Home>Articles>How Much To Rotate The Valve On A Co2 Kegerator PSI

Articles

How Much To Rotate The Valve On A Co2 Kegerator PSI

Modified: February 27, 2024

Looking for articles on how to properly rotate the valve on your CO2 kegerator at the right PSI? Check out our informative guides for all the details you need.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the wonderful world of CO2 kegerators! If you’re a beer enthusiast or a bar owner looking to serve draft beer with perfection, understanding the ins and outs of a CO2 kegerator is essential. One vital aspect to consider when setting up and maintaining a CO2 kegerator is the proper PSI or pressure per square inch.

A CO2 kegerator, also known as a beer dispenser or keg fridge, is a refrigeration unit designed to store and dispense draft beer from kegs. It provides a convenient and cost-effective way to have fresh beer on tap at home or in a bar setting. With a CO2 kegerator, you can say goodbye to bottles and cans and enjoy a freshly poured pint whenever you desire.

Now, let’s delve into the details of how a CO2 kegerator works. At its core, a kegerator works by utilizing a pressurized CO2 tank to force carbon dioxide into the keg, pushing the beer out through a faucet. The amount of pressure maintained inside the kegerator, measured in PSI, plays a crucial role in the quality and taste of the beer.

Proper PSI is key to achieving the ideal beer carbonation and serving temperature. If the pressure is too low, the beer will pour flat and lack carbonation. On the other hand, excessive pressure can result in over-carbonation, leading to excessive foam and a rough pouring experience.

The optimal PSI for a CO2 kegerator depends on various factors, including the style of beer being served, desired carbonation level, and the temperature inside the kegerator. It’s important to strike the right balance and adjust the PSI accordingly to ensure a perfect pour every time.

In the following sections, we will dive deeper into the importance of proper PSI in a CO2 kegerator, the factors to consider when determining PSI, recommended PSI ranges for different beer styles, common issues with improper PSI, and how to adjust the PSI in a CO2 kegerator.

So, grab a cold one, sit back, and let’s explore the fascinating world of CO2 kegerators and the role PSI plays in delivering the perfect pint of beer!

Key Takeaways:

- Proper PSI is crucial for optimal beer carbonation, flavor, and pouring efficiency in a CO2 kegerator. Adjusting PSI based on beer style, desired carbonation level, and temperature ensures a delightful drinking experience.

- Understanding and adjusting the PSI in a CO2 kegerator is essential for serving perfectly carbonated draft beer. It allows for customization based on beer style, personal preference, and troubleshooting common carbonation issues.

Read more: How To Build A Co2 Kegerator

What is a CO2 Kegerator?

A CO2 kegerator is a specialized refrigeration unit designed to store and dispense draft beer directly from kegs. It provides a convenient and efficient way to enjoy fresh and perfectly carbonated beer at home or in commercial establishments like bars, restaurants, and pubs.

The heart of a CO2 kegerator is its ability to maintain the correct pressure per square inch (PSI) inside the keg, which is crucial for carbonation and dispensing. It accomplishes this by utilizing a CO2 tank, regulator, and beer lines to deliver carbon dioxide to the keg, ensuring a steady flow of carbonated beer when needed.

CO2 kegerators come in various sizes, with options ranging from countertop models to full-size units capable of housing multiple kegs. They typically feature a temperature control mechanism to ensure that the beer is chilled to the desired serving temperature, usually between 36°F and 42°F (2°C and 6°C).

One of the significant advantages of using a CO2 kegerator is the elimination of the need for individual beer bottles or cans. This not only reduces waste but also enhances the freshness and flavor of the beer. With a kegerator, you can serve draft beer with minimal oxygen exposure, preserving the beer’s taste and aroma.

In addition to the convenience and freshness factors, owning a CO2 kegerator can also be cost-effective in the long run. Buying beer in kegs is often cheaper per ounce compared to purchasing bottles or cans, making it an attractive option for beer enthusiasts who regularly enjoy draft beer.

CO2 kegerators are not limited to commercial establishments; they have become increasingly popular among beer enthusiasts who want to enjoy the draft beer experience at home. Home kegerators are available in various sizes and designs to fit different spaces, allowing individuals to recreate the bar atmosphere and have a constant supply of their favorite beer on tap.

With a CO2 kegerator, the days of worrying about flat beer or running out of your favorite brew are over. It offers a unique and enjoyable way to savor draft beer, ensuring that every pour is fresh, carbonated, and perfectly chilled.

How does a CO2 Kegerator Work?

A CO2 kegerator works by utilizing a pressurized system to store, dispense, and carbonate beer directly from kegs. Understanding the key components and their interactions will help us grasp the inner workings of this ingenious beer dispensing system.

Here’s a step-by-step breakdown of how a CO2 kegerator works:

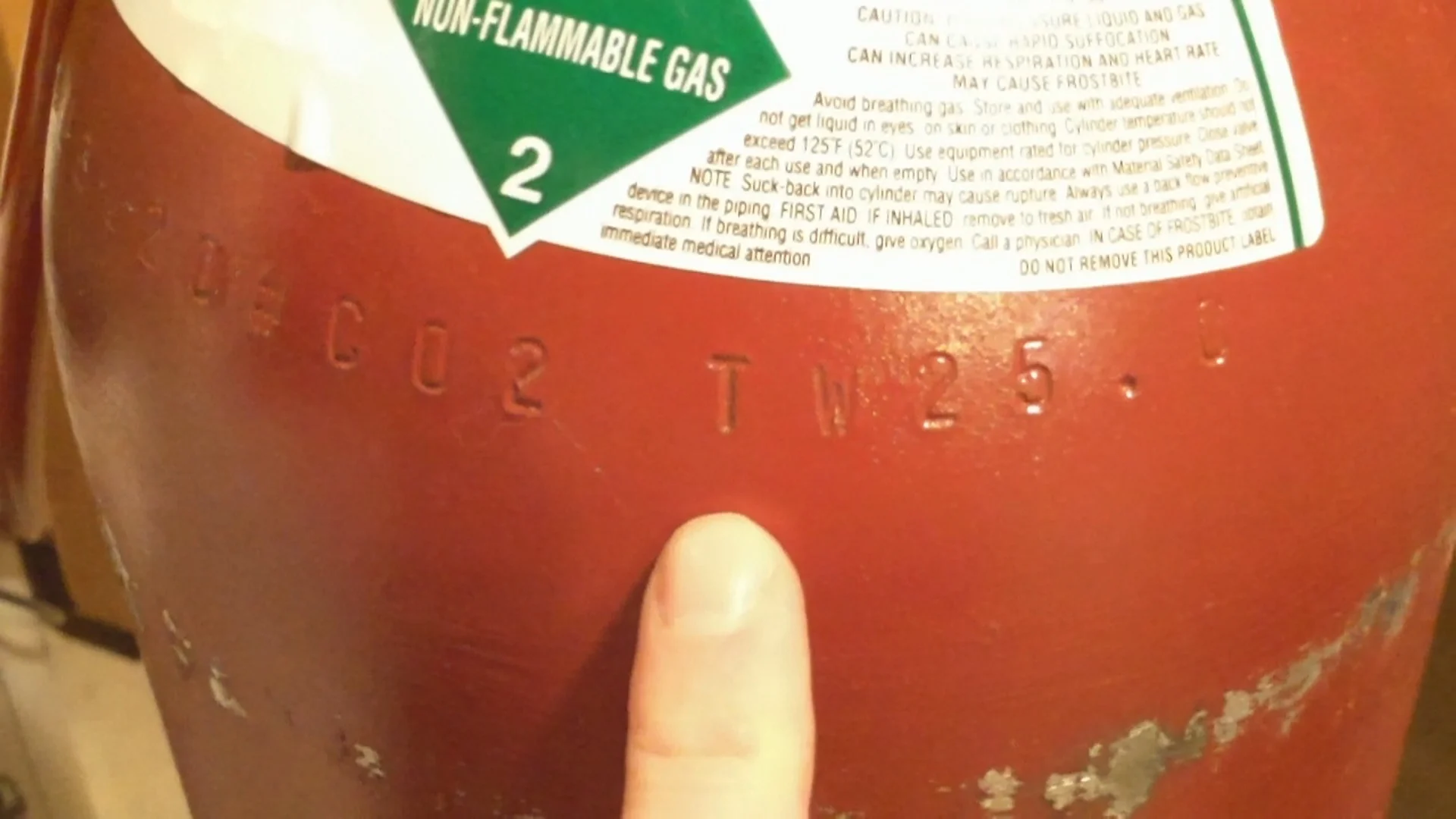

- CO2 Tank: The kegerator is equipped with a CO2 tank that contains carbon dioxide gas under pressure. This tank is the source of the carbonation for the beer.

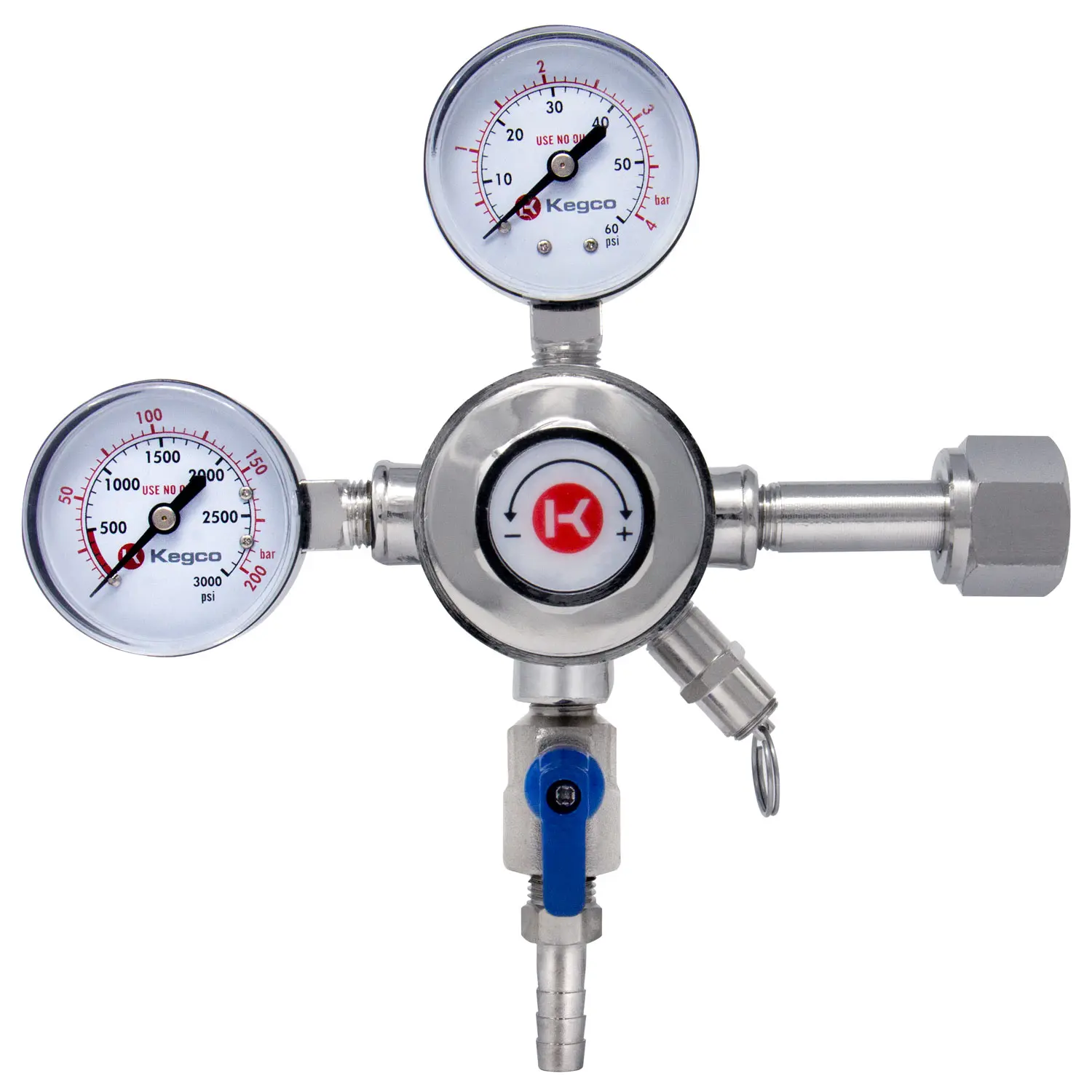

- Regulator: The CO2 tank is connected to a regulator, which controls the flow and pressure of the gas. The regulator allows you to adjust the PSI inside the kegerator to achieve the desired carbonation level.

- Beer Keg: The kegerator accommodates a standard beer keg, which contains the beer to be dispensed. The keg has both a liquid (beer) and a gas (carbon dioxide) line.

- Gas Line: The gas line connects the regulator to the gas inlet on the keg. It allows the pressurized carbon dioxide from the tank to enter the keg.

- Beer Line: The beer line carries the carbonated beer from the keg to the faucet. It is typically made of food-grade vinyl or stainless steel and is carefully sized to balance the flow and maintain the right amount of carbonation.

- Faucet: The faucet is where the carbonated beer is dispensed. It is connected to the beer line and can be opened or closed to control the flow.

- Cooling System: The kegerator has a built-in refrigeration system that keeps the beer at the desired temperature. It ensures that the beer stays cold and refreshing, enhancing the overall drinking experience.

Now, here’s how everything comes together:

- First, make sure the CO2 tank is properly connected to the regulator and turned on. The pressure should be adjusted according to the recommended PSI for the specific beer style you’re serving.

- Next, connect the gas line to the gas inlet on the keg. This allows carbon dioxide to enter the keg and carbonate the beer.

- With the kegs pressurized, the carbon dioxide dissolves into the beer, creating the desired carbonation level.

- When you’re ready to pour a beer, open the faucet, and the carbonated beer in the keg will flow through the beer line and out of the faucet.

- Adjust the faucet opening and pressure as needed to control the pour and maintain a proper balance between carbonation and foam.

- The cooling system in the kegerator keeps the beer keg at the desired temperature, ensuring a refreshing and enjoyable drinking experience.

By following these steps, a CO2 kegerator delivers perfectly chilled, carbonated, and delicious draft beer on demand. Whether you’re enjoying a refreshing lager, a hoppy IPA, or a smooth stout, a kegerator ensures that your beer is always ready to be enjoyed straight from the tap.

Importance of Proper PSI in a CO2 Kegerator

When it comes to serving draft beer from a CO2 kegerator, having the correct pressure per square inch (PSI) is of utmost importance. The PSI setting directly affects the carbonation level, pouring speed, and overall quality of the beer. Here are some key reasons why maintaining the proper PSI is crucial:

1. Optimal Carbonation: The right PSI ensures that the beer in the keg is adequately carbonated. Carbon dioxide (CO2) is introduced into the keg to create the desired level of carbonation. Too much or too little pressure can result in under-carbonated or over-carbonated beer, both of which can be disappointing to the palate.

2. Flavor and Mouthfeel: The carbonation level greatly impacts the flavor, aroma, and mouthfeel of the beer. Proper PSI allows the beer to retain its intended characteristics, providing a balanced and enjoyable drinking experience. Under-carbonated beer may taste flat and lack the desired effervescence, while over-carbonated beer can be excessively fizzy and harsh on the palate.

3. Pouring Efficiency: Maintaining the right PSI ensures a smooth and efficient beer pour. The appropriate pressure allows the beer to flow out of the faucet with the ideal amount of foam, enhancing the visual appeal and preventing excessive foam that can lead to wasted beer.

4. Beverage Stability: Beer stability refers to the ability of the beer to maintain its desired characteristics over time. Proper PSI helps to ensure that the beer remains stable by preventing the absorption of oxygen into the beer, which can lead to oxidation, off-flavors, and a shorter shelf life. The right pressure also helps to prevent excessive foaming and carbonation loss when the keg is not in use.

5. Consistency: Consistency is key when it comes to serving beer. By having a consistent PSI setting, you can ensure that each pour from the kegerator delivers the same high-quality beer with the right level of carbonation and foam. This is particularly important in commercial establishments where customers expect a consistent beer experience.

6. Avoiding Waste: Improper PSI settings can result in excessive foam during the pour. Excessive foam not only affects the overall beer experience but also leads to wasted beer. By maintaining the proper pressure, you can minimize foam and reduce beer waste, ensuring that you get the most out of each keg.

Overall, having the correct PSI setting in a CO2 kegerator is vital for achieving optimal carbonation, flavor, pouring efficiency, and beverage stability. By paying attention to PSI and making appropriate adjustments, you can ensure that every pour from your kegerator delivers a refreshing and satisfying drink.

Factors to Consider when Determining PSI for a CO2 Kegerator

When it comes to determining the proper pressure per square inch (PSI) for a CO2 kegerator, several factors come into play. Understanding these factors will help you set the appropriate PSI for achieving the desired carbonation level and optimal beer pouring experience. Here are the key factors to consider:

Read more: How Adjust Co2 Kegerator

1. Beer Style:

Each beer style has its own recommended carbonation level and serving pressure. Lighter styles such as lagers or pilsners typically require lower PSI, while heavier styles like stouts or certain Belgian ales may need higher PSI for proper carbonation. Consult the guidelines or recommendations provided by the beer manufacturer or brewery to determine the ideal PSI for the specific beer style you’re serving.

2. Desired Carbonation Level:

The level of carbonation you desire in your beer also influences the PSI setting. Different beer styles have varying levels of carbonation, ranging from lightly carbonated to highly effervescent. Consider whether you want a subtle, smooth carbonation or a more pronounced, bubbly carbonation and adjust the PSI accordingly.

3. Temperature:

The temperature at which you are storing and serving the beer affects the PSI setting. As temperature increases, the solubility of carbon dioxide decreases, requiring higher pressure to maintain the desired carbonation level. Conversely, colder temperatures increase carbon dioxide solubility, allowing for lower PSI. Refer to the recommended temperature range for the beer style and adjust the pressure accordingly.

4. Carbonation Method:

The method used to carbonate the beer, whether through natural carbonation (priming sugar in bottles) or forced carbonation (using a CO2 tank), can impact the PSI setting. Be aware that beer carbonated naturally will require a lower PSI compared to beer that has been force carbonated.

5. Keg Volume:

The volume of beer remaining in the keg can also play a role in determining the PSI. As the keg empties, the pressure inside may need to be adjusted to prevent excessive foaming or under-carbonation. Pay attention to the keg level and make adjustments as necessary to maintain the desired carbonation level throughout the keg’s lifespan.

6. Experimentation and Personal Preference:

Ultimately, finding the ideal PSI for your specific setup may require some experimentation. It is important to keep track of your findings and notes to achieve consistent results. Additionally, personal preference plays a significant role in determining the perfect carbonation level and pouring experience. Tweak the PSI to align with your taste preferences and the preferences of those you are serving.

By considering these factors and making adjustments accordingly, you can determine the proper PSI for your CO2 kegerator, ensuring that the beer is carbonated to perfection and poured with precision. Remember, it may take a bit of trial and error to find the sweet spot, but with patience and attention to detail, you’ll create a memorable draft beer experience.

Recommended PSI Ranges for Different Beer Styles

When it comes to serving draft beer from a CO2 kegerator, it’s essential to adjust the pressure per square inch (PSI) to achieve the ideal carbonation and pouring experience for different beer styles. Here are some recommended PSI ranges for popular beer styles:

1. Lager/Pilsner:

For light and crisp lagers or pilsners, the recommended PSI range is typically between 10 and 14 PSI. This range ensures a moderate level of carbonation and a smooth, refreshing pour.

Read more: Where To Get Co2 For A Kegerator

2. Pale Ale/IPA:

For hop-forward beers like pale ales or IPAs, a slightly higher PSI range of 12 to 16 PSI is often recommended. This range promotes a slightly more effervescent carbonation level that complements the hop flavors and aromas.

3. Wheat Beer/Witbier:

Wheat beers or witbiers, known for their light and creamy mouthfeel, typically benefit from a PSI range of 9 to 12. This lower pressure range maintains a softer carbonation level, resulting in a smooth and velvety texture.

4. Amber Ale/Porter:

Amber ales and porters, with their malty and robust characteristics, generally do well with a slightly higher PSI range of 12 to 14. This range adds a touch more carbonation that helps balance out the richer flavors and enhances the overall experience.

5. Stout:

Stouts are often served at a lower pressure compared to other beer styles. A PSI range of 8 to 12 is commonly recommended, ensuring a gentler carbonation level that allows the flavors of chocolate, coffee, and roasted malt to shine without excessive foaming.

Read more: How Much Co2 Does A Kegerator Use

6. Belgian Ale:

Belgian ales, known for their complexity and yeast-driven flavors, generally benefit from a slightly higher PSI range of 12 to 16. This range creates a lively effervescence that enhances the beer’s unique characteristics and provides a pleasant mouthfeel.

Keep in mind that these recommended PSI ranges serve as a starting point, and adjustments may be necessary based on personal preference and specific beer recipes. It’s always a good practice to consult the brewery’s recommendations or guidelines for the specific beer you’re serving and make adjustments accordingly.

Remember to monitor the carbonation level, pouring speed, and overall quality of the beer as you make changes to the PSI. It may take some experimentation to find the perfect balance, but with practice and attention to detail, you’ll be able to serve each beer style with optimal carbonation and a delightful pouring experience.

Common Issues with Improper PSI in a CO2 Kegerator

Maintaining the proper pressure per square inch (PSI) is crucial in a CO2 kegerator to ensure optimal carbonation and a smooth pouring experience. When the PSI is not set correctly, several issues can arise that affect the taste, appearance, and overall quality of the beer being served. Here are some common issues that can occur with improper PSI:

1. Excessive Foam:

One of the most common issues with improper PSI is excessive foam during the pour. High PSI can lead to fast and turbulent beer flow, causing excessive foaming and resulting in wasted beer. This not only affects the visual appeal of the pour but can also affect the overall taste and drinking experience.

2. Flat Beer:

Conversely, if the PSI is too low, the beer may pour flat with minimal carbonation. Flat beer lacks the desired effervescence and can often taste dull or lifeless. This can be disappointing for beer enthusiasts who expect a refreshing and bubbly experience.

Read more: How To Use A Kegerator Co2 Regulator

3. Inconsistent Carbonation:

Improper PSI settings can lead to inconsistent carbonation throughout the keg. This means that some portions of the keg may have more or less carbonation than others. Inconsistency in carbonation can result in an unbalanced taste and a lack of uniformity in the beer’s texture.

4. Poor Flavor and Aroma:

The carbonation level greatly affects the flavor and aroma of beer. When the PSI is not set correctly, the beer may lack the desired level of carbonation, resulting in a flat or overly fizzy taste. This can diminish the overall enjoyment of the beer and mask the subtleties of the flavor profile.

5. Shortened Shelf Life:

If the PSI is too high or too low, it can affect the stability of the beer and shorten its shelf life. Excessive pressure can lead to oxidation and off-flavors, while low pressure levels can cause the beer to go stale more quickly. Maintaining the proper PSI ensures that the beer remains fresh and enjoyable for a longer period.

6. Pouring Speed:

The PSI setting also impacts the pouring speed and control. If the pressure is too high, the beer may pour too quickly, making it difficult to achieve a smooth and controlled pour. On the other hand, too low of a pressure can result in a slow and sluggish pour that may frustrate both the bartender and the customer.

These common issues highlight the importance of setting the proper PSI in a CO2 kegerator. It is crucial to find the right balance to ensure optimal carbonation, a consistent flavor profile, and an enjoyable pouring experience. Regular monitoring and adjustments of the PSI will help mitigate these issues and maintain the highest standards of beer quality and customer satisfaction.

Read more: How To Fix Co2 Leak In Kegerator

How to Adjust the PSI in a CO2 Kegerator

Adjusting the pressure per square inch (PSI) in a CO2 kegerator is a crucial step in maintaining the desired carbonation level and achieving the perfect pour. If you find that the PSI needs to be adjusted, follow these steps to make the necessary changes:

1. Gather the Required Tools:

Before making any adjustments, ensure you have the necessary tools on hand. You’ll need a CO2 regulator, a wrench or screwdriver (depending on the type of regulator), and a pressure gauge to measure the PSI accurately.

2. Vent the Keg Pressure:

Start by relieving the pressure inside the keg. This can be done by releasing the pressure relief valve on the keg lid or by disconnecting the gas line from the keg. It’s essential to release any built-up pressure to ensure a safe adjustment process.

3. Access the CO2 Regulator:

Locate the CO2 regulator on your kegerator. This is typically connected to the CO2 tank by a threaded connection. Use a wrench or screwdriver to loosen the nut, allowing you to remove the regulator from the tank.

Read more: How To Change Co2 Tank In Kegerator

4. Adjust the PSI Setting:

Once the regulator is removed, you’ll notice a dial or knob on the front or top of the regulator. This is used to adjust the PSI. Turn the dial clockwise to increase the pressure or counterclockwise to decrease it. Make small adjustments, usually in increments of 1 or 2 PSI, until you reach the desired setting.

5. Measure the PSI:

Attach a pressure gauge to the regulator to measure the PSI accurately. This will help you gauge the amount of pressure you’ve set. Ensure the gauge is securely attached and then slowly open the CO2 tank valve to allow gas to flow into the regulator. Read the gauge to determine the current PSI setting.

6. Test the Carbonation and Pour:

After making adjustments, it’s crucial to test the carbonation levels and the pour. Reconnect the gas line to the keg, and give it some time for the beer to settle and reach the adjusted pressure. Pour a sample beer and observe the carbonation level and the pour speed. Make further adjustments if needed until you achieve the desired results.

7. Monitor and Repeat as Necessary:

Once you’re satisfied with the carbonation levels and pour, monitor the beer over time to ensure the PSI remains consistent. Factors such as temperature changes or keg volume may require slight adjustments. Regularly check the PSI and make any necessary changes to maintain optimal carbonation levels.

Remember, adjusting the PSI in a CO2 kegerator may require some trial and error to find the perfect balance. Take note of the adjustments made and the resulting carbonation levels to establish a consistent and enjoyable beer pouring experience.

By following these steps, you’ll be able to adjust the PSI in your CO2 kegerator with confidence, allowing you to serve perfectly carbonated and refreshing draft beer.

Conclusion

A CO2 kegerator brings the joy of freshly poured draft beer to your home or establishment. Understanding the importance of proper pressure per square inch (PSI) and its role in achieving the perfect carbonation and pouring experience is a key aspect of maximizing the enjoyment of your beer.

We explored the fundamentals of a CO2 kegerator, learning how it works and the crucial role PSI plays in delivering a satisfying pint of beer. Maintaining the correct PSI ensures optimal carbonation, flavor, and pouring efficiency, providing a delightful sensory experience for beer enthusiasts.

We discussed the factors to consider when determining PSI, such as beer style, desired carbonation level, temperature, carbonation method, keg volume, and personal preference. Adjusting the PSI according to these factors allows you to tailor the carbonation to each specific beer style and achieve the desired taste and mouthfeel.

Additionally, we highlighted the recommended PSI ranges for different beer styles as a starting point for setting the appropriate pressure. These ranges provide guidelines to ensure a balanced carbonation level and an enjoyable drinking experience for each beer style you serve.

Furthermore, we examined common issues that can arise from improper PSI, such as excessive foam, flat beer, inconsistent carbonation, poor flavor and aroma, shortened shelf life, and pouring speed problems. Understanding these issues helps you troubleshoot and make corrections to deliver high-quality beer to your customers or guests.

Lastly, we discussed the steps to adjust the PSI in a CO2 kegerator, emphasizing the importance of monitoring and making small incremental adjustments to find the optimal setting. Testing the carbonation levels and pour after each adjustment ensures that you achieve the desired results before serving the beer to your customers or enjoying it yourself.

By mastering the art of adjusting PSI and fine-tuning the carbonation in your CO2 kegerator, you can elevate the beer-drinking experience, impress your guests, and enjoy the full flavors and aromas of your favorite brews.

Cheers to the perfect pour!

Frequently Asked Questions about How Much To Rotate The Valve On A Co2 Kegerator PSI

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Much To Rotate The Valve On A Co2 Kegerator PSI”