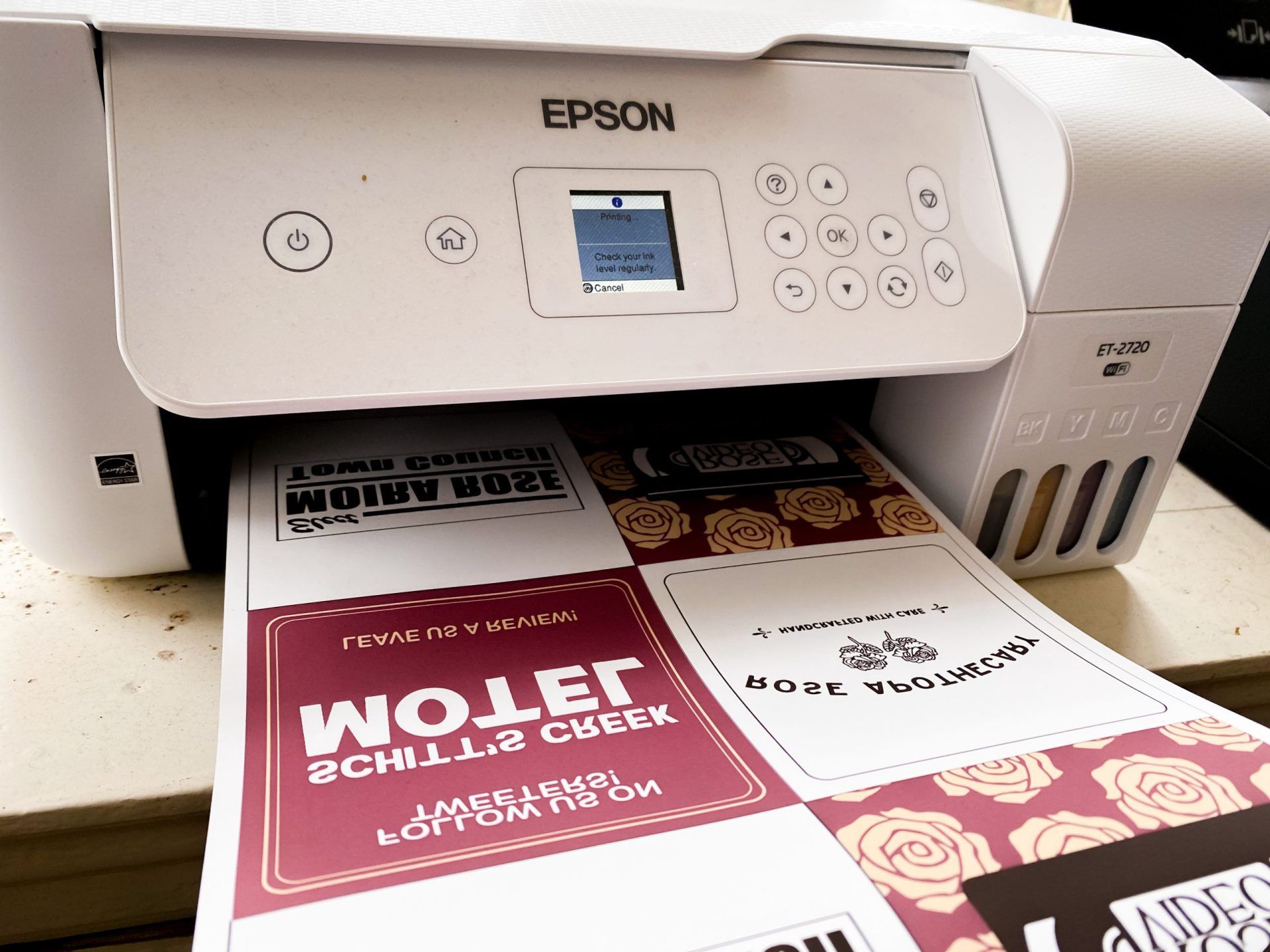

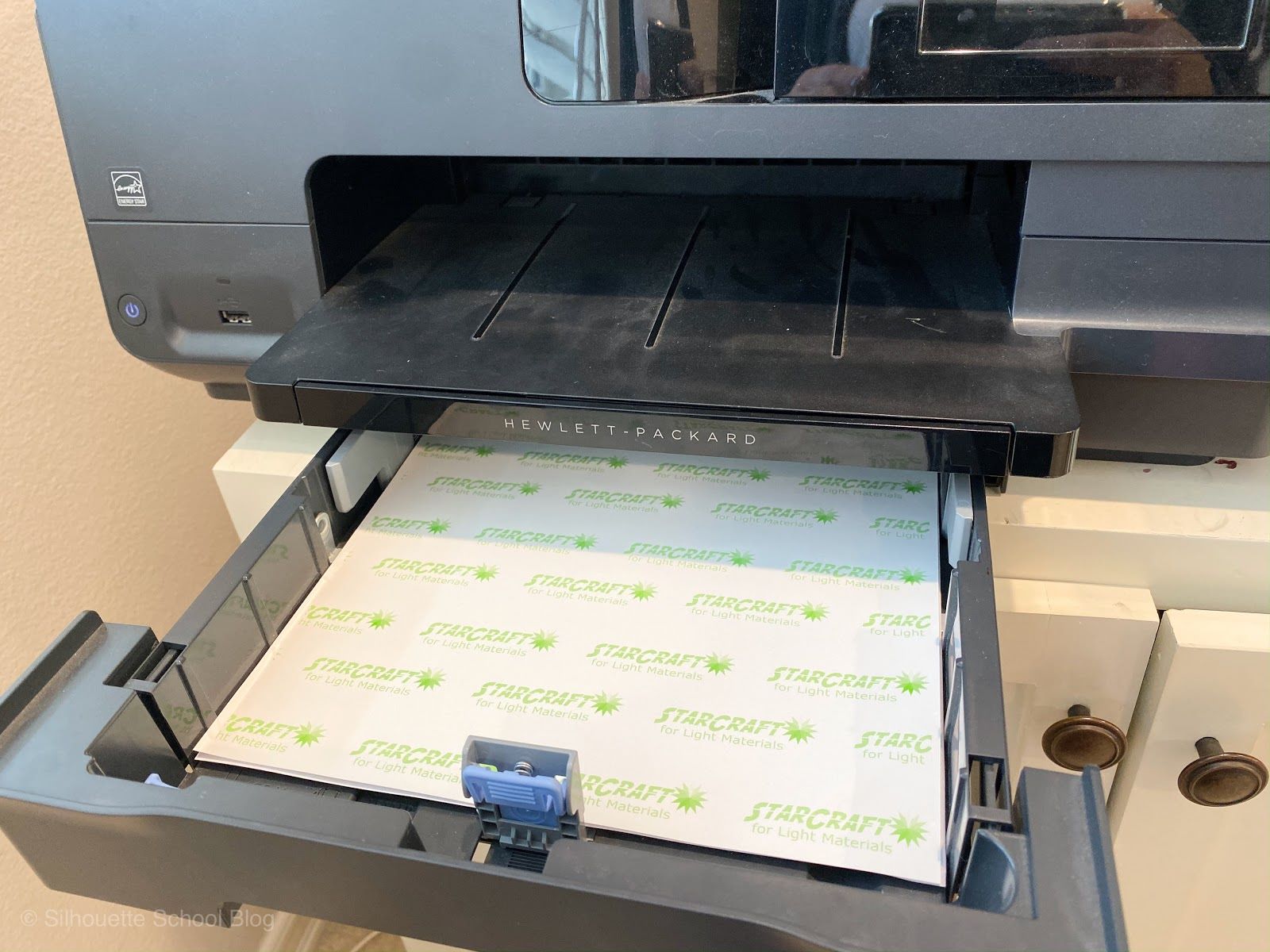

As you embark on the captivating journey of utilizing sublimation paper in your printer, the process of loading the paper is a pivotal step that necessitates precision and attention to detail. Properly loading the sublimation paper not only ensures smooth passage through the printer but also contributes to the impeccable quality of the final prints.

Prior to loading the sublimation paper, it’s imperative to familiarize yourself with the specific loading mechanism of your printer. Different printer models feature varying methods for loading paper, and understanding the intricacies of your printer’s paper handling system is essential for seamless integration of the sublimation paper.

Begin by accessing the paper input tray of your printer and adjusting the paper guides to align with the dimensions of the sublimation paper. Ensuring a snug and precise fit within the paper input tray minimizes the risk of misalignment and ensures consistent feeding of the sublimation paper during the printing process.

Next, carefully fan the stack of sublimation paper to prevent any potential adhesion between the sheets, which could impede the feeding process and compromise the print quality. It’s crucial to handle the sublimation paper with care to avoid creases, folds, or damage to the specialized coating, as these imperfections can adversely impact the transfer of designs onto the substrate.

Once the sublimation paper is fanned and free of any imperfections, gently place it within the paper input tray, ensuring that the stack is neatly aligned and does not exceed the designated paper capacity specified by the printer’s guidelines. Overloading the paper input tray can lead to feeding issues and hinder the smooth passage of the sublimation paper through the printer.

After securely positioning the sublimation paper within the paper input tray, it’s essential to adjust the paper guides to firmly support the edges of the paper stack, preventing any lateral movement or misalignment during the printing process. Proper alignment and support are integral to facilitating consistent and precise feeding of the sublimation paper.

By meticulously following these steps to load the sublimation paper into your printer, you’re laying the foundation for seamless and efficient printing, setting the stage for the next crucial phase: adjusting the printer settings to optimize the output with sublimation paper.

**

Make sure the sublimation paper is placed in the printer tray with the printable side facing up. Adjust the paper guides to fit the size of the paper to prevent any misalignment during printing.

Adjusting Printer Settings

**

With the sublimation paper seamlessly loaded into your printer, the next pivotal phase involves fine-tuning the printer settings to align with the unique properties of the sublimation paper and maximize the quality and precision of the printed designs. Adjusting the printer settings with meticulous attention to detail is instrumental in optimizing the sublimation printing process and ensuring exceptional results.

Commence the optimization process by accessing the printer’s settings menu and navigating to the print quality or media type options, where you can specify the substrate type as “sublimation paper” or an equivalent setting that corresponds to the specialized characteristics of the sublimation paper. This selection prompts the printer to calibrate its internal parameters to accommodate the sublimation paper, including adjustments to ink density, print head positioning, and heat application.

Furthermore, it’s advisable to fine-tune the print resolution to a high setting, thereby enhancing the clarity, detail, and vibrancy of the printed designs on the sublimation paper. Opting for a higher print resolution contributes to the meticulous reproduction of intricate patterns, gradients, and color nuances, resulting in visually stunning and professional-grade prints.

Calibrating the heat settings of the printer is another critical aspect of optimizing the printing process with sublimation paper. Depending on the specific requirements of the sublimation paper and the substrate to which the designs will be transferred, adjusting the heat settings ensures that the sublimation process occurs with precision, facilitating the seamless transition of dye particles from the paper to the substrate.

Moreover, it’s essential to verify that the ink settings are tailored to the characteristics of sublimation ink, ensuring that the printer utilizes the designated sublimation ink cartridges and that the ink density is optimized for vibrant and enduring prints. Sublimation inks are formulated to interact synergistically with the sublimation paper and the designated substrates, culminating in exceptional color fidelity and durability.

By methodically adjusting the printer settings to harmonize with the unique requirements of sublimation paper, you’re poised to unleash the full potential of this specialized medium and achieve breathtaking prints that captivate with their vividness and longevity. With the printer settings meticulously fine-tuned, it’s time to embark on the exhilarating phase of printing your designs with sublimation paper.

**

Read more: How To Clean A Sublimation Printer

Printing with Sublimation Paper

**

As you stand on the threshold of bringing your designs to life with sublimation paper, the process of printing marks the culmination of meticulous preparation and optimization, culminating in the realization of vibrant and enduring designs on a diverse array of substrates. Printing with sublimation paper is an exhilarating endeavor that encapsulates the fusion of artistry and cutting-edge technology, resulting in visually striking and long-lasting prints.

Prior to initiating the printing process, it’s prudent to conduct a test print on regular paper to assess the alignment, clarity, and color accuracy of the designs. This preliminary step allows for adjustments to be made to the design file and printer settings, ensuring that the final prints on the sublimation paper reflect the intended vision with precision and fidelity.

Once the test print has been meticulously scrutinized and any necessary refinements have been implemented, it’s time to embark on the transformative process of printing your designs onto the sublimation paper. Commence by selecting the desired design file on your computer and initiating the print command, ensuring that the printer settings are meticulously aligned with the properties of the sublimation paper and the designated substrate.

As the printer meticulously transfers the designs onto the sublimation paper, it’s essential to monitor the printing process to ascertain that the paper is feeding smoothly and that the designs are being reproduced with exceptional clarity and vibrancy. The seamless interplay of the printer, sublimation paper, and sublimation ink culminates in the realization of designs that transcend the confines of traditional printing, exuding a captivating allure and enduring resilience.

Upon the completion of the printing process, delicately handle the printed sublimation paper to prevent any smudging or smearing of the designs. The printed designs are now poised for the transformative phase of sublimation, wherein heat and pressure will facilitate the transfer of the designs from the paper to the designated substrate, resulting in visually stunning and enduring creations.

By embarking on the exhilarating journey of printing with sublimation paper, you’re poised to unleash a realm of creative possibilities and elevate your artistic endeavors to unprecedented heights. The captivating allure of sublimation printing lies in its ability to imbue designs with vividness, longevity, and versatility, transcending conventional printing techniques and opening the door to a myriad of innovative applications.

With the designs impeccably printed on the sublimation paper, the transformative process of sublimation awaits, wherein the designs will be transferred onto a diverse array of substrates, heralding the dawn of a new era in personalized and bespoke creations.

**

Conclusion

**

As we draw the curtain on this enlightening journey into the realm of sublimation printing, it’s evident that the utilization of sublimation paper in your printer heralds a paradigm shift in the realm of creative expression and personalized craftsmanship. The intricate process of leveraging sublimation paper to bring designs to life on a diverse array of substrates epitomizes the fusion of artistry and cutting-edge technology, culminating in visually stunning and enduring creations that captivate with their vibrancy and resilience.

Throughout this comprehensive guide, we’ve navigated the intricate nuances of sublimation paper, from understanding its unique properties to meticulously preparing the printer, loading the paper, and fine-tuning the printer settings to optimize the printing process. Each phase of this transformative journey underscores the meticulous attention to detail and the unwavering commitment to achieving exceptional print quality and longevity.

By comprehending the specialized characteristics of sublimation paper and mastering the art of seamlessly integrating it into your printer, you’ve embarked on a transformative odyssey that transcends the confines of conventional printing. The allure of sublimation printing lies in its ability to imbue designs with unparalleled vibrancy, clarity, and durability, breathing life into personalized apparel, bespoke home decor, and an array of other creative ventures.

As you venture forth into the realm of printing with sublimation paper, armed with the knowledge and insights garnered from this guide, you’re poised to unlock a world of creative possibilities and elevate your artistic endeavors to unprecedented heights. The fusion of sublimation paper, sublimation ink, and your printer culminates in the realization of designs that transcend the ordinary, exuding a captivating allure and enduring resilience.

Whether you’re a seasoned crafter, a small business owner seeking to offer personalized creations, or an enthusiast exploring the boundless potential of sublimation printing, the utilization of sublimation paper in your printer heralds a new chapter in your creative journey. Embrace the transformative power of sublimation printing, where designs come to life with unparalleled vibrancy and endurance, leaving an indelible impression on a myriad of substrates.

With the knowledge and expertise acquired from this guide, you’re primed to embark on a captivating odyssey of sublimation printing, where each creation embodies the seamless convergence of artistry and innovation, transcending the ordinary and embracing the extraordinary.

Frequently Asked Questions about How To Put Sublimation Paper In Printer

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Put Sublimation Paper In Printer”