Home>Articles>What Is The Electromagnet In An Electric Motor Called

Articles

What Is The Electromagnet In An Electric Motor Called

Modified: October 20, 2024

Discover what the electromagnet in an electric motor is called and how it works. Read our informative articles on this fascinating topic.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Electric motors play a crucial role in various applications, from powering industrial machinery to running household appliances. At the heart of every electric motor lies an essential component called the electromagnet. This article will explore the fundamentals of electromagnets in electric motors, how they work, and their significance in driving the functionality of these motors.

Electric motors are widely used due to their efficiency, reliability, and versatility. They come in different sizes and power capacities to cater to diverse requirements. Whether you’re using a ceiling fan, a washing machine, or a car, chances are you’re benefiting from the power of an electric motor.

Understanding the principles behind electric motors is essential to comprehend the electromagnet’s function within them. Electric motors rely on magnetism and electromagnetism to convert electrical energy into mechanical energy, enabling them to perform various tasks efficiently. To grasp the concept of the electromagnet in electric motors, we first need to delve into the basics of these motors.

Key Takeaways:

- Electromagnets are the powerhouse of electric motors, creating magnetic fields for efficient energy conversion and precise control. They drive the functionality of motors in diverse applications, from industrial machinery to household appliances.

- Different types of electromagnets, from wound coils to permanent magnets, offer versatility and adaptability in motor design. Their unique characteristics cater to specific requirements, ensuring efficient and precise operation.

Read more: What Is An Electric Motor Capacitor?

The Basics of an Electric Motor

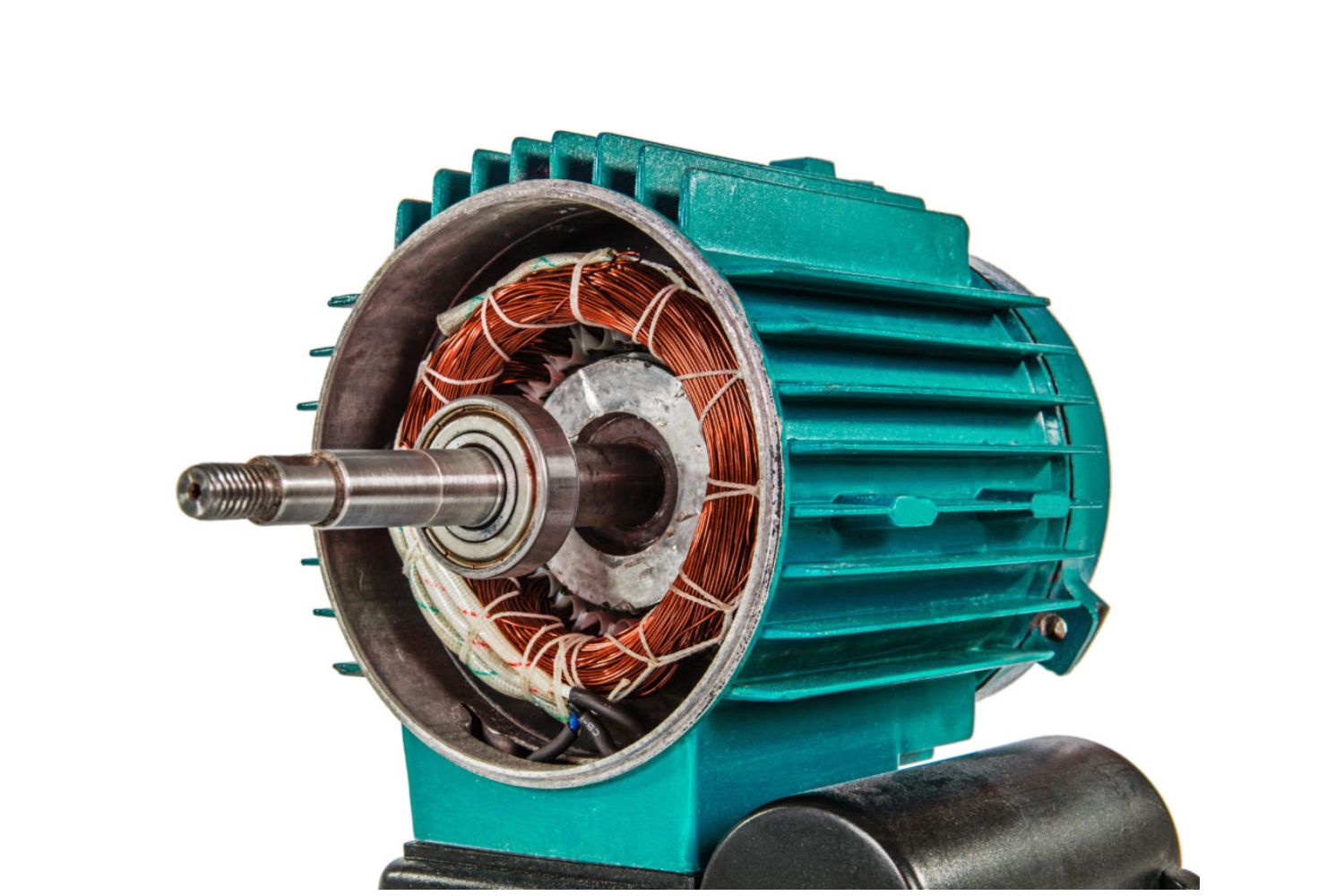

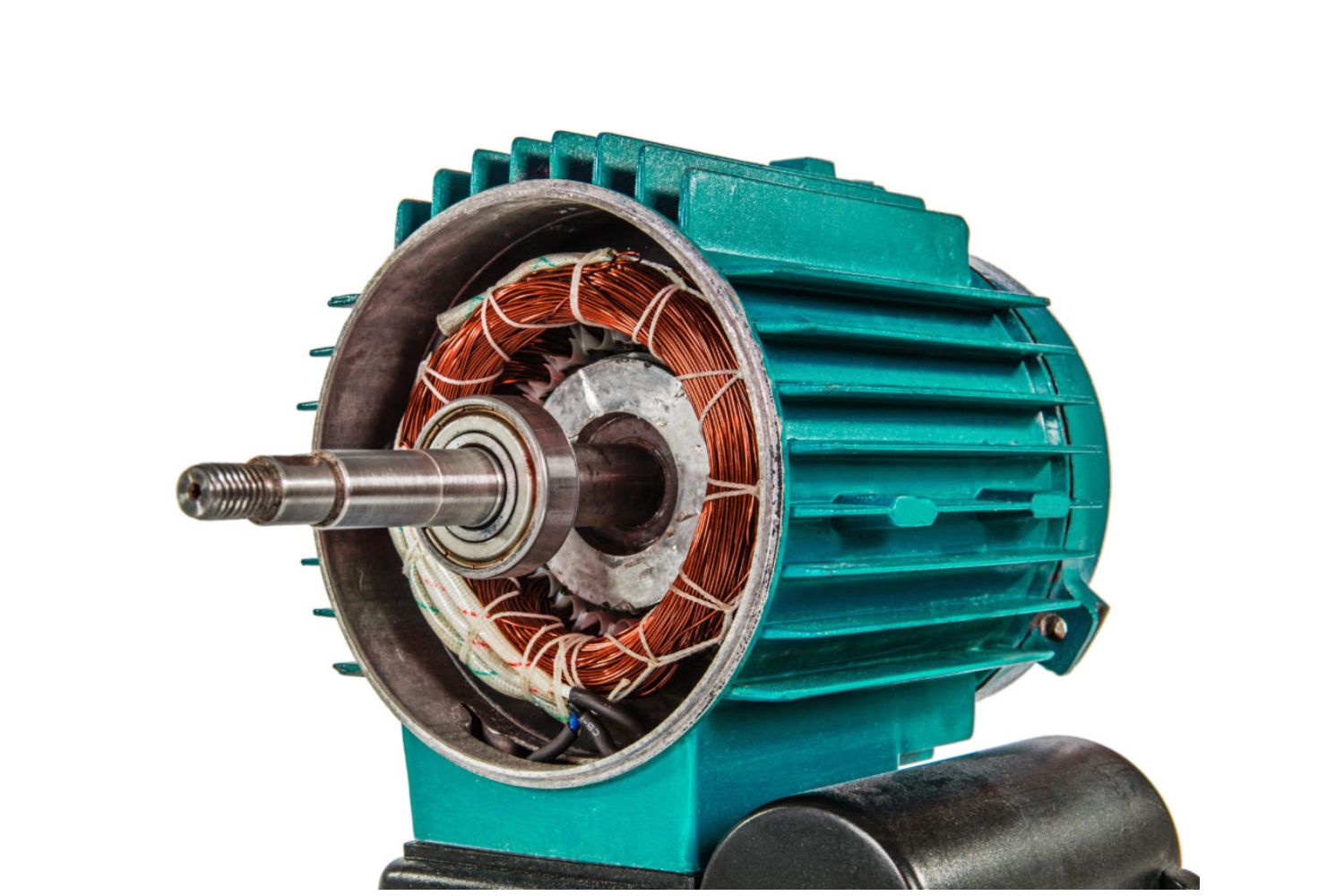

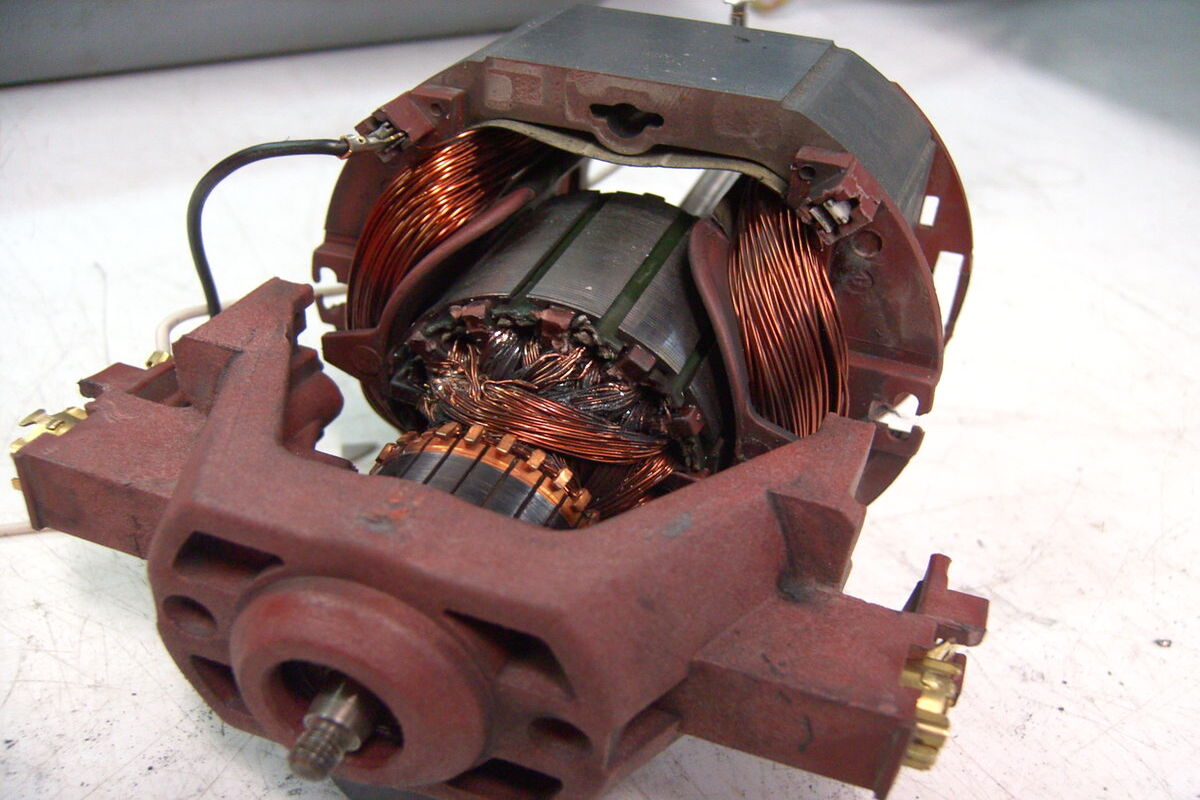

An electric motor is a device that converts electrical energy into mechanical energy. It consists of several components working together to create rotational motion. The primary components of an electric motor include the stator, rotor, and the electromagnet.

The stator is the stationary part of the motor and is typically made up of multiple coils of wire wrapped around a metal core. These coils are connected to an external power source, supplying the necessary current to generate a magnetic field.

The rotor, on the other hand, is the rotating part of the motor. It is mounted on a shaft and sits inside the stator. The rotor contains a series of electromagnets or permanent magnets that interact with the magnetic field produced by the stator. When current flows through the electromagnets in the rotor, it creates a magnetic field that interacts with the stator’s magnetic field, resulting in rotational motion.

The electromagnet, which we will focus on in this article, is a crucial component of an electric motor. It is responsible for generating the magnetic field required to induce motion in the rotor. Unlike permanent magnets that have a fixed magnetic field, electromagnets can be controlled by varying the current passing through their coils.

Now that we have a basic understanding of electric motors, let’s dive into the concept of electromagnetism and its role in driving the functionality of these motors.

Understanding Electromagnetism

Electromagnetism is a fundamental concept in physics that describes the relationship between electricity and magnetism. It was first discovered by the Danish physicist Hans Christian Ørsted in 1820. He observed that an electric current flowing through a wire created a magnetic field around it.

In electromagnetism, an electric field is produced by stationary electric charges, while a magnetic field is created by moving electric charges or electric currents. When an electric current flows through a conductor, such as a wire, it generates a magnetic field around the conductor. This phenomenon is the basis for electromagnetism.

Electromagnets utilize this concept to generate a strong magnetic field by passing an electric current through a coil of wire wound around a ferromagnetic core. The ferromagnetic material, such as iron or steel, enhances the magnetic properties of the coil, making the resulting magnetic field stronger.

The strength of the magnetic field produced by an electromagnet depends on various factors, including the number of turns in the coil, the magnitude of the current flowing through it, and the properties of the core material. By controlling these factors, the strength of the electromagnet can be adjusted to meet specific requirements.

Electromagnetism is not only significant in the context of electric motors but also finds applications in various other fields. It is used in generators, transformers, magnetic resonance imaging (MRI) machines, particle accelerators, and many other devices.

Now that we have a grasp of the fundamentals of electromagnetism, let’s move on to exploring the specific role of electromagnets in electric motors.

The Role of Electromagnet in Electric Motors

The electromagnet is a crucial component of an electric motor, playing a vital role in its functionality. It is responsible for creating the magnetic field needed to induce motion in the rotor, thereby generating the mechanical energy required for the motor to perform its task.

When an electric current passes through the coils of the electromagnet, it generates a magnetic field around the coils. This magnetic field interacts with the magnetic field produced by the stator, which is the stationary part of the motor, resulting in rotational motion.

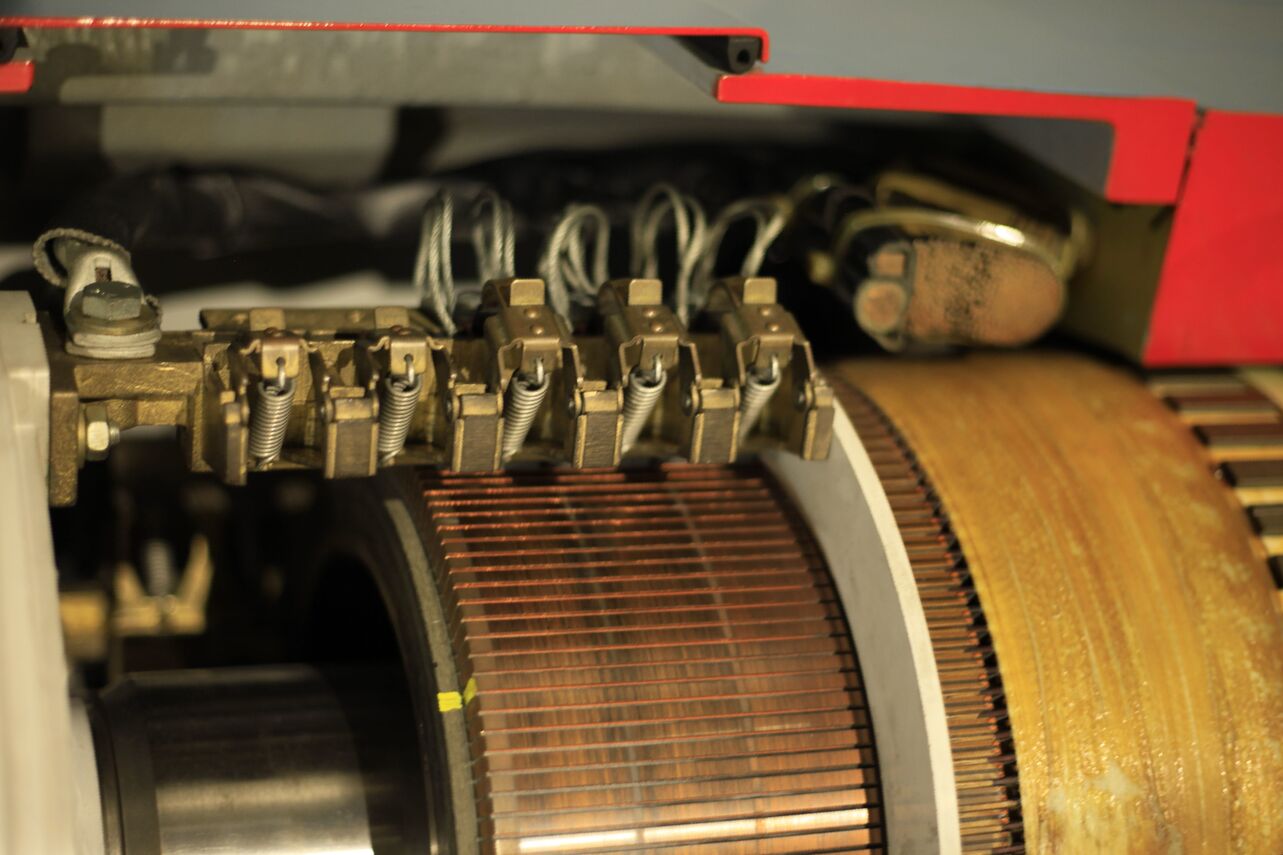

The electromagnet is typically located in the rotor of the motor. It can be either a wound electromagnet, which consists of a coil of wire wound around a ferromagnetic core, or a permanent magnet that generates a constant magnetic field. Both types of electromagnets have their advantages and are chosen based on the specific requirements of the motor.

For electric motors that require a high degree of control over the magnetic field, such as those used in industrial machinery, wound electromagnets are commonly used. These electromagnets allow for precise adjustment of the magnetic field strength by varying the current passing through the coil. By controlling the electromagnet, the speed and torque of the motor can be easily regulated.

On the other hand, permanent magnets are often used in smaller motors, such as those found in household appliances. These magnets generate a constant magnetic field without the need for an external power source. They are reliable, efficient, and require less maintenance compared to wound electromagnets.

Regardless of the type used, the electromagnet plays a pivotal role in creating the magnetic field required to induce motion in the rotor of the electric motor. Without the electromagnet, the motor would not be able to convert electrical energy into mechanical energy and perform its intended function.

Now that we understand the role of the electromagnet in electric motors, let’s explore the components that make up an electromagnet and how they work together to create the magnetic field.

Components of an Electromagnet

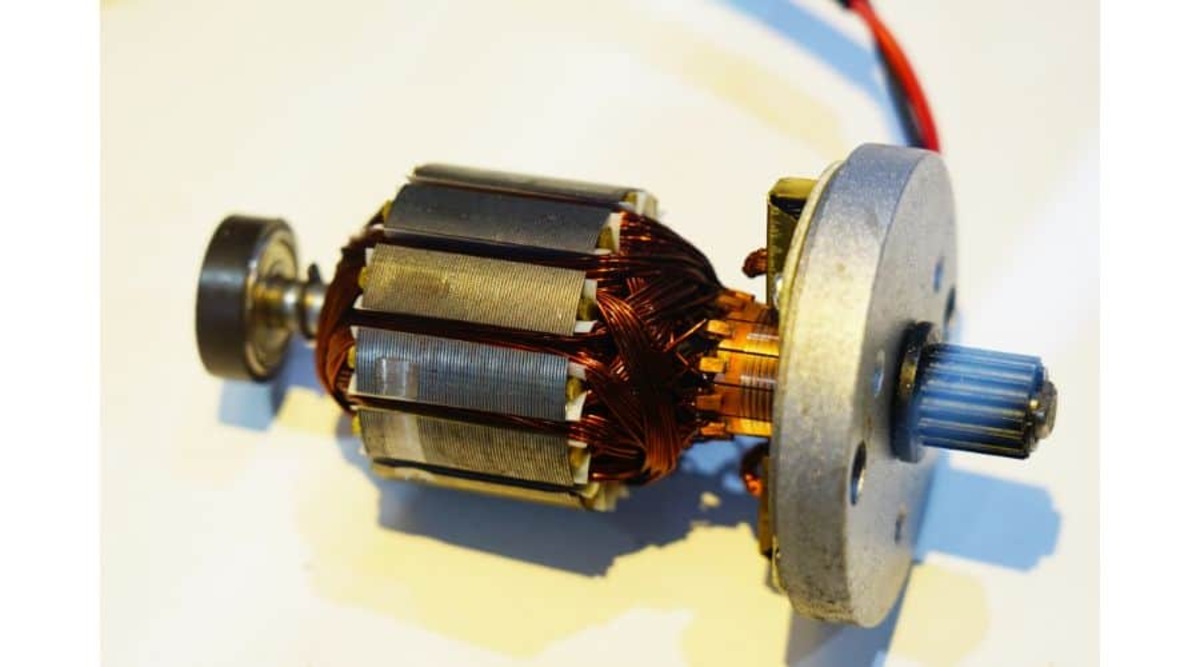

An electromagnet is composed of several key components that work together to create a magnetic field. These components include the core material, the coil, and the power source.

The core material is a ferromagnetic substance that enhances the magnetic properties of the electromagnet. Common materials used as the core include iron, steel, and nickel. The core’s role is to concentrate and channel the magnetic flux produced by the coil, making the magnetic field stronger.

The coil, also known as the winding, is made up of insulated wire. It is wound around the core to form multiple loops or turns. When an electric current flows through the coil, it creates a magnetic field around the core based on the right-hand rule, where the direction of the magnetic field lines is determined by the direction of the current flow. Increasing the number of turns in the coil increases the strength of the magnetic field produced by the electromagnet.

The power source, typically a direct current (DC) supply, provides the necessary electrical energy to drive the electromagnet. It is connected to the ends of the coil, allowing the current to flow through and generate the magnetic field. The power source should provide the appropriate voltage and current to meet the electromagnet’s requirements, ensuring optimal performance.

Additionally, to control the magnetic field strength and achieve the desired functionality, the electromagnet may be equipped with an adjustable magnetic field control device. This device, such as a rheostat or a variable resistor, allows for the regulation of the current flowing through the coil. By adjusting the current, the strength of the magnetic field can be increased or decreased as needed.

Together, the core, coil, and power source form the essential components of an electromagnet. The interaction between these components enables the creation of a magnetic field, which plays a crucial role in driving the functionality of an electric motor.

Next, let’s delve into the working principle of an electromagnet in an electric motor to better understand its role in converting electrical energy into mechanical energy.

The electromagnet in an electric motor is called the armature. It is a core component that interacts with the magnetic field to produce motion.

Read more: What Causes An Electric Motor To Overheat

The Working Principle of an Electromagnet in an Electric Motor

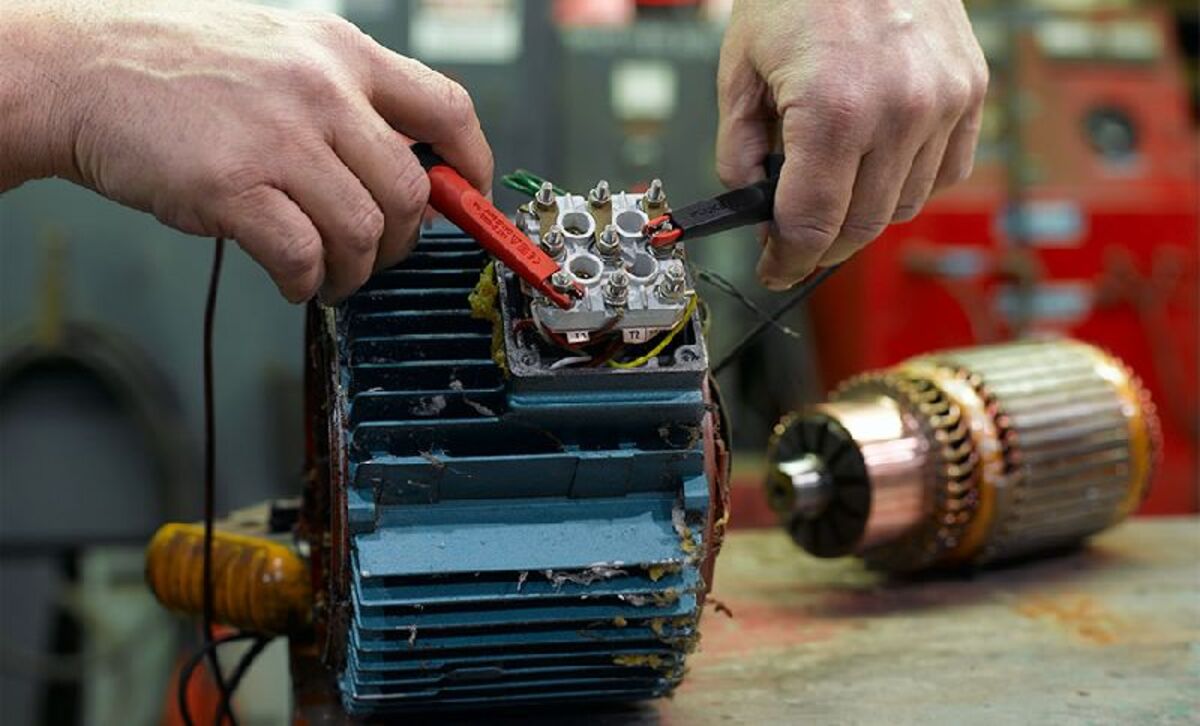

The working principle of an electromagnet in an electric motor involves the interaction between the magnetic fields produced by the stationary stator and the rotating rotor. This interaction creates a force that induces rotational motion, allowing the conversion of electrical energy into mechanical energy.

When an electric current flows through the coils of the electromagnetic stator, it generates a magnetic field around the stator. This magnetic field remains stationary due to the fixed position of the stator.

Simultaneously, the rotor, which houses the electromagnet, also contains a magnetic field. This magnetic field can be generated by either a wound electromagnet or a permanent magnet, depending on the motor type.

As the rotor spins, the magnetic field of the rotor interacts with the magnetic field of the stationary stator. These magnetic fields are either attracted to each other or repelled, depending on their polarities.

The interaction between the magnetic fields causes a force that pushes or pulls the rotor, inducing rotational motion. This rotational motion is transferred from the rotor to an external load, such as a fan blade or a conveyor belt, enabling the motor to perform its intended task.

The speed and torque of the motor can be controlled by adjusting the current flowing through the coils of the electromagnet. Increasing the current will strengthen the magnetic field, resulting in higher torque and faster rotation. Conversely, decreasing the current will weaken the magnetic field, reducing the torque and slowing down the rotation.

The working principle of an electromagnet in an electric motor relies on the electromagnetic phenomenon, where the interaction between magnetic fields generates a force. By harnessing this force, electrical energy is transformed into mechanical energy, allowing the motor to achieve its desired function.

Now that we have covered the working principle of an electromagnet in an electric motor, let’s dive into the importance of electromagnets in driving the functionality of these motors.

Importance of Electromagnets in Electric Motors

Electromagnets play a vital role in the functionality and efficiency of electric motors. Without electromagnets, electric motors would not be able to convert electrical energy into mechanical energy and perform their intended tasks. Here are some key reasons why electromagnets are important in electric motors:

1. Magnetic Field Generation: Electromagnets are responsible for creating the magnetic field required to induce motion in the rotor of the motor. This magnetic field interacts with the stationary stator’s magnetic field and generates a force that drives the rotation of the motor. The ability to control the strength of the magnetic field allows for precise regulation of the motor’s speed and torque.

2. Efficient Energy Conversion: The use of electromagnets in electric motors ensures efficient energy conversion. By adjusting the current flowing through the coils of the electromagnet, the magnetic field strength can be optimized. This optimization minimizes energy loss and improves the motor’s overall efficiency, resulting in reduced energy consumption.

3. Versatility: Electromagnets offer versatility in electric motor design. They can be wound electromagnets or permanent magnets, allowing flexibility in motor construction and performance. Wound electromagnets provide greater control and adjustability, making them suitable for applications that require precise speed control, such as industrial machinery. Permanent magnets, on the other hand, offer simplicity, reliability, and maintenance-free operation, making them ideal for smaller motors used in various household appliances.

4. Adaptability and Compatibility: Electromagnets can be designed to generate magnetic fields with specific strengths and characteristics, tailored to meet the requirements of different applications. This adaptability ensures that electric motors can be effectively utilized across various industries, from aerospace to automotive, from manufacturing to home appliances. Additionally, electromagnets can be easily integrated into existing motor designs, allowing for compatibility and seamless upgrades.

5. Control and Precision: The ability to control the magnetic field by adjusting the current in the electromagnet enables precise control and operation of the electric motor. This level of control allows for precise speed regulation, direction control, and torque adjustment, making electromagnets essential in applications that require high precision and accuracy, such as robotics, medical equipment, and CNC machines.

Overall, electromagnets are integral to the efficient and effective operation of electric motors. They provide the necessary magnetic fields for motion induction, enable energy conversion, offer versatility in motor design, and allow for precise control and adaptability. These characteristics make electromagnets a key component in driving the functionality and performance of electric motors in a wide range of applications.

Now that we’ve explored the importance of electromagnets in electric motors, let’s delve into the different types of electromagnets commonly used in these motors.

Types of Electromagnets Used in Electric Motors

Electric motors utilize various types of electromagnets to generate the magnetic fields required for their operation. The choice of electromagnet type depends on factors such as the motor’s size, power requirements, and intended application. Here are some common types of electromagnets used in electric motors:

1. Wound Electromagnets: Wound electromagnets, also known as field coils, consist of a coil of wire wound around a ferromagnetic core. The wire is typically made of copper or aluminum and is insulated to prevent short circuits. Wound electromagnets allow for precise control of the magnetic field strength by varying the current flowing through the coil. They are commonly used in motors that require adjustable speed control and high torque, such as those used in industrial machinery and electric vehicles.

2. Permanent Magnets: Permanent magnets are another type of electromagnet used in electric motors. These magnets are made from materials with high magnetic properties, such as neodymium, ferrite, or samarium cobalt. Permanent magnets generate a constant magnetic field without the need for an external power source. They are commonly used in smaller motors, such as those found in household appliances and computer fans, due to their simplicity, reliability, and efficiency.

3. Hybrid Electromagnets: Hybrid electromagnets combine the benefits of both wound electromagnets and permanent magnets. They incorporate a combination of wound coils and permanent magnets in the motor design. The wound coils provide adjustable control over the magnetic field strength, while the permanent magnets offer additional magnetic field stability and efficiency. Hybrid electromagnets are often used in electric vehicles and high-performance motors that require a balance between control and power.

4. Variable Reluctance Electromagnets: Variable reluctance electromagnets are unique in their design and operation. They consist of a ferromagnetic rotor with teeth and a stator with multiple wound coils. The teeth on the rotor create variations in the magnetic reluctance as they pass the coils, inducing a rotational force. Variable reluctance electromagnets are commonly used in stepper motors and in applications that require precise control and positioning, such as robotics and automation systems.

5. Hybrid Stepper Motor Electromagnets: Hybrid stepper motors combine the features of permanent magnets and variable reluctance electromagnets. The rotor includes permanent magnets, while the stator contains both wound coils and teeth for variable reluctance. This combination allows for precise control of the rotor’s position, making hybrid stepper motors suitable for applications that require high precision and accuracy, such as 3D printers, CNC machines, and robotics.

These are just a few examples of the various types of electromagnets used in electric motors. Each type has its advantages and applications, offering different levels of control, power, and efficiency. The choice of electromagnet type depends on the specific requirements of the motor and the intended use in different industries and applications.

Now that we have explored the different types of electromagnets, let’s summarize the key points of the article.

Conclusion

Electric motors, with their ability to convert electrical energy into mechanical energy, have revolutionized countless industries and powered our everyday devices. At the heart of every electric motor, the electromagnet plays a crucial role in generating the magnetic field needed for motion induction. Through the principles of electromagnetism and magnetic field interaction, electric motors are able to efficiently perform a wide range of tasks.

We have explored the basics of an electric motor, understanding its components, such as the stator, rotor, and electromagnet. We also delved into the concept of electromagnetism, recognizing its role in creating magnetic fields through the flow of electric current. Understanding the importance of electromagnets in electric motors, we discovered their significance in efficient energy conversion, versatility in design, adaptability, and precision control.

We discussed different types of electromagnets commonly used in electric motors, such as wound electromagnets, permanent magnets, hybrid electromagnets, variable reluctance electromagnets, and hybrid stepper motor electromagnets. Each type has its unique characteristics and is chosen based on the motor’s requirements and intended application.

From powering industrial machinery to running household appliances, electric motors have become an indispensable part of our daily lives. Their ability to efficiently convert electrical energy to mechanical energy, facilitated by electromagnets, enables us to enjoy the comfort and convenience of modern technology.

In conclusion, electromagnets are the driving force behind the functionality and performance of electric motors. Their ability to create magnetic fields, control their strength, and induce rotational motion enables the motors to perform a wide range of tasks with precision and efficiency. As technology continues to advance, electromagnets will continue to play a critical role in powering our world.

Thank you for joining us on this journey to explore the world of electromagnets in electric motors. We hope this article has provided you with valuable insights into this fascinating field.

Frequently Asked Questions about What Is The Electromagnet In An Electric Motor Called

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is The Electromagnet In An Electric Motor Called”