Articles

How Hot Can Electrical Wire Get

Modified: December 7, 2023

Discover the answer to how hot electrical wire can get in this informative article. Learn about the temperature limits and potential hazards.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Electrical wires play a crucial role in our daily lives, providing the necessary power to run our appliances, lighting, and electronic devices. However, we often overlook the fact that electrical wires can generate significant heat when they are in use. Understanding how hot electrical wires can get is crucial for ensuring the safety and efficiency of our electrical systems.

In this article, we will explore the various factors that can affect the temperature of electrical wires, the potential dangers of overheating, and the importance of proper wire sizing and installation. By gaining a better understanding of these concepts, homeowners, electricians, and DIY enthusiasts can make informed decisions to promote the longevity and safety of their electrical systems.

Key Takeaways:

- Proper wire sizing, insulation, and environmental considerations are crucial to prevent wire overheating. Regular inspections and adherence to safety measures ensure efficient and safe electrical systems.

- Understanding the risks of wire overheating and implementing proper safety precautions can prevent fire hazards and ensure the longevity of electrical systems. Professional guidance and routine maintenance are essential for electrical safety.

Read more: How Hot Can Glass Get

Factors Affecting Wire Temperature

Several factors contribute to the temperature of electrical wires during operation. Understanding these factors is essential for evaluating the potential risks of overheating. Here are some of the key factors:

- Current (Ampacity): The amount of current flowing through a wire directly affects its temperature. When a wire carries a high current, it experiences increased resistance, leading to greater heat generation. It is crucial to consider the ampacity rating of the wire and ensure it can handle the intended current load.

- Wire Insulation: The type and quality of insulation surrounding the wire affect its ability to dissipate heat. Different insulation materials have different temperature ratings. If the wire’s insulation is not suitable for the operating temperature, it can lead to insulation breakdown and fire hazards.

- Conductivity and Resistance: The conductivity of the wire material and its resistance play a role in determining the wire temperature. Higher resistance results in more heat being generated. Copper wires, known for their excellent conductivity, tend to have lower resistance and, therefore, generate less heat compared to aluminum wires with higher resistance.

- Environmental Conditions: The surrounding environmental conditions can impact the temperature of electrical wires. High ambient temperatures, restricted airflow, and proximity to heat sources can all contribute to increased wire temperature. It is important to consider these factors when planning and installing electrical wiring.

By considering these factors, homeowners and electricians can gain a deeper understanding of why wires may heat up and take appropriate measures to prevent overheating and potential hazards.

Ampacity and Wire Insulation

Ampacity refers to the maximum amount of current that a wire can safely carry without overheating. It is an important factor to consider when selecting the appropriate wire size for a specific electrical application. Exceeding the ampacity rating can lead to excessive heat generation, which can damage the wire insulation and increase the risk of fire.

Wire insulation serves a vital role in protecting the wire from external factors and preventing short circuits. Different types of wire insulation have varying temperature ratings, indicating the maximum temperature they can withstand without experiencing degradation. Common types of insulation include PVC (Polyvinyl Chloride), THHN (Thermoplastic High Heat-resistant Nylon-coated), and XHHW (Cross-linked Polyethylene High Heat and Moisture-resistant).

It is crucial to choose wire insulation with a temperature rating appropriate for the intended application. If the wire insulation is not designed to handle the operating temperature, it can melt, crack, or become brittle, jeopardizing the safety and functionality of the electrical system. Consulting the National Electrical Code (NEC), local regulations, and industry standards can provide guidance on the appropriate ampacity and insulation requirements for different electrical installations.

Additionally, it’s important to note that conductors bundled together can also affect their ampacity. When multiple wires are bundled, their ability to dissipate heat decreases, leading to a potential increase in temperature. This is known as ampacity derating. Therefore, proper spacing and airflow around bundled wires should be ensured to prevent excessive heat buildup.

Regular inspection of wire insulation is essential to detect any signs of wear, damage, or degradation. If insulation appears cracked, worn, or discolored, it is essential to replace the wire promptly to avoid potential hazards. Proper wire sizing, selection of appropriate insulation, and regular maintenance are crucial steps to ensure safe and efficient electrical systems.

Conductivity and Resistance

In the context of electrical wires, conductivity refers to the ability of a material to conduct electricity. Materials with higher conductivity allow electricity to flow more easily, resulting in less resistance and heat generation. Copper is widely recognized for its excellent conductivity and is commonly used in electrical wiring due to its low resistance.

On the other hand, materials with lower conductivity, such as aluminum, have higher resistance and can generate more heat when current flows through them. However, aluminum wires are still used in some applications, especially in larger-scale projects, due to their lower cost and lighter weight compared to copper.

The resistance of a wire is determined by both its length and cross-sectional area. Longer wires have higher resistance, which can lead to more significant heat generation. Thicker wires with larger cross-sectional areas have lower resistance, allowing for better current flow and reduced heat buildup.

It’s important to consider both conductivity and resistance when selecting the appropriate wire size for an electrical installation. In situations where high current flows through a wire, such as circuits powering heavy appliances or machinery, using wires with higher conductivity, like copper, can help minimize heat generation and improve overall efficiency.

Proper wire sizing, taking into account the potential current load, can help ensure that wires do not become overheated. Consulting relevant codes, standards, and professional electricians can provide guidance on selecting the appropriate wire size based on the specific electrical requirements.

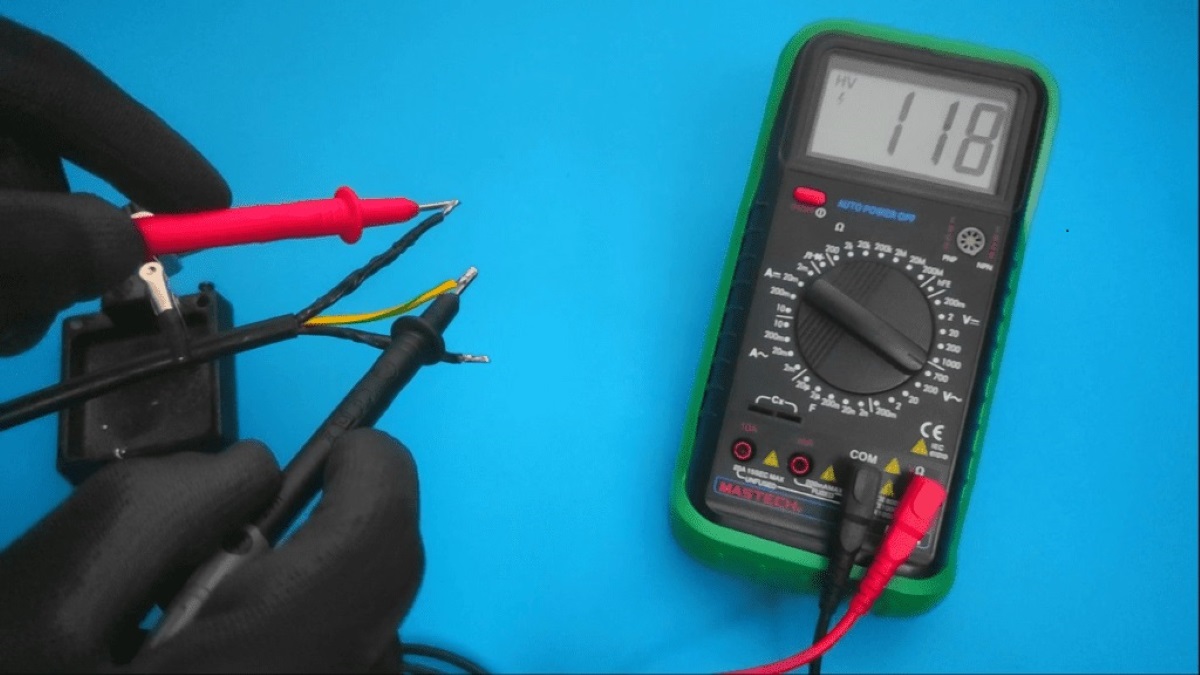

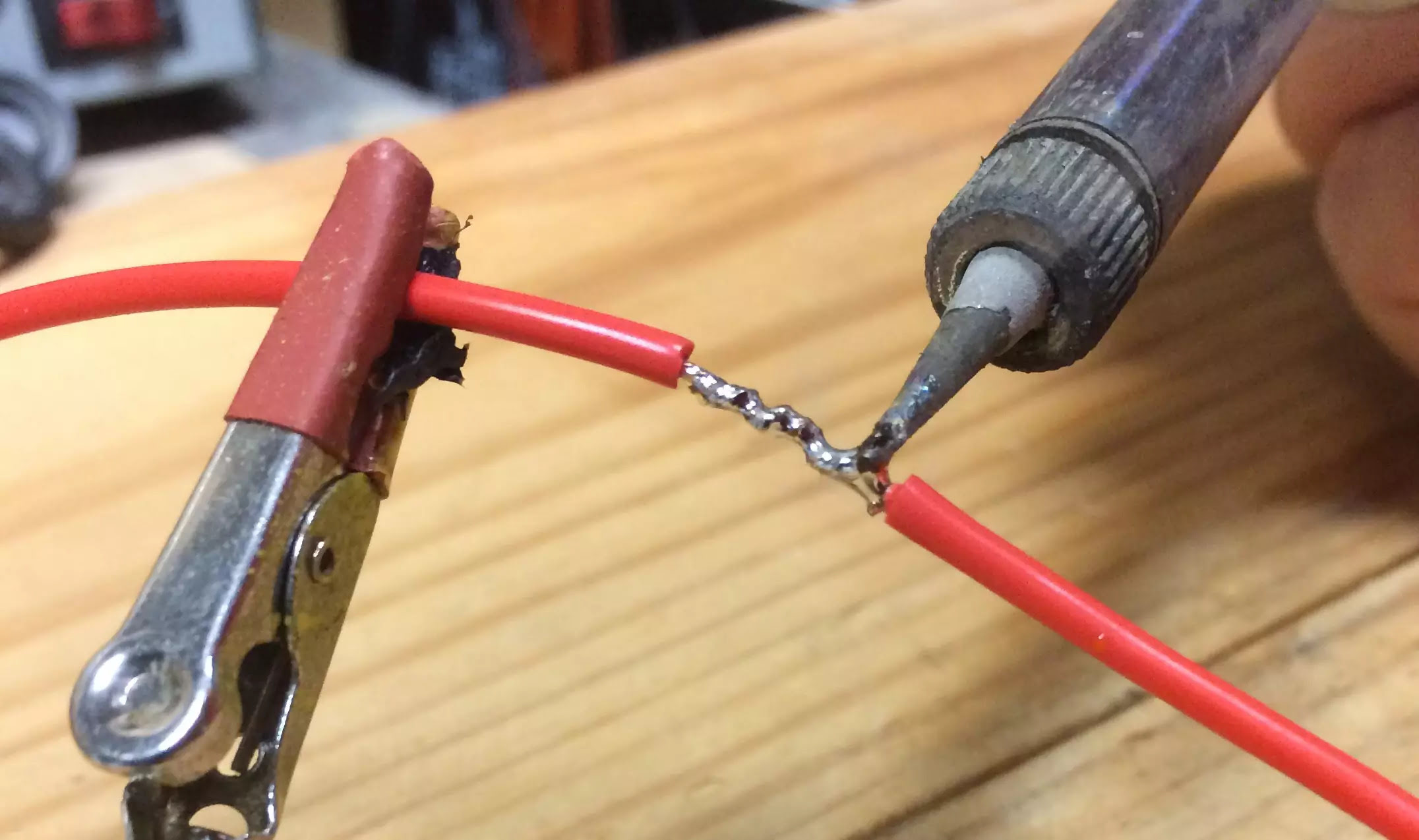

Regular inspection of wires and connections is crucial to detect any signs of increased resistance or overheating. Loose or corroded connections can lead to higher resistance and excessive heat buildup. If any issues are found, they should be promptly addressed to maintain the safety and performance of the electrical system.

Environmental Conditions

The surrounding environmental conditions can have a significant impact on the temperature of electrical wires. Understanding and considering these conditions are crucial to prevent overheating and ensure the safe operation of electrical systems.

One of the primary environmental factors that affect wire temperature is ambient temperature. High ambient temperatures can cause wires to operate at elevated temperatures, increasing the risk of overheating. It is important to select wires with insulation suitable for the expected ambient temperature range and take measures to mitigate heat buildup, such as proper ventilation and insulation.

Similarly, restricted airflow around wires can hinder heat dissipation, leading to higher temperatures. Electrical installations should allow adequate spacing around wires and consider the use of ventilation techniques to promote airflow and prevent excessive heat buildup.

Proximity to heat sources also plays a role in wire temperature. If wires are installed close to heat-emitting equipment or located in areas with high heat sources, such as ovens or furnaces, they are more likely to experience increased temperatures. It is essential to take appropriate measures, such as using insulation or heat barriers, to protect wires in these scenarios.

Moisture and humidity levels in the environment can also impact wire temperature. Water can reduce the insulation properties of wires and increase the risk of short circuits. Therefore, it’s important to ensure proper moisture protection and consider using moisture-resistant wire insulation in areas prone to dampness.

Environmental factors should be carefully assessed during the planning and installation of electrical wiring systems. Proper wiring techniques, insulation selection, and protective measures can help mitigate the impact of environmental conditions and maintain the integrity of the electrical system.

Regular inspections and maintenance should also be conducted to identify and address any issues related to environmental conditions that may affect wire temperature. By staying vigilant and proactive, homeowners and electricians can ensure the safety and reliability of electrical systems in various environmental settings.

Electrical wire can get hot enough to cause a fire if it is overloaded or damaged. Be sure to use the correct gauge wire for the electrical load and inspect for any signs of wear or damage.

Read more: How Hot Can A Toaster Oven Get

Effects of Overheating

Overheating of electrical wires can have several adverse effects on the performance, safety, and longevity of electrical systems. Understanding these effects is crucial for identifying and addressing potential issues before they lead to more significant problems.

One of the primary consequences of wire overheating is insulation degradation. When wires operate at temperatures higher than their designed limits, the insulation surrounding them can deteriorate, become brittle, or even melt. Damaged insulation increases the risk of short circuits, electrical arcing, and potential fire hazards.

Overheating also affects the conductive properties of wires. As wires heat up, their resistance increases, which can lead to voltage drops along the circuit. This diminished voltage can impact the performance and efficiency of connected devices, causing them to malfunction or operate below optimal levels.

In addition to insulation and performance issues, overheating can also damage wire connections. When wires are subject to high temperatures, the terminals, connectors, and junctions can become loose or corroded. Loose connections can cause arcing, leading to further heat generation, increased resistance, and potential fire hazards.

Overheating also poses risks to the overall electrical system. As wires overheat, they become more susceptible to structural damage, increasing the likelihood of mechanical failures such as wire breakage or insulation cracks. These failures can result in power interruptions, complete system failures, or even electrical shocks.

Furthermore, the excessive heat generated by overheating wires can radiate to nearby combustible materials, increasing the risk of fire. The combination of compromised insulation, loose connections, and high temperatures can create a dangerous situation, putting lives and property at risk.

It is important to note that the effects of overheating are not always immediately apparent. Some issues may develop slowly over time, making regular inspections and maintenance critical for early detection and prevention of potential hazards.

To mitigate the effects of overheating, it is crucial to identify and address the underlying causes promptly. This includes ensuring proper wire sizing and insulation selection, maintaining secure and clean connections, and implementing adequate ventilation and cooling methods in areas prone to heat buildup.

By taking proactive measures to prevent wire overheating and addressing any issues that arise, homeowners and electricians can promote the safety, performance, and longevity of electrical systems.

Fire Hazards and Safety Precautions

Overheating of electrical wires poses significant fire hazards that can result in devastating consequences. It is crucial to understand these risks and take appropriate safety precautions to prevent fire incidents.

One of the primary causes of electrical fires is the breakdown of wire insulation due to excessive heat. When the insulation surrounding wires deteriorates, it increases the risk of short circuits, electrical arcing, and sparks. These electrical faults can ignite nearby combustible materials, leading to rapid fire spread.

To minimize the risk of fire caused by wire overheating, the following safety precautions should be implemented:

- Proper wire sizing and installation: Ensuring that wires are properly sized and installed according to applicable codes and standards is essential. Using wires with adequate ampacity and appropriate insulation ratings can help prevent excessive heat buildup and reduce the risk of insulation breakdown.

- Regular inspections: Regular inspections of electrical systems, including wires, connections, and insulation, are crucial for early detection of any signs of overheating or insulation degradation. Any issues found during inspections should be promptly addressed to prevent potential fire hazards.

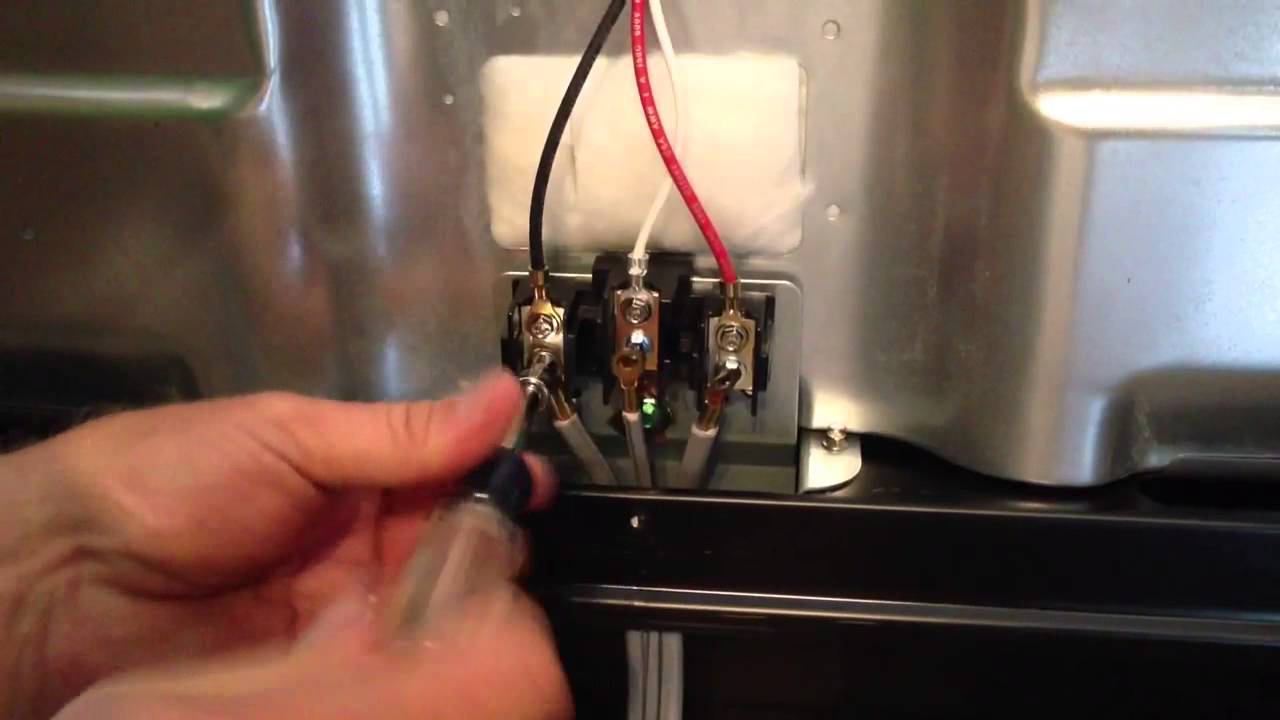

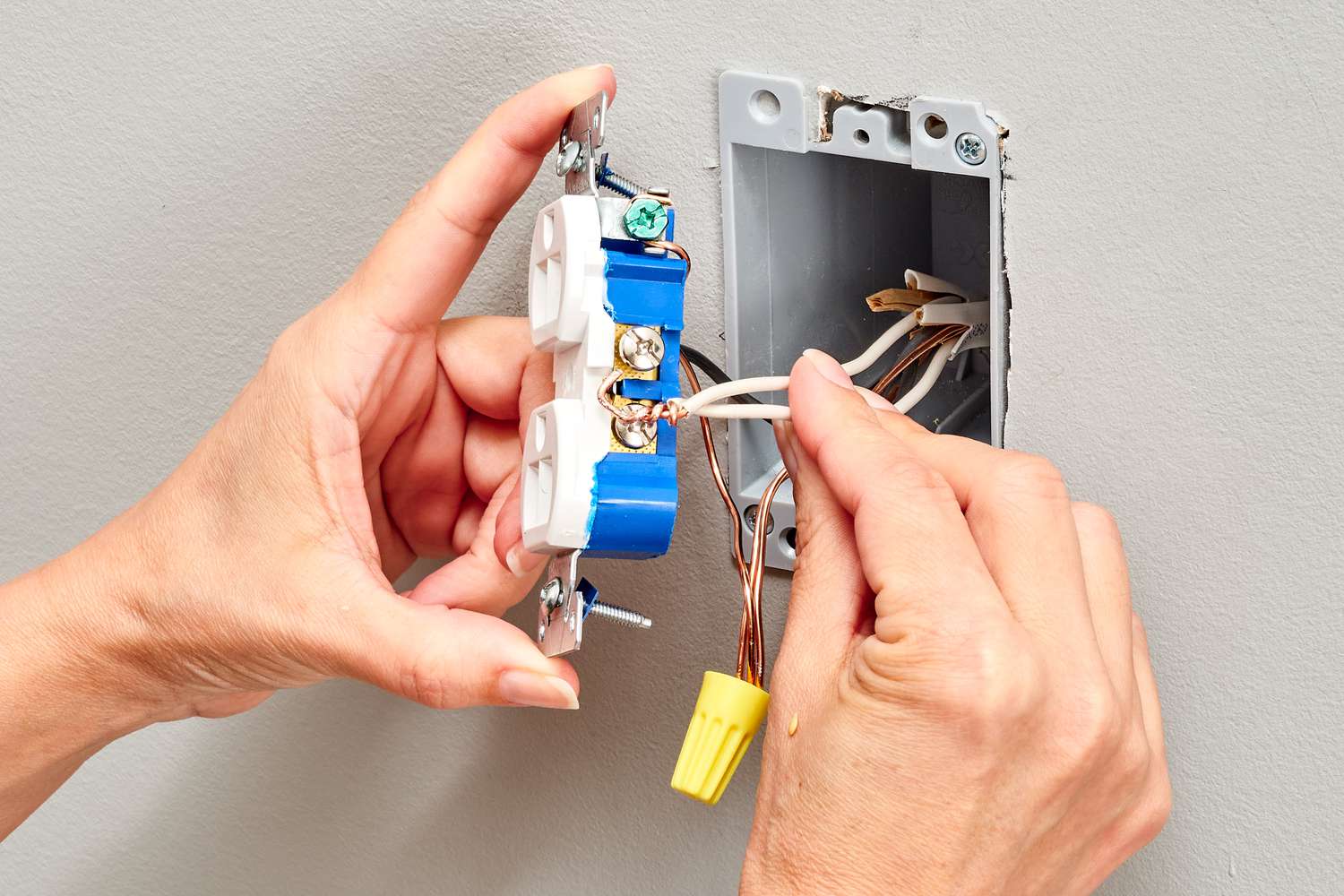

- Correct wire connections: Loose or improperly made wire connections can create resistance and heat buildup. Ensuring secure and tight connections, using appropriate connectors and terminals, helps prevent electrical faults and reduces the risk of fire.

- Proper wire routing and spacing: Wires should be installed with proper spacing, avoiding overcrowding or bundling that can impede heat dissipation. Adequate ventilation should be provided to prevent excessive heat buildup, especially in enclosed spaces or areas with high ambient temperatures.

- Protection from physical damage: Wires should be protected from physical damage, such as being crushed or pierced by sharp objects. Damaged wires can lead to insulation breakdown and an increased risk of fire.

- Responsible use of electrical equipment: Avoid overloading circuits and using electrical equipment beyond their capacity. Overloading can cause wires to heat up and potentially lead to fire incidents. Distribute the electrical load evenly across multiple circuits to prevent overheating.

It is important to have a fire safety plan in place, including functioning smoke detectors, fire extinguishers, and clear evacuation routes. Regularly review and practice the fire safety plan with household members to ensure everyone is prepared in case of an emergency.

Electrical work should always be performed by qualified professionals who adhere to proper installation practices and local electrical codes. Hiring a licensed electrician for electrical projects ensures the highest level of safety and reduces the risk of fire hazards caused by electrical wiring.

By following these safety precautions, homeowners and electricians can significantly reduce the risk of fire incidents related to wire overheating and ensure the safety of their properties and loved ones.

The Importance of Proper Wire Sizing and Installation

Proper wire sizing and installation are crucial aspects of electrical systems that directly impact their performance, safety, and longevity. It is essential to understand the importance of these factors to ensure the efficient and hazard-free operation of electrical systems.

One of the primary reasons for proper wire sizing is to prevent overheating. Wires that are undersized for the intended current load can experience higher resistance, resulting in increased heat generation. Overheating can lead to insulation degradation, electrical faults, and potential fire hazards. Conversely, using oversized wires can result in unnecessary material costs and can complicate wire routing and installation.

Wire sizing is determined based on the expected current load, taking into account factors such as the length of the wire, the type of insulation used, and the environmental conditions. Consulting relevant codes, standards, and professional electricians can help ensure the appropriate wire gauge is selected to handle the expected current without overheating.

Proper wire installation is equally important as proper sizing. Incorrect installation can lead to loose connections, inadequate wire support, and increased risk of electrical faults. Loose connections can cause resistance, overheating, and potential fire hazards. Poor wire support can lead to mechanical stress, bending, or rubbing against other surfaces, which can damage the wire insulation and increase the risk of electrical faults.

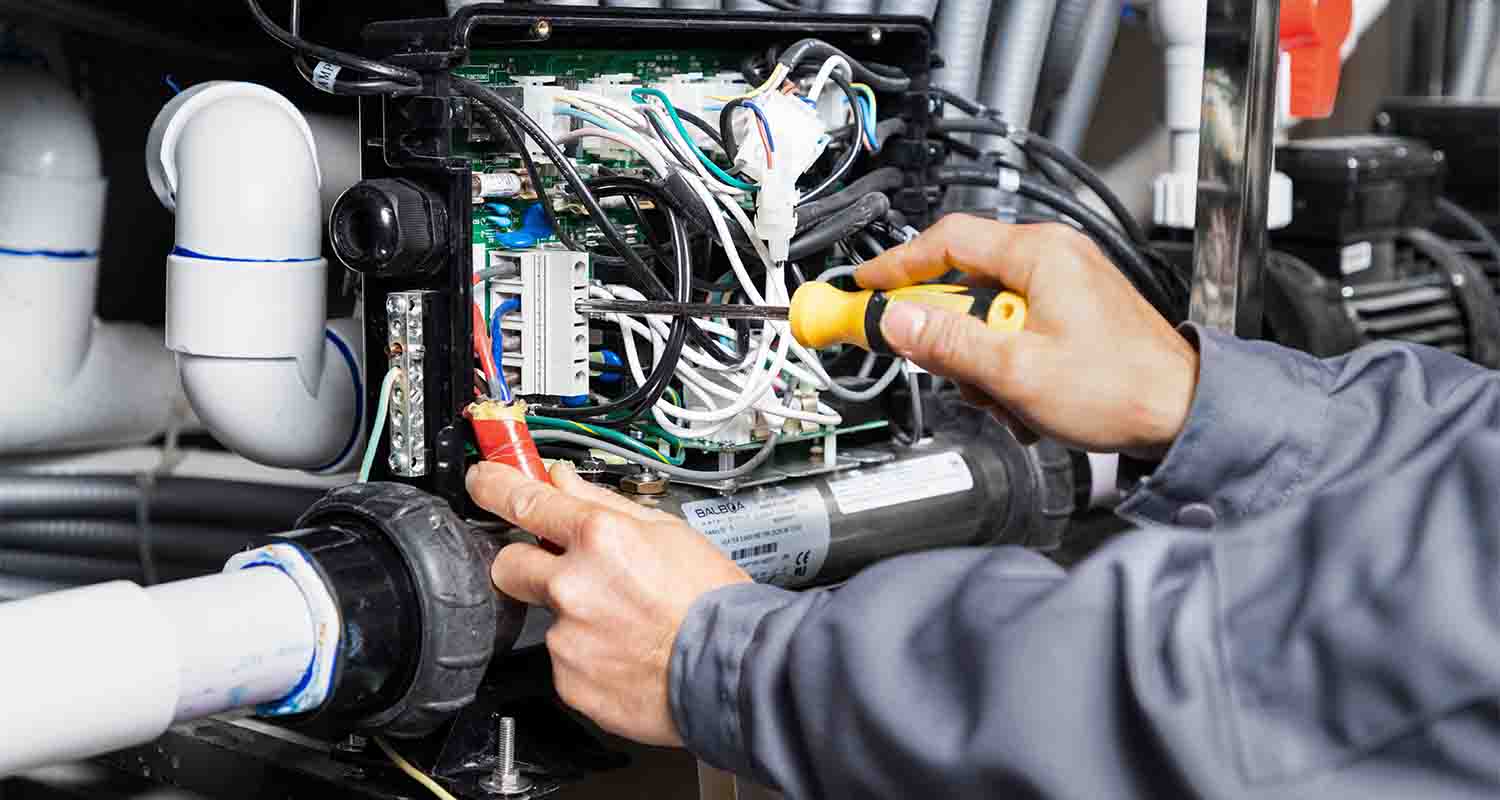

During installation, it is crucial to follow industry standards and best practices. Wires should be routed in a manner that avoids sharp edges, heat sources, and areas prone to moisture. Proper wire support, such as using conduit or cable trays, should be implemented to ensure the wires are securely mounted and protected from physical damage. Moreover, proper insulation stripping and termination techniques should be employed to ensure secure and reliable connections.

Regular inspections of installed wiring systems are essential to identify any signs of wear, damage, or degradation. Loose connections, damaged insulation, or improper wire routing should be addressed promptly to prevent potential hazards. Attention to detail during installation and regular maintenance can help mitigate risks and ensure the longevity and safety of electrical systems.

It is important to note that electrical work should always be carried out by qualified professionals who are knowledgeable about local electrical codes and standards. Hiring a licensed electrician ensures that proper wire sizing and installation practices are followed and that the electrical system meets regulatory requirements.

Proper wire sizing and installation are fundamental for the efficient and safe operation of electrical systems. By emphasizing the importance of these factors and adhering to industry best practices, homeowners, electricians, and DIY enthusiasts can create electrical systems that are reliable, efficient, and built to last.

Case Study: Examples of Wire Overheating Incidents

Examining real-life examples of wire overheating incidents highlights the potential risks and consequences that can arise from inadequate wire sizing, improper installation, or other factors. The following case studies offer valuable insights into the importance of addressing wire overheating and implementing proper safety measures.

Case Study 1: Residential Fire

In a residential home, the electrical wires supplying power to a circuit were undersized for the load. Over time, the wires heated up, causing insulation degradation and exposing bare wire. This resulted in an electrical fault, leading to a fire that quickly spread throughout the home. The investigation revealed that the undersized wires could not handle the current load, leading to excessive heat and insulation breakdown.

Case Study 2: Industrial Equipment Failure

In an industrial setting, a manufacturing facility experienced repeated equipment failures in a particular area. Upon inspection, it was discovered that the wires supplying power to the equipment were insufficiently sized. The inadequate wire gauge led to excessive heat generation, causing electrical faults and equipment downtime. Proper wire sizing and installation resolved the issue, preventing further equipment failures and production interruptions.

Case Study 3: Commercial Building Incident

In a commercial building, several wires located in a concealed space overheated and ignited nearby combustible insulation. The cause of the overheating was determined to be congested wiring, poor ventilation, and high ambient temperatures. The wires were not properly spaced or supported, impeding heat dissipation. As a result, insulation breakdown occurred, leading to a fire that caused extensive damage to the building’s structure.

These case studies highlight the potential dangers of wire overheating and the importance of proper wire sizing, installation, and maintenance. In each scenario, the consequences of neglecting these critical factors resulted in significant property damage, potential injuries, and disrupted operations.

To prevent similar incidents, it is essential to consult qualified professionals, adhere to electrical codes and regulations, and conduct regular inspections of electrical systems. Proper wire sizing, considering the expected current load and environmental conditions, and employing appropriate installation techniques are vital for preventing wire overheating and minimizing associated risks.

By studying these case studies and learning from real-world examples, homeowners, electricians, and industry professionals can gain a deeper understanding of the implications of wire overheating and take the necessary precautions to ensure the safety and reliability of electrical systems.

Read more: How Hot Can Stove Top Get

Conclusion

Understanding how hot electrical wires can get and the factors that contribute to their temperature is crucial for maintaining the safety and efficiency of electrical systems. By considering factors such as ampacity, wire insulation, conductivity, resistance, and environmental conditions, homeowners, electricians, and DIY enthusiasts can make informed decisions to prevent wire overheating.

The consequences of wire overheating can be severe, ranging from insulation degradation and performance issues to electrical faults, equipment failures, and fire hazards. It is essential to prioritize proper wire sizing and installation, regular inspections, and adherence to electrical codes and standards.

Proper wire sizing ensures that wires can handle the intended current load without excessive heat generation. This involves selecting the appropriate wire gauge and considering the insulation’s temperature rating. Additionally, correct wire installation techniques, including secure connections, proper wire routing, and adequate spacing, promote efficient heat dissipation and minimize the risk of wire overheating.

Environmental conditions, such as ambient temperature, airflow, and proximity to heat sources, should also be carefully considered during the installation and operation of electrical systems. Awareness of these factors allows for the implementation of appropriate measures to prevent excessive heat buildup.

Regular inspections and maintenance of electrical systems are crucial for early detection of signs of wire overheating, such as insulation degradation, loose connections, or damaged wires. Promptly addressing any identified issues can prevent further damage and potential hazards.

By prioritizing proper wire sizing and installation, homeowners and professionals can ensure the safety, reliability, and longevity of electrical systems. Consulting with licensed electricians, following relevant codes and regulations, and investing in routine maintenance are key steps towards mitigating the risks associated with wire overheating.

Remember, electrical safety is a collective responsibility. By staying informed, taking the necessary precautions, and seeking professional guidance when needed, we can create an environment where electrical systems operate efficiently and safely for years to come.

Frequently Asked Questions about How Hot Can Electrical Wire Get

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Hot Can Electrical Wire Get”