Articles

How Much Does An AC Compressor Cost

Modified: August 16, 2024

Discover the average cost of AC compressor replacement in this informative article. Learn about factors that affect the price and find tips to save money.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

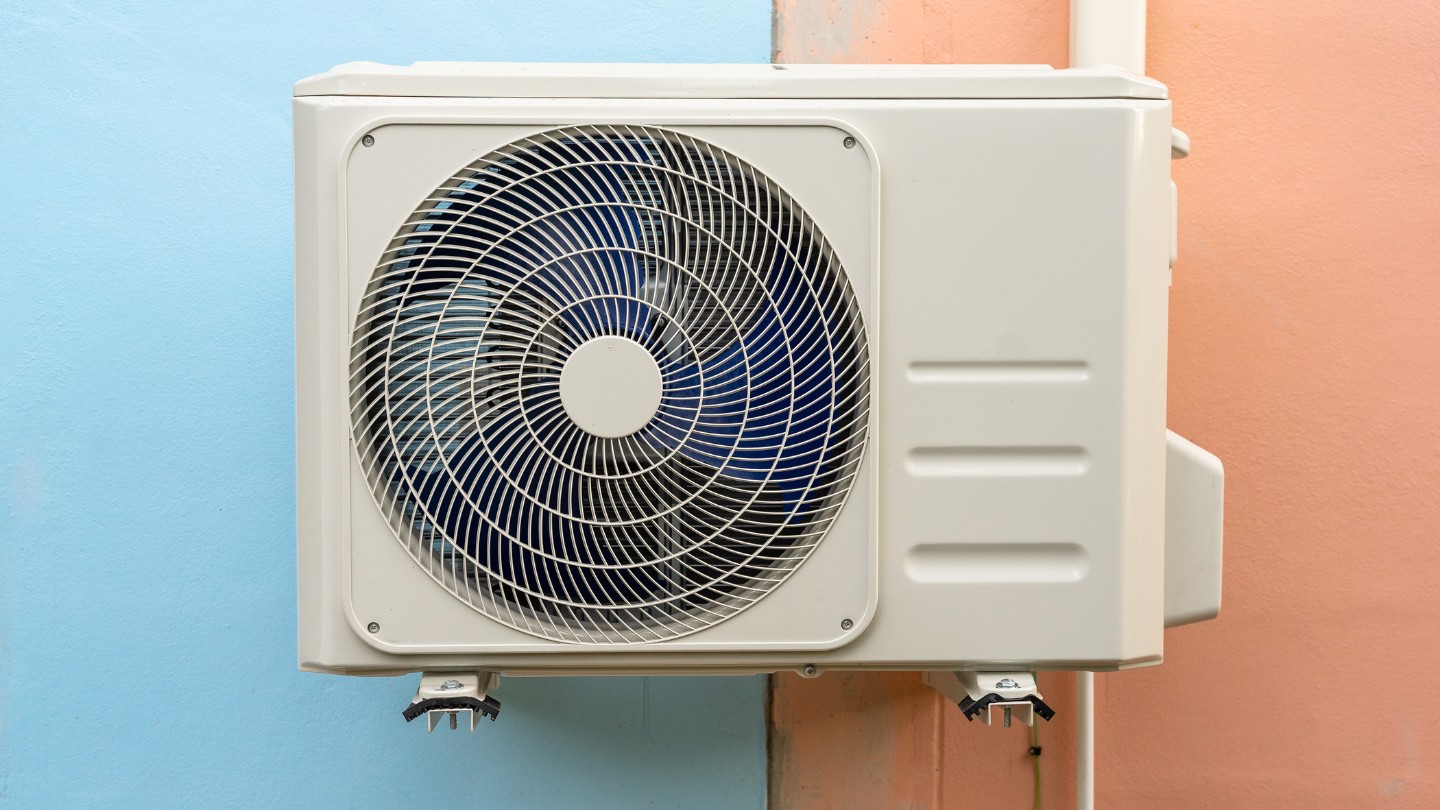

Welcome to our comprehensive guide on AC compressor costs. When it comes to maintaining the comfort of your home or office, a functional air conditioning system is essential. The AC compressor plays a crucial role in the cooling process by pressurizing the refrigerant and sending it through the system, enabling the exchange of heat from inside to outside.

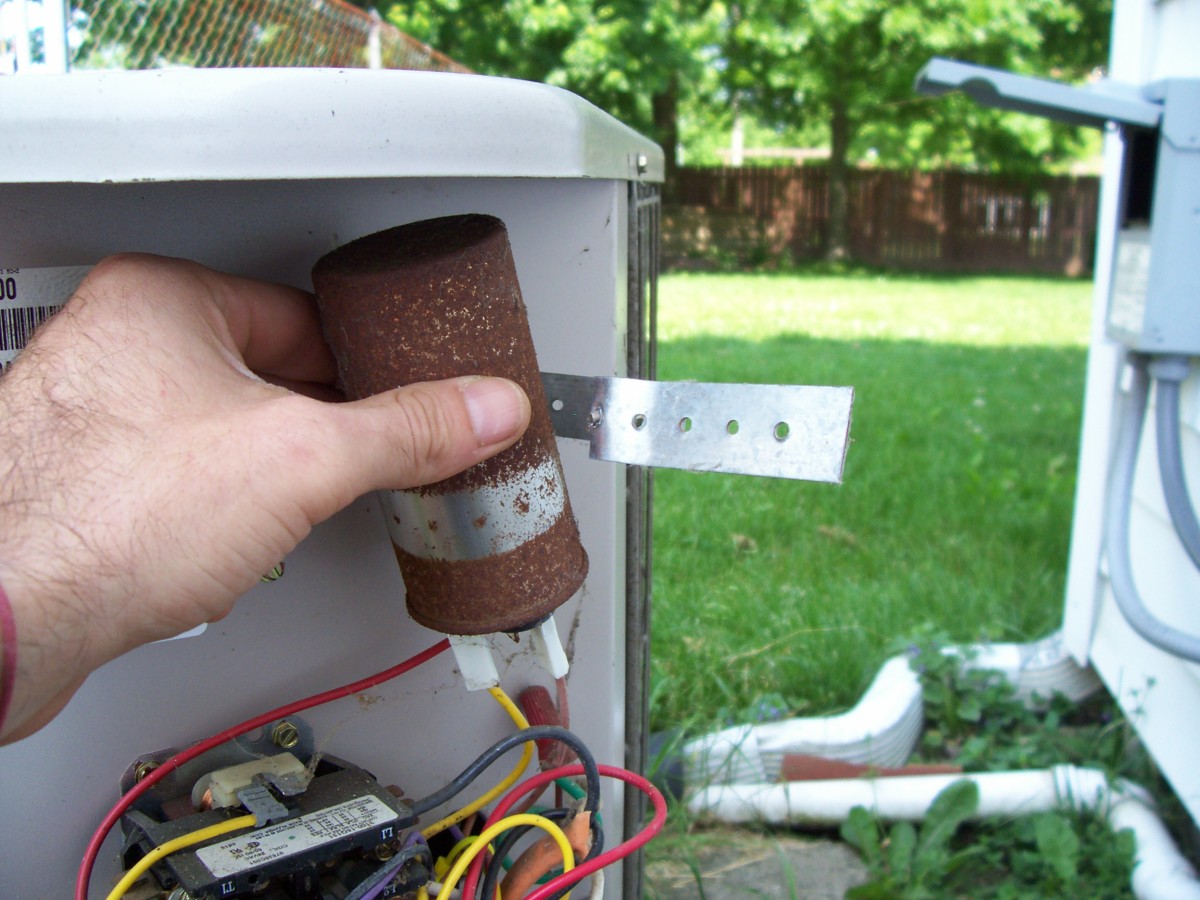

However, like any other mechanical component, AC compressors can malfunction or wear out over time, leading to reduced cooling capacity or a complete breakdown of the system. When faced with such issues, it’s important to understand the factors that influence the cost of AC compressor replacement or repair.

In this article, we will delve into the various factors that can impact the cost of an AC compressor, explore different types of compressors, discuss average cost ranges, offer tips on how to save money, and discuss whether to opt for DIY installation or hire a professional.

So, without further ado, let’s explore the world of AC compressor costs and learn how to make informed decisions when it comes to maintaining your cooling system.

Key Takeaways:

- Understanding the factors that influence AC compressor costs, such as compressor type, system size, and warranty coverage, can help you make informed decisions and align with your budget and requirements.

- Opting for professional installation and investing in energy-efficient compressors can lead to long-term savings and improved system performance, while engaging in regular maintenance and comparing quotes can help minimize AC compressor costs.

Factors Influencing AC Compressor Costs

Several factors come into play when determining the cost of an AC compressor. Understanding these factors can help you estimate the potential expenses and make informed decisions. Here are some key factors influencing AC compressor costs:

- Compressor Type: The type of compressor your air conditioning system uses can significantly impact the cost. There are various types of compressors available, including reciprocating compressors, scroll compressors, and rotary compressors. Each type has its own price range based on factors such as efficiency, performance, and durability.

- System Size: The size or tonnage of your air conditioning system plays a role in compressor costs. Larger systems require more powerful compressors, which tend to be more expensive than smaller ones. It’s important to choose a compressor that matches the specifications of your AC system.

- Manufacturer: The brand and manufacturer of the AC compressor can influence the cost. Well-known brands with reputations for high-quality products may charge a premium for their compressors. However, these compressors often offer better performance and durability, making them a worthwhile investment in the long run.

- Warranty Coverage: Many AC compressors come with warranties that can vary in duration and coverage. Compressors with longer warranties may have higher upfront costs but provide added peace of mind in case of any issues. Consider the warranty coverage when comparing prices and choose one that suits your needs.

- Installation Complexity: The complexity of installing or replacing an AC compressor can affect the cost. If the installation requires additional modifications or adjustments to the existing system, it may result in higher labor charges. Factors such as accessibility, ductwork modifications, and electrical connections can all impact the installation cost.

- Location: The geographical location can also impact AC compressor costs. Areas with higher living costs or where HVAC contractors have higher overhead expenses may have higher overall prices for compressor replacement or repair services.

It’s important to consider these factors when estimating the cost of an AC compressor. Keep in mind that prices may vary based on your specific circumstances and the market conditions in your area. Consulting with HVAC professionals and obtaining multiple quotes can help you get a better understanding of the potential costs involved.

AC Compressor Types

When it comes to AC compressors, there are several types to choose from. Each type operates differently and has its own advantages and disadvantages. Understanding the different compressor types can help you make an informed decision when it comes to replacing or upgrading your AC system. Let’s explore some common AC compressor types:

- Reciprocating Compressors: Reciprocating compressors, also known as piston compressors, are the most common type found in residential and small commercial AC systems. They work by using a piston that moves up and down to compress the refrigerant. Reciprocating compressors are reliable and provide good performance, but they can be louder and have more moving parts, increasing the chances of wear and tear.

- Scroll Compressors: Scroll compressors operate with two spiral-shaped scroll elements. One scroll remains stationary, while the other orbits around it, creating pockets of gas that get trapped, compressed, and discharged. Scroll compressors are more energy-efficient, quieter, and have fewer moving parts than reciprocating compressors. They are commonly used in residential air conditioning systems.

- Rotary Compressors: Rotary compressors use rotating vanes or blades to compress the refrigerant. They are known for their smooth and quiet operation. Rotary compressors come in two types: rotary vane and rotary screw. Rotary vane compressors are commonly used in small to medium-sized AC systems, while rotary screw compressors are more suitable for larger commercial applications.

- Centrifugal Compressors: Centrifugal compressors are used in large-scale commercial and industrial HVAC systems. They use centrifugal force to compress the refrigerant. Centrifugal compressors are highly efficient and can handle high cooling capacities. However, they are costly and require complex installation and maintenance.

Each type of AC compressor has its own performance characteristics, energy efficiency ratings, and price ranges. It’s important to consider your specific cooling needs, budget, and system requirements when selecting an AC compressor type. Consulting with HVAC professionals can help you determine the most suitable compressor type for your specific application.

Average Cost of AC Compressors

The cost of an AC compressor can vary depending on various factors, such as the type of compressor, brand, system size, and location. On average, the cost of a new AC compressor can range from $500 to $2000 or more, including both the cost of the compressor unit itself and the labor for installation. Here’s a breakdown of the average cost range for different types of compressors:

- Reciprocating Compressors: The average cost of a reciprocating compressor typically ranges from $500 to $1000.

- Scroll Compressors: Scroll compressors have an average cost range of $800 to $1500.

- Rotary Compressors: The average cost of rotary compressors can vary significantly based on the type and size. Rotary vane compressors can range from $1000 to $2000, while rotary screw compressors for larger applications can cost $2000 to $4000 or more.

- Centrifugal Compressors: Centrifugal compressors are more commonly used in industrial applications and have a higher price range. The average cost can start from $3000 and go up to $10,000 or more, depending on the size and specifications.

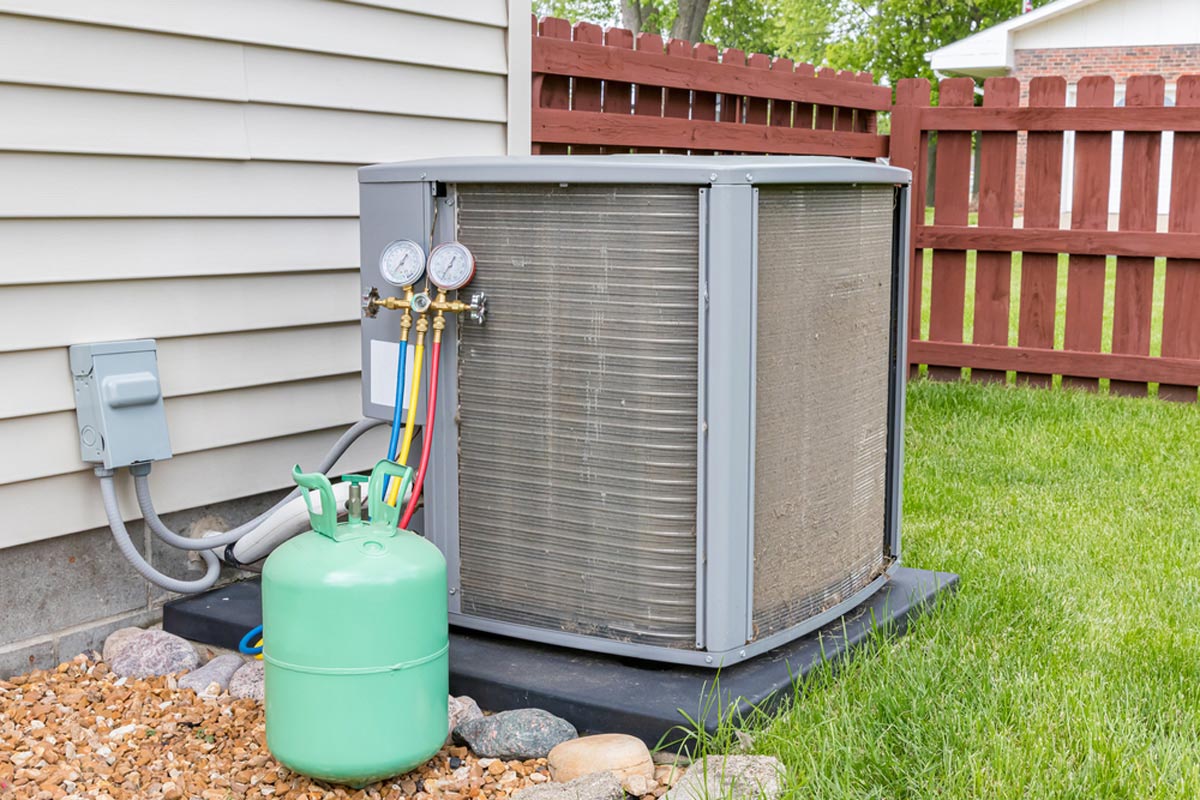

It’s important to note that these cost ranges are estimates and can vary based on factors such as brand, warranty coverage, installation complexity, and local market conditions. Additionally, these costs may not include other associated expenses, such as refrigerant recharge or any additional repairs or modifications required during the installation process.

When considering the cost of an AC compressor, it’s crucial to weigh the upfront investment against the long-term benefits. A higher-quality and more efficient compressor may come with a higher price tag initially but can save you money in the long run through improved energy efficiency and reliability.

It’s recommended to consult with HVAC professionals to obtain accurate and personalized cost estimates for your specific AC compressor needs. They can assess your system and provide recommendations based on your budget and requirements.

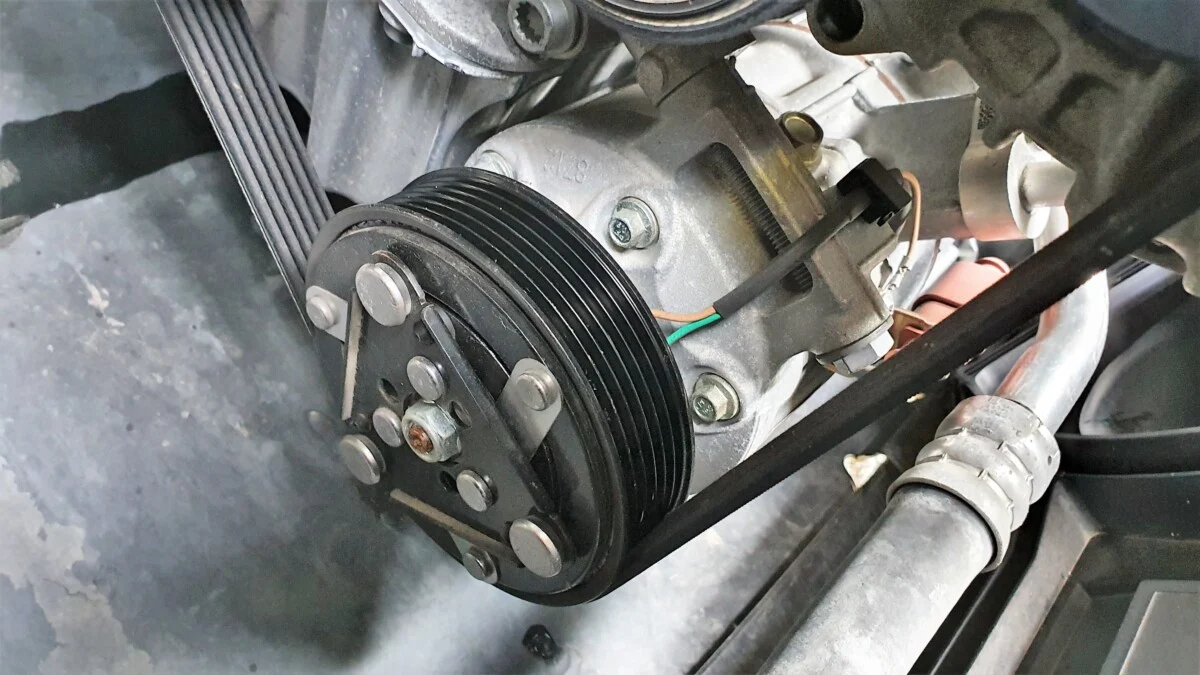

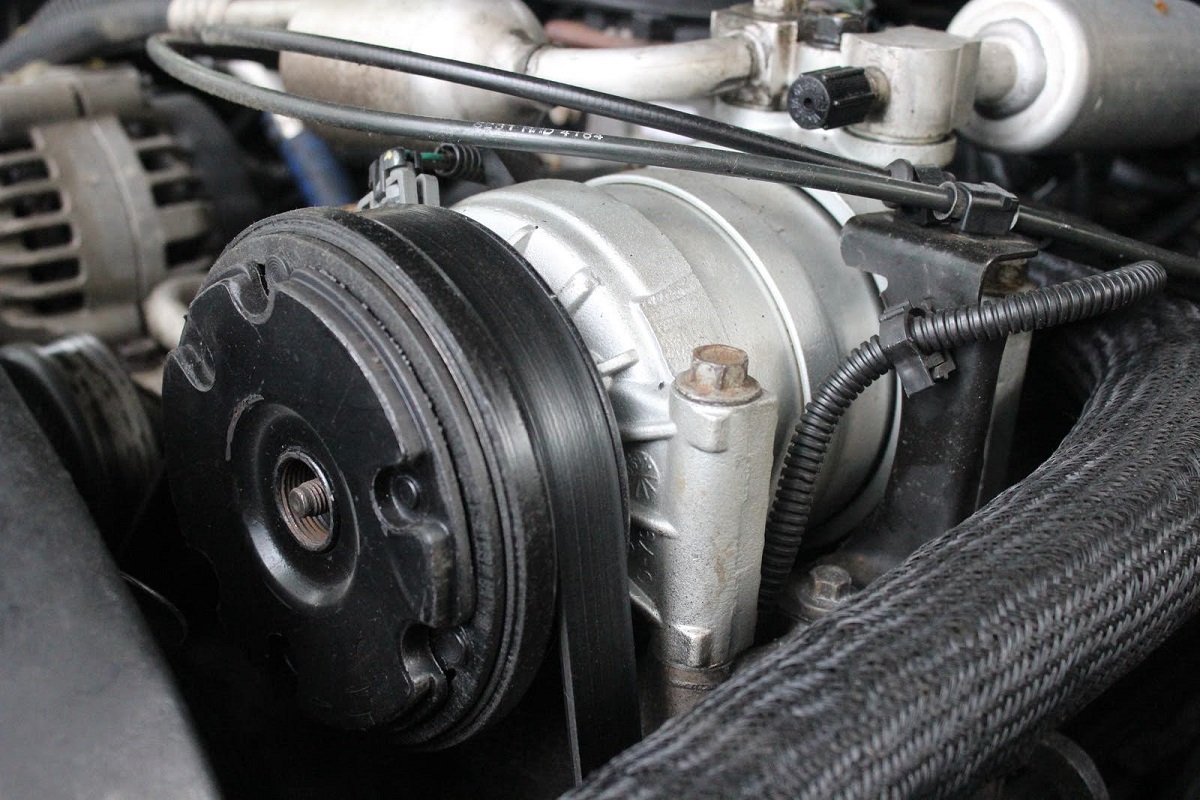

When replacing an AC compressor, it’s important to consider the cost of the part itself as well as the labor involved in installation. Prices can vary widely based on the make and model of the vehicle, so it’s best to get multiple quotes from reputable mechanics or shops.

How to Save Money on AC Compressor Costs

Replacing or repairing an AC compressor can be a significant expense. However, there are ways to save money without compromising on the quality or performance of your cooling system. Here are some tips to help you reduce AC compressor costs:

- Regular Maintenance: One of the best ways to prolong the lifespan of your AC compressor and reduce the likelihood of expensive repairs or replacements is by performing regular maintenance. Schedule annual maintenance checks with a professional HVAC technician to ensure that your system is in good condition, the compressor is properly lubricated, and any potential issues are addressed early on.

- Prompt Repairs: If you notice any issues with your AC system, such as decreased cooling performance or unusual sounds, address them promptly. Ignoring minor problems can lead to more significant compressor damage and higher repair costs. Don’t hesitate to contact a professional for assistance when needed.

- Energy Efficiency: Investing in an energy-efficient AC compressor can save you money in the long run by reducing your energy consumption and lowering your utility bills. Look for compressors with high SEER (Seasonal Energy Efficiency Ratio) ratings, as they indicate better energy efficiency. Although energy-efficient compressors may have a higher upfront cost, the savings on energy bills can offset the initial investment over time.

- Compare Quotes: When it’s time to repair or replace your AC compressor, don’t settle for the first quote you receive. Take the time to research and obtain multiple quotes from reputable HVAC contractors in your area. Comparing prices, warranties, and services can help you find the best deal without compromising on quality.

- Consider Refurbished Compressors: If budget is a concern, you may consider purchasing a refurbished AC compressor. Refurbished compressors have been professionally examined, repaired, and tested to ensure they meet performance standards. While they can be a more affordable option, it’s essential to source them from reputable suppliers and check for warranties to safeguard your investment.

- Maintain Proper Insulation: Ensure that your home or office is properly insulated to minimize heat transfer. Good insulation will lessen the workload on your AC compressor, leading to lower energy consumption and reduced wear and tear.

- Regularly Clean and Replace Air Filters: Clogged or dirty air filters can restrict airflow, forcing the compressor to work harder to cool your space. Regularly clean or replace your air filters to keep your system running efficiently and reduce strain on the compressor.

By following these tips, you can optimize the performance of your AC compressor, minimize the risk of costly repairs, and save money on energy bills. Remember that proper maintenance and timely repairs are key to avoiding expensive compressor replacements and maximizing the lifespan of your cooling system.

DIY vs. Professional Installation

When it comes to installing or replacing an AC compressor, you may be wondering whether to tackle the task yourself or hire a professional. While DIY installation may seem like a cost-effective option, it’s important to consider the complexities and potential risks involved. Here’s a comparison of DIY vs. professional installation to help you make an informed decision:

DIY Installation:

Pros:

- Cost Savings: DIY installation can save you money on labor costs, especially if you are confident in your skills and have experience working with HVAC systems.

- Flexibility: You have control over the installation process, allowing you to work at your own pace and according to your schedule.

Cons:

- Lack of Knowledge and Experience: HVAC systems are complex, and a compressor installation requires specific technical knowledge and skills. Improper installation can result in system damage, poor performance, and safety hazards.

- Voided Warranties: Many manufacturers require professional installation to validate the warranty. If you install the compressor yourself, you may risk voiding the warranty and being responsible for any future repairs or replacements.

- Potential Safety Risks: Working with refrigerant and electrical components can be hazardous if not done correctly. Improper handling can lead to personal injury, equipment damage, or environmental harm.

Professional Installation:

Pros:

- Expertise and Experience: HVAC professionals have the necessary skills and knowledge to handle AC compressor installations, ensuring proper installation and optimal performance.

- Time-Saving: Professionals can complete the installation efficiently and effectively, minimizing downtime and inconvenience.

- Warranty Coverage: Professional installation typically guarantees warranty validation, protecting you from costly repairs or replacements in case of issues.

Cons:

- Higher Initial Cost: Professional installation comes with a price tag for labor and expertise, which can increase the upfront cost.

- Scheduling Dependencies: Relying on professional installation may involve waiting for an available appointment that fits your schedule.

In general, unless you are experienced in HVAC installations and confident in your abilities, it is recommended to opt for professional installation. HVAC professionals have the necessary skills, tools, and expertise to ensure a proper and safe installation. Their knowledge of local codes and regulations can also help you avoid potential legal issues.

However, if you do decide to go the DIY route, it’s crucial to thoroughly research the installation process, follow manufacturer guidelines, and prioritize safety precautions. Take into account local regulations, obtain the necessary permits if required, and consider having a professional review your work to ensure it meets industry standards.

Remember, the goal is to have a properly functioning AC compressor that provides efficient cooling while maintaining safety and warranty coverage. Consulting with HVAC professionals and obtaining quotes for professional installation can provide a clear understanding of the costs involved and help you make an informed decision based on your specific situation and budget.

Conclusion

Understanding AC compressor costs is essential for maintaining the comfort and functionality of your air conditioning system. By considering the factors that influence AC compressor costs, such as compressor type, system size, warranty coverage, and installation complexity, you can make informed decisions that align with your budget and requirements.

When it comes to choosing an AC compressor, there are various types available, each with its own advantages and price ranges. Reciprocating compressors, scroll compressors, rotary compressors, and centrifugal compressors offer different levels of performance and efficiency, so it’s important to select one that suits your specific cooling needs.

The cost of an AC compressor can range from $500 to $2000 or more, depending on the type, brand, system size, location, and warranty coverage. It’s important to weigh the upfront investment against long-term savings and performance benefits. Energy-efficient compressors may have a higher initial cost but can lead to lower energy consumption and utility bills in the long run.

To save money on AC compressor costs, engage in regular maintenance, promptly address repairs, compare quotes from multiple HVAC professionals, consider refurbished compressors, maintain proper insulation, and regularly clean and replace air filters. These strategies can help optimize the performance of your AC compressor and reduce expenses.

When it comes to installation, it’s generally recommended to opt for professional installation to ensure proper and safe installation, warranty validation, and optimal system performance. HVAC professionals have the expertise and experience to handle AC compressor installations efficiently and effectively.

In conclusion, investing in a high-quality AC compressor and prioritizing regular maintenance and professional installation can improve the longevity, performance, and energy efficiency of your air conditioning system. By understanding the factors that influence AC compressor costs and following cost-saving strategies, you can maintain a cool and comfortable environment while keeping expenses under control.

Frequently Asked Questions about How Much Does An AC Compressor Cost

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Much Does An AC Compressor Cost”