Articles

What Makes An Electric Motor More Powerful

Modified: September 2, 2024

Discover the secrets behind powerful electric motors with our informative articles. Explore the key factors that contribute to enhanced motor performance and efficiency.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Electric motors play a crucial role in a wide range of industries and applications. From powering appliances and vehicles to driving industrial machinery, electric motors are an essential component of many everyday devices. The power of an electric motor is a key factor that determines its performance and efficiency. But what exactly makes an electric motor more powerful? In this article, we will explore the various factors that influence motor power and discuss how to enhance its performance.

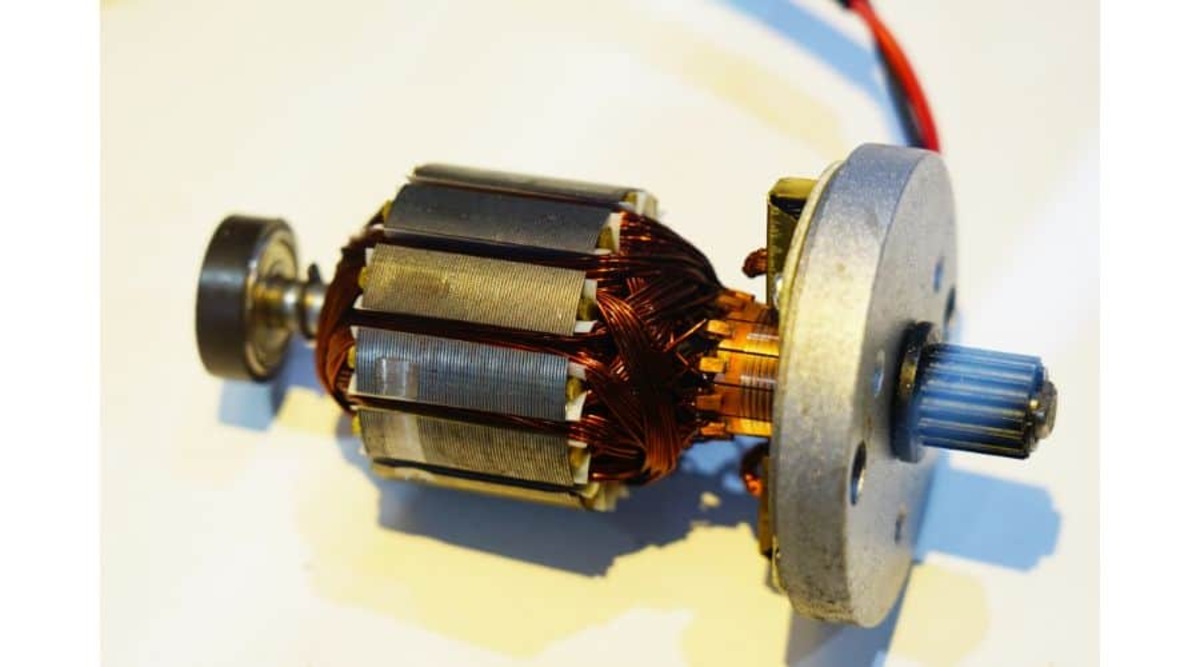

Understanding the inner workings of an electric motor is essential to grasp the concept of motor power. Electric motors function by converting electrical energy into mechanical energy through the interaction of magnetic fields. Inside the motor, a rotor, usually made of coils, spins within a stator, which contains permanent magnets or electromagnets. This spinning motion generates mechanical power that drives the motor’s intended application.

Several factors contribute to the power output of an electric motor. Each of these factors affects the overall power of the motor and can be adjusted to optimize performance. Let’s dive into the key factors influencing motor power:

Key Takeaways:

- Optimizing voltage, current, wire size, magnetic field strength, efficiency, and motor design can enhance the power output of electric motors, driving innovation and efficiency across various industries.

- Balancing power output and energy efficiency is crucial for maximizing the potential of electric motors. Careful consideration and optimization of key factors can lead to more powerful and efficient motor performance.

Read more: What Is An Electric Motor Capacitor?

Understanding Electric Motors

Electric motors are complex devices that utilize electromagnetic principles to convert electrical energy into mechanical energy. They consist of several key components that work together to achieve this conversion process.

At the core of an electric motor is the rotor, which is the rotating part. The rotor is usually made up of wire coils wound around a metal core. These coils create an electromagnetic field when a current flows through them. Surrounding the rotor is the stator, which is the stationary part of the motor. The stator contains permanent magnets or electromagnets that produce a magnetic field.

When electricity is supplied to the motor, it creates a magnetic field in the rotor. The interaction of this magnetic field with the stator’s magnetic field creates a force that causes the rotor to rotate. This rotation, in turn, generates mechanical power. The speed of the rotor’s rotation is determined by the frequency and amplitude of the electrical signal applied to the motor.

Electric motors come in various types, including DC motors and AC motors. DC motors operate using direct current, while AC motors run on alternating current. Both types have their advantages and are used in different applications based on their specific characteristics.

DC motors are known for their simplicity and control, making them suitable for applications that require precise speed control or high starting torque. They are widely used in robotics, electric vehicles, and small appliances.

On the other hand, AC motors are more common in industrial and residential applications. They are efficient and require less maintenance compared to DC motors. AC motors can be further classified into synchronous and asynchronous motors based on the way the rotor rotates in relation to the stator’s magnetic field.

Understanding the basics of how electric motors work is key to comprehending the factors that influence their power output. Let’s explore these factors in more detail to understand what makes an electric motor more powerful.

Factors Influencing Motor Power

The power output of an electric motor is influenced by several factors that affect its performance and efficiency. These factors determine the motor’s ability to convert electrical energy into mechanical power. Let’s explore the key factors that influence motor power:

-

Voltage

The voltage supplied to the motor plays a significant role in determining its power output. Higher voltages generally result in higher power output. This is because higher voltages allow for greater current flow through the motor’s coils, which translates into a stronger magnetic field and increased torque. However, it’s important to ensure that the motor is designed to handle the specific voltage supplied to avoid damage or overheating.

-

Current

The current flowing through the motor is directly proportional to its power output. A higher current results in a stronger magnetic field, which leads to increased torque and power. However, it’s crucial to balance the current to prevent exceeding the motor’s rated capacity, as excessive current can cause overheating and damage to the motor.

-

Read more: What Causes An Electric Motor To Overheat

Wire Size

The size and thickness of the wire used in the motor’s coils can impact its power output. Thicker wires have lower resistance, allowing for higher current flow and reducing power loss due to resistance. This results in improved power efficiency and output. Additionally, using high-quality copper wire with good conductivity further enhances the motor’s power and performance.

-

Magnetic Field Strength

The strength of the magnetic field produced by the motor’s coils has a direct impact on its power output. By increasing the number of turns in the coil or using stronger permanent magnets or electromagnets in the stator, the magnetic field strength can be enhanced. A stronger magnetic field leads to increased torque and power, resulting in a more powerful motor.

-

Efficiency

The efficiency of an electric motor also affects its power output. Higher efficiency means less energy is lost as heat, resulting in more of the electrical energy being converted into mechanical power. Factors that contribute to motor efficiency include the design and materials used, as well as minimizing friction and resistance within the motor.

-

Motor Design

The design of the motor itself has a significant impact on its power output. Factors such as the number of poles, the configuration of the coils, and the type of rotor and stator all play a role. Motors designed for high power applications often incorporate advanced features such as improved cooling mechanisms, optimized magnetic flux paths, and reduced internal losses, resulting in higher power output.

By carefully considering and optimizing these factors, it is possible to enhance the power output of an electric motor and improve its overall performance. In the next section, we will explore some ways to enhance motor power.

Voltage

Voltage is a critical factor that directly affects the power output of an electric motor. Voltage refers to the electrical potential difference applied to the motor, which determines the rate of flow of electrons through the motor’s coils. Higher voltage levels generally lead to higher power output.

When a higher voltage is supplied to the motor, it allows for a greater current flow through the coils. This increased current results in a stronger magnetic field, which, in turn, leads to increased torque and power output. Therefore, increasing the voltage can enhance the motor’s power capabilities.

However, it’s important to note that increasing the voltage beyond the motor’s rated capacity can be detrimental. Excessively high voltage can lead to overheating and damage to the motor. Therefore, it’s crucial to operate the motor within the specified voltage range provided by the manufacturer.

Conversely, operating the motor at lower voltage than its rated capacity will result in reduced power output. Insufficient voltage can lead to a weaker magnetic field and lower torque, impacting the motor’s ability to produce mechanical power. In such cases, the motor may struggle to perform its intended function and may even stall in extreme cases.

It’s important to consider the power supply available and choose a motor that is compatible with the voltage range provided. This ensures that the motor can operate optimally and deliver the desired power output for its intended application.

Furthermore, maintaining a stable and consistent voltage supply is crucial for ensuring consistent motor performance. Voltage fluctuations can negatively impact motor operation and reduce power output. Therefore, it’s recommended to use voltage regulators or stabilizers to provide a steady voltage supply to the motor and prevent any adverse effects on its power output.

In summary, voltage is a crucial factor that directly affects the power output of an electric motor. Choosing the right voltage supply and ensuring its stability is essential to optimize the motor’s power capabilities and ensure reliable operation.

Current

Current is another important factor that directly influences the power output of an electric motor. Current refers to the flow of electrons through the motor’s coils, which generates the magnetic field necessary for the motor’s operation.

The greater the current flowing through the motor, the stronger the magnetic field generated, resulting in increased torque and power output. Therefore, higher current levels generally lead to a more powerful motor.

However, it is important to note that the current should be within the motor’s rated capacity. Excessive current can cause the motor to overheat, potentially leading to damage or reduced lifespan. It is therefore crucial to ensure that the motor is designed to handle the desired current levels.

On the other hand, insufficient current can result in reduced power output. A weaker current flow leads to a less intense magnetic field, resulting in lower torque and diminished power. In such cases, the motor may struggle to perform its intended tasks and may not achieve the desired level of power.

To optimize the motor’s power output, it is essential to provide the appropriate current supply. This can be achieved by ensuring that the power source can deliver the required current capacity. Additionally, using proper conductors and minimizing resistance in the motor’s wiring can help facilitate a higher current flow and enhance power output.

Furthermore, controlling and regulating the current flow can be beneficial in certain applications. Motor speed controllers, such as variable frequency drives (VFDs), allow for precise control of the motor’s speed and, in turn, the current flow. By adjusting the current to the desired level, the power output of the motor can be optimized for different operating conditions.

In summary, current is a crucial factor that directly impacts the power output of an electric motor. Providing the appropriate current levels while staying within the motor’s rated capacity is essential for maximizing its power capabilities and ensuring efficient and reliable operation.

Wire Size

Wire size is an often overlooked factor that can significantly influence the power output of an electric motor. The size and thickness of the wire used in the motor’s coils play a crucial role in determining its power capabilities.

Thicker wires have lower electrical resistance compared to thinner wires. Lower resistance allows for a higher current flow through the coils, resulting in increased power output. This is because less energy is lost as heat due to resistance, and more electrical energy can be efficiently converted into mechanical power.

Using thicker wires also helps minimize voltage drops across the length of the wire. Voltage drops can occur when the wire resistance causes a decrease in voltage as the current flows through the wire. By reducing voltage drops, more electrical energy can be effectively delivered to the motor, resulting in improved power output.

In addition to wire thickness, the quality and conductivity of the wire material also influence power output. High-quality copper wire is commonly used in motors due to its excellent electrical conductivity. Copper wire with good conductivity allows for better current flow and reduces power loss, ultimately enhancing the motor’s power capabilities.

It’s important to note that selecting the appropriate wire size should be based on the motor’s current rating and the specific application requirements. Undersized wires can lead to excessive resistance and higher operating temperatures, leading to decreased power output and potential damage to the motor. Conversely, oversized wires may result in unnecessary cost and bulk while providing no additional benefits in terms of power output.

When designing or rewinding a motor, consulting relevant wire size charts or consulting with experts can help determine the optimal wire gauge for the desired power output. It’s crucial to consider factors such as operating currents, ambient temperature, and the length of the wire run.

Overall, the size and quality of the wire used in the motor’s coils have a direct impact on its power output. By using appropriately sized wires with good conductivity, power losses due to resistance can be minimized, leading to improved power efficiency and increased power output.

Magnetic Field Strength

The magnetic field strength in an electric motor is a crucial factor that directly influences its power output. The strength of the magnetic field determines the torque and rotational force generated by the motor, ultimately affecting its power capabilities.

There are several ways to enhance the magnetic field strength in an electric motor:

-

Read more: How To Make An Electric Motor Variable Speed

Increasing the number of turns in the coil:

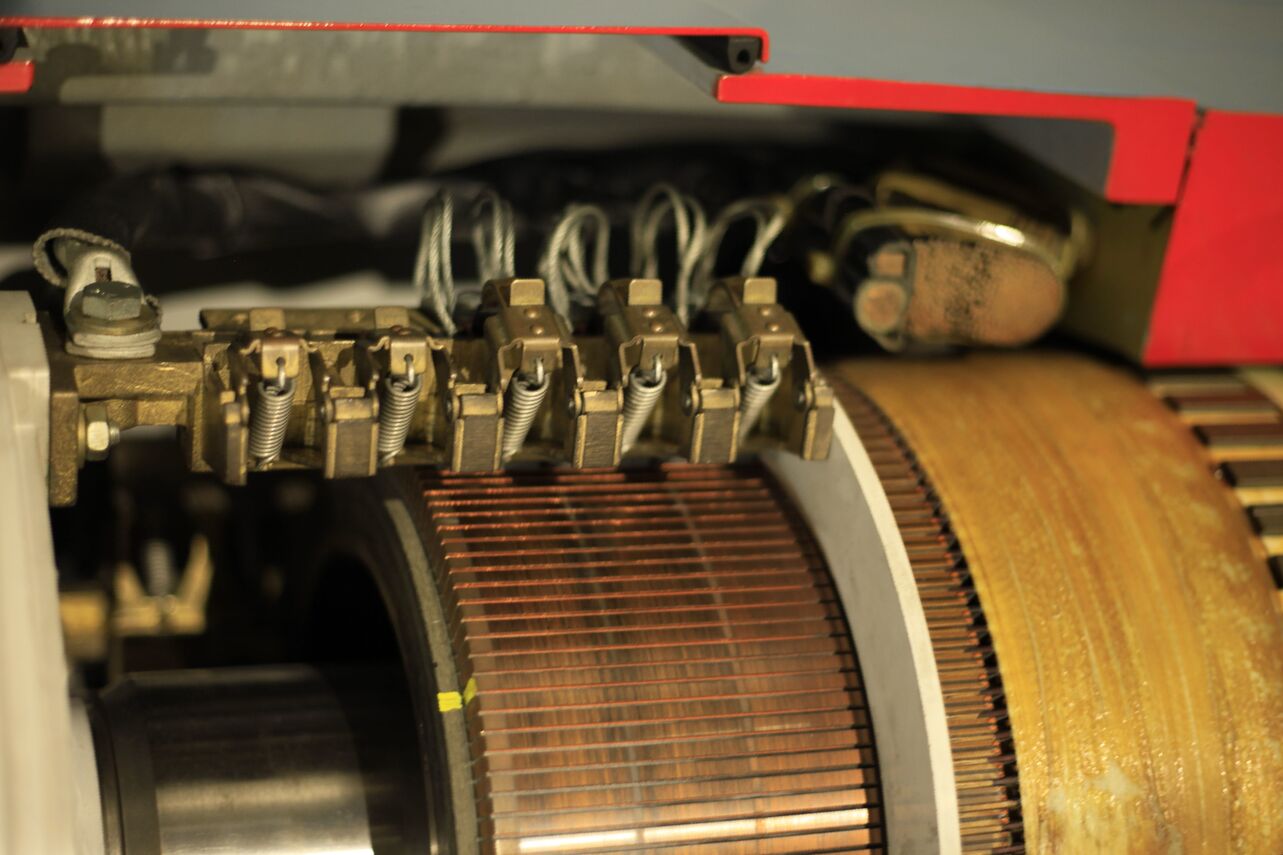

By increasing the number of wire turns in the motor’s coils, the magnetic field strength can be enhanced. More turns result in a stronger magnetic field, which translates to increased torque and power output. However, it’s essential to ensure that the coil winding is within the motor’s design limits to avoid overheating or excessive current.

-

Using stronger permanent magnets or electromagnets:

The strength of the magnets used in the stator has a direct impact on the magnetic field strength. Using permanent magnets with higher magnetic properties or electromagnets with stronger current flow can significantly improve the motor’s power output.

-

Optimizing the magnetic circuit:

The design and configuration of the motor’s magnetic circuit can have a significant effect on the magnetic field strength. Ensuring proper alignment, efficient magnetic flux paths, and minimizing magnetic losses can help enhance the field strength and overall power output.

It’s important to note that increasing the magnetic field strength should be done within the motor’s design limits. Excessive field strength may lead to saturation or overheating, compromising the motor’s performance and longevity.

Additionally, different motor types have varying approaches to achieving magnetic field strength. For example, in a permanent magnet motor, the use of high-quality permanent magnets with excellent magnetic properties is crucial for maximizing power output. In an induction motor, optimizing the design of the windings and the magnetic circuit is key to enhancing the magnetic field strength.

Ultimately, by focusing on increasing the magnetic field strength within the motor’s design limits, it is possible to enhance its power output. Proper selection and optimization of the coil winding, magnet choice, and magnetic circuit design contribute to maximizing the motor’s power capabilities and delivering the desired performance.

Efficiency

The efficiency of an electric motor is a critical factor that impacts its power output. Efficiency refers to the ratio of useful output power to the input power required to operate the motor. A more efficient motor converts a higher percentage of the input electrical energy into mechanical power.

Improving the efficiency of an electric motor can lead to a higher power output while minimizing energy losses. Here are some factors that contribute to motor efficiency:

-

Design and materials:

The motor’s design and the materials used in its construction play a significant role in determining its efficiency. Motors designed with better airflow and cooling mechanisms help dissipate heat more effectively, reducing energy losses. Choosing high-quality materials with low resistance and improved conductivity can also enhance efficiency.

-

Friction and resistance reduction:

Minimizing friction and resistance within the motor can reduce energy losses and improve efficiency. Using high-quality bearings, lubricating moving parts, and reducing internal losses such as eddy currents can help optimize motor efficiency.

-

Loss reduction:

Efficiency can be improved by reducing losses in different motor components. These losses include copper losses due to electrical resistance in the windings, iron losses due to magnetic hysteresis and eddy currents, and mechanical losses due to bearing and rotational friction. Using proper insulation, high-quality magnetic materials, and optimizing the motor’s mechanical structure can help minimize these losses and enhance efficiency.

-

Operating conditions:

The motor’s efficiency can be influenced by the operating conditions such as temperature and speed. Operating the motor within the recommended temperature range helps maintain optimal efficiency. Moreover, matching the motor’s speed to the specific load requirements through speed control techniques improves efficiency by reducing wasted energy.

By focusing on improving efficiency, the power output of an electric motor can be maximized while reducing energy waste. A more efficient motor not only delivers higher power output but also helps save energy and reduce operating costs in the long run.

It’s worth noting that motor efficiency is usually provided as a percentage, indicating the ratio of output power to input power. When selecting a motor, looking for a higher efficiency rating ensures better overall performance and a more powerful motor.

In summary, optimizing the design, materials, and operating conditions of an electric motor can lead to improved efficiency and increased power output. Minimizing energy losses and maximizing the conversion of input electrical energy into useful mechanical power are key to achieving higher motor efficiency and performance.

Motor Design

The design of an electric motor is a crucial factor that significantly influences its power output. Motor design encompasses various aspects, including the number of poles, coil configuration, and the type of rotor and stator used. These design elements can have a significant impact on the motor’s power capabilities.

Here are some key design considerations that can enhance motor power:

-

Number of poles:

The number of poles in an electric motor directly affects its power output. The poles are the electromagnets or permanent magnets in the stator that generate the magnetic field. Motors with a higher number of poles generally offer higher torque and power output. It’s important to select a motor with the appropriate number of poles based on the specific application requirements.

-

Coil configuration:

The configuration of the coils in the motor’s winding affects its power capabilities. Different coil configurations, such as lap winding or wave winding, can impact power output, torque, and efficiency. Choosing the right coil configuration based on the motor’s design and intended application is crucial for optimizing power performance.

-

Type of rotor and stator:

The type of rotor and stator used in the motor can also influence its power output. Different rotor designs, such as squirrel cage or wound rotors, offer varying performance characteristics. Likewise, the type of stator, whether it uses permanent magnets or electromagnets, affects the magnetic field strength and power output. Selecting the appropriate rotor and stator design based on the desired power requirements is essential.

-

Cooling mechanisms:

The cooling mechanisms employed in the motor’s design can also impact power output. Motors designed with efficient cooling mechanisms, such as fan cooling or liquid cooling, help dissipate heat effectively, preventing overheating and allowing for continuous high-power operation.

-

Efficient magnetic flux paths:

Optimizing the magnetic flux paths within the motor is crucial for maximizing power output. Proper design of the magnetic circuit ensures that the magnetic field generated by the stator effectively interacts with the rotor, resulting in increased torque and power. Analyzing and optimizing the magnetic paths using computer simulations and advanced design techniques can help enhance motor power.

When developing or selecting an electric motor, considering these design elements and their impact on power output is essential. Collaborating with motor design experts and utilizing advanced design tools can assist in optimizing the motor’s design for maximum power capabilities.

It’s important to note that motor design should align with the specific application requirements. Different applications may prioritize factors such as torque, speed, or efficiency over raw power output. Therefore, tailoring the motor’s design to the intended application is crucial for achieving the desired power performance.

In summary, the design of an electric motor plays a significant role in determining its power output. By considering factors such as the number of poles, coil configuration, rotor and stator type, cooling mechanisms, and efficient magnetic flux paths, the motor’s power capabilities can be optimized to meet the requirements of the intended application.

Enhancing Motor Power

Enhancing the power output of an electric motor can be achieved by optimizing various factors and implementing key strategies. Here are some approaches to enhance motor power:

-

Optimize voltage and current:

Ensuring that the motor is operated at the correct voltage within its rated capacity is crucial. Supplying the motor with a higher voltage can increase power output, but it’s essential to avoid exceeding the motor’s limits. Similarly, optimizing the current flow by using proper conductors and minimizing resistance can enhance power output.

-

Upgrade wire size and quality:

Using thicker wires with improved conductivity can reduce electrical resistance and minimize power losses. By selecting the appropriate wire size and utilizing high-quality copper wire, current flow can be enhanced, improving power output.

-

Enhance the magnetic field:

Increasing the magnetic field strength is key to enhancing motor power. This can be achieved by increasing the number of turns in the coil, using stronger permanent magnets or electromagnets, and optimizing the magnetic circuit design. By maximizing the magnetic field strength, torque and power output are increased.

-

Improve efficiency:

Enhancing motor efficiency leads to greater power output. Efforts should focus on minimizing energy losses through design optimization, reducing friction and resistance, and selecting high-quality materials. Maximizing efficiency ensures that more electrical energy is efficiently converted into useful mechanical power.

-

Consider motor design:

Choosing the right motor design, including the number of poles, coil configuration, rotor and stator type, and cooling mechanisms, is crucial for maximizing power output. Collaborating with motor design experts and utilizing advanced design tools can help optimize the motor’s design for enhanced power performance.

It’s important to note that enhancing motor power should be done within the motor’s specified limits and taking into account the specific application requirements. Operating the motor beyond its capabilities can result in overheating, reduced lifespan, or even motor failure.

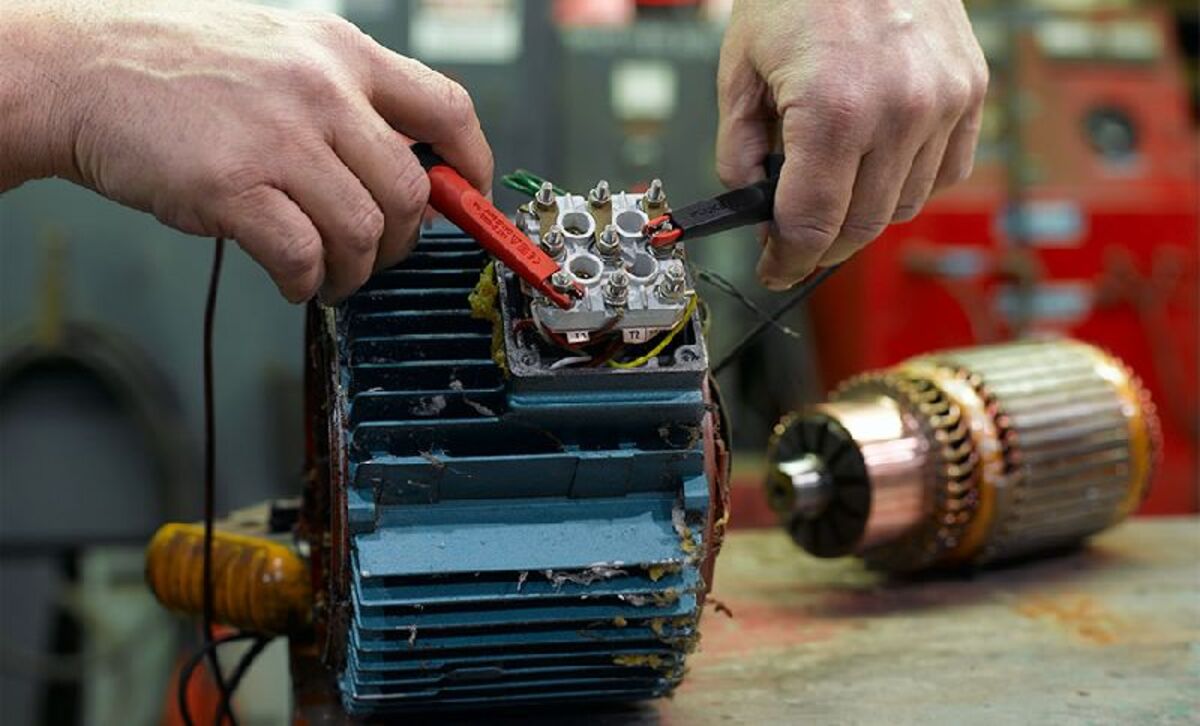

Regular maintenance and periodic inspection of the motor can also help to identify any issues or inefficiencies that may impact power output. Proper lubrication, cleaning, and addressing any wear and tear can ensure optimal motor performance and sustained power output over time.

Ultimately, enhancing motor power requires a comprehensive approach that involves optimizing voltage, current, wire size, magnetic field strength, efficiency, and motor design. By considering and implementing these strategies, it is possible to maximize the power output of an electric motor for various applications.

Read more: What Does An Electric Motor Do

Conclusion

Electric motors are essential components in a wide range of industries and applications, powering everything from household appliances to industrial machinery. Understanding what makes an electric motor more powerful can help optimize its performance and efficiency.

The power output of an electric motor is influenced by several key factors. Voltage and current directly affect power output, with higher levels generally resulting in increased power capabilities. The size and quality of the wire used in the motor’s coils also play a role, with thicker wires and better conductivity enhancing power output.

The strength of the magnetic field generated by the motor is crucial for achieving higher power output. Various strategies, such as increasing coil turns and using stronger magnets, can enhance the magnetic field strength. Optimal motor design, including choosing the right number of poles, coil configuration, and cooling mechanisms, also contributes to power efficiency.

Maintaining an efficient motor design and minimizing energy losses through friction and resistance reduction can further enhance power output. By operating the motor within its rated voltage and current limits, and considering factors like wire size, magnetic field strength, and efficiency, the power output of an electric motor can be maximized.

In conclusion, by carefully considering and optimizing the factors affecting power output, it is possible to enhance the power capabilities of an electric motor. Whether it’s selecting the appropriate voltage supply, upgrading wires, enhancing the magnetic field, improving efficiency, or optimizing the motor’s design, each step contributes to achieving a more powerful and efficient electric motor.

Ultimately, the goal is to strike a balance between power output and energy efficiency, ensuring that the motor performs at its best while minimizing waste. By focusing on these factors, we can harness the full potential of electric motors and drive innovation in various industries.

Frequently Asked Questions about What Makes An Electric Motor More Powerful

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Makes An Electric Motor More Powerful”