Home>Articles>How Do You Shape Aluminum Stock With Hand Tools

Articles

How Do You Shape Aluminum Stock With Hand Tools

Modified: January 19, 2024

Learn how to shape aluminum stock with hand tools in this informative article. Discover the techniques and tools needed for successful aluminum shaping.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Aluminum stock is a versatile material that can be molded and shaped to create a wide range of objects and structures. While power tools such as saws and drills are often used to shape aluminum, there are times when hand tools can be just as effective, especially for smaller projects or when working in tight spaces. In this article, we will explore the process of shaping aluminum stock with hand tools and provide valuable insights to help you achieve successful results.

Before diving into the techniques and methods of shaping aluminum stock, it is essential to gather the necessary tools. While the specific tools required may vary depending on the project, there are a few essential hand tools that are commonly used:

- Files: Both flat and half-round files are useful for removing material and smoothing sharp edges.

- Sanding blocks: These are handy for achieving a smooth and polished finish on the aluminum surface.

- Hammers: A variety of hammers, including ball peen and rubber mallets, are indispensable for shaping and bending aluminum.

- Hand saw: A fine-toothed hacksaw or coping saw can be used to cut aluminum stock to the desired length.

- Drill and bits: A handheld electric drill with various drill bits allows for creating holes and adding additional features to the aluminum.

- Pliers: Needle-nose pliers and vice grips can be helpful for holding and manipulating the aluminum during the shaping process.

- Measuring tools: A tape measure, ruler, and calipers are essential for accurately measuring and marking the aluminum stock.

Now that we have our tools ready, let’s explore the different methods for shaping aluminum stock with hand tools.

Key Takeaways:

- Mastering the art of shaping aluminum stock with hand tools requires the right tools, precision, and patience. From sanding and filing to hammering and bending, each method offers unique possibilities for creating custom aluminum structures.

- Prioritizing safety measures, such as wearing protective gear and securing the work surface, is crucial when shaping aluminum stock with hand tools. By following valuable tips and techniques, you can achieve impressive results with finesse and precision.

Read more: How To Shape Brass With Hand Tools

Tools Required for Shaping Aluminum Stock

When it comes to shaping aluminum stock with hand tools, having the right tools is crucial for achieving precise and satisfactory results. Here are the essential tools you will need:

- Files: Files are one of the most important tools for shaping aluminum. Choose a flat file for removing material quickly and a half-round file for contouring and smoothing edges. These files come in various sizes and coarseness, so select the appropriate ones based on the size and thickness of your aluminum stock.

- Sanding blocks: Sanding blocks are essential for achieving a smooth and polished finish on the aluminum surface. You can use sandpaper of different grits (from coarse to fine) to gradually remove scratches and imperfections. Wrap the sandpaper around the sanding block for better control and even sanding.

- Hammers: A variety of hammers are useful for shaping and bending aluminum stock. A ball peen hammer is great for creating curves and shaping intricate details, while a rubber mallet helps avoid marring the aluminum surface. Choose hammers with comfortable grips and the appropriate weight for your project.

- Hand saw: A fine-toothed hand saw, such as a hacksaw or coping saw, is necessary for cutting aluminum stock to the desired length. Ensure that the blade is sharp and suitable for cutting metal. Consider using a miter box or a guide to make straight and accurate cuts.

- Drill and bits: A handheld electric drill with various drill bits allows you to create holes and add additional features to the aluminum. Use high-speed steel (HSS) or carbide bits specifically designed for metal drilling. Lubricating the drill bit with cutting oil while drilling will prolong the tool’s life and help prevent overheating.

- Pliers: Needle-nose pliers and vice grips are helpful for holding and manipulating the aluminum during the shaping process. They provide a secure grip and allow for precise positioning when bending or forming the stock.

- Measuring tools: Accurate measurements are crucial when shaping aluminum stock. You will need a tape measure, ruler, and calipers to ensure precise dimensions and positioning. A combination square can also be used for marking perpendicular lines and checking angles.

Having these tools at your disposal will enable you to shape aluminum stock with precision and efficiency. Now that you are well-equipped, let’s explore the different methods for shaping aluminum stock using hand tools.

Methods for Shaping Aluminum Stock

When it comes to shaping aluminum stock with hand tools, there are several methods you can employ. Each method serves a different purpose, allowing you to achieve the desired shape and form. Let’s explore the most common methods for shaping aluminum stock:

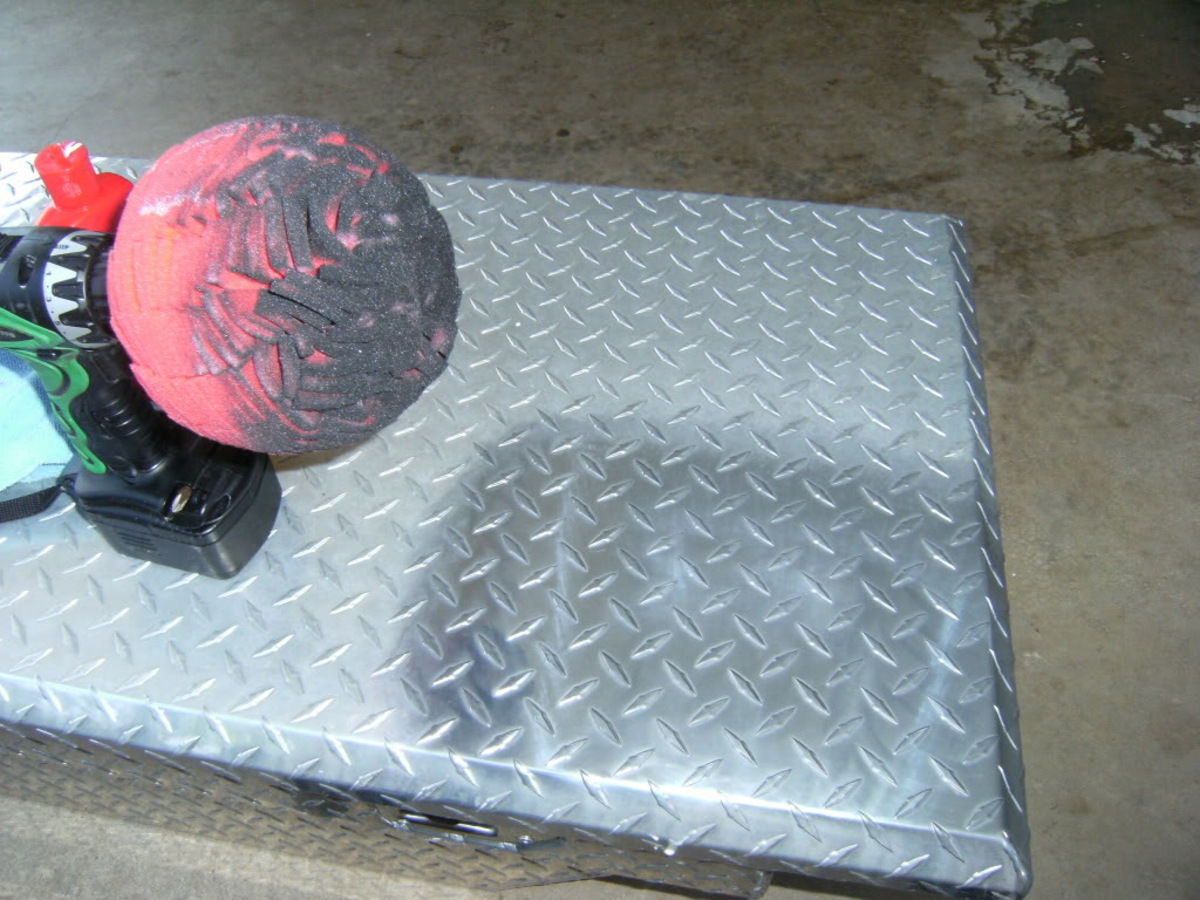

- Sanding and Filing: Sanding and filing are fundamental techniques used to shape and refine aluminum stock. Start by using coarse-grit sandpaper or a file to remove excess material and create basic contours. Gradually progress to finer-grit sandpaper or a finer file to smooth out the surface and create a polished finish. Remember to wear protective gloves and safety goggles when working with sandpaper or files to prevent injury.

- Hammering and Bending: Hammering and bending are effective techniques for shaping aluminum stock into curves or angles. Use a ball-peen hammer or a rubber mallet to gently tap the aluminum, gradually shaping it to the desired form. A bending brake or vice grips can also be used to create precise bends and angles. Be mindful of the thickness and strength of the aluminum stock to avoid deformation or damage.

- Sawing and Cutting: Sawing and cutting are essential methods for resizing aluminum stock or creating specific shapes. Use a fine-toothed hand saw, such as a hacksaw or coping saw, to cut through the aluminum. Secure the aluminum stock in a vise or clamp to ensure stability and accuracy. When making straight cuts, use a miter box or a guide to maintain a consistent and precise cutting angle.

- Drilling and Punching: Drilling and punching allow you to create holes and add additional features to the aluminum stock. Use a handheld electric drill with a suitable drill bit to drill holes of various sizes. Ensure that the drill bit is specifically designed for metal drilling and work at a moderate speed to prevent overheating. For smaller holes or precise indentations, you can use a center punch or nail and hammer to create a starting point.

- Folding and Forming: Folding and forming techniques are used to create complex shapes or structures from aluminum stock. Use pliers or a bending brake to make precise folds along predetermined lines. A combination of bending, hammering, and filing may be necessary to achieve the desired shape. Ensure that you work slowly and carefully, taking breaks as needed to avoid fatigue and mistakes.

Experiment with these methods to find the techniques that work best for your project. Remember to practice patience and precision when shaping aluminum stock with hand tools, and always prioritize safety by wearing appropriate protective gear.

When shaping aluminum stock with hand tools, use a file with a fine grit to smooth out rough edges and create precise shapes. This will help you achieve a clean and professional finish.

Safety Measures to Follow

When shaping aluminum stock with hand tools, safety should always be a top priority. Here are some important safety measures to keep in mind:

- Protective Gear: Wear safety goggles to protect your eyes from flying debris, especially when sanding, filing, or cutting aluminum. Gloves will help protect your hands from sharp edges and reduce the risk of cuts or abrasions. Additionally, consider wearing a dust mask when sanding or filing to avoid inhaling aluminum particles.

- Secure Work Surface: Use a stable workbench or work surface to secure the aluminum stock. Ensure that it is clamped or anchored securely to prevent movement or slipping during the shaping process. This will reduce the risk of accidents and provide better control over the tools.

- Proper Tool Usage: Familiarize yourself with the correct usage and handling of each hand tool. Follow the manufacturer’s instructions and guidelines to prevent accidents and injuries. Always use tools for their intended purposes and avoid using excessive force, which can lead to tool breakage or improper shaping.

- Workspace Organization: Keep your workspace organized and free from clutter. This will minimize the risk of tripping, falling, or accidentally knocking over tools, reducing the chances of injury. Additionally, ensure that the area is well-lit, allowing for clear visibility of the workpiece and tools.

- Sharp and Properly Maintained Tools: Ensure that your tools are sharp and in good condition. Dull tools may require more force to use, increasing the risk of slipping and accidents. Regularly inspect your tools for any damage or wear and maintain them properly to ensure optimal performance and safety.

- Avoid Excessive Force: When shaping aluminum stock, avoid applying excessive force, especially when hammering or bending. Aluminum is a relatively soft metal and can deform or break if subjected to excessive pressure. Use controlled and gradual force to shape the aluminum stock, allowing for precise manipulation without causing damage.

- Take Breaks: Shaping aluminum stock can be a time-consuming process. It is important to take regular breaks to prevent fatigue and maintain focus. Fatigue can lead to loss of control and increased risk of accidents. Listen to your body, stay hydrated, and rest when needed.

By following these safety measures, you can greatly minimize the risk of accidents and injuries while shaping aluminum stock with hand tools. Remember to always prioritize your safety and well-being throughout the shaping process.

Tips for Successful Shaping with Hand Tools

Shaping aluminum stock with hand tools requires skill, patience, and attention to detail. To help you achieve successful results, here are some valuable tips to keep in mind:

- Plan and Measure: Before starting any shaping process, plan out your design and measure the aluminum stock accurately. Mark the areas where you need to cut, bend, or shape the stock to ensure precision and avoid mistakes.

- Start with Coarse Grit: When sanding or filing, it’s generally best to start with a coarse grit and gradually progress to finer grits. This helps to remove material efficiently and achieve a smooth finish. Be patient and take your time to ensure a polished result.

- Secure Stock Properly: Ensure that your aluminum stock is securely clamped or anchored to prevent movement during shaping. This will allow you to work with more control and accuracy, reducing the risk of accidents and achieving better results.

- Use Gentle Hammering: Hammering is often required when shaping aluminum stock. Use a gentle tapping motion rather than forceful strikes to gradually shape the aluminum. This will prevent the stock from becoming distorted or damaged.

- Practice Controlled Bending: When bending aluminum, apply controlled pressure and make small adjustments at a time. This will help you achieve the desired bend without putting excess stress on the metal. Use pliers or a bending brake to ensure precise angles and curves.

- Choose the Right Cutting Tool: Select the appropriate cutting tool for your specific project. A fine-toothed saw, such as a hacksaw or coping saw, works well for cutting aluminum stock. Ensure that the blade is sharp and suitable for cutting metal, and use a miter box or guide for straight cuts.

- Drill with Care: When drilling holes in aluminum stock, start with a smaller pilot hole before using larger drill bits. This will prevent the drill from skating across the surface. Use moderate speed and apply light, constant pressure to avoid overheating and maintain control.

- Frequent Check and Adjust: Continuously check the progress of your shaping and make necessary adjustments along the way. Regularly measure the dimensions, check angles, and ensure the shape is coming together as planned. This will help you catch any errors early on and make necessary corrections.

- Practice Patience: Shaping aluminum stock with hand tools requires patience and attention to detail. Take your time and work deliberately, making small adjustments and refinements as needed. Rushing the process can lead to mistakes and unsatisfactory results.

- Constantly Evaluate: Step back and evaluate your progress frequently. Compare the actual shape with your plan or design to ensure that you are on track. Make adjustments as necessary to achieve the desired outcome.

By following these tips, you can enhance your skills in shaping aluminum stock with hand tools and achieve successful results. Remember to practice and gain experience over time, as this will further improve your technique and ability to shape aluminum with precision.

Read more: How To Shape Metal With Hand Tools

Conclusion

Shaping aluminum stock with hand tools is a rewarding process that allows you to create a wide variety of objects and structures. By utilizing the right tools, following safety measures, and employing effective techniques, you can achieve impressive results with precision and finesse.

In this article, we discussed the essential tools required for shaping aluminum stock, such as files, sanding blocks, hammers, hand saws, drills, pliers, and measuring instruments. Each tool plays a crucial role in the shaping process, and having them at your disposal will enable you to work efficiently and achieve the desired outcome.

We explored different methods for shaping aluminum stock, including sanding and filing, hammering and bending, sawing and cutting, drilling and punching, as well as folding and forming. Each method offers unique possibilities for shaping aluminum into various forms, allowing you to bring your creative ideas to life.

Throughout the shaping process, we emphasized the importance of maintaining safety measures. Wearing proper protective gear, securing the work surface, using tools correctly, keeping the workspace organized, and avoiding excessive force are essential for preventing accidents and ensuring a safe working environment.

Additionally, we provided valuable tips for successful shaping with hand tools, such as planning and measuring, starting with coarse grit, securing stock properly, using gentle hammering and controlled bending, choosing the right cutting tool, drilling with care, and practicing patience. These tips will help you achieve precise results and improve the overall quality of your work.

In conclusion, shaping aluminum stock with hand tools requires technical skill, attention to detail, and practice. With the right tools, techniques, and safety precautions, you can create intricate and customized aluminum structures that suit your needs and preferences. So, roll up your sleeves, gather your tools, and let your creativity flow as you embark on the fascinating journey of shaping aluminum stock with hand tools.

Frequently Asked Questions about How Do You Shape Aluminum Stock With Hand Tools

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Do You Shape Aluminum Stock With Hand Tools”