Home>Articles>How Much Does It Cost For The Co2 For A Kegerator

Articles

How Much Does It Cost For The Co2 For A Kegerator

Modified: August 23, 2024

Discover the average cost of CO2 for a kegerator and get insightful articles on various topics. Enhance your knowledge with our informative articles.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of kegerators! For beer enthusiasts and homebrewers, having a kegerator is a great way to enjoy draft beer from the comfort of your own home. However, one important aspect of maintaining a kegerator is understanding the cost of CO2, as it plays a vital role in dispensing that perfect pint.

CO2, or carbon dioxide, is used to carbonate and dispense beer from kegs. It is an essential component of any kegerator setup, ensuring that your beer is properly carbonated and served at the desired pressure. But how much does it actually cost to keep your kegerator running smoothly?

In this article, we will dive into the world of CO2 costs for kegerators, exploring the different factors that can affect pricing and providing tips on how to manage these expenses effectively.

Key Takeaways:

- Understanding the factors that influence CO2 costs for kegerators, such as cylinder size, supplier choice, and usage rates, empowers beer enthusiasts to make informed decisions and manage expenses effectively.

- By implementing tips to reduce CO2 costs, such as optimizing pressure, efficient cooling, and sharing expenses, kegerator owners can enjoy draft beer at home while being mindful of their budget and environmental impact.

Read more: How To Build A Co2 Kegerator

Understanding CO2 and Kegerators

Before we delve into the costs associated with CO2 for kegerators, let’s first understand the role that CO2 plays in the keg dispensing process.

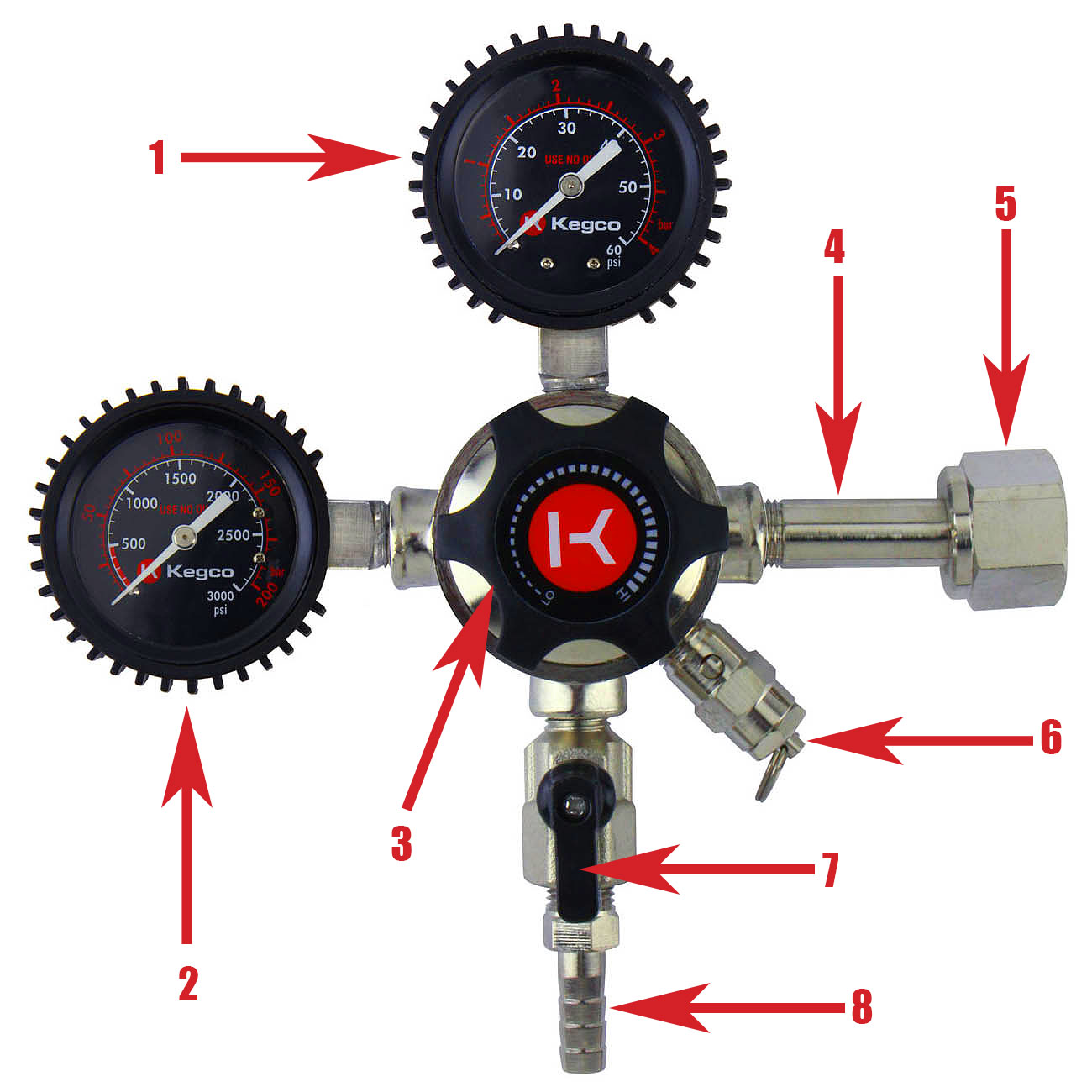

CO2 is a colorless and odorless gas that is widely used for carbonation purposes in the beverage industry. When it comes to kegerators, CO2 is typically stored in a canister or tank and connected to the keg through a regulator and tubing system. The regulator allows you to control the flow and pressure of the CO2 gas.

When the CO2 is released into the keg, it replaces the air inside the keg, preventing oxidation and maintaining the freshness of the beer. It also helps carbonate the beer, creating that desirable effervescence and creamy head. Without an adequate supply of CO2, your beer would be flat and lackluster.

Kegerators, or beer dispensing refrigerators, are designed to not only keep your kegs chilled but also to provide a means of carbonating and dispensing your favorite brews. They usually come equipped with a CO2 tank holder and a built-in tap system, allowing you to enjoy draft beer at home with ease.

Now that we have a basic understanding of how kegerators and CO2 work together, let’s explore the various factors that can influence the cost associated with CO2 usage.

Factors Affecting CO2 Costs

When it comes to the cost of CO2 for kegerators, several factors come into play. Understanding these factors will help you determine and manage your CO2 expenses more effectively. Let’s take a closer look at the key factors that can affect CO2 costs:

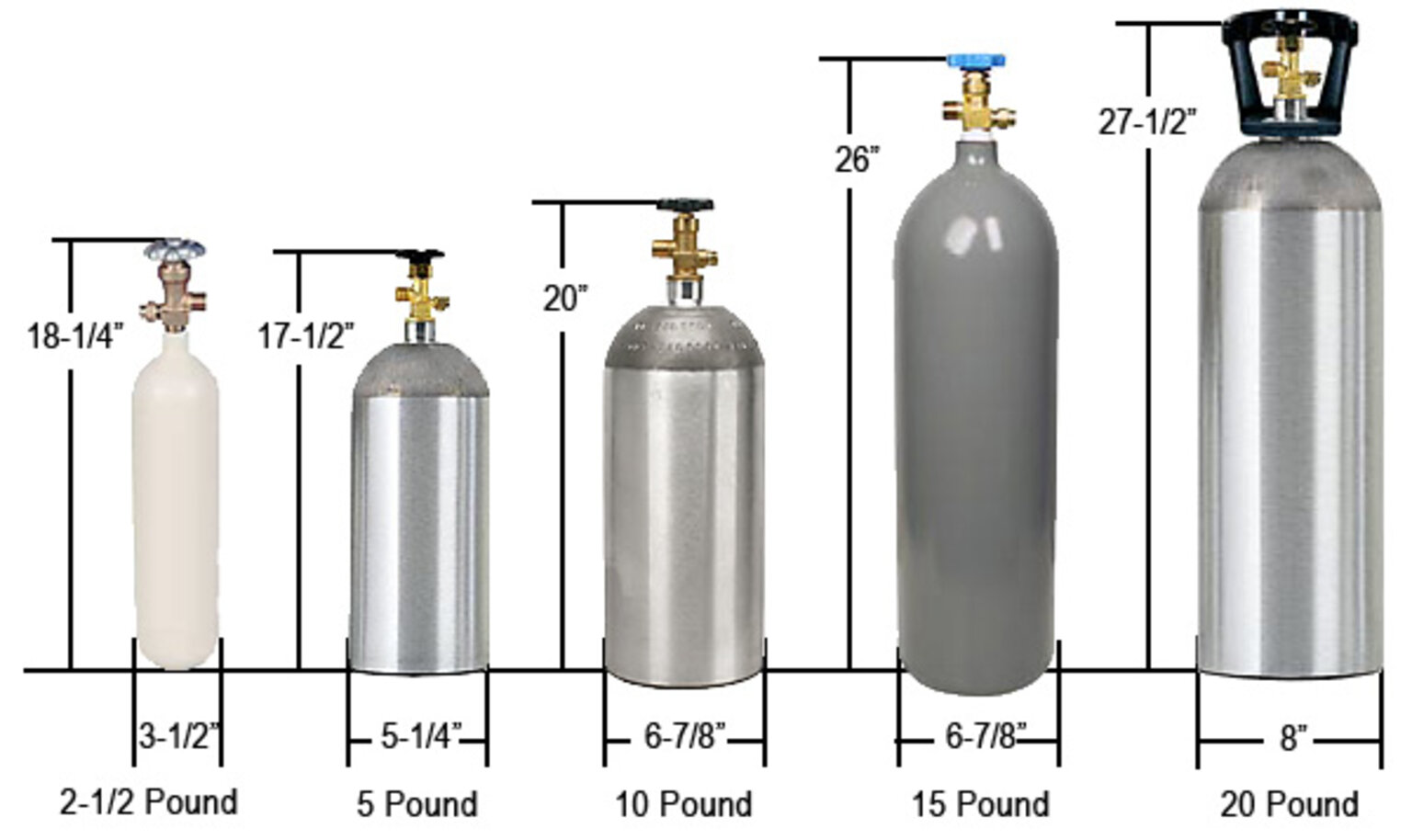

- Cylinder Size: The size of the CO2 cylinder or tank can significantly impact the overall cost. Larger tanks can hold more CO2, which means fewer refills and potentially lower costs in the long run. However, larger tanks also come with a higher upfront investment.

- CO2 Supplier: The supplier you choose to purchase your CO2 from can also affect the cost. Prices can vary between suppliers, so it’s worth shopping around and comparing prices to ensure you’re getting the best deal.

- Location: The location where you purchase your CO2 can influence the cost. Prices may differ based on local taxes, transportation fees, and other factors specific to your area.

- CO2 Purity: The purity level of the CO2 gas can impact pricing. Higher purity levels may come at a premium, but they are often preferred to maintain the quality and taste of your beer.

- Dispensing Method: The type of kegerator system you have can affect CO2 costs as well. For example, a direct-draw system, where the keg is located directly under the tap, may require less CO2 compared to a long-draw system that requires more tubing and connections.

It’s important to consider these factors when estimating the cost of CO2 for your kegerator. By doing so, you can make informed decisions about cylinder size, suppliers, and other variables to help control your expenses.

Calculation Methods for CO2 Usage

Calculating CO2 usage is an essential step in understanding and estimating your CO2 costs for your kegerator. While it may seem complex, there are simple methods you can utilize to determine the approximate amount of CO2 you will consume. Here are a few commonly used calculation methods:

- Gas Line Length: One way to approximate CO2 usage is by considering the length of your gas lines. The longer the lines, the more CO2 is required to overcome resistance and maintain proper pressure. As a general rule of thumb, you can estimate around 0.5-1 pound of CO2 per foot of gas line.

- Keg Volume: Another method involves considering the volume of the keg you are using. Different keg sizes will require varying amounts of CO2. For instance, a standard 5-gallon keg may consume around 0.5-0.8 pounds of CO2 for carbonation and dispensing.

- Usage Rate: Estimating your CO2 usage rate based on your kegerator’s frequency and demand can provide a more accurate calculation. Consider factors such as how often you dispense beer and the average amount dispensed per serving. This method requires tracking your keg usage over time to determine a reliable rate.

While these calculation methods can provide a rough estimate of CO2 usage, it’s important to note that individual factors such as temperature, carbonation levels, and dispensing pressure can affect the actual consumption. Monitoring and adjusting your CO2 usage based on observation and experience will help optimize your calculations over time.

By employing these calculation methods, you can have a better understanding of your CO2 consumption and anticipate the associated costs more accurately for your kegerator.

Average CO2 Consumption for Kegerators

When it comes to CO2 consumption for kegerators, it’s important to note that individual usage can vary based on several factors, such as system setup, dispensing frequency, and personal preferences. However, we can provide you with some average figures to give you a general idea of what to expect.

For a standard 5-gallon keg, you can typically expect to consume around 0.5-0.8 pounds of CO2 during the carbonation and dispensing process. This estimate takes into account average carbonation levels and the pressure required to serve the beer adequately.

Keep in mind that this consumption estimate can fluctuate depending on various factors. For example, if you prefer highly carbonated beers or higher dispensing pressures, you may go through CO2 more quickly. Conversely, if you prefer lower carbonation levels or use a more efficient system, your consumption may be lower.

It’s also worth noting that CO2 is not only used for dispensing beer but also for purging kegs and maintaining pressure when not in use. These additional uses can contribute to overall CO2 consumption as well.

To get a more accurate understanding of your own kegerator’s CO2 consumption, consider tracking your usage over a period of time. Keep a log of how many kegs you go through and how much CO2 you refill during that period. This data will help you determine your specific consumption patterns and better estimate your ongoing CO2 costs.

Remember, the average CO2 consumption figures provided here are meant as general guidelines. Your actual consumption may vary depending on your specific setup and usage habits. Monitoring your usage regularly and making adjustments as needed will help you manage your CO2 costs more effectively.

When calculating the cost of CO2 for a kegerator, consider the size of the CO2 tank, the refill cost, and the frequency of refills. Larger tanks may have a higher upfront cost but can be more cost-effective in the long run.

Read more: How Adjust Co2 Kegerator

Determining the Cost for CO2

Now that we have an understanding of CO2 consumption for kegerators, let’s dive into how we can determine the cost associated with CO2 for your setup.

There are a few key factors to consider when calculating the cost of CO2:

- CO2 Price per Pound: The first step is to determine the price per pound of CO2. This can vary depending on your supplier and location. Reach out to different suppliers and inquire about their pricing to find the best deal.

- CO2 Usage: Calculate your CO2 usage based on the factors we discussed earlier, such as gas line length, keg volume, and usage rate. By estimating your CO2 consumption, you can determine how many pounds of CO2 you will need over a specific period of time.

- Refill Frequency: Consider how often you will need to refill your CO2 supply. This will depend on your kegerator setup, the number of kegs you go through, and your consumption rate. Some individuals may need to refill monthly, while others may only need to refill every few months.

Once you have gathered this information, you can calculate the cost for your CO2 by multiplying the price per pound by the number of pounds you need for a specific time period or by each refill. This will give you an estimate of how much you can expect to spend on CO2 for your kegerator.

It’s important to note that prices can fluctuate over time, and it’s always a good idea to keep an eye on the market to ensure you are getting the best deal. Additionally, consider any additional costs such as delivery fees or tank rentals, as these can also impact the overall cost.

By determining the cost of CO2 for your kegerator, you can better plan and budget for this essential component. Regularly assess your usage and costs to identify any areas where you can optimize and reduce expenses, such as adjusting your dispensing pressure or finding a more affordable supplier.

Remember, understanding the cost of CO2 helps you make informed decisions and ensures that you can continue to enjoy the delicious delights of your kegerator without breaking the bank.

Factors to Consider in CO2 Purchasing

When it comes to purchasing CO2 for your kegerator, there are several important factors to consider. These factors will not only impact the quality of your CO2 but also the overall cost and convenience of maintaining your kegerator. Let’s explore these factors in more detail:

- Purity: The purity of the CO2 gas is crucial for the taste and quality of your beer. Ensure that the CO2 supplier you choose provides high-quality, food-grade CO2. Look for suppliers that offer CO2 with a purity level of 99.9% or higher to ensure the best results.

- Supplier Reputation: It’s important to purchase CO2 from a reliable and reputable supplier. Do some research, read reviews, and ask fellow beer enthusiasts for recommendations. Choosing a trustworthy supplier will ensure that you receive quality CO2 and reliable service.

- Price: Naturally, price is a significant factor to consider when purchasing CO2. Contact multiple suppliers and compare prices to find the best deal. However, keep in mind that the lowest price may not always guarantee the highest quality. Strive for a balance between cost-effectiveness and quality.

- Refill Availability: Check if your chosen CO2 supplier offers convenient refill options. You’ll want to make sure that refilling your CO2 tank is easy and accessible. Some suppliers may have multiple locations or offer delivery services, which can make the refill process more convenient for you.

- Local Regulations: Be aware of any local regulations or restrictions regarding CO2 tanks. Some areas may have specific rules regarding tank sizes, certifications, or transportation. Ensure that your chosen supplier and tank comply with these regulations to avoid any issues.

- Additional Services: Consider any additional services or benefits provided by the CO2 supplier. Some suppliers may offer tank inspections, maintenance, or exchange programs, which can save you time and effort. Others may provide cleaning and testing services for your CO2 lines.

Taking these factors into account will help you select the right supplier and source of CO2 for your kegerator. By choosing a reputable supplier and ensuring you have high-quality CO2, you can enjoy better-tasting beer and a smoother overall kegerator experience.

Tips for Reducing CO2 Costs

Managing CO2 costs for your kegerator is essential for both your budget and the environment. Here are some tips to help you reduce your CO2 expenses while still enjoying the perfect pint:

- Optimize CO2 Pressure: Adjusting the dispensing pressure to the minimum required level can help conserve CO2. Experiment with different pressures to find the sweet spot where your beer is still properly carbonated without unnecessary waste.

- Regular Maintenance: Proper maintenance of your kegerator system is crucial for minimizing CO2 waste. Regularly check for any leaks in your connections, faucets, and tubing, and promptly address any issues. Sealing any leaks will prevent CO2 from escaping unnecessarily.

- Efficient Cooling: Ensure that your kegerator is properly insulated and operating at optimal cooling efficiency. Good insulation and temperature control will prevent excessive CO2 usage due to overcompensating for warm temperatures.

- Avoid Overcarbonation: Be mindful of your carbonation levels. Overcarbonating your beer can lead to excessive CO2 usage and waste. Follow recommended carbonation guidelines for the style of beer you are dispensing.

- Consider Keg Size: Opt for larger kegs instead of smaller ones if it suits your consumption needs and habits. With a larger keg, you will have longer periods between refills, reducing the frequency of CO2 purchases and refills.

- Efficient Dispensing: Train yourself and others on efficient pouring techniques to minimize foam and beer wastage. Foam requires additional CO2 to dispense, so minimizing excessive foaming can help you conserve CO2.

- Share CO2 Costs: If you have friends or family members who also enjoy homebrewing or kegging their beer, consider sharing the cost of CO2 and bulk purchasing. This can help reduce individual costs and ensure more efficient use of the gas.

- Reuse CO2: In some cases, you may be able to reuse CO2 from kegs that were not fully emptied. By transferring the remaining beer to another keg, you can avoid wasting the CO2 used for carbonation.

- Explore Bulk Purchasing: Consider purchasing CO2 in larger quantities if it makes financial sense for you. Buying in bulk can often result in lower unit prices, saving you money in the long run.

By implementing these tips and being mindful of your CO2 usage, you can effectively reduce your CO2 costs while still enjoying the benefits of your kegerator.

Conclusion

Understanding the cost of CO2 for your kegerator is essential for budgeting and maintaining a smooth beer dispensing experience. By considering the factors that affect CO2 costs and implementing strategies to reduce consumption, you can effectively manage your expenses while still enjoying the pleasure of draft beer at home.

Factors such as cylinder size, CO2 supplier, location, and CO2 purity all play a role in determining the overall cost. By selecting the right supplier, ensuring high-quality CO2, and considering refill availability, you can make a well-informed purchasing decision.

It’s also important to calculate your CO2 usage based on your specific setup and habits. Tracking gas line length, keg volumes, and usage rates can help you estimate how much CO2 you will need and how often you’ll have to refill your supply.

To reduce CO2 costs, optimizing pressure, performing regular maintenance, and efficient cooling are crucial. Avoiding overcarbonation, selecting larger kegs, and promoting efficient pouring techniques can further conserve CO2. Additionally, exploring bulk purchasing options and sharing costs with others can help save money in the long run.

In conclusion, managing CO2 costs for your kegerator requires attention to various factors and implementing smart strategies. By being mindful of your CO2 usage, you can enjoy your favorite draft beer while keeping your expenses in check.

So, raise a glass, cheers to the perfect pint, and enjoy the delightful world of kegerators with the knowledge of how to optimize your CO2 costs!

Frequently Asked Questions about How Much Does It Cost For The Co2 For A Kegerator

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Much Does It Cost For The Co2 For A Kegerator”