Articles

How To Know If AC Compressor Is Bad

Modified: January 6, 2024

Learn how to identify if your AC compressor is malfunctioning with these informative articles. Find out common signs of a bad AC compressor and get expert advice on troubleshooting and maintenance.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

The AC compressor plays a vital role in the cooling system of your car or home air conditioning unit. It is responsible for compressing and circulating the refrigerant, which is essential for cooling the air. However, over time, the AC compressor can develop issues, leading to poor performance or a complete breakdown of the cooling system.

Recognizing the signs of a failing AC compressor is crucial to prevent further damage and costly repairs. In this article, we will discuss the common symptoms of a bad AC compressor and provide you with some tips on how to identify if your AC compressor is in need of attention.

Key Takeaways:

- Pay attention to strange noises, lack of cooling, compressor clutch failure, and AC system pressure issues as they are common symptoms of a failing AC compressor. Prompt inspection and maintenance can prevent further damage.

- Conduct visual and basic tests to assess the compressor’s condition, but consult a professional for comprehensive diagnostics. Addressing issues promptly ensures a comfortable and efficient cooling system.

Read more: How To Know If Car AC Compressor Is Bad

Symptoms of a Bad AC Compressor

An AC compressor that is starting to fail can exhibit various symptoms. It’s important to pay attention to these signs to avoid potential damage to your cooling system. Here are some common symptoms of a bad AC compressor:

- Strange Noises: One of the first signs of a failing AC compressor is unusual noises. You may hear grinding, squealing, or banging sounds coming from the compressor unit. These noises can indicate a worn-out bearing or damaged internal components. If you notice any unusual sounds coming from your AC system, it’s a good idea to have it inspected by a professional.

- Lack of Cooling: If you start to notice that your AC system is not producing enough cool air or if the air is not as cold as it used to be, the AC compressor could be to blame. A compressor that is failing or not functioning properly may not be able to circulate the refrigerant effectively, resulting in insufficient cooling performance.

- Compressor Clutch Failure: The AC compressor is equipped with a clutch that engages and disengages to control the compressor’s operation. If the clutch fails to engage or disengage properly, it can cause issues with the cooling system. You may notice that the AC blows warm air even when the system is turned on, indicating a problem with the compressor clutch.

- AC System Pressure Issues: A failing AC compressor can also lead to abnormal pressure levels in the AC system. If the compressor is not functioning correctly, it may result in low or high pressure readings on the AC gauges. Low pressure can indicate a refrigerant leak or a failing compressor, while high pressure can signify a restriction in the system or an overworking compressor.

If you experience any of these symptoms, it’s essential to have your AC system inspected by a qualified technician. They can diagnose the issue and recommend the necessary repairs or replacements to restore the proper functionality of your AC compressor.

Strange Noises

One of the common indications of a bad AC compressor is the presence of strange noises coming from the unit. These noises can range from grinding and squealing to banging or clicking sounds. It’s crucial to pay attention to these auditory cues as they can offer valuable insight into the health of your compressor.

Here are some of the possible causes of the strange noises associated with a failing AC compressor:

- Worn-out Bearings: The compressor contains bearings that help facilitate smooth rotation. Over time, these bearings can wear out, leading to grinding or squealing noises. If you hear these sounds, it may indicate the need for bearing replacement.

- Damaged Internal Components: The internal components of the compressor, such as pistons, valves, or rods, can suffer damage due to wear and tear or lack of lubrication. This damage can result in banging or clicking sounds when the compressor is running.

- Refrigerant Leak: A refrigerant leak can cause hissing or bubbling noises as the refrigerant escapes from the system. This can also put unnecessary strain on the compressor, leading to abnormal sounds.

- Loose or Misaligned Parts: If certain parts of the compressor or the AC system become loose or misaligned, it can cause vibrations and rattling noises. These noises can indicate the need for adjustments or repairs.

If you notice any strange noises coming from your AC compressor, it’s important not to ignore them. Ignoring such sounds can lead to further damage and potentially a complete breakdown of the compressor. Schedule an inspection with a qualified technician who can diagnose the issue and recommend the necessary repairs or replacements to get your AC system back to optimal performance.

Lack of Cooling

If you’ve noticed that your AC system is not producing enough cool air or that the air is not as cold as it used to be, it could be an indication of a failing AC compressor. The compressor is responsible for compressing the refrigerant and circulating it through the system to cool the air. When the compressor is not functioning correctly, it can lead to a lack of cooling in your AC system.

There are several reasons why a failing AC compressor can result in a lack of cooling:

- Inadequate Refrigerant Circulation: When the AC compressor fails, it may not be able to properly circulate the refrigerant throughout the system. This means that the cool air you expect from your AC vents may not be as cold or may not be present at all. It’s essential to have a professional inspect the compressor and check the refrigerant levels to ensure that the system is properly charged.

- Reduced Efficiency: A failing AC compressor may also exhibit reduced efficiency, meaning that it is not compressing the refrigerant as effectively as it should. This can result in the air conditioning system working harder to achieve the desired cooling, ultimately leading to insufficient cooling performance.

- Restricted Airflow: In some cases, a failing AC compressor can cause restricted airflow within the system. This can be due to obstructions or blockages caused by compressor components that are not functioning correctly. Restricted airflow can significantly impact the cooling capacity of your AC unit.

If you are experiencing a lack of cooling from your AC system, it’s important to have it inspected by a professional technician. They can assess the condition of the compressor and determine the underlying cause of the issue. Whether it requires repair or replacement, addressing a failing AC compressor will help restore the cooling performance of your air conditioning system and ensure your comfort during the hot summer months.

Compressor Clutch Failure

The compressor clutch is an essential component of the AC compressor. It engages and disengages to control the operation of the compressor in response to the cooling demands of the AC system. When the compressor clutch fails, it can lead to significant issues with the overall functionality of the AC system.

Here are some signs that may indicate a compressor clutch failure:

- Warm Air: If you notice that your AC system is blowing warm air even when it is turned on, it can be a sign of a failing compressor clutch. The clutch is responsible for engaging the compressor, which allows it to compress the refrigerant and produce cold air. When the clutch fails to engage properly, the compressor does not function as it should, resulting in warm air from the vents.

- Intermittent Cooling: A failing compressor clutch may also cause intermittent cooling. You may experience periods where the AC system blows cold air and then suddenly transitions to warm air. This inconsistency in cooling performance can be attributed to the erratic engagement and disengagement of the clutch.

- Unusual Noises: Another sign of compressor clutch failure is the presence of strange noises. You may hear grinding, squealing, or rattling sounds coming from the AC compressor unit. These noises can indicate a malfunctioning clutch mechanism and should be inspected by a professional technician.

- Increased AC Cycling: A failing compressor clutch can cause the AC system to cycle more frequently. This means that the compressor engages and disengages rapidly, leading to excessive wear and tear on both the clutch and the compressor itself. Increased cycling can result in reduced overall efficiency and performance of the AC system.

If you observe any of these symptoms, it’s important to have your AC system checked by a qualified technician. They can diagnose whether the issue lies with the compressor clutch and recommend the necessary repairs or replacements. Addressing compressor clutch failure promptly will help ensure the proper functioning of your AC system and maintain your comfort in hot weather conditions.

If your AC is blowing warm air, making strange noises, or leaking refrigerant, it could be a sign of a bad compressor. Have a professional technician inspect and diagnose the issue for an accurate assessment.

Read more: How Do I Know If My AC CapACitor Is Bad?

AC System Pressure Issues

AC system pressure issues can be a clear indication of a failing AC compressor. The compressor plays a crucial role in maintaining the proper pressure levels within the AC system, so any abnormalities can point to a problem with this component.

Here are some pressure-related symptoms that may suggest a problem with the AC compressor:

- Low Pressure: If your AC system is experiencing low pressure, it could be due to a refrigerant leak or a failing compressor. A leak in the refrigerant lines can lead to a loss of pressure, affecting the cooling performance of the system. Similarly, a failing compressor may not be able to compress the refrigerant effectively, resulting in lower pressure levels.

- High Pressure: Conversely, high pressure readings in the AC system can also indicate an issue with the compressor. A restriction in the system or an overworking compressor can cause the pressure to rise abnormally. High pressure can put unnecessary strain on the components and may lead to further damage if not addressed promptly.

- Fluctuating Pressure: If you notice that the pressure readings in your AC system are fluctuating significantly, it could be a sign of compressor malfunction. Fluctuating pressure can indicate issues with the compressor’s ability to maintain a consistent and stable pressure level.

- Abnormal Cycling: Another symptom of AC system pressure issues related to the compressor is frequent cycling. If the compressor is not functioning correctly, it may cause the system to cycle on and off more frequently than usual. This can result in inconsistent cooling performance and increased wear on the compressor.

If you suspect pressure-related issues with your AC system, it is crucial to have it inspected by an experienced technician. They can assess the pressure levels, identify any underlying problems with the compressor or other components, and recommend the appropriate repairs or replacements. Prompt attention to AC system pressure issues will help ensure the proper functioning of your cooling system and prevent further damage.

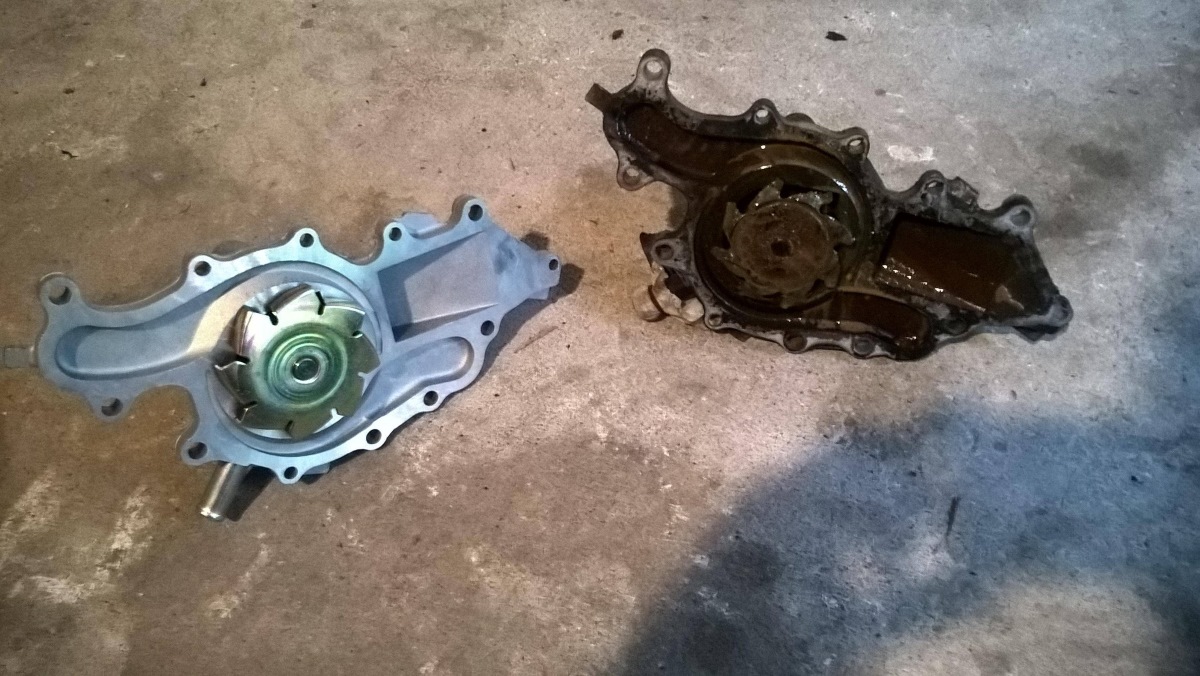

Visual Inspection

A visual inspection of your AC compressor can provide valuable clues about its overall condition and potential issues. While it’s always recommended to have a professional technician inspect your AC system, conducting a visual inspection yourself can help you spot any visible signs of compressor damage or wear.

Here are some areas to check during a visual inspection of the AC compressor:

- Physical Damage: Look for any signs of physical damage on the compressor unit, such as dents, cracks, or leaks. Physical damage can indicate that the compressor has experienced significant stress or impact, which can affect its performance and reliability.

- Oil Stains: Oil stains around the compressor can be an indication of a refrigerant leak or a failing seal. Look for any visible signs of oil leaks or stains, which may require immediate attention and repair.

- Loose or Broken Connections: Check the connections and fittings around the compressor for any signs of looseness or damage. Loose or broken connections can potentially cause refrigerant leaks or restrict the flow of refrigerant, affecting the performance of the AC system.

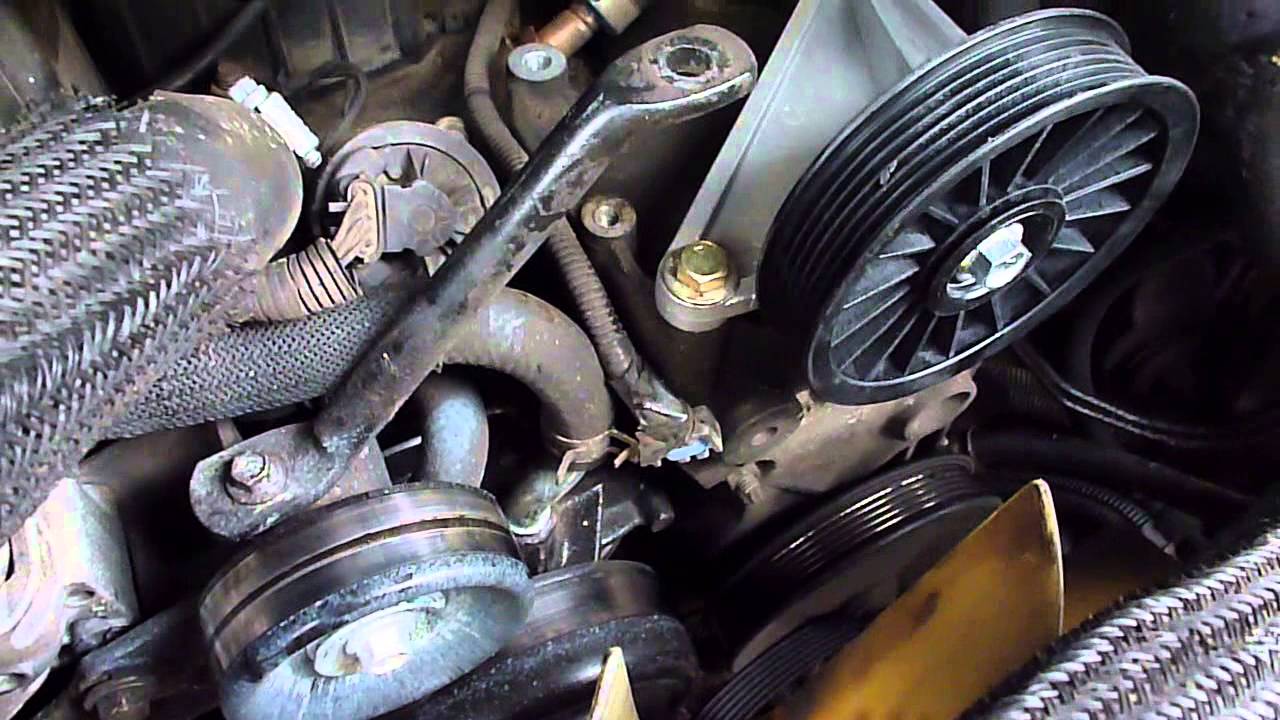

- Belt Condition: If your AC system is belt-driven, inspect the condition of the belt that connects the compressor to the engine. Look for any signs of wear, cracks, or fraying. A worn-out or damaged belt can affect the compressor’s functionality and may need to be replaced.

- Electrical Connections: Ensure that all electrical connections related to the compressor are secure and free from corrosion. Loose or corroded electrical connections can cause electrical faults and affect the operation of the compressor.

While a visual inspection can provide some initial insights, it’s important to note that not all issues with the AC compressor are visible to the naked eye. To accurately diagnose any problems, it’s recommended to consult a professional who can perform a comprehensive inspection and address any underlying issues.

Remember, if you notice any visible signs of damage or abnormalities during your visual inspection, it’s essential to have your AC system assessed by a qualified technician. They can determine the extent of the issue and recommend the appropriate repairs or replacements to ensure the optimal performance of your AC compressor and cooling system.

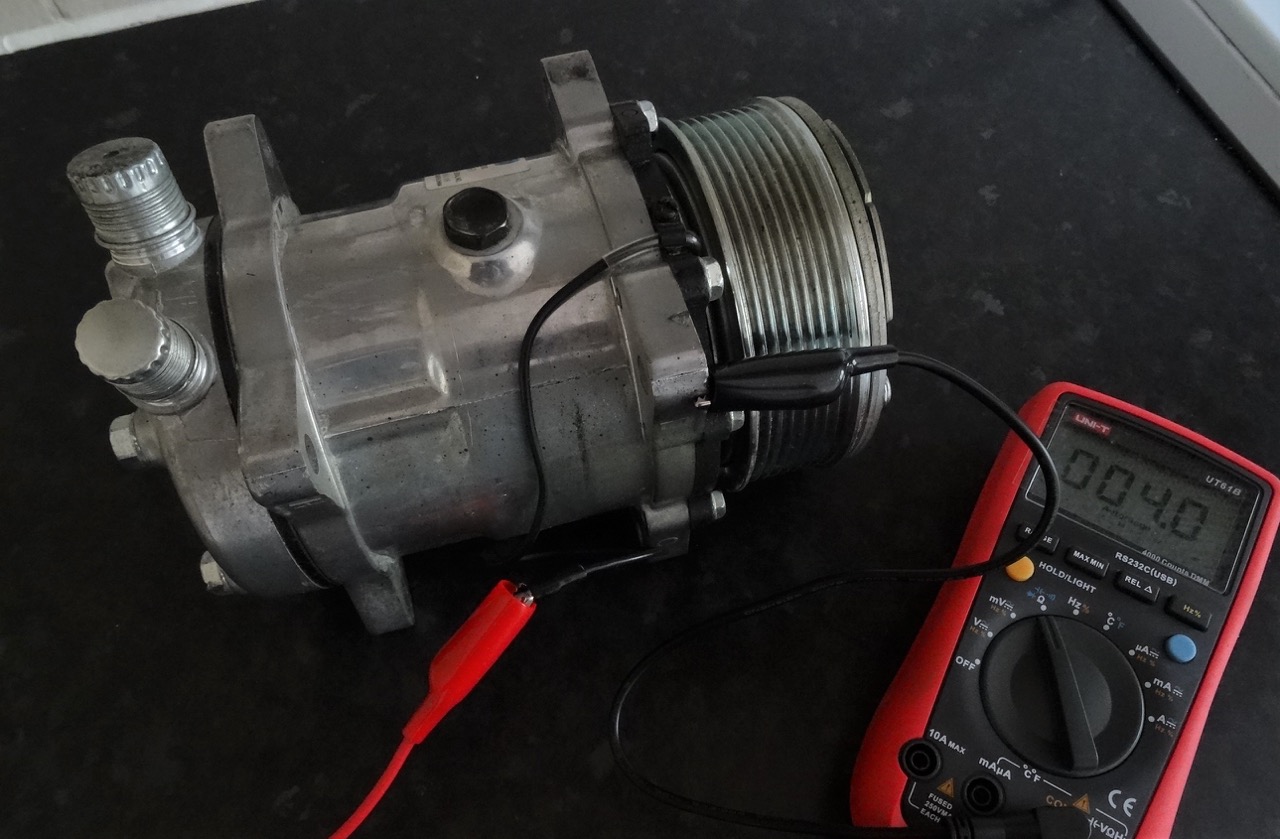

Testing the Compressor

If you suspect that your AC compressor is experiencing issues, it’s essential to conduct proper testing to confirm the diagnosis. While some tests require specialized tools and equipment, there are a few basic checks you can perform to evaluate the functionality of the compressor.

Here are some methods for testing the AC compressor:

- AC System Performance: Start by turning on your AC system and assessing its cooling performance. Pay attention to the airflow and the temperature of the air coming from the vents. If the cooling is insufficient or the air is not as cold as it should be, it could indicate a problem with the compressor.

- AC System Pressure Check: Use an AC manifold gauge set to measure the pressure levels in your AC system. Connect the high and low-pressure gauges to the corresponding ports on the AC lines. Compare the pressure readings to the manufacturer’s specifications. Abnormally high or low pressure levels can signal compressor malfunction or other issues within the system.

- Compressor Clutch Engagement: Observe the behavior of the compressor clutch when the AC system is turned on. The clutch should engage and disengage smoothly. If the compressor clutch does not engage at all or engages erratically, it could indicate a problem with the clutch mechanism.

- Electrical Testing: Use a multimeter to check the electrical connections of the compressor. Ensure that there is proper voltage reaching the compressor and that the electrical components are functioning correctly. Faulty electrical connections or components can impair the performance of the compressor.

While these tests can provide some initial insights, it’s important to note that a comprehensive assessment of the AC compressor often requires professional expertise and specialized equipment. A qualified technician can perform advanced diagnostics, such as leak testing, compressor performance testing, or internal component inspections, to accurately diagnose any issues.

If you suspect that your AC compressor is experiencing problems and the basic tests indicate a potential issue, it’s best to consult with a licensed HVAC technician. They will have the necessary expertise to thoroughly assess the compressor and recommend the appropriate repairs or replacements to restore the proper functioning of your AC system.

Conclusion

The AC compressor is a critical component of your air conditioning system, responsible for compressing and circulating the refrigerant, which is essential for cooling the air. Recognizing the signs of a failing AC compressor is crucial to prevent further damage and ensure the optimal performance of your cooling system.

In this article, we discussed the common symptoms of a bad AC compressor, including strange noises, lack of cooling, compressor clutch failure, and AC system pressure issues. These symptoms serve as indicators that your AC compressor may be in need of attention.

We also covered the importance of conducting a visual inspection to check for physical damage, oil stains, loose or broken connections, and belt condition. While a visual inspection can provide initial insights, it’s crucial to consult a professional technician for a thorough assessment.

Additionally, we discussed the basic tests you can perform to evaluate the functionality of the AC compressor, such as checking the AC system performance, measuring pressure levels, monitoring compressor clutch engagement, and testing electrical connections. However, it’s important to note that comprehensive testing and diagnostics require the expertise of a licensed technician and specialized equipment.

If you suspect that your AC compressor is experiencing problems, it’s recommended to seek the assistance of a qualified HVAC technician. They can accurately diagnose the issue and recommend the necessary repairs or replacements to restore the proper functioning of your AC system.

By promptly addressing a failing AC compressor, you can avoid further damage to your cooling system and ensure a comfortable and cool environment during hot weather conditions.

Frequently Asked Questions about How To Know If AC Compressor Is Bad

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Know If AC Compressor Is Bad”