Articles

How Does A AC Compressor Work

Modified: January 6, 2024

Learn how AC compressors work in this informative article. Discover the science behind AC systems and gain insights into their functioning.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

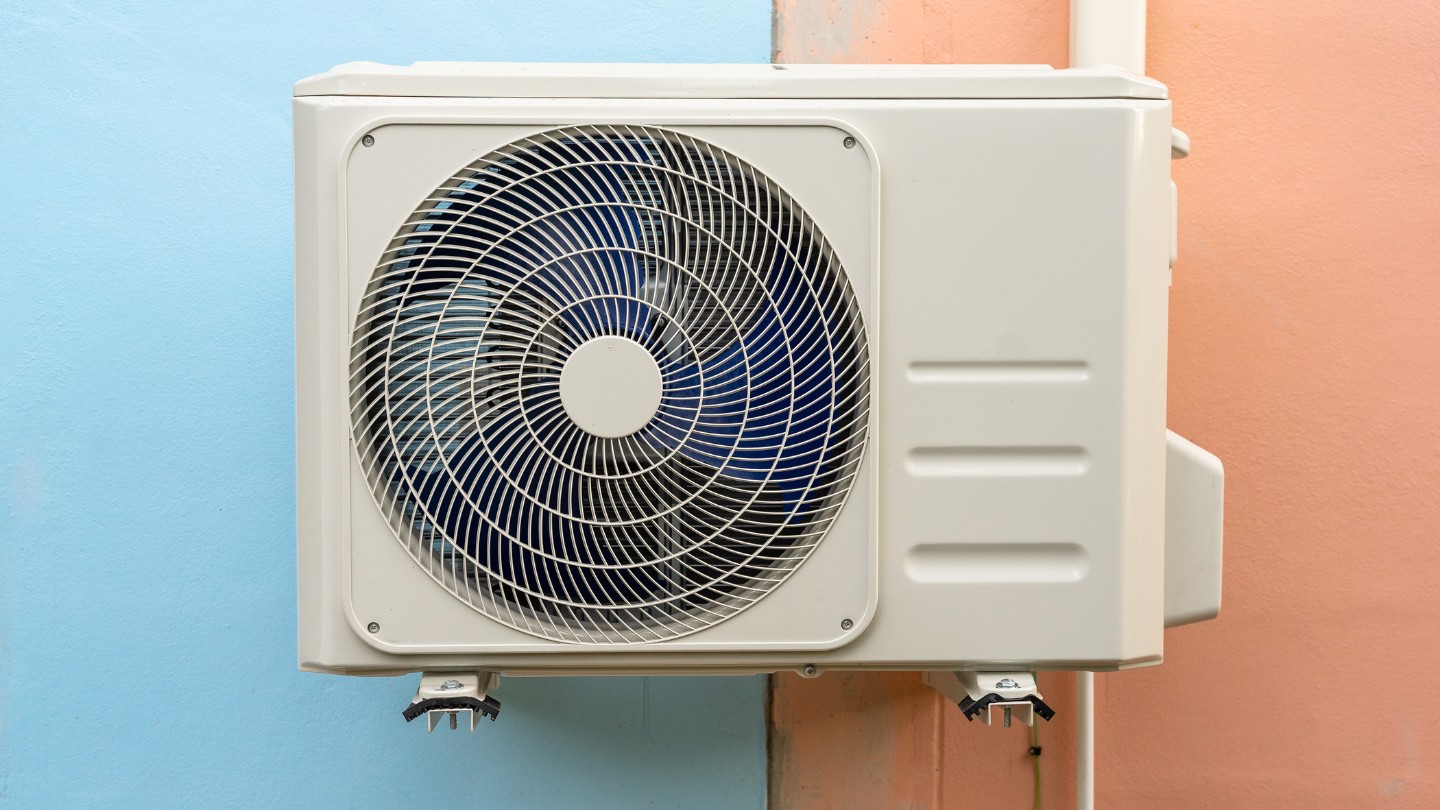

The AC compressor is a vital component of an air conditioning system that plays a crucial role in its cooling process. It is responsible for compressing and circulating the refrigerant, allowing the system to effectively cool the air in your home or workplace. Understanding how an AC compressor works can help you troubleshoot potential issues, make informed decisions when purchasing a new unit, and take better care of your existing system to ensure its optimal performance.

In this article, we will explore the components of an AC compressor, delve into its working principle, discuss the different types of compressors available, and highlight the factors that can affect its performance. We will also provide some maintenance and troubleshooting tips to help you keep your AC compressor in top shape.

So, let’s dive into the world of AC compressors and uncover the fascinating mechanisms behind their cooling prowess.

Key Takeaways:

- Understanding the working principle and components of an AC compressor is essential for troubleshooting, making informed purchasing decisions, and ensuring optimal system maintenance for cool and comfortable indoor environments.

- Factors such as cooling load, refrigerant type, compressor speeds, and efficiency ratings significantly impact AC compressor performance. Proper maintenance, including cleaning, monitoring refrigerant levels, and checking for leaks, is crucial for long-term efficiency and effectiveness.

Read more: What Causes An AC Compressor To Stop Working

Components of an AC Compressor

The AC compressor consists of several key components that work together to facilitate the cooling process. Let’s take a closer look at each of these components:

1. Compressor Motor

The compressor motor is the power source that drives the entire AC compressor. It provides the necessary energy to initiate the compression process by powering the piston movement. The motor is typically electrically driven and is designed to withstand the high pressures and temperatures associated with the compression of refrigerant gases.

2. Piston

The piston is a crucial component of the AC compressor responsible for compressing the refrigerant gas. It moves up and down within a cylinder, creating a vacuum that draws in the low-pressure refrigerant vapor. As the piston moves upward, it compresses the vapor, raising its pressure and temperature.

3. Valve

Valves within the AC compressor play a vital role in controlling the flow of refrigerant gas. The suction valve allows the low-pressure refrigerant vapor to enter the compressor cylinder during the intake phase, while the discharge valve allows the compressed refrigerant gas to exit the cylinder and flow into the condenser. These valves ensure the proper direction and timing of the gas flow, allowing for efficient compression and cooling.

Read more: How Does A Refrigerator Compressor Work

4. Condenser

The condenser is where the compressed refrigerant gas is cooled and condensed back into a liquid state. It is typically a heat exchanger located outside the building or in an outdoor unit. As the high-pressure gas enters the condenser, it releases heat to the surroundings, causing it to condense into a high-pressure liquid. This cooled liquid is then sent to the expansion valve, where it undergoes further cooling and expansion.

These components of an AC compressor work together to create the necessary pressure and temperature differentials for the cooling process. Understanding how each component functions is essential in diagnosing and resolving any issues that may arise with your AC compressor.

Working Principle of an AC Compressor

The AC compressor operates on a cyclic process known as the compression cycle. This cycle involves four key stages: the intake of low-pressure refrigerant gas, compression to high-pressure gas, expansion to low-pressure gas, and the cooling process. Let’s explore each stage in detail:

1. Compression Cycle

The compression cycle begins with the intake of low-pressure refrigerant gas from the evaporator. The refrigerant gas enters the compressor through the suction valve, and the compressor motor powers the piston movement. As the piston moves downward, it creates a suction force that draws the gas into the compressor cylinder.

2. High-pressure Gas Stage

Once the low-pressure gas is drawn into the compressor cylinder, the piston starts moving upward. As it moves upward, the volume of the cylinder decreases, causing the gas to be compressed. This compression increases the pressure and temperature of the gas, transforming it into a high-pressure gas.

Read more: How Long Does An AC Compressor Last

3. Low-pressure Gas Stage

After the gas is compressed to a high-pressure state, it moves out of the cylinder through the discharge valve. It then enters the condenser, where it releases heat to the surroundings and begins to cool down. As the gas cools, its pressure decreases, and it transitions into a low-pressure gas.

4. Cooling Process

The low-pressure gas is sent to the expansion valve, which regulates its flow into the evaporator. As the gas enters the evaporator, it undergoes a phase change from a liquid to a vapor state. This evaporation process absorbs heat from the surrounding air, resulting in the cooling of the air. The cooled air is then circulated back into the building, providing a more comfortable environment.

By following this compression cycle, the AC compressor efficiently compresses and circulates the refrigerant gas, allowing for effective cooling of the air in your space.

Types of AC Compressors

There are several types of AC compressors available, each with its own unique design and operating characteristics. Let’s explore three common types of AC compressors:

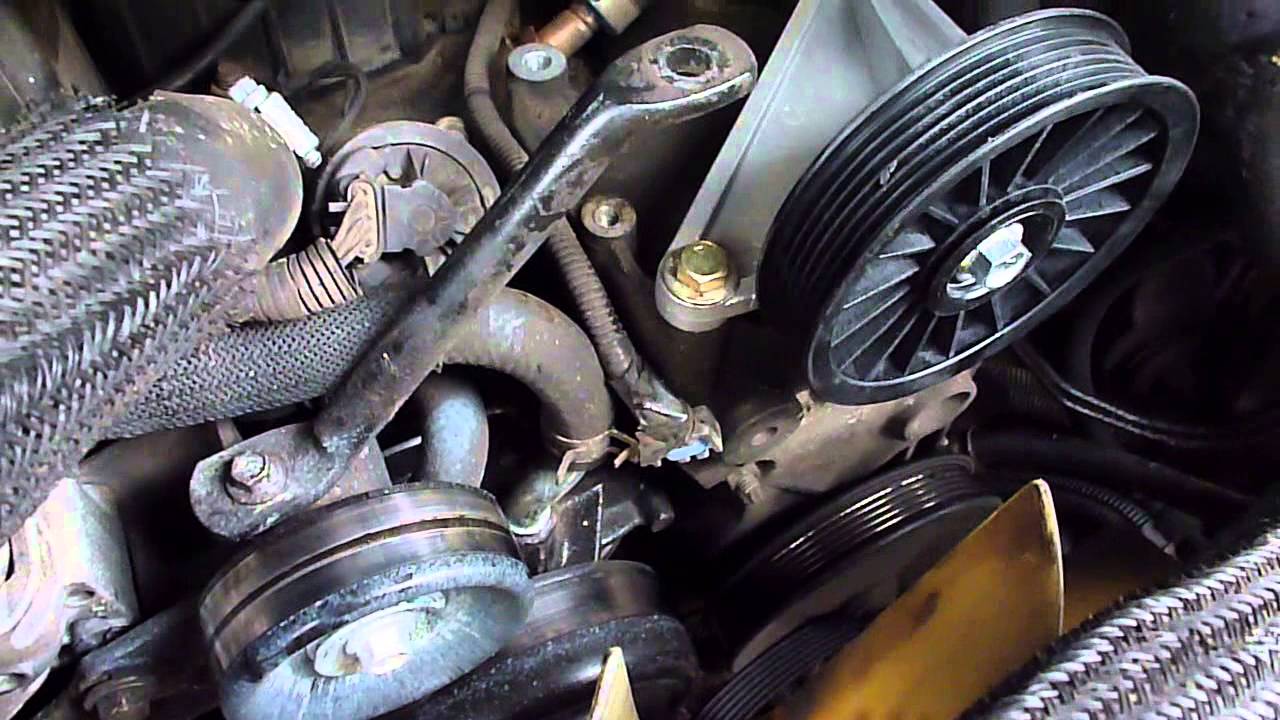

1. Reciprocating Compressors

Reciprocating compressors, also known as piston compressors, are the most common type of AC compressor found in residential and commercial air conditioning systems. These compressors use a piston and cylinder arrangement to compress the refrigerant gas. As the piston moves up and down, it creates pressure differentials that facilitate the compression process. Reciprocating compressors are known for their durability and reliability but can be a bit noisy compared to other types.

Read more: How Much Does An AC Compressor Cost

2. Rotary Compressors

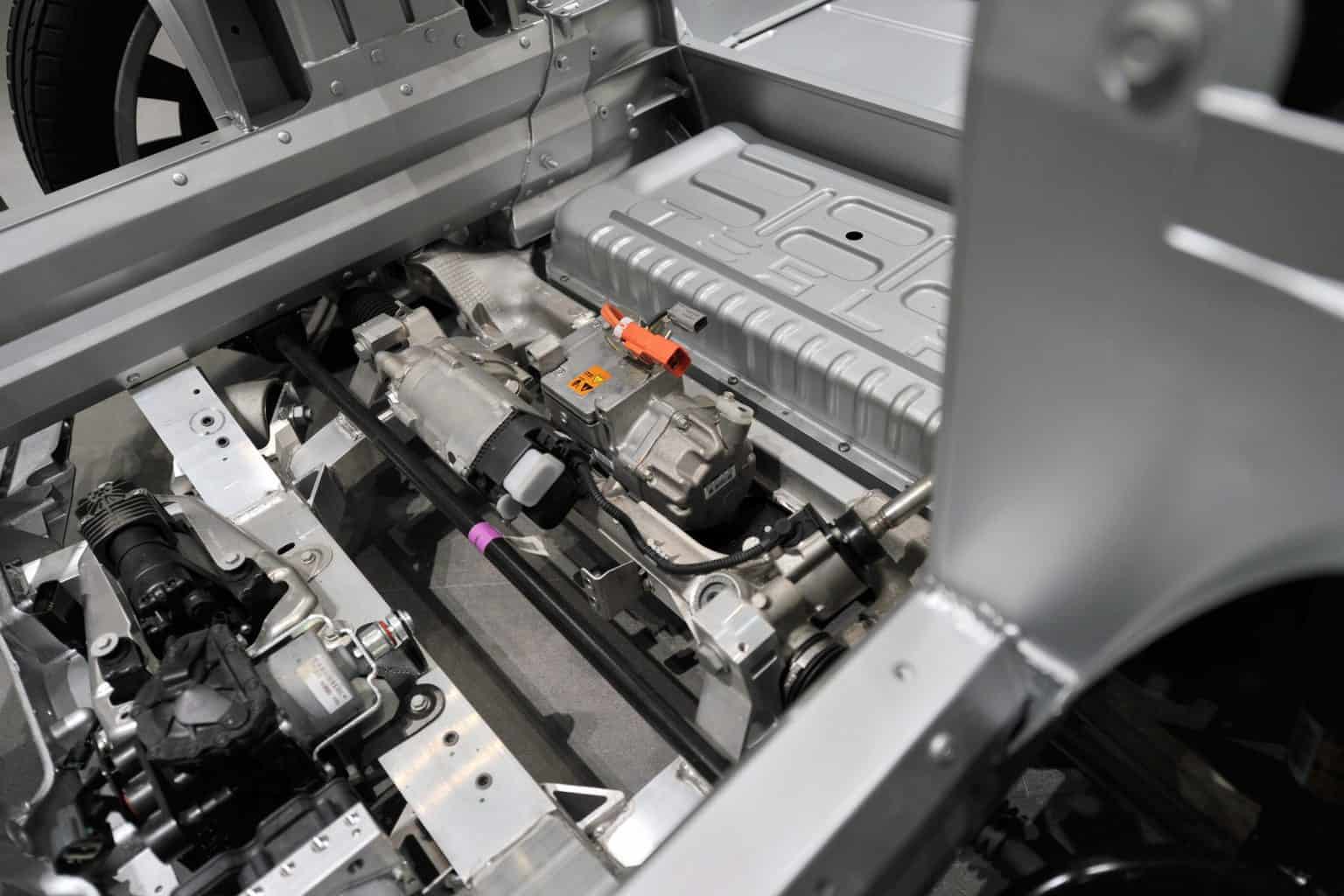

Rotary compressors are another popular type of AC compressor used in various cooling systems. They operate using a rotating mechanism rather than pistons. Rotary compressors can be either vane-type or screw-type. Vane-type compressors use rotating vanes to compress the refrigerant gas, while screw-type compressors use two interlocking rotating screws. Rotary compressors are known for their compact size, efficiency, and quiet operation. They are commonly used in small to medium-sized cooling applications.

3. Scroll Compressors

Scroll compressors are highly efficient and widely used in residential and commercial air conditioning systems. They consist of two spiral-shaped scrolls or disks—one stationary and one orbiting—that interlock to compress the refrigerant gas. Scroll compressors have fewer moving parts, making them quieter, more reliable, and less prone to wear and tear. They also operate more smoothly and provide better energy efficiency compared to other compressor types.

The choice of compressor type depends on factors such as cooling load requirements, space limitations, and budget. Each type has its advantages and disadvantages, so it’s essential to consider these factors when selecting the right compressor for your air conditioning system.

Factors Affecting AC Compressor Performance

The performance of an AC compressor is influenced by various factors that can affect its efficiency and overall effectiveness in cooling. Let’s explore some of the key factors that impact AC compressor performance:

1. Cooling Load

The cooling load refers to the amount of heat that needs to be removed from a space to maintain a desired temperature. The size of the cooling load can vary based on factors such as room size, insulation levels, number of occupants, and heat-generating appliances. An AC compressor needs to be properly sized to match the cooling load of the space it is serving. Undersized compressors will struggle to cool the space efficiently, while oversized compressors may cycle on and off frequently, leading to energy waste and reduced compressor lifespan.

Read more: How To Change AC Compressor

2. Refrigerant Type

The choice of refrigerant used in the AC system can impact the performance of the compressor. Different refrigerants have varying thermodynamic properties, such as heat absorption and release capabilities. Refrigerants with higher heat transfer capacities can enhance the efficiency of the AC system and reduce the workload on the compressor. Additionally, the type of refrigerant used should comply with environmental regulations and industry standards to ensure safe and sustainable operation.

3. Compressor Speeds

The speed at which the AC compressor operates can greatly influence its performance. Some compressors come with multiple speed settings that allow for more precise control and adaptability. Variable speed compressors can adjust their speed based on the cooling demands of the space. Operating the compressor at lower speeds when cooling requirements are low can result in energy savings and reduce wear and tear on the system. On the other hand, when higher cooling demands are present, the compressor can ramp up its speed to meet the load effectively.

4. Efficiency Ratings

AC compressors come with efficiency ratings that indicate how well they convert electrical energy into cooling output. The Seasonal Energy Efficiency Ratio (SEER) is a commonly used rating that measures the cooling output of an AC system relative to the energy input. Higher SEER ratings indicate greater energy efficiency. Choosing a compressor with a higher SEER rating can result in lower energy consumption, reduced utility bills, and a more environmentally friendly operation.

By considering these factors and selecting an AC compressor that aligns with your specific cooling needs and circumstances, you can ensure optimal performance, energy efficiency, and longevity of your air conditioning system.

Maintenance and Troubleshooting Tips for AC Compressors

To keep your AC compressor running smoothly and prevent potential issues, regular maintenance is essential. Here are some maintenance and troubleshooting tips to help you take care of your AC compressor:

Read more: How To Test An AC Compressor

1. Regular Cleaning

Keeping the AC compressor clean is crucial for its optimal performance. Regularly clean the exterior of the compressor unit by removing any debris, dirt, or leaves that may have accumulated. Use a soft brush or a vacuum cleaner to gently clean the fins and coils. Be careful not to bend the fins during the cleaning process. A clean compressor unit allows for better airflow and heat dissipation, ensuring efficient operation.

2. Monitoring Refrigerant Levels

Check the refrigerant levels in your AC system regularly. Low refrigerant levels can put stress on the compressor and affect its performance. If you notice a significant drop in cooling efficiency or warm air blowing from the vents, it may indicate a refrigerant leak. Contact a professional technician to inspect your system and address any refrigerant issues. Never attempt to handle refrigerant yourself, as it requires specialized equipment and knowledge.

3. Checking for Leaks

Inspect your AC system for any refrigerant or oil leaks. Leaks can cause a drop in pressure and result in poor compressor performance. Look for oil stains or signs of refrigerant leakage around the compressor unit, refrigerant lines, and connections. If you suspect a leak, contact a qualified technician to repair it promptly before it leads to further compressor damage.

4. Lubrication

AC compressors require proper lubrication to reduce friction and prevent excessive wear on moving parts. Some compressors are sealed and do not require lubrication, while others may have access ports for lubricant checks and refills. Consult your compressor’s manual or manufacturer’s recommendations to determine the lubrication requirements. If lubrication is necessary, ensure that you use the correct type and quantity of lubricant for optimal performance.

Remember, if you encounter any significant issues or suspect a problem with your AC compressor, it is best to seek professional assistance. HVAC technicians have the knowledge and expertise to diagnose and address compressor issues to ensure the longevity and efficiency of your AC system.

Conclusion

The AC compressor is a vital component of an air conditioning system, responsible for compressing and circulating the refrigerant gas in order to cool the air in your living and working spaces. Understanding how the AC compressor works, its key components, and its operating principles can help you troubleshoot issues, make informed decisions when purchasing a new unit, and ensure proper maintenance of your existing system.

We explored the components of an AC compressor, including the compressor motor, piston, valve, and condenser, and learned about their respective roles in the compression and cooling process. Additionally, we discussed the different types of AC compressors, such as reciprocating, rotary, and scroll compressors, each with its own advantages and applications.

Factors like cooling load, refrigerant type, compressor speeds, and efficiency ratings can significantly affect the performance of an AC compressor. Properly sizing the compressor to match the cooling load, choosing the right refrigerant, and considering energy efficiency ratings can contribute to optimal performance and energy savings.

To keep your AC compressor in good working condition, regular maintenance is essential. This includes cleaning the compressor unit to ensure proper airflow and heat dissipation, monitoring refrigerant levels to prevent leaks and performance issues, checking for refrigerant and oil leaks, and if needed, lubricating the compressor as per manufacturer’s instructions.

In conclusion, understanding the working principle of an AC compressor, knowing its components, and taking proper care of it through regular maintenance are keys to ensuring that your air conditioning system operates efficiently, providing you with cool and comfortable environments during the hot summer months.

Remember, if you encounter any significant issues or suspect a problem with your AC compressor, it is always recommended to seek professional assistance to diagnose and resolve the issue effectively.

Frequently Asked Questions about How Does A AC Compressor Work

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Does A AC Compressor Work”