Articles

Kegerator Beer Coupler How It Works

Modified: August 16, 2024

Learn how a kegerator beer coupler works with our informative articles. Become an expert on kegerator maintenance and troubleshooting.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of beer enthusiasts and home brewers where the joy of sipping a perfectly chilled pint of beer is at your fingertips. If you are someone who loves the idea of having draft beer in the comfort of your own home, then a kegerator is a must-have item for your setup. But to unlock the true potential of your kegerator, you need to understand and appreciate the role of a vital component – the kegerator beer coupler.

A kegerator beer coupler is a device that connects the beer keg to the beer line. It acts as the intermediary between the pressurized keg and the draft beer dispensing system. The coupler allows the beer to flow from the keg to the tap, ensuring a smooth and controlled pour every time.

While the concept of a beer coupler may seem simple, there are several components and mechanisms at play that contribute to its seamless functionality. In this article, we will take a closer look at the key components of a kegerator beer coupler, how it works, the different types available, common issues you may encounter, and tips for proper maintenance and cleaning.

So, whether you are a beer enthusiast who wants to enjoy a cold draft beer at home or a home brewer looking to perfect your craft, understanding the intricacies of a kegerator beer coupler is essential to ensure a premium beer drinking experience.

Key Takeaways:

- The kegerator beer coupler is a vital component that connects the keg to the beer tap, ensuring a smooth and controlled flow of beer while maintaining carbonation and flavor.

- Regular maintenance and cleaning of the kegerator beer coupler are essential to ensure optimal performance and a consistently delicious draft beer experience.

Read more: How To Work A Kegerator

What is a Kegerator Beer Coupler?

A kegerator beer coupler is a crucial component of a draft beer system that allows you to dispense beer directly from a keg. It acts as the interface between the keg and the beer tap, ensuring a smooth flow of beer with the right amount of carbonation and pressure.

The main purpose of a kegerator beer coupler is to connect the beer keg to the beer line, which is connected to the beer faucet or tap. It serves as a valve that controls the release of beer from the keg into the dispensing system.

Beer couplers are specifically designed to fit different types of kegs, including those used for domestic and imported beers. There are various coupler styles available, each tailored to match the specific fitting and valve arrangement of the keg they are intended for.

A typical kegerator beer coupler consists of several key components:

- Probe: The probe is a metal tube that extends into the keg and punctures the keg’s valve or spear to allow beer to flow out. It has a seal to prevent loss of carbonation and maintain pressure.

- Check Valve: The check valve is located inside the coupler and prevents beer from flowing back into the gas line. It ensures that only beer is dispensed when the tap is opened.

- Gas Line Port: The gas line port connects to the CO2 tank or regulator to provide the necessary pressure for pushing the beer out of the keg.

- Beer Line Port: The beer line port connects to the beer line running from the coupler to the beer tap or faucet. It allows the beer to flow from the keg to the tap, ready to be served.

By securely connecting the keg to the dispensing system and controlling the flow of beer, the kegerator beer coupler ensures a consistent and high-quality draft beer experience. It not only enables you to enjoy your favorite beer right from the keg but also helps maintain the carbonation and overall freshness of the beer.

Now that we have a better understanding of what a kegerator beer coupler is and its essential components, let’s explore how it works in more detail.

Components of a Kegerator Beer Coupler

A kegerator beer coupler consists of several components that work together to connect the keg to the beer tap and facilitate the smooth dispensing of beer. Understanding these components will give you a better grasp of how the kegerator beer coupler functions. Let’s take a closer look at each of these components:

- Probe: The probe is a long, hollow metal tube that extends into the keg and punctures the keg valve or spear. It allows beer to flow out of the keg when the tap is opened. The probe is usually made of stainless steel to ensure durability and resistance to corrosion.

- Check Valve: The check valve is located inside the coupler and is responsible for controlling the flow of beer. It prevents beer from flowing back into the gas line when the tap is closed. This ensures that only beer is dispensed when the tap is opened, maintaining the integrity of the beer and preventing any contamination.

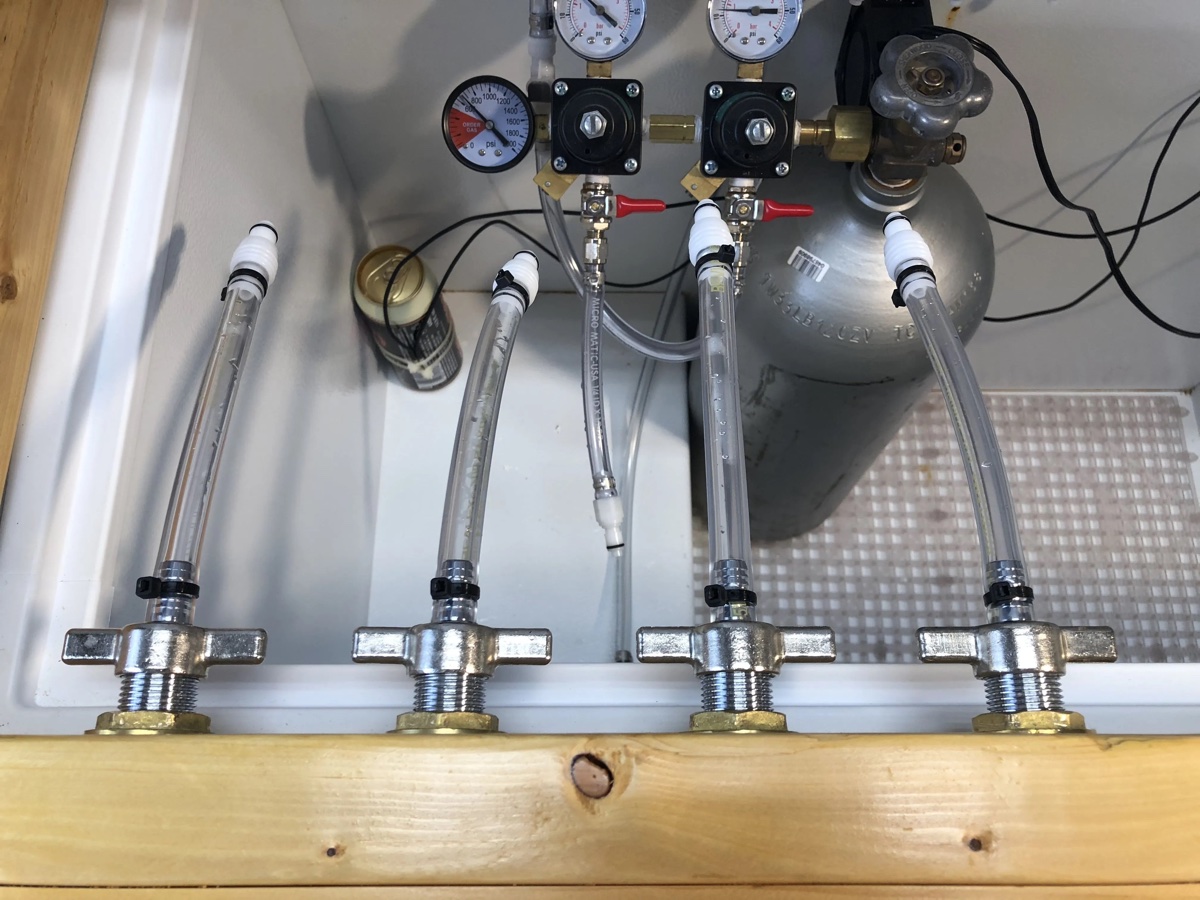

- Gas Line Port: The gas line port is a threaded connection that allows the kegerator beer coupler to be connected to the CO2 tank or regulator. The gas line supplies pressurized CO2 to the keg, which pushes the beer out when the tap is opened. The pressure can be adjusted to achieve the desired carbonation level and flow rate.

- Beer Line Port: The beer line port is another threaded connection on the kegerator beer coupler. It connects the coupler to the beer line, which carries the beer from the keg to the tap. The beer line is typically made of food-grade, odorless, and tasteless materials such as vinyl or polyethylene to ensure the beer’s purity and quality.

- Handle: The handle is the part of the kegerator beer coupler that is operated to open or close the flow of beer. When the handle is pulled or pushed, it engages or disengages the coupler’s internal mechanism, allowing the beer to flow or stop flowing. The handle is designed to be ergonomic and easy to grip for smooth operation.

- Seal/Gasket: The seal or gasket is a rubber or silicone ring that creates a tight seal between the kegerator beer coupler and the keg. It prevents leaks and loss of carbonation, ensuring that the beer remains properly pressurized inside the keg.

These components work in harmony to maintain the integrity of the beer, control the flow, and ensure a consistent and enjoyable beer drinking experience. Now that we have explored the components of a kegerator beer coupler, let’s delve into how it actually works.

How does the Kegerator Beer Coupler work?

The kegerator beer coupler plays a crucial role in the dispensing of draft beer, allowing you to enjoy a smooth and controlled pour. Understanding how it works will help you appreciate the intricate mechanisms at play. Let’s explore the step-by-step process of how the kegerator beer coupler operates:

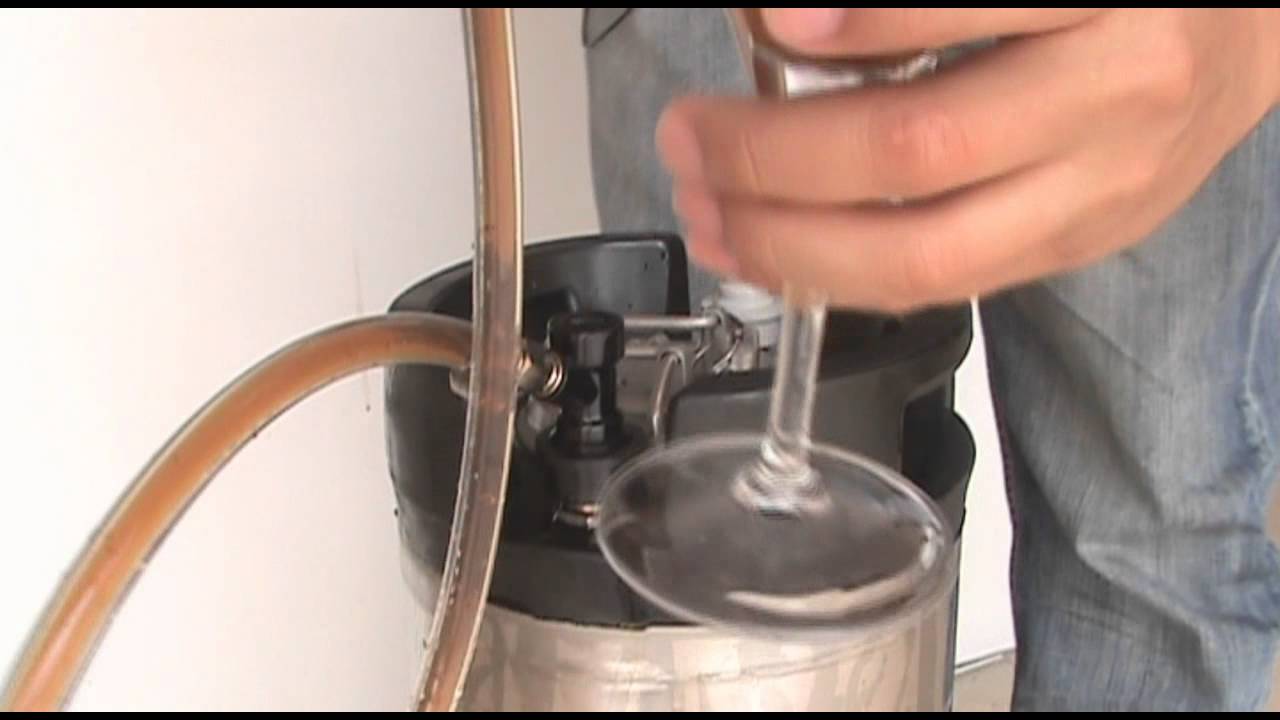

- Connecting the Coupler: The first step is to securely connect the kegerator beer coupler to the keg. This is done by aligning the coupler’s probe with the keg valve or spear, ensuring a tight and sealed connection.

- Puncturing the Keg: Once the coupler is properly connected, the probe is pushed into the keg valve or spear. This punctures the keg, allowing beer to flow out when the tap is opened.

- Engaging the Coupler: The handle on the coupler is then operated, typically by pulling or pushing it. This engages the coupler’s internal mechanism, opening the pathway for beer to flow from the keg.

- Controlling the Pressure: As the beer flows out of the keg, the pressure inside the keg is released. However, the kegerator beer coupler still maintains a level of pressure to ensure a controlled flow rate. The pressure is regulated by the CO2 gas supplied through the gas line port.

- Dispensing the Beer: With the coupler engaged and pressure regulated, the beer is ready to be dispensed. When the tap or beer faucet is opened, the beer flows through the beer line and out of the tap, ready to be enjoyed.

- Shutting off the Flow: To stop the flow of beer, the tap is closed, cutting off the pathway from the keg. The check valve in the kegerator beer coupler prevents any backflow, ensuring that only beer is dispensed when the tap is opened.

- Sealing and Maintaining Pressure: When the tap is closed, the coupler maintains a seal between the keg and the beer line. This prevents any beer from leaking, while the CO2 gas continues to pressurize the keg, keeping the beer fresh and carbonated until the next pour.

The kegerator beer coupler acts as the control center of the draft beer dispensing system, regulating the flow and maintaining the integrity of the beer. It ensures that each pour is smooth, properly carbonated, and free from any contaminants.

Now that we have explored how the kegerator beer coupler works, let’s move on to understanding the different types of beer couplers available for various beer kegs.

When using a kegerator beer coupler, make sure to properly align and secure it to the keg to prevent leaks and ensure a smooth pour. Always follow the manufacturer’s instructions for best results.

Types of Kegerator Beer Couplers

When it comes to kegerator beer couplers, there are several different types available, each designed to accommodate specific keg fittings and valve arrangements. It is essential to use the correct type of coupler for your keg to ensure a proper connection and optimal beer dispensing. Let’s explore some of the most common types of kegerator beer couplers:

- D System: The D system coupler, also known as the American Sankey coupler, is the most widely used type in the United States. It is designed to fit most domestic beers, including popular brands like Budweiser, Miller, and Coors. The D system coupler features a 5/8-inch probe and a flat top with a lever handle for easy operation.

- S System: The S system coupler, or European Sankey coupler, is commonly used for European beers. It has a longer probe compared to the D system, measuring 7/8 inches, and typically features a metal lever handle for dispensing. The S system coupler is compatible with brands like Heineken, Stella Artois, and Pilsner Urquell.

- G System: The G system coupler, also known as Grundy or National Sankey, is primarily used in German breweries. It has a probe size similar to the D system, but with a unique twist-lock connection. The G system coupler is often found in kegs of popular German beers like Paulaner and Spaten.

- M System: The M system coupler, or European Slider coupler, is used for certain European beers, particularly those from Belgium. It features a unique bayonet-style connection with a sliding collar for attachment. The M system coupler is commonly used for brands like Hoegaarden, Leffe, and Duvel.

- U System: The U system coupler, or European Extractor coupler, is commonly used in the UK. It has a similar design to the S system coupler but with a shorter probe length. The U system coupler is compatible with popular British beers like Guinness and Boddingtons.

- Tapping System: Some specialty beers, such as craft beers and certain imported brews, may require a specific tapping system coupler. These couplers are specifically designed by the brewery to fit their kegs and ensure optimal beer dispensing.

It is crucial to choose the right coupler that matches the keg you are using to ensure a proper connection and a seamless beer dispensing experience. Be sure to check the markings on your keg or consult with your local supplier or brewery to determine the appropriate type of coupler to use.

Now that we have explored the different types of kegerator beer couplers, let’s address some common issues you may encounter with these couplers and how to resolve them.

Read more: What Is a Kegerator and What Is It Used For?

Common Issues with Kegerator Beer Couplers

While kegerator beer couplers are designed to provide a seamless beer dispensing experience, there are a few common issues that you may encounter. Understanding these issues and knowing how to address them will help you troubleshoot and maintain your kegerator system. Let’s explore some of the most common issues with kegerator beer couplers:

- Leaking: One of the most common issues with kegerator beer couplers is leaking. This can occur due to a faulty seal or gasket between the coupler and the keg. Check that the seal is in good condition and properly seated. If there is a leak, try tightening the coupler or replacing the seal.

- Blockages: Sometimes, the beer line or the coupler itself can get clogged with debris or sediment from the beer. This can result in a slow or inconsistent flow of beer. To resolve this, you can remove the coupler and clean it thoroughly. Flush out any debris from the beer line as well.

- Foaming: Excessive foam can be an issue when pouring beer. This can be caused by improper temperature or pressure settings. Ensure that your kegerator is set to the correct temperature for the type of beer you are dispensing. Additionally, check that the CO2 pressure is properly regulated to maintain the ideal carbonation level.

- Incorrect Coupler Type: Using the wrong type of coupler for your keg can result in difficulty connecting or poor beer flow. Make sure you have the correct coupler style that matches your keg. Refer to the previous section on types of kegerator beer couplers to ensure you are using the right one.

- Worn-out Parts: Over time, the components of the kegerator beer coupler may wear out, leading to issues with connection, leakage, or dispensing. If you notice any signs of wear, such as loose fittings or damaged seals, it may be time to replace the worn-out parts of the coupler.

If you encounter any of these issues with your kegerator beer coupler, it is essential to address them promptly to ensure a smooth and enjoyable beer dispensing experience. Regular maintenance and inspection of your kegerator system can help prevent these issues from arising in the first place.

In the next section, we will provide some useful tips for maintaining and cleaning your kegerator beer coupler to keep it in optimal condition.

Tips for Maintaining and Cleaning a Kegerator Beer Coupler

Proper maintenance and regular cleaning of your kegerator beer coupler are essential to ensure optimal performance and the longevity of your system. By following these tips, you can keep your coupler in pristine condition and enjoy a consistently delicious draft beer experience:

- Regular Inspection: Periodically inspect your kegerator beer coupler for any signs of wear or damage. Check the seals, fittings, and connections for tightness and ensure there are no leaks. Replace any worn or damaged parts to maintain a proper seal.

- Cleanliness: Cleanliness is crucial for maintaining the quality of your beer and the functionality of your coupler. After each keg kicks, it is important to flush the coupler with a sanitation solution to remove any residual beer or bacteria. Follow the manufacturer’s instructions or use a commercial beer line cleaner.

- Disassemble and Soak: For a more thorough cleaning, disassemble the coupler and soak the components in a cleaning solution. This will help remove any stubborn residue and ensure that each part is sanitized. Scrub gently with a brush or sponge to remove any buildup.

- Rinse Thoroughly: After cleaning, rinse all parts of the coupler with clean water to remove any traces of the cleaning solution. Ensure that no residue is left behind that could affect the taste or quality of the beer.

- Proper Storage: When not in use, it is important to store your kegerator beer coupler in a clean and dry environment. This will prevent any dust, dirt, or moisture from affecting its functionality. Cover the coupler with a protective cap or wrap it in a clean cloth to keep it free from contaminants.

- Regular Line Cleaning: In addition to cleaning the coupler, it is crucial to regularly clean the beer lines in your kegerator. Residual beer and bacteria can build up inside the lines over time, affecting the taste and quality of the beer. Follow the manufacturer’s instructions or consult a professional for guidance on how often and how to clean the beer lines.

By following these maintenance and cleaning tips, you can ensure that your kegerator beer coupler remains in top-notch condition and consistently delivers high-quality draft beer. Remember, a well-maintained coupler leads to a better beer drinking experience.

To conclude, the kegerator beer coupler is a vital component of any draft beer system, connecting the keg to the tap and allowing for the smooth dispensing of beer. Understanding its components, how it works, the different types available, and how to maintain and clean it will help you make the most of your kegerator and enjoy fresh, cold draft beer at home.

Conclusion

In conclusion, the kegerator beer coupler is an essential component of any draft beer system, enabling you to enjoy the convenience and freshness of draft beer right in the comfort of your own home. By connecting the keg to the beer tap, the coupler ensures a smooth and controlled flow of beer, maintaining the carbonation and flavor of your favorite brews.

We have explored the various components of a kegerator beer coupler, including the probe, check valve, gas line port, beer line port, handle, and seal. These components work together to provide a seamless beer dispensing experience.

There are different types of couplers available, each designed to fit specific keg fittings and valve arrangements. It is crucial to use the correct type of coupler for your keg to ensure proper connection and optimal beer flow. These types include the D system, S system, G system, M system, U system, and specialty tapping system couplers.

While kegerator beer couplers are designed to provide a seamless experience, there are common issues that may arise, such as leaking, blockages, foaming, incorrect coupler type, and worn-out parts. Regular maintenance, inspection, and cleaning of your coupler can help address and prevent these issues.

To maintain your kegerator beer coupler, it is important to regularly inspect, clean, and sanitize it. This involves flushing the coupler with a sanitation solution, disassembling and soaking the components, rinsing thoroughly, and storing it in a clean and dry environment. Additionally, regularly cleaning the beer lines in your kegerator is essential to maintain the quality of your beer.

In summary, understanding the components, functioning, and maintenance of a kegerator beer coupler is crucial for optimal performance and a premium draft beer experience. By following the tips and guidelines provided in this article, you can ensure that your kegerator beer coupler continues to deliver fresh, cold, and delicious draft beer for years to come.

Frequently Asked Questions about Kegerator Beer Coupler How It Works

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “Kegerator Beer Coupler How It Works”