Articles

How To Vacuum An AC System

Modified: February 26, 2024

Learn how to effectively vacuum an AC system with our informative articles. Get expert tips and step-by-step instructions to ensure a clean and efficient cooling system.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

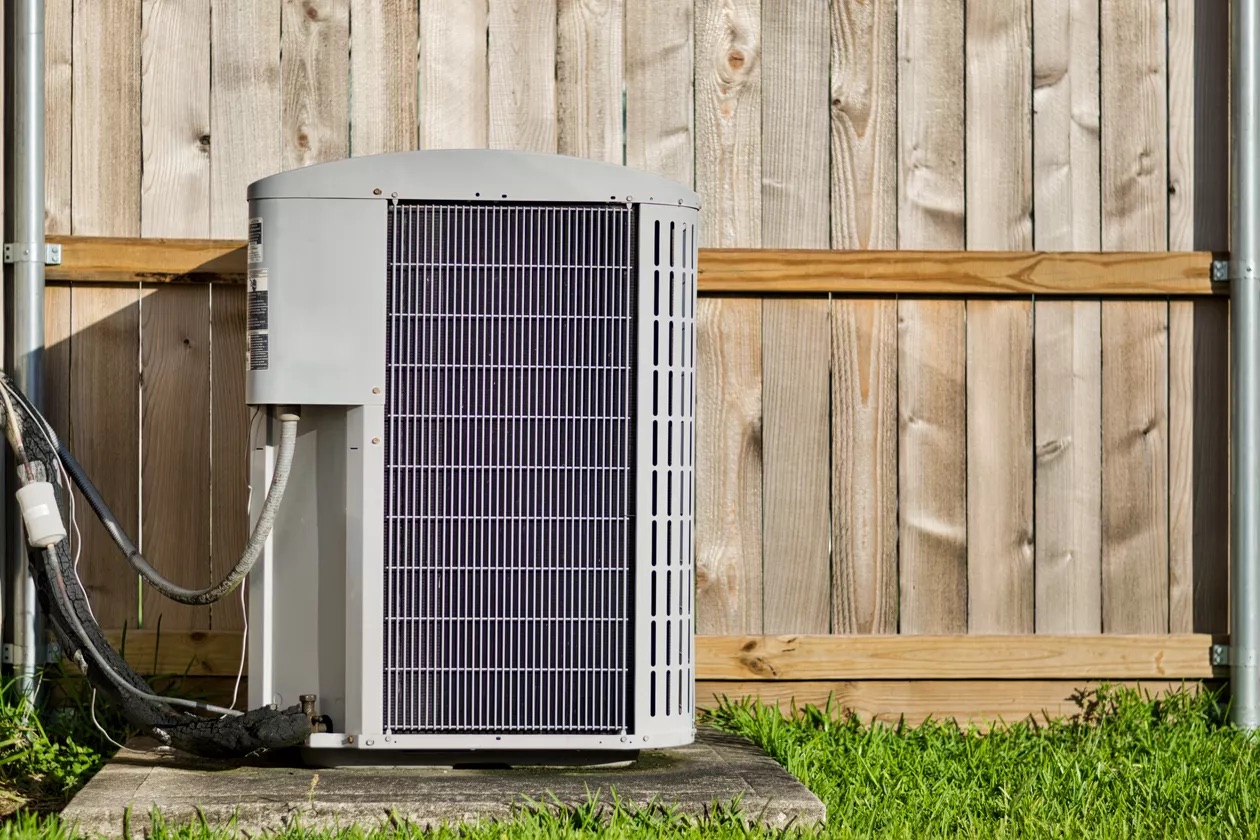

When it comes to maintaining a comfortable indoor environment, a well-functioning air conditioning (AC) system plays a crucial role. However, over time, AC systems can accumulate moisture, air, and other contaminants that can hinder their performance. To ensure optimal cooling efficiency and prevent potential damage, it’s essential to regularly vacuum the AC system.

Vacuuming an AC system involves removing any unwanted particles, air, and moisture from the system. This process not only helps to improve cooling performance but also extends the lifespan of the AC components. By following a few simple steps, you can easily vacuum an AC system and keep it running smoothly.

In this article, we will guide you through the step-by-step process of vacuuming an AC system, highlighting the necessary equipment and precautions along the way. So, let’s get started on making your AC system operate at its best efficiency.

Key Takeaways:

- Regularly vacuuming your AC system is crucial for maintaining optimal cooling efficiency and extending the lifespan of its components. Follow the step-by-step process to ensure effective and safe maintenance.

- Properly vacuuming and recharging your AC system with the right equipment and techniques will help you save energy, money, and enjoy a comfortable indoor environment. Remember to follow manufacturer’s guidelines for safety and effectiveness.

Read more: How To Pull A Vacuum On HVAC

Step 1: Gather Necessary Equipment

Before you begin vacuuming your AC system, it’s important to ensure that you have all the necessary equipment. Here’s a list of tools and items you’ll need:

- Vacuum pump: This is the primary tool used to create a vacuum in the AC system. Make sure you have a vacuum pump with sufficient capacity for your specific system.

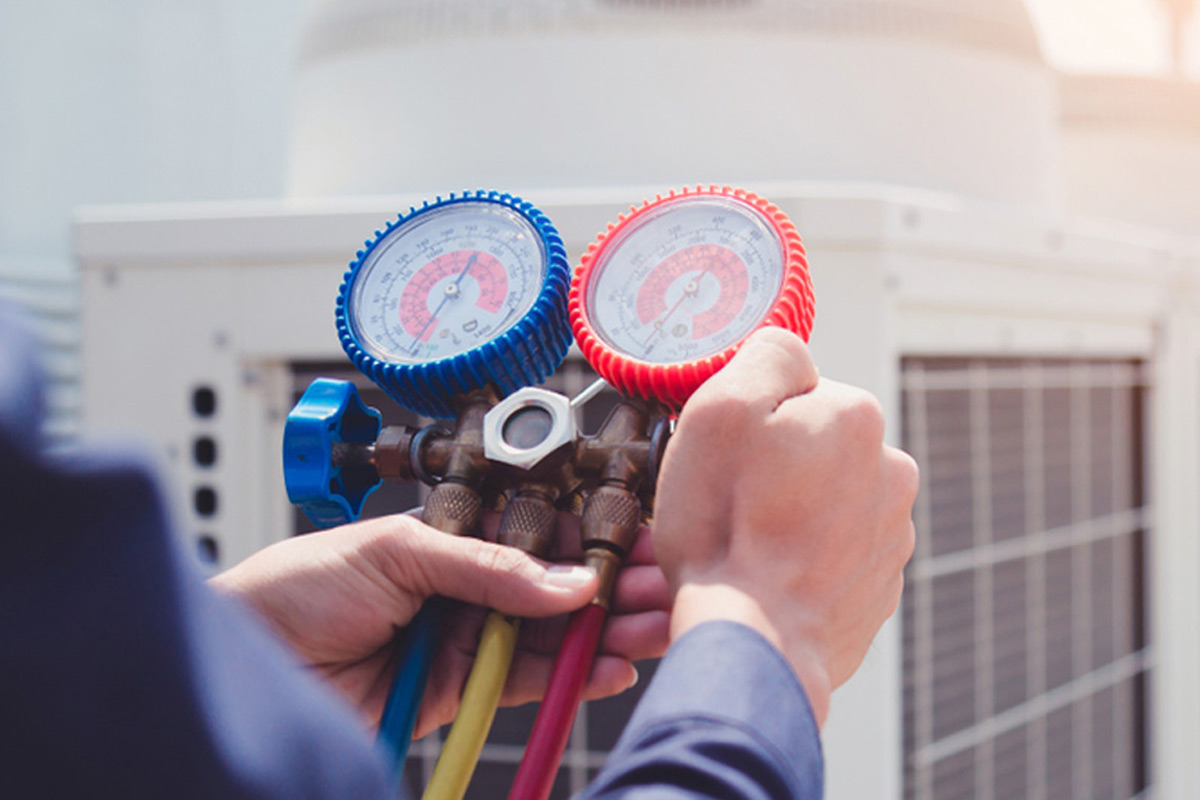

- Manifold gauge set: This tool allows you to monitor the pressure and vacuum levels in the AC system. Look for a gauge set that is compatible with your system’s refrigerant type.

- Vacuum pump oil: Check the manufacturer’s instructions for the specific type of oil recommended for your vacuum pump. Make sure you have enough oil on hand.

- Refrigerant recovery machine (optional): If you need to remove refrigerant from the system before vacuuming, a recovery machine is essential. This is typically required when servicing older AC units.

- Safety goggles and gloves: Protect your eyes and hands from any potential hazards during the vacuuming process by wearing appropriate safety gear.

- Sealed containers: You’ll need containers to store any refrigerant that you recover from the system. Make sure the containers are sealed tightly to prevent any leaks or spills.

- Torch and leak detection solution: These tools are helpful for identifying any leaks in the AC system. Use a torch to inspect the components, and apply the leak detection solution to pinpoint any leaks.

- Wrenches and pliers: These basic tools will come in handy when removing and tightening connections in the AC system.

Once you have all the necessary equipment gathered, you’re ready to move on to the next step: turning off and disconnecting the AC system.

Step 2: Turn Off and Disconnect the AC System

Before you begin vacuuming the AC system, it’s crucial to ensure your safety by turning off the power and disconnecting the system. Follow these steps:

- Locate the electrical panel or circuit breaker that controls the AC unit. Switch off the power to prevent any accidental electrical shocks.

- Find the main disconnect switch, typically located near the outdoor unit or in the mechanical room. Turn the switch to the “Off” position to cut off power to the entire AC system.

- Next, disconnect the AC unit from the power supply. Depending on the setup, this may involve unplugging the unit or shutting off the electrical breaker that connects the AC system.

- Ensure that all power sources are disconnected to eliminate any risk of electrical accidents while working on the system.

Taking these precautions will help prevent any potential electrical hazards and ensure your safety throughout the vacuuming process. Once you have turned off and disconnected the AC system, you can proceed to the next step: locating the service ports.

Step 3: Locate the Service Ports

After ensuring the safety of the AC system by turning off and disconnecting the power, the next step is to locate the service ports. These ports are where you will connect the vacuum pump and gauge set to the AC system. Here’s how to find the service ports:

- Consult the AC system’s manual or schematic to identify the location of the service ports. In most cases, the ports are located on the refrigerant lines near the outdoor unit.

- Look for two ports labeled “high-pressure” and “low-pressure.” The high-pressure port is usually connected to the smaller refrigerant line, while the low-pressure port is connected to the larger line.

- The service ports may be protected by small caps to prevent debris from entering. Remove the caps using a wrench or your fingers, being careful not to lose them.

- Inspect the service ports for any signs of damage or corrosion. If you notice any issues, it’s best to address them before proceeding with the vacuuming process.

Once you have located the service ports and ensured their accessibility, you’re ready to move on to the next step: attaching the vacuum pump.

Step 4: Attach the Vacuum Pump

With the service ports located, it’s time to connect the vacuum pump to the AC system. Attaching the vacuum pump properly will ensure a secure and effective vacuuming process. Follow these steps:

- Take one end of the vacuum hose and connect it to the intake port of the vacuum pump.

- Attach the other end of the hose to the low-pressure service port on the AC system. Ensure that the connection is tight and secure to prevent any leaks during the vacuuming process.

- Check the manufacturer’s instructions for your specific vacuum pump to determine the appropriate oil to use. Fill the vacuum pump with the recommended oil up to the recommended level. This lubricates the pump and helps maintain its efficiency.

- Before you start the vacuum pump, make sure the valves on the manifold gauge set are closed. This will prevent air from entering the system prematurely.

- If your gauge set has a third hose, connect it to a vacuum gauge and attach the other end to the center port of the manifold gauge set. This allows you to monitor the vacuum pressure during the vacuuming process.

Once you have successfully attached the vacuum pump and ensured all connections are tight, you’re ready to move on to the next step: evacuating the AC system.

Read also: 15 Incredible HVAC Vacuum Pump For 2024

Step 5: Evacuate the AC System

Now that you have the vacuum pump attached to the AC system, it’s time to start the evacuation process. This step involves removing air, moisture, and other contaminants from the system to create a vacuum. Follow these steps to properly evacuate the AC system:

- Start by turning on the vacuum pump and allowing it to run for a few minutes to stabilize its operation.

- Open the valves on the manifold gauge set, including both the high-pressure and low-pressure sides. This will allow the vacuum pump to pull a low-pressure vacuum on the AC system.

- Monitor the vacuum gauge, which is connected to the center port of the manifold gauge set. As the vacuum pump operates, it will start pulling out air and moisture from the AC system.

- Continue running the vacuum pump for at least 30 minutes to ensure a thorough evacuation of the system. This duration may vary depending on the size and condition of the AC system.

- During this process, you may hear some noise coming from the vacuum pump, which is normal. However, if you notice unusual noises or vibrations, it’s best to stop the pump and check for any issues.

It’s important to note that the length of time required for the evacuation process may vary depending on the specific AC system and its condition. Some systems may require a longer evacuation time to remove stubborn contaminants thoroughly.

Once you have completed the evacuation process, you can move on to the next step: monitoring the gauges to ensure proper vacuum levels.

When vacuuming an AC system, make sure to use a high-quality vacuum pump to remove all air and moisture from the system before recharging it with refrigerant. This will ensure optimal performance and prevent damage to the components.

Step 6: Monitor the Gauges

After initiating the evacuation process, it’s crucial to monitor the gauges to ensure that the AC system is reaching the correct vacuum levels. Proper monitoring helps to ensure that the evacuation is effective and thorough. Follow these steps to monitor the gauges:

- Refer to the manufacturer’s specifications or guidelines to determine the target vacuum level for your specific AC system. This information can typically be found in the system’s manual or on a nameplate.

- Observe the readings on both the high-pressure and low-pressure gauges of the manifold gauge set. The high-pressure gauge should show a low pressure, close to zero, while the low-pressure gauge should indicate a deep vacuum, often measured in inches of mercury (inHg).

- Monitor the gauges closely and make sure they are stable at the desired vacuum level. The stabilization of the gauges indicates that the AC system has been properly evacuated, and the vacuum pump has effectively removed air and moisture.

- If the gauges fluctuate or do not reach the target vacuum level, there may be a leak or other issue in the AC system that needs to be addressed. In such cases, it’s recommended to stop the vacuuming process and inspect the system for any potential leaks.

- Continue monitoring the gauges for a sufficient amount of time to ensure that the vacuum level remains stable. This duration may vary based on the specific AC system and its size.

Monitoring the gauges throughout the evacuation process is essential to verify the effectiveness of the vacuuming and ensure that the AC system is ready for the next steps. Once you have confirmed stable and appropriate vacuum levels, you can proceed to the next step: maintaining vacuum pressure.

Step 7: Maintain Vacuum Pressure

Once you have achieved the desired vacuum level and verified the stability of the gauges, it’s important to maintain the vacuum pressure to ensure that the AC system remains free of contaminants. Follow these steps to properly maintain vacuum pressure:

- Keep the vacuum pump running and the manifold gauge set valves open to maintain the vacuum pressure in the system.

- Check the vacuum gauge periodically to ensure that the pressure remains stable within the desired range. This will help ensure that the system is properly sealed and that there are no leaks or other issues.

- If you notice a gradual increase in the vacuum pressure, this may indicate a leak in the system. In such cases, it’s important to stop the vacuuming process and perform a thorough inspection to identify and address the source of the leak.

- Continue maintaining the vacuum pressure for a sufficient duration as recommended by the manufacturer or based on industry standards. This duration may typically range from 30 minutes to a few hours.

- While maintaining the vacuum pressure, it’s important to avoid any disruptions that could introduce contaminants back into the system. Ensure that all connections are secure and any service ports that were opened are sealed properly.

Maintaining proper vacuum pressure is necessary to ensure the effectiveness of the evacuation process and prepare the AC system for the next steps. Once you have successfully maintained the vacuum pressure for the required duration, you can proceed to the next step: releasing refrigerant if necessary.

Step 8: Release Refrigerant If Necessary

In some cases, it may be necessary to release the refrigerant from the AC system before proceeding with further maintenance or repairs. Releasing the refrigerant ensures that the system is emptied and ready for any necessary servicing. Follow these steps if refrigerant release is needed:

- If your AC system requires refrigerant removal, ensure that you have a refrigerant recovery machine. This machine is designed to safely recover the refrigerant from the system and store it for proper disposal or reuse.

- Connect the recovery machine to the high-pressure and low-pressure service ports of the AC system using the appropriate hoses and fittings.

- Follow the instructions provided by the manufacturer of the recovery machine to initiate the refrigerant recovery process. This typically involves activating the machine and allowing it to pull the refrigerant from the system.

- Monitor the recovery machine’s display or gauges to ensure that the refrigerant is being effectively and safely removed from the AC system.

- Once the refrigerant has been completely recovered, disconnect the recovery machine from the service ports. Ensure that you seal any openings to prevent any air or contaminants from entering the AC system.

Releasing the refrigerant, if necessary, is important for ensuring the safety of the environment and complying with environmental regulations. It is crucial to handle refrigerant in a responsible and environmentally-friendly manner to minimize any negative impact.

After releasing the refrigerant, you can proceed to the next step: disconnecting the vacuum pump.

Read more: How To Use An AC Vacuum Pump

Step 9: Disconnect the Vacuum Pump

Once you have completed the necessary vacuuming and refrigerant release steps, it’s time to disconnect the vacuum pump from the AC system. Follow these steps to safely disconnect the vacuum pump:

- Turn off the vacuum pump and disconnect the power supply to ensure safety.

- Close the valves on the manifold gauge set to isolate the vacuum pressure from the AC system.

- Loosen the hose connection between the vacuum pump and the low-pressure service port on the AC system. Carefully remove the hose, ensuring that any residual pressure is released safely.

- If you used a third hose for monitoring vacuum pressure, disconnect it from the vacuum gauge and the center port of the manifold gauge set.

- Inspect the connections for any signs of leaks or damage. If any issues are detected, they should be addressed before proceeding with further steps.

Disconnecting the vacuum pump properly ensures that the AC system is ready for the next stage of maintenance or operation. It’s important to handle the equipment with care and follow safety precautions to prevent any accidents or damages.

With the vacuum pump disconnected, you can move on to the final step: recharging the AC system.

Step 10: Recharge the AC System

After completing the vacuuming process and disconnecting the pump, it’s time to recharge the AC system with refrigerant. Recharging the system involves adding the appropriate amount of refrigerant to ensure optimal cooling performance. Follow these steps to recharge the AC system:

- Consult the AC system’s manufacturer specifications or guidelines to determine the exact amount and type of refrigerant recommended for your specific unit.

- If necessary, replace any earlier removed components, such as filter driers or valves, to ensure the system’s proper function.

- Attach a refrigerant charging hose to the high-pressure service port of the AC system. Make sure the connection is secure and tight.

- Connect the other end of the charging hose to a refrigerant source, such as a refrigerant cylinder or charging station.

- Open the valve on the charging hose to allow refrigerant to flow into the system. Monitor the pressure gauges on the manifold gauge set to ensure that the refrigerant is being charged properly.

- Refer to the manufacturer’s instructions or guidelines to determine the appropriate charging procedure for your specific AC system. This may involve slowly adding refrigerant while monitoring system pressure or using an automated charging process.

- Continue charging the AC system until the target refrigerant level is achieved. Be cautious not to overcharge the system, as this can lead to inefficiency and potential damage.

- Once the desired refrigerant level is reached, close the valve on the charging hose and carefully disconnect it from the service port.

- Inspect all connections and ensure they are secure and free of leaks. Use leak detection solution or a torch, if needed, to check for any potential leaks.

Recharging the AC system properly is crucial for restoring its cooling efficiency and performance. Following the manufacturer’s recommendations and guidelines ensures that the system operates optimally and extends its lifespan.

With the AC system successfully recharged, you have completed the necessary steps to vacuum and maintain an AC system. Regular vacuuming helps to remove contaminants, improve cooling performance, and prolong the life of the AC components.

Remember to refer to the manufacturer’s instructions and guidelines throughout the vacuuming and recharging process to ensure safety and optimize the effectiveness of the procedures.

By following these steps, you can confidently and effectively maintain and optimize your AC system for optimal cooling comfort.

Conclusion

Properly vacuuming an AC system is essential for maintaining its performance, efficiency, and longevity. By effectively removing air, moisture, and contaminants from the system, you can ensure optimal cooling and extend the lifespan of the components. Following the step-by-step process outlined in this article will help you successfully vacuum your AC system.

Remember to gather the necessary equipment, including a vacuum pump, manifold gauge set, and safety gear, before you begin. Turning off and disconnecting the AC system is crucial for your safety and the proper function of the vacuuming process. Locating the service ports and attaching the vacuum pump will allow you to create a vacuum and evacuate the system effectively.

Throughout the process, monitoring the gauges and maintaining vacuum pressure are essential to ensure the effectiveness of the vacuuming. Releasing refrigerant, if necessary, must be done safely and responsibly, while disconnecting the vacuum pump should be performed with care and attention to proper procedures.

Finally, recharging the AC system with the appropriate amount and type of refrigerant will restore its cooling capacity. Following the manufacturer’s recommendations and guidelines ensures optimal performance and efficiency.

Regularly vacuuming your AC system helps to keep it running smoothly and efficiently, saving you energy and money while providing a comfortable indoor environment. By following these steps and using the right equipment, you can confidently perform this maintenance task and enjoy the benefits of a well-functioning AC system.

Remember to refer to the manufacturer’s instructions and guidelines throughout the vacuuming and recharging process to ensure safety and optimize the effectiveness of the procedures. By following these steps, you can maintain and optimize your AC system for optimal cooling comfort.

Frequently Asked Questions about How To Vacuum An AC System

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Vacuum An AC System”