Articles

How Long Should Gas Line Be For Kegerator

Modified: January 19, 2024

Discover the ideal length for gas lines in kegerators. Read our informative articles to learn how long your gas line should be for optimal performance.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Setting up a kegerator at home is an exciting venture for beer enthusiasts. It allows you to enjoy a perfectly chilled draft beer without having to go to a bar or pub. You might have done your research on the different components needed for a kegerator, such as the keg, CO2 tank, and regulator. However, one important aspect that often gets overlooked is the length of the gas line.

The gas line is responsible for delivering the CO2 from the tank to the keg, ensuring proper carbonation and dispensing of the beer. While it may seem like a minor detail, the length of the gas line plays a crucial role in maintaining the quality and consistency of your pour. In this article, we will explore the factors to consider when determining the ideal length of the gas line for your kegerator.

Key Takeaways:

- Maintaining the ideal gas line length for your kegerator is crucial for preserving carbonation and achieving a perfect pour. Factors like keg placement, temperature, and regulator type all play a role in determining the optimal length.

- Proper installation, regular maintenance, and troubleshooting are essential for ensuring the smooth operation of your gas line. By following guidelines and being attentive to potential issues, you can enjoy consistently high-quality draft beer at home.

Factors to Consider

When deciding on the length of the gas line for your kegerator, there are several factors to take into consideration. These factors will ensure that your beer remains carbonated and that you achieve the perfect pour every time. Let’s explore these factors in detail:

- Keg Placement: The location of your keg in relation to the CO2 tank plays a pivotal role in determining the length of the gas line. If the keg is placed far away from the tank, a longer gas line will be required to compensate for the distance.

- Temperature: The temperature at which your keg is stored will affect the carbonation levels. Warmer temperatures cause the beer to lose carbonation faster, resulting in a flat pour. In such cases, a shorter gas line can be used to maintain higher pressure and carbonation levels.

- Restrictions: Any obstructions or restrictions in the pathway of the gas line can affect the pressure and flow of the CO2. It is essential to account for these restrictions and ensure that the gas line length is adjusted accordingly.

- CO2 Regulator: The type of CO2 regulator you use can impact the length of the gas line. Different regulators have different flow rates, and this should be taken into account when determining the appropriate length.

- Beer Line Length: The length of the beer line can also have an indirect impact on the gas line length. If you have a longer beer line, you might need a shorter gas line to maintain the proper balance of pressure.

Considering these factors will help you determine the optimal length for your gas line, ensuring that your beer remains carbonated and that you achieve the desired pour.

The Ideal Length

Determining the ideal length for your gas line is essential to maintain the quality of your beer and ensure a smooth pour. While there is no one-size-fits-all answer, there are general guidelines that can help you make an informed decision.

Firstly, it is recommended to keep the gas line as short as possible. This helps to minimize the distance the gas needs to travel, reducing the potential for pressure loss and ensuring efficient carbonation. However, it is crucial not to make the gas line too short, as this can result in excessively high pressure, leading to over-carbonation and foamy pours.

A common rule of thumb is to aim for a gas line length of around 5-10 feet. This range provides a good balance between preserving carbonation levels and avoiding excessive pressure. However, it is important to consider the specific factors mentioned earlier that may impact your kegerator setup.

For kegerators kept at cooler temperatures, a shorter gas line may be suitable. With colder beer, the CO2 remains better dissolved, and shorter lines can help maintain the appropriate pressure for carbonation. On the other hand, if your kegerator is kept at warmer temperatures, a longer gas line may be necessary to compensate for the faster loss of carbonation.

It’s important to note that while shorter gas lines are generally preferred, excessively short lines can lead to high pressure and foamy pours. By keeping the general guidelines in mind and considering the specific conditions of your kegerator setup, you can determine the ideal length for your gas line.

It’s worth mentioning that experimentation may be necessary to find the perfect balance. You may need to adjust the length of the gas line and monitor the impact on carbonation levels and pour quality. By making small adjustments and observing the results, you can fine-tune your kegerator setup to achieve the desired carbonation and pour characteristics.

Remember, the ideal length of the gas line will vary depending on various factors, and it’s ultimately about finding the right balance for your specific kegerator setup.

Calculating the Length

To ensure proper carbonation and dispensing of your beer, it is crucial to calculate the appropriate length for your gas line. While there are no hard and fast rules, you can follow a simple formula to estimate the ideal length:

1. Determine the desired carbonation level for your beer. This is typically measured in volumes of CO2, which indicates the amount of carbonation in the beer.

2. Refer to a carbonation chart or online calculator to find the recommended pressure for your desired carbonation level and the temperature at which your keg is stored. The pressure is typically measured in PSI (pounds per square inch).

3. Measure the vertical distance between the keg and the CO2 tank. This is measured from the bottom of the keg to the regulator.

4. Calculate the pressure drop caused by the vertical distance. As a general rule of thumb, for every 1 foot of vertical distance, there will be a pressure drop of approximately 0.5 PSI.

5. Calculate the pressure drop caused by the length of the gas line. As a general guideline, for every 1 foot of gas line, there will be a pressure drop of approximately 0.2 PSI.

6. Add the pressure drops from the vertical distance and the gas line length to the recommended pressure from the carbonation chart. This will give you the total pressure that needs to be maintained at the regulator.

By calculating the pressure drop and considering the recommended pressure for carbonation, you can determine the appropriate length for your gas line. Remember, these calculations provide a starting point, and some adjustments may be required based on personal preference and the specific characteristics of your kegerator setup.

It is worth noting that these calculations provide an estimation, and it is recommended to periodically test and adjust your setup to ensure optimal carbonation and pour quality.

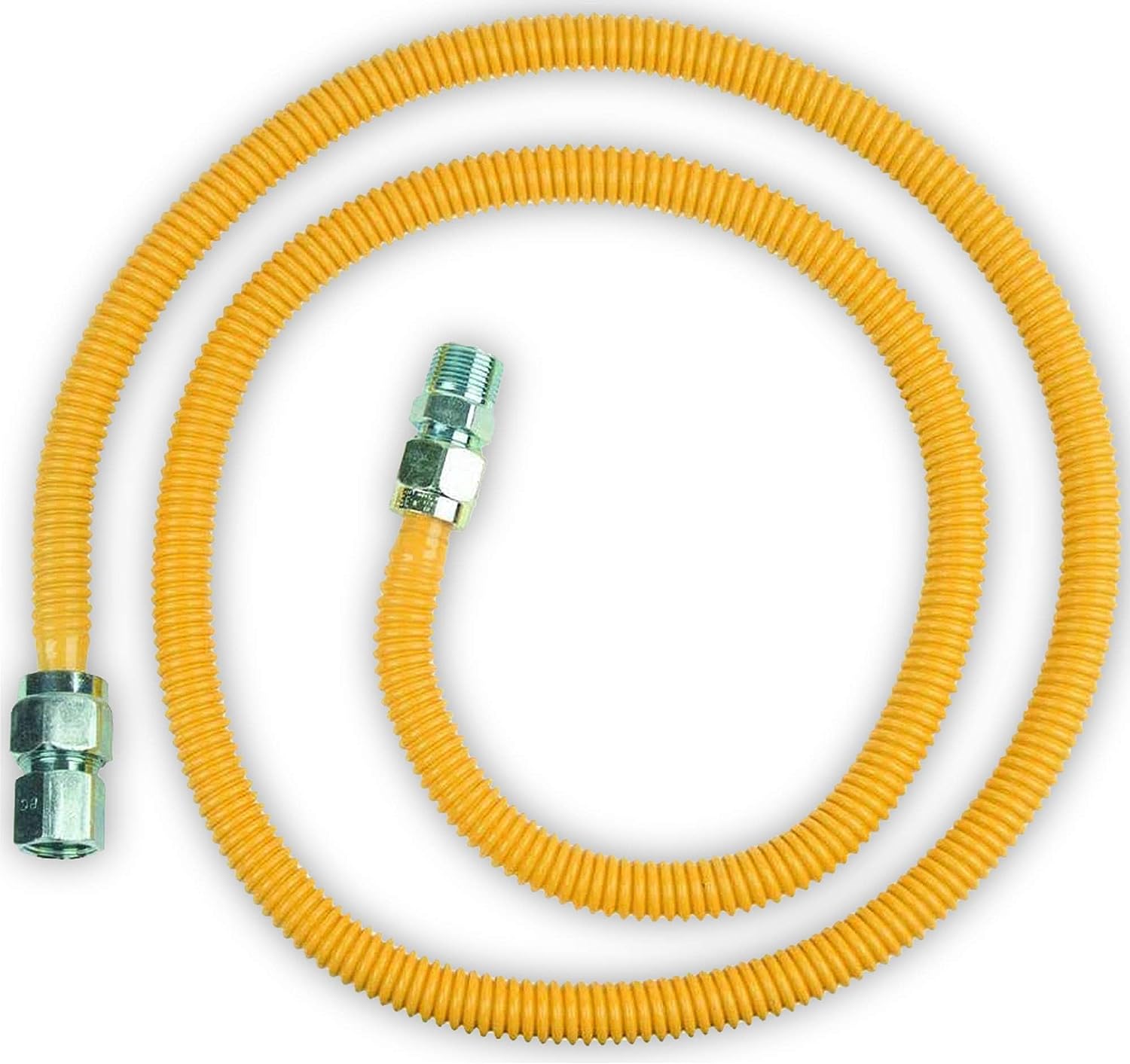

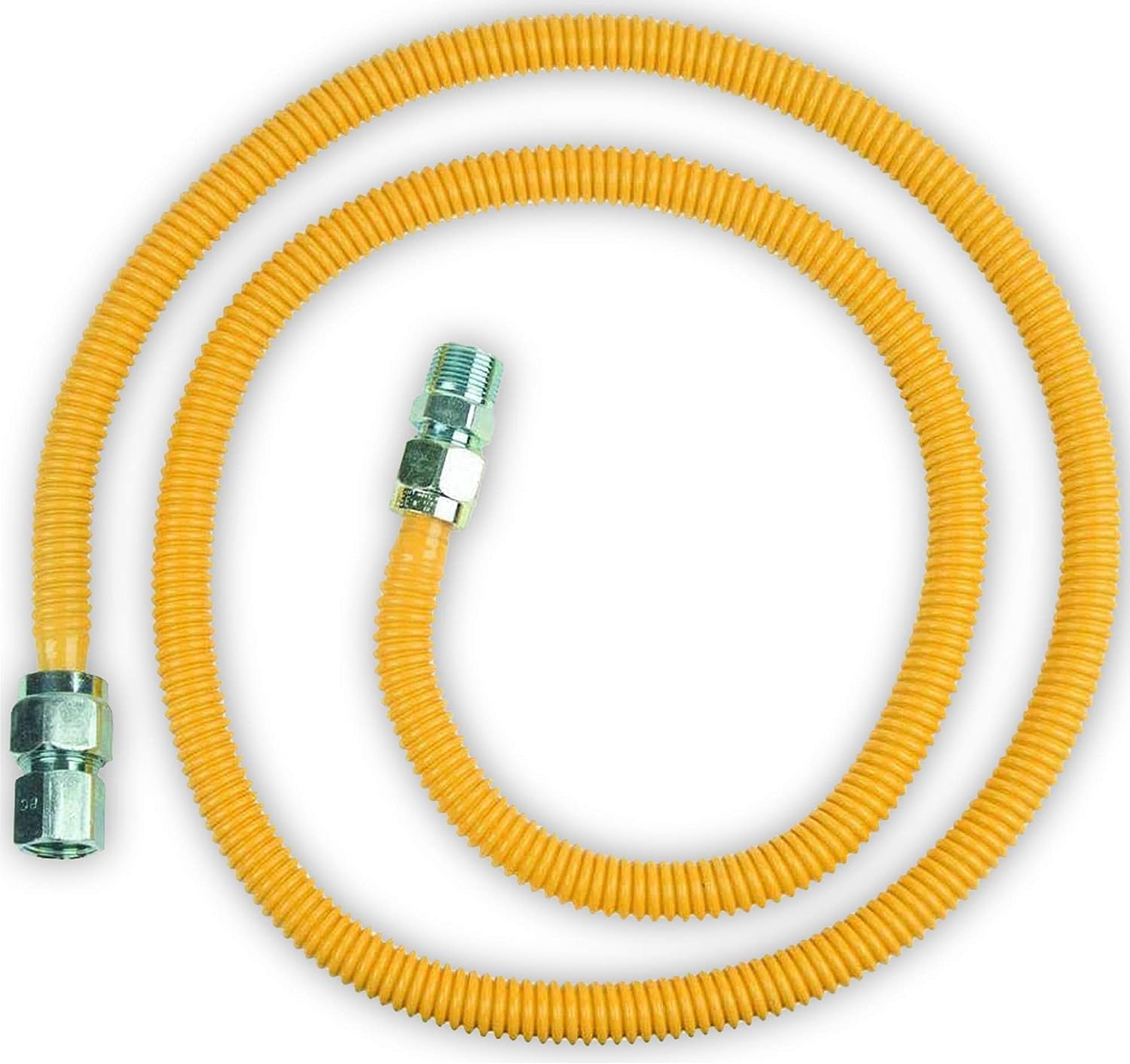

The length of the gas line for a kegerator should be long enough to reach from the CO2 tank to the keg, with some extra length for flexibility and ease of use. It’s recommended to use a line that is around 5-6 feet long.

Installation Tips

Proper installation of the gas line is essential to ensure a smooth and efficient operation of your kegerator. Here are some tips to help you install the gas line correctly:

- Use high-quality gas line: Invest in a high-quality gas line that is suitable for your kegerator setup. Avoid using low-quality tubing as it may affect the taste and quality of your beer.

- Securely connect the gas line: Ensure that the gas line is securely connected to both the CO2 tank and the keg. Use appropriate fittings and clamps to prevent any leaks.

- Properly position the gas line: Avoid kinks or bends in the gas line as this can restrict the flow of CO2 and affect carbonation. Use zip ties or clips to secure the line in place and keep it neat and organized.

- Regularly check for leaks: It is essential to regularly check for any leaks in your gas line. Apply a solution of soapy water to the connections and look for any bubbles. If you notice any leaks, tighten the connections or replace any faulty parts.

- Keep the gas line clean: Clean the gas line regularly to prevent the buildup of residue or contaminants. Follow the manufacturer’s recommendations for cleaning and maintenance.

- Monitor and adjust pressure: Monitor the pressure on the regulator and make any necessary adjustments to ensure proper carbonation. Start with the recommended pressure based on the carbonation chart and make adjustments as needed to achieve the desired pour quality.

- Consider using a secondary regulator: If you have multiple kegs with different carbonation levels, consider using a secondary regulator to control the pressure for each keg individually.

By following these installation tips, you can ensure that your gas line is set up correctly, allowing for optimal carbonation and a smooth dispensing experience.

Read more: How To Clean Lines On A Kegerator

Troubleshooting

Even with proper installation and calculations, issues may still arise with your gas line and kegerator setup. Here are some common troubleshooting tips to help you identify and resolve any problems:

- Excessive foaming: If you experience excessive foaming during the pour, it may indicate a problem with the carbonation level or the gas line length. Adjust the pressure and length of the gas line based on the specific situation, aiming to find the right balance that minimizes foaming.

- Flat beer: If your beer tastes flat or lacks carbonation, it may indicate that the gas line is either too long or the pressure is too low. Adjusting the gas line length or increasing the pressure can help restore carbonation levels.

- Leaks: If you notice gas leaks or hissing sounds around the connections, it is crucial to address them immediately. Check all the fittings and connections, ensuring they are tightly secured and free of any damage or wear. Replace any faulty parts if necessary.

- Inconsistent pressure: If you notice inconsistent pressure on the regulator or varying carbonation levels in your kegs, it may indicate a problem with the regulator or a leak in the gas line. Inspect the regulator and connections for any issues and replace any faulty components as needed.

- Frozen lines: In colder environments, it is possible for the gas line to freeze, especially if it is placed near the cooling lines of the kegerator. If you experience frozen lines, consider insulating the gas line or adjusting its positioning to prevent freezing.

- Improper carbonation: If the carbonation level of your beer is consistently off, despite adjusting the gas line length and pressure, it may be worth considering other factors such as the temperature, quality of the beer, or the condition of the CO2 tank. Assess these factors to ensure they are not affecting the carbonation process.

If you encounter any issues or are unsure how to resolve a problem with your gas line, don’t hesitate to consult with a professional or seek advice from homebrewing communities. They can provide valuable insights and help troubleshoot any specific issues you may encounter during your kegerator journey.

Conclusion

The length of the gas line for your kegerator is an important factor that can greatly impact the carbonation and dispensing of your beer. By considering various factors such as keg placement, temperature, restrictions, and the type of regulator, you can determine the ideal length for your gas line.

It is generally recommended to keep the gas line as short as possible while maintaining the appropriate pressure for carbonation. A range of 5-10 feet is a good starting point, but adjustments may be necessary based on your specific kegerator setup and preferences.

Calculating the length involves considering the desired carbonation level, recommended pressure, vertical distance, and the estimated pressure drop caused by the length of the gas line. It is important to periodically test and adjust the setup to ensure optimal carbonation and pour quality.

During installation, be sure to use high-quality gas line, securely connect the gas line, properly position it, and regularly check for leaks. Additionally, follow good maintenance practices to keep the gas line clean and monitor and adjust the pressure as needed.

If issues arise, such as excessive foaming, flat beer, leaks, inconsistent pressure, frozen lines, or improper carbonation, troubleshooting steps can help identify and resolve the problems. Seek professional assistance or consult with homebrewing communities if needed.

In conclusion, the gas line length is a crucial aspect of your kegerator setup that should not be overlooked. By considering the various factors, ensuring proper installation, and troubleshooting any issues that may arise, you can achieve optimal carbonation and enjoy a perfect pour of your favorite draft beer from the comfort of your own home.

Frequently Asked Questions about How Long Should Gas Line Be For Kegerator

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Long Should Gas Line Be For Kegerator”