Home>Articles>Which Types Of Conduit Bodies Are Used To Provide A Pull Point On A Straight Conduit Run?

Articles

Which Types Of Conduit Bodies Are Used To Provide A Pull Point On A Straight Conduit Run?

Modified: May 6, 2024

Find out which types of conduit bodies are commonly used to provide a pull point on a straight conduit run. Explore our informative articles for more insights.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

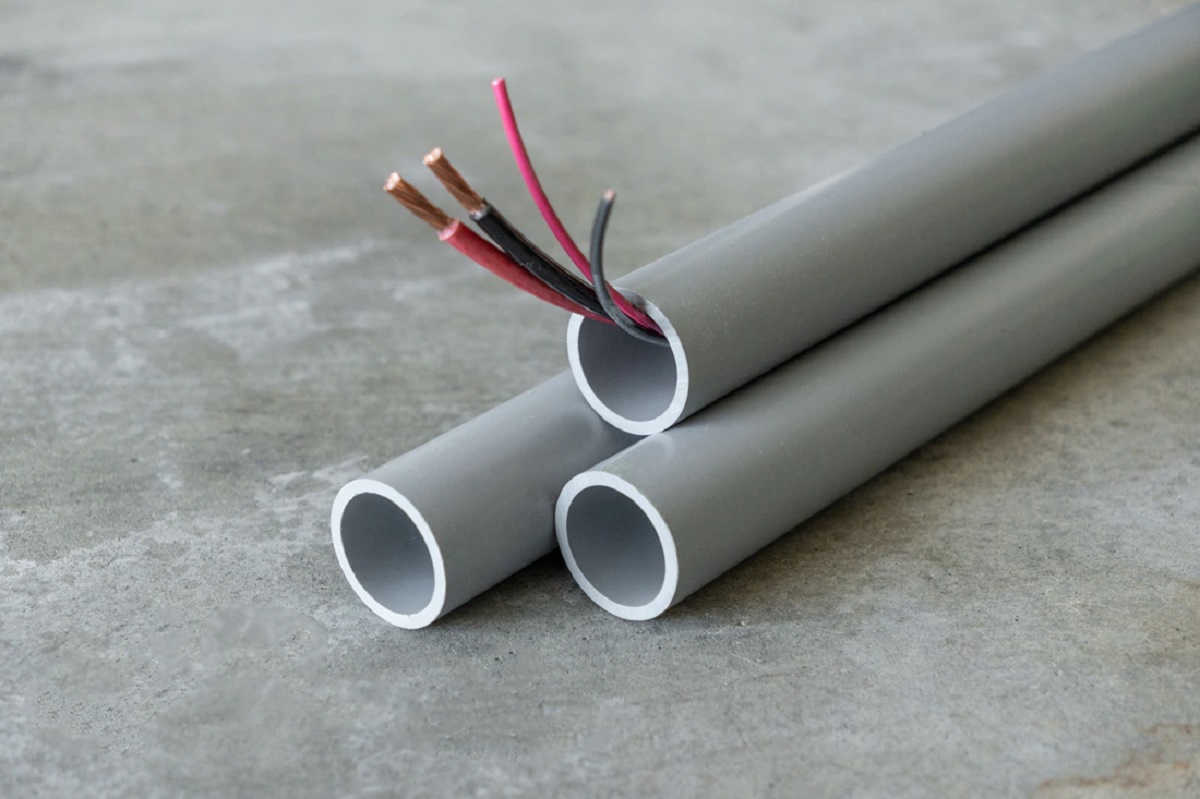

When it comes to electrical installations, conduit systems play a crucial role in keeping wires and cables organized and protected. A conduit run, especially a straight one, needs to provide a designated point for pulling the wires through, ensuring ease of installation and maintenance.

In order to achieve this, conduit bodies are used along the conduit run to serve as pull points. These conduit bodies not only facilitate the pulling of wires but also provide accessibility for future modifications or repairs. In this article, we will explore the different types of conduit bodies that are commonly used to provide a pull point on a straight conduit run.

By understanding the purpose and characteristics of these conduit bodies, electricians and installers can make informed decisions when planning and implementing electrical installations, ensuring both efficiency and safety.

Key Takeaways:

- Conduit bodies, such as LB, LL, and T types, are essential for creating pull points in straight conduit runs, facilitating wire pulling and ensuring accessibility for future maintenance and modifications.

- Pull points in straight conduit runs can be established using pull boxes, conduit bodies with pull elbows, threaded conduit openings, pull tape or rope, and wire pulling tools, ensuring efficient and organized wire installation.

Read more: What Is A Conduit Body Used For

Conduit Bodies

Conduit bodies, also known as junction boxes or conduit fittings, are components that are installed along a conduit run to provide a point of connection and access for wires and cables. They are typically made of durable materials such as metal or PVC and are designed to withstand the rigors of electrical installations.

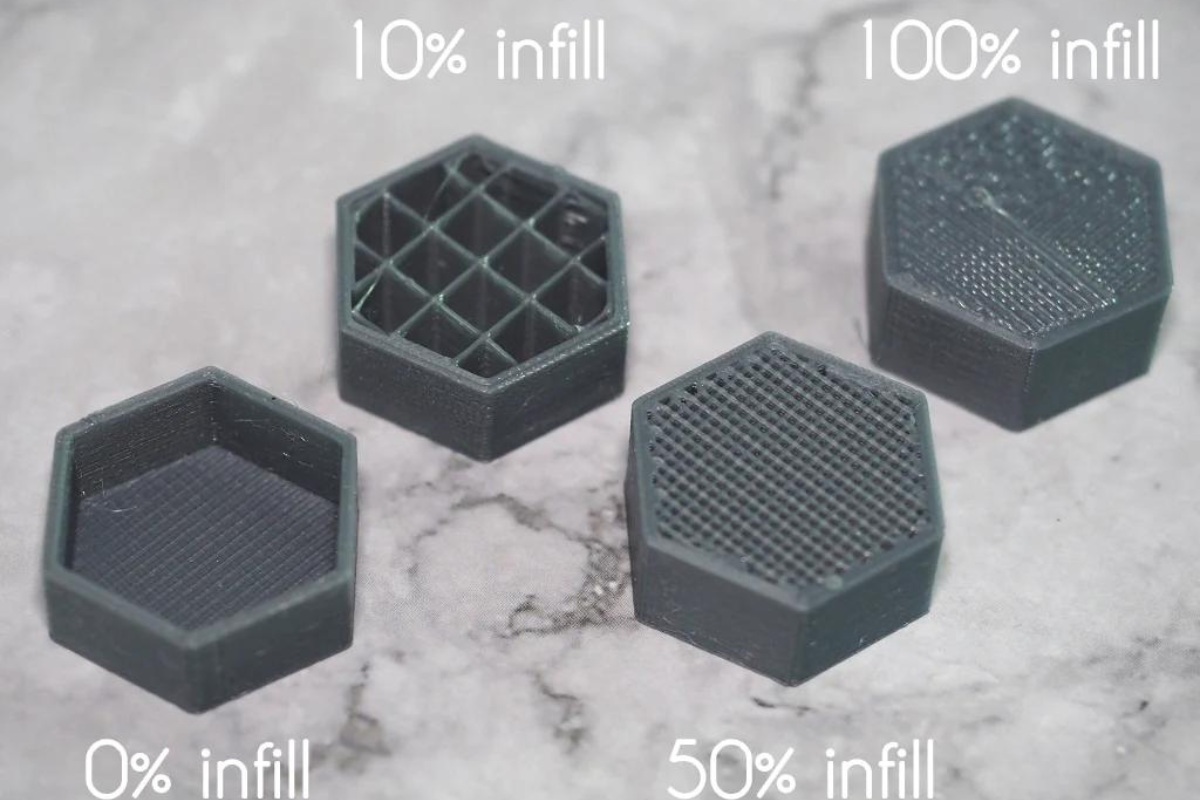

These conduit bodies come in various shapes and sizes, depending on the specific application and the type of conduit being used. Some common shapes include rectangular, round, and square, but they all serve the same fundamental purpose of facilitating wire pulling and providing access to the conduit.

Conduit bodies are equipped with threaded openings or knockouts to accommodate conduit connectors or fittings. These openings allow for the installation of wires, cables, or additional conduit sections, depending on the specific configuration required.

It is worth noting that conduit bodies are different from conduit elbows or bends, which are used to change the direction of a conduit run. While elbows are used for making turns, conduit bodies primarily serve the purpose of providing a pull point and accessibility within a straight conduit run.

Purpose of Conduit Bodies in a Straight Conduit Run

The use of conduit bodies in a straight conduit run serves several important purposes that contribute to the overall functionality and efficiency of an electrical installation.

Firstly, conduit bodies act as pull points, providing a designated location for pulling wires and cables through the conduit. This makes the installation process much easier and ensures that the wires are properly routed and organized within the system. Without conduit bodies, it would be challenging to pull wires through long stretches of conduit, increasing the risk of tangling or damaging the wires.

Secondly, conduit bodies allow for easy access to the interior of the conduit. This is particularly beneficial for future modifications and repairs. If there is a need to add or remove wires or make changes to the electrical system, conduit bodies provide a convenient entry point for electricians to access the conduit without having to dismantle the entire run. This saves time and effort during maintenance or upgrades.

Moreover, conduit bodies contribute to the overall safety of the electrical installation. They help to protect the wires and cables from external elements such as moisture, dust, and physical damage. By enclosing the electrical wiring within the conduit and providing a secure connection point, conduit bodies minimize the risk of electrical hazards and ensure compliance with safety regulations.

Lastly, conduit bodies also assist in managing wiring stress and preventing excessive bending or pulling of wires. They provide enough space for wire bending and allow for proper spacing between the wires, reducing the likelihood of damage or failure due to strain. This is especially crucial in industrial or commercial settings where the electrical system may be subject to constant vibrations or movements.

Overall, the inclusion of conduit bodies in a straight conduit run enhances the functionality, accessibility, and safety of the electrical installation. It streamlines the wire pulling process, facilitates future modifications, and protects the wiring from external elements, ensuring a reliable and efficient electrical system.

Use conduit bodies such as LB, LL, LR, or C to provide a pull point on a straight conduit run. These bodies allow for easy access to pull and maintain wires.

Types of Conduit Bodies

There are several different types of conduit bodies available, each designed to serve specific functions and accommodate different installation requirements. Here are the most commonly used types:

- LB Conduit Body: The LB conduit body, also known as the “Lightning Bend,” is shaped like the letter “L.” It is typically used to make a 90-degree turn in a conduit run. LB conduit bodies are often used when the conduit needs to change direction horizontally, either upward or downward.

- LL Conduit Body: The LL conduit body, also known as the “Long Turn,” has a longer radius than the LB. It is used to make a more gradual 90-degree turn, reducing the likelihood of wire damage from tight bends. LL conduit bodies are commonly used in larger conduit runs or situations where there are multiple bends required.

- LR Conduit Body: The LR conduit body, also known as the “Long Radius,” is similar to the LL but is used for turning a conduit run vertically. It allows for a smooth and gradual 90-degree turn, ensuring proper wire management and minimizing stress on the cables.

- T Conduit Body: The T conduit body, also known as the “Tee,” is used when a conduit run needs to branch off in a perpendicular direction. It features three openings: one for the main conduit run and two for attaching additional conduit sections.

- C Conduit Body: The C conduit body, also known as the “Crossover,” is designed for applications where two conduits need to cross paths. It provides a junction point for the conduits to intersect without disrupting the continuity of the wiring.

- FS Conduit Body: The FS conduit body, also known as the “Flat Square,” is a flat, rectangular conduit body that is often used in tight spaces where a 90-degree bend is required. Its compact design allows for easy installation and access to the wires within the conduit.

These are just a few examples of the different types of conduit bodies available. Choosing the right type depends on the specific needs of the electrical installation, including the direction of the conduit run, the degree of turns required, and any branching or crossover points.

It is important to consult the relevant electrical codes and standards to ensure that the chosen conduit bodies comply with safety regulations and are suitable for the intended application.

Pull Points in a Straight Conduit Run

In a straight conduit run, pull points are essential for facilitating the process of pulling wires through the conduit. These pull points serve as designated locations where the wires can be easily accessed and guided through the conduit, ensuring a smooth and efficient installation.

Here are some common methods and techniques used to create pull points in a straight conduit run:

- Pull Boxes: Pull boxes are large conduit bodies that are specifically designed to provide ample space for wire pulling. They are typically installed at intervals along the conduit run, allowing for easy access and maneuverability of the wires. Pull boxes are particularly useful in long conduit runs or installations where multiple wires need to be pulled simultaneously.

- Conduit Bodies with Pull Elbows: Some conduit bodies are specially designed with built-in pull elbows. These elbows are angled connectors located at the sides of the conduit body, providing a direct and accessible path for pulling wires. The pull elbows eliminate the need for separate pulling elbows and ensure a smooth transition for the wires as they enter and exit the conduit body.

- Threaded Conduit Openings: Conduit bodies with threaded openings or knockouts can be used as pull points. By attaching conduit connectors or fittings to these openings, wires can be easily pulled through the conduit. The threaded openings provide a secure and sealed connection for the wires, ensuring proper wire management and protecting them from external elements.

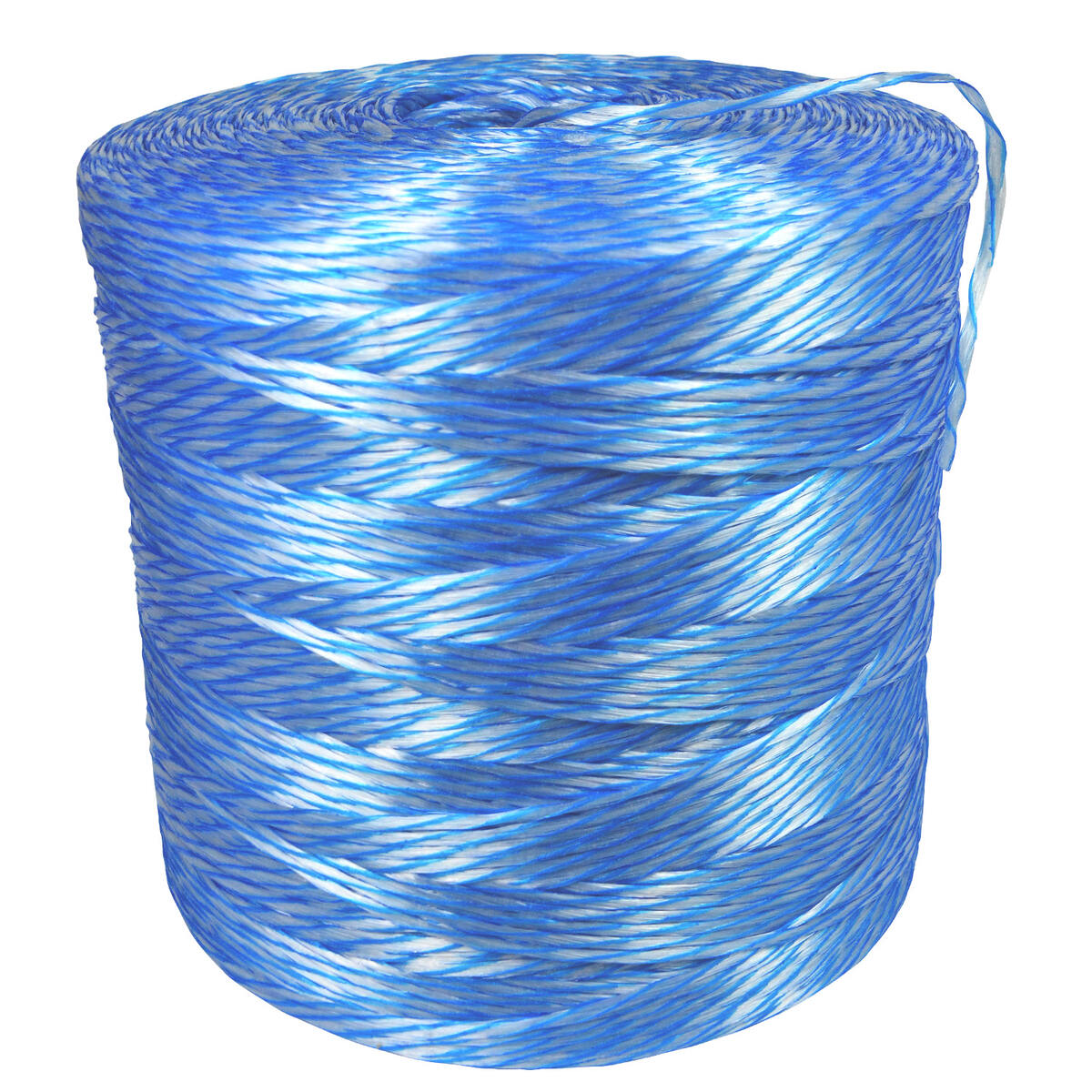

- Pull Tape or Rope: Pull tape or rope can be threaded through the conduit before the wire pulling process. By attaching the tape or rope to the wires, installers can easily pull the wires through the entire conduit run. This method is often used when there are long or complex conduit runs where access to pull boxes or conduit bodies is limited.

- Wire Pulling Tools: Various wire pulling tools, such as fish tapes or conduit rods, can be used to navigate through the conduit and guide the wires. These tools help to push or pull the wires along the conduit, ensuring a proper and secure installation process.

Creating appropriate pull points in a straight conduit run is essential for minimizing wire damage, reducing installation time, and ensuring a successful electrical installation. By strategically placing pull boxes, utilizing conduit bodies with pull elbows, using pull tape or rope, and employing wire pulling tools, electricians can effectively manage the wire pulling process, ensuring a neat and organized configuration within the conduit.

Conclusion

Conduit bodies play a crucial role in providing pull points and ensuring the functionality and efficiency of a straight conduit run. They not only facilitate the pulling of wires but also provide accessibility for future modifications and repairs. By selecting the appropriate conduit bodies, electricians and installers can ensure a smooth and secure installation process while adhering to safety standards.

We explored the different types of conduit bodies commonly used in a straight conduit run, including LB, LL, LR, T, C, and FS conduit bodies. Each type serves a specific function, such as making turns, branching off, or crossing over, depending on the specific requirements of the installation. By understanding the purpose and characteristics of these conduit bodies, professionals can make informed decisions when planning and implementing electrical systems.

Pull points are crucial in a straight conduit run, providing designated locations for pulling wires through the conduit. Pull boxes, conduit bodies with pull elbows, threaded conduit openings, pull tape or rope, and wire pulling tools are all viable options for creating effective pull points. These methods help streamline the wire pulling process, minimize wire damage, and ensure a successful and organized installation.

In conclusion, the use of conduit bodies and the establishment of pull points in a straight conduit run are essential for efficient and safe electrical installations. By utilizing the appropriate conduit bodies and implementing proper wire pulling techniques, electricians can achieve a neat and reliable configuration of wires within the conduits, enhancing the overall functionality and longevity of the electrical system.

Remember to always consult electrical codes and standards to ensure compliance and safety in any electrical installation project. With careful planning and the appropriate use of conduit bodies, professionals can optimize their installations and provide a reliable electrical infrastructure for years to come.

Interested in mastering the art of electrical installations? Learning how to navigate conduits is crucial, and our next piece on wire pulling offers practical guidance for efficiently threading cables through various conduit types. This step-by-step guide helps streamline your wiring projects, ensuring you're equipped to handle any challenge with confidence. Don't miss out—dive into our helpful insights to improve your skills today!

Frequently Asked Questions about Which Types Of Conduit Bodies Are Used To Provide A Pull Point On A Straight Conduit Run?

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “Which Types Of Conduit Bodies Are Used To Provide A Pull Point On A Straight Conduit Run?”