Articles

What Size Conduit For 100 Amp Service

Modified: May 6, 2024

Discover the ideal size of conduit for a 100 amp service in our informative articles. Save time and make informed decisions for your electrical needs.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to our comprehensive guide on conduit sizing for a 100 amp service. Whether you are a homeowner planning to upgrade your electrical system or a contractor working on a new construction project, understanding the proper conduit size is crucial. Conduit plays a vital role in protecting and organizing electrical wiring, ensuring the safety and efficiency of the entire electrical system.

In this article, we will explore the various factors to consider when choosing the right conduit size for a 100 amp service. We will discuss the different types of conduit available and highlight the installation guidelines that need to be followed. By the end, you will have a clear understanding of how to select and properly install conduit to meet the requirements of a 100 amp electrical service.

So, let’s dive in and explore the world of conduit sizing for a 100 amp service!

Key Takeaways:

- Proper conduit sizing for a 100 amp service is crucial for safety and efficiency. Consider wire size, number of wires, bend radius, conduit material, length, and environmental factors for a successful installation.

- Adhering to NEC guidelines and local codes, choosing the right conduit type, and following installation best practices are essential for a safe and compliant 100 amp service. Seek professional assistance for complex projects.

Read more: What Size Of Conduit For A 200 Amp Service

Understanding Conduit Size for Electrical Service

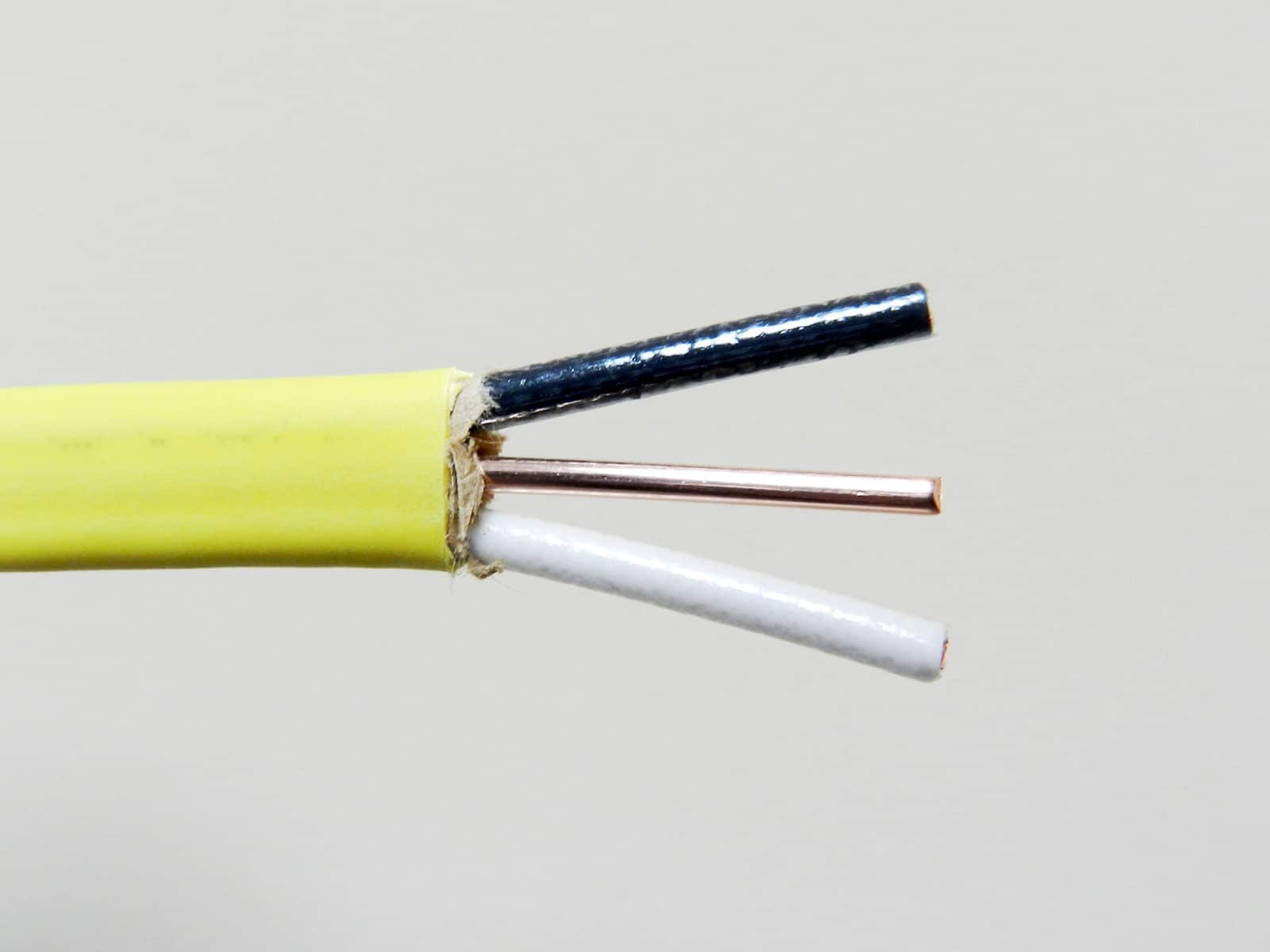

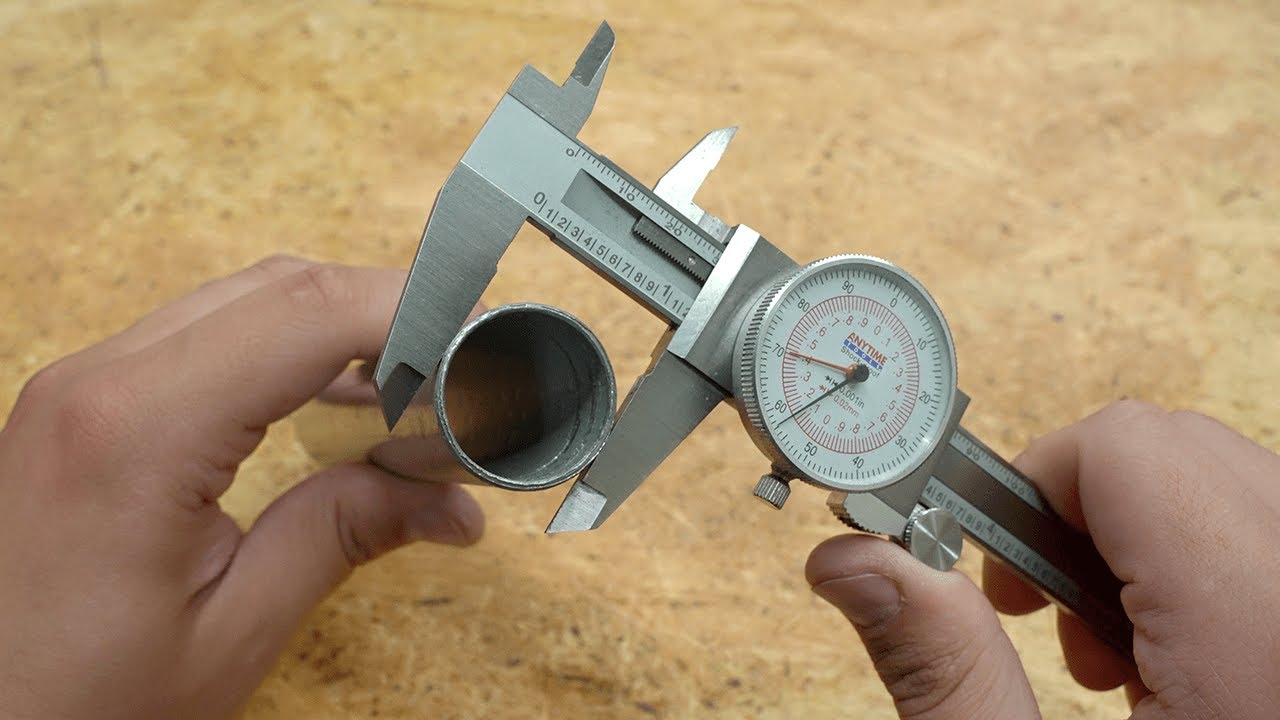

Conduit is a tubing system used to protect and route electrical wires in buildings. It serves as a protective covering for the wires, safeguarding them from damage and providing a secure pathway for electrical currents. When it comes to electrical service, conduit size refers to the inside diameter of the conduit, which determines the maximum number and size of wires that can be installed within it.

Conduit size is crucial because it affects the overall performance and safety of the electrical system. If the conduit is too small, it can lead to overheating of the wires, reduced capacity, and potential hazards. On the other hand, oversized conduit may not provide adequate protection and may result in disorganized wiring.

When determining the right conduit size for an electrical service, several factors need to be taken into consideration:

- Wire Size: The size of the wires that will be installed in the conduit is a key factor in determining the appropriate conduit size. The National Electrical Code (NEC) provides guidelines on the minimum conduit size required for different wire sizes.

- Number of Wires: The number of wires that need to be installed in the conduit plays a role in conduit sizing. This includes both the hot wires and the neutral wires. The NEC specifies the maximum fill capacity for each conduit size to ensure proper spacing and prevent overheating.

- Bend Radius: The conduit size should allow for proper bending of the wires without damaging them. The NEC provides guidelines for the minimum bend radius based on the wire size to prevent excessive stress on the wires.

- Conduit Length: The total length of the conduit run impacts the conduit size. Longer conduit runs may require larger sizes to accommodate voltage drop and reduce resistance.

- Environmental Factors: The environment in which the conduit will be installed should also be considered. Certain areas may have specific requirements based on factors such as moisture, temperature, and potential exposure to chemicals or corrosive substances.

By considering these factors, electrical contractors and homeowners can determine the appropriate conduit size for their specific electrical service needs.

Factors to Consider

When determining the conduit size for a 100 amp service, there are several important factors that need to be taken into consideration. These factors will help ensure the proper functioning and safety of the electrical system. Let’s explore the key factors to consider:

- Wire Size: The size of the wires that will be installed in the conduit is a critical consideration. The National Electrical Code (NEC) provides guidelines on the minimum conduit size required for different wire sizes. It is essential to choose a conduit size that can accommodate the selected wire size to prevent overcrowding and overheating.

- Number of Wires: The number of wires to be installed in the conduit is another important factor. This includes both the hot wires and the neutral wires. The NEC specifies the maximum fill capacity for each conduit size to ensure proper spacing and prevent overheating. It is crucial to calculate the total number of wires to be installed and choose a conduit size that provides sufficient space.

- Bend Radius: The bend radius is the minimum radius at which a conduit can be safely bent without damaging the wires. It is important to select a conduit size that allows for proper bending of the wires within the recommended bend radius. This will prevent unnecessary stress and potential damage to the wires.

- Conduit Material: The type of conduit material also needs to be considered. Different conduit materials have varying capacities and limitations. Some common conduit materials include PVC (Polyvinyl Chloride), EMT (Electrical Metallic Tubing), and RMC (Rigid Metal Conduit). Each material has its advantages and requirements, and the appropriate material should be chosen based on factors such as durability, corrosiveness, and compatibility with the environment.

- Conduit Length: The length of the conduit run plays a role in determining the conduit size. Longer conduit runs may require larger sizes to accommodate voltage drop and reduce resistance. It is important to calculate the total length of the conduit run and choose a size that can handle the electrical load comfortably.

- Environmental Factors: Consideration must be given to the environmental conditions in which the conduit will be installed. Factors such as moisture, temperature fluctuations, exposure to chemicals, and corrosiveness should be taken into account. Certain areas may have specific requirements to ensure the conduit’s durability and resistance to environmental elements.

By carefully considering these factors, you can choose the appropriate conduit size for a 100 amp service that meets the requirements of your electrical system and ensures its safe and efficient operation.

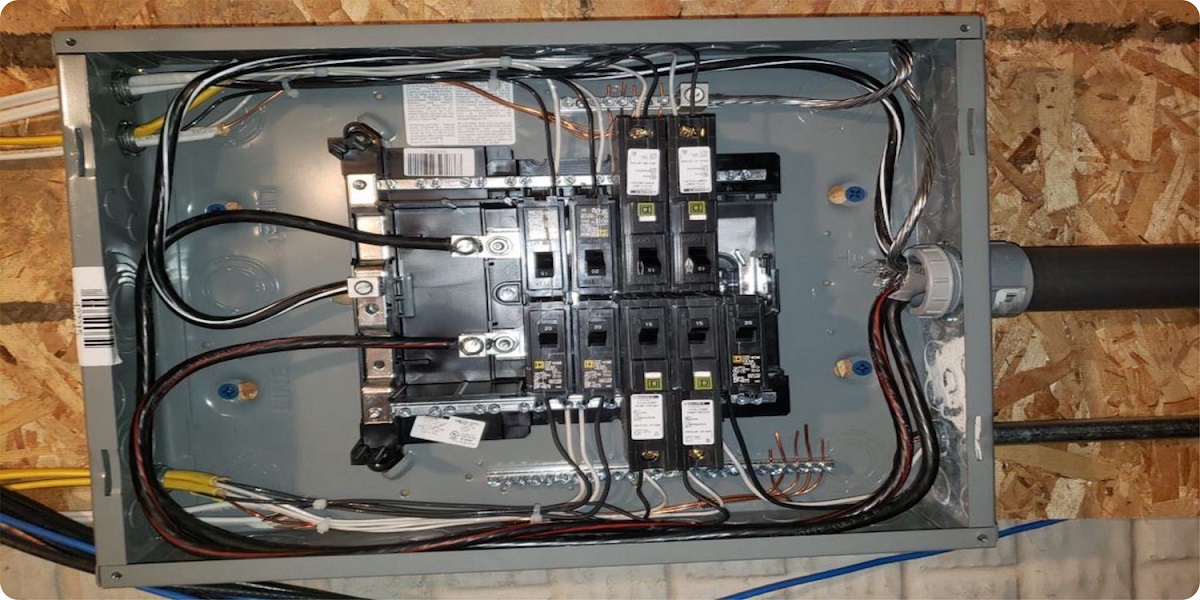

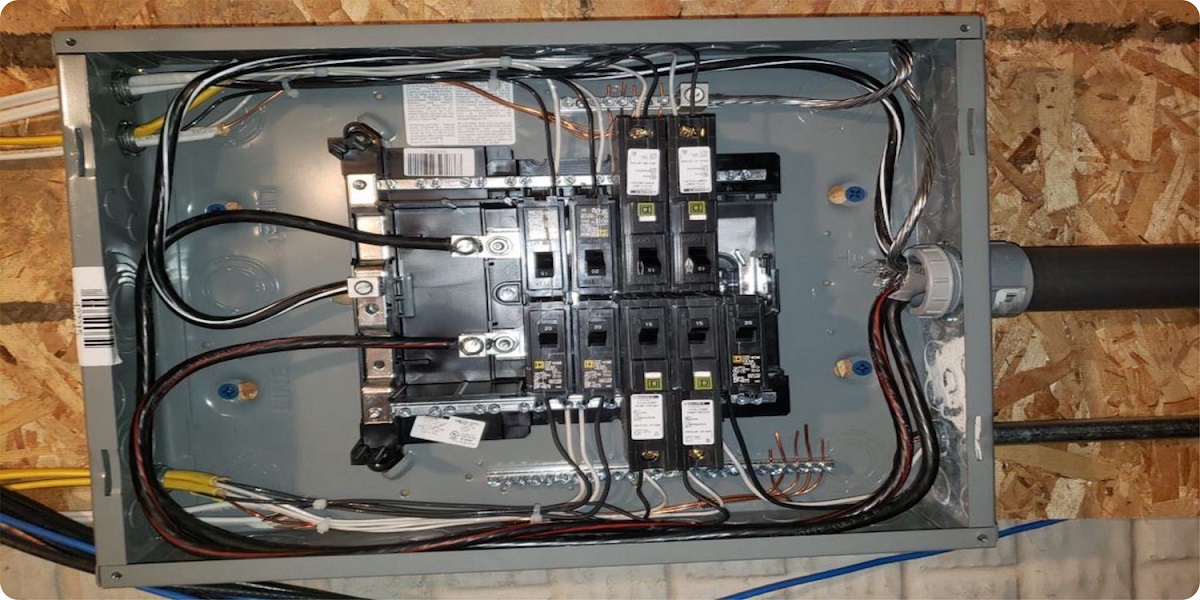

Conduit Sizing for 100 Amp Service

When it comes to sizing conduit for a 100 amp service, it is important to follow the guidelines provided by the National Electrical Code (NEC) and take into account the specific requirements of your electrical system. Here are some key points to consider when determining the conduit size for a 100 amp service:

- Wire Size: The wire size plays a crucial role in determining the conduit size for a 100 amp service. The NEC provides guidelines for the minimum conduit size required for different wire sizes. For a 100 amp service, commonly used wire sizes include 2 AWG, 3 AWG, or 4 AWG. The appropriate conduit size should allow for easy installation of these wire sizes.

- Number of Wires: The number of wires to be installed in the conduit also needs to be considered. A 100 amp service typically requires two hot wires (Phase A and Phase B) and one neutral wire. Additionally, a ground wire is required for safety purposes. This means a minimum of four wires will be installed in the conduit. The NEC specifies the maximum fill capacity for each conduit size, so it is crucial to choose a conduit size that can accommodate these wires comfortably.

- Bend Radius: When sizing conduit for a 100 amp service, it is important to consider the bend radius of the wires. The NEC provides guidelines for the minimum bend radius based on the wire size. The conduit size should allow for proper bending of the wires without causing damage or excessive stress. It is recommended to choose a conduit size that provides adequate space for easy wire bending.

- Conduit Material: The choice of conduit material is another consideration. PVC (Polyvinyl Chloride) is commonly used for residential electrical installations and is suitable for a 100 amp service. EMT (Electrical Metallic Tubing) is another option, offering better protection in commercial or industrial settings. The conduit material should be chosen based on factors such as durability, compatibility with the environment, and local building codes.

- Conduit Length: The total length of the conduit run is an important factor when sizing conduit for a 100 amp service. Longer conduit runs may require larger conduit sizes to account for voltage drop and reduce resistance. It is recommended to calculate the total length of the conduit run and choose a size that can handle the electrical load effectively.

- Environmental Factors: Consideration should be given to the environmental conditions in which the conduit will be installed. Moisture, temperature fluctuations, exposure to chemicals, and corrosiveness can affect the durability and performance of the conduit. Choose a conduit size and material that can withstand the specific environmental factors in the installation location.

By considering these factors and adhering to the NEC guidelines, you can choose the appropriate conduit size for a 100 amp service. Working with a qualified electrician or following local electrical codes is recommended to ensure a safe and compliant installation.

When determining the size of conduit for a 100 amp service, it is recommended to use a 1.5 inch conduit to allow for proper wire installation and future upgrades. Always consult local electrical codes and regulations before installation.

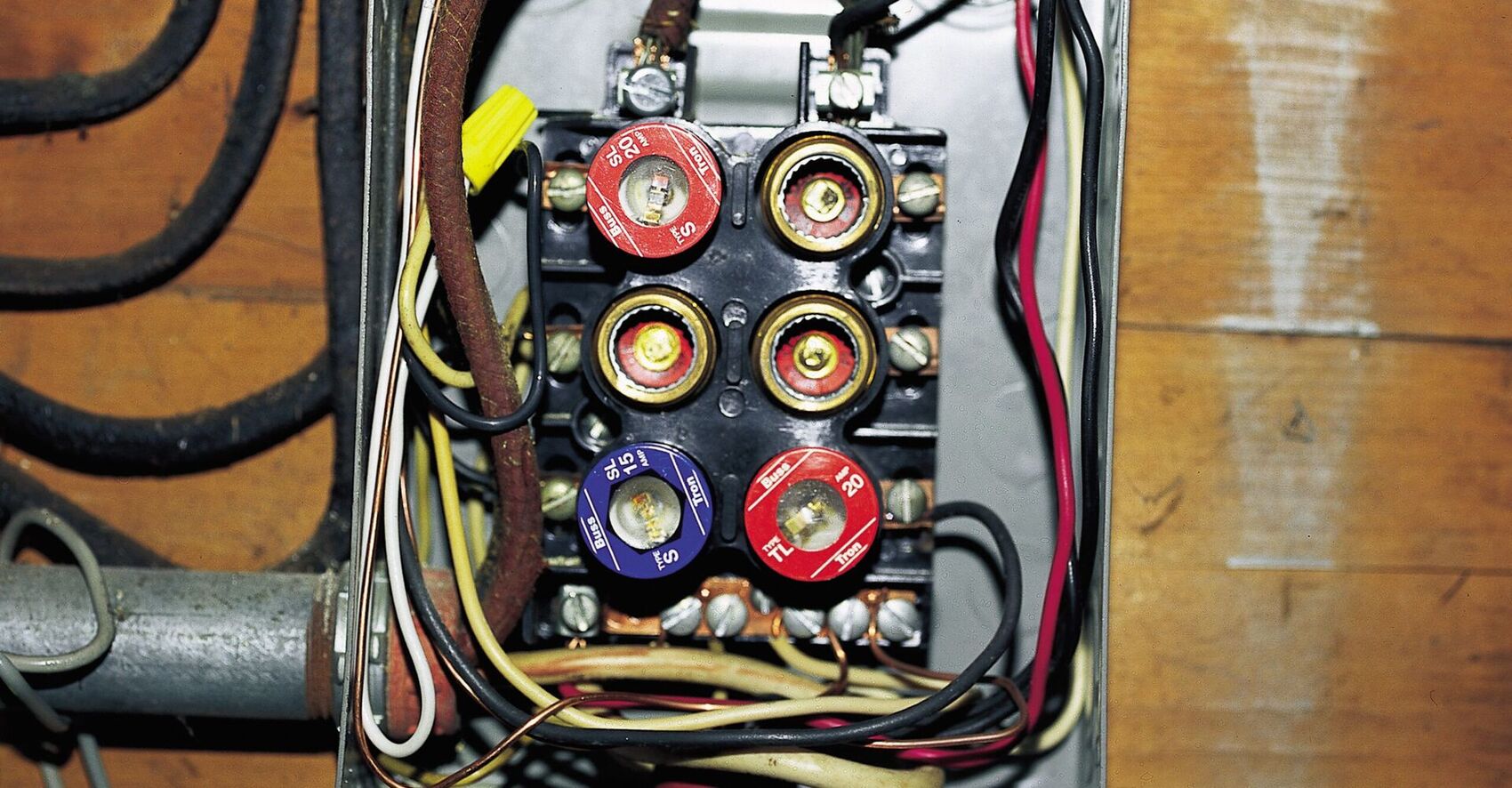

Types of Conduit for 100 Amp Service

When it comes to selecting the right conduit for a 100 amp service, there are several options available. The type of conduit you choose will depend on factors such as the specific requirements of your electrical system, the installation environment, and local building codes. Here are some common types of conduit used for a 100 amp service:

- PVC (Polyvinyl Chloride) Conduit: PVC conduit is a popular choice for residential electrical installations. It is lightweight, easy to work with, and cost-effective. PVC conduit is available in different sizes and can be easily cut and assembled using PVC fittings. It provides good insulation and protection for the wires. PVC conduit is suitable for both aboveground and belowgrade installations, but be sure to choose the appropriate schedule (thickness) and type (rigid or flexible) based on your specific needs.

- EMT (Electrical Metallic Tubing): EMT conduit is made of thin-walled steel tubes and is commonly used in commercial or industrial settings. It offers better physical protection compared to PVC conduit and is resistant to impact and corrosion. EMT conduit is easy to bend and install, making it a popular choice among electricians. However, EMT conduit is not suitable for outdoor or underground use unless it is protected against moisture and corrosion by a suitable coating or PVC jacket.

- RMC (Rigid Metal Conduit): RMC is a heavy-duty conduit made of thick-walled steel. It provides excellent protection for the wires and is highly durable. RMC is typically used in industrial and high-risk electrical installations where maximum protection is required, such as in areas prone to physical damage or hazardous environments. RMC requires specialized tools and equipment for bending and installation.

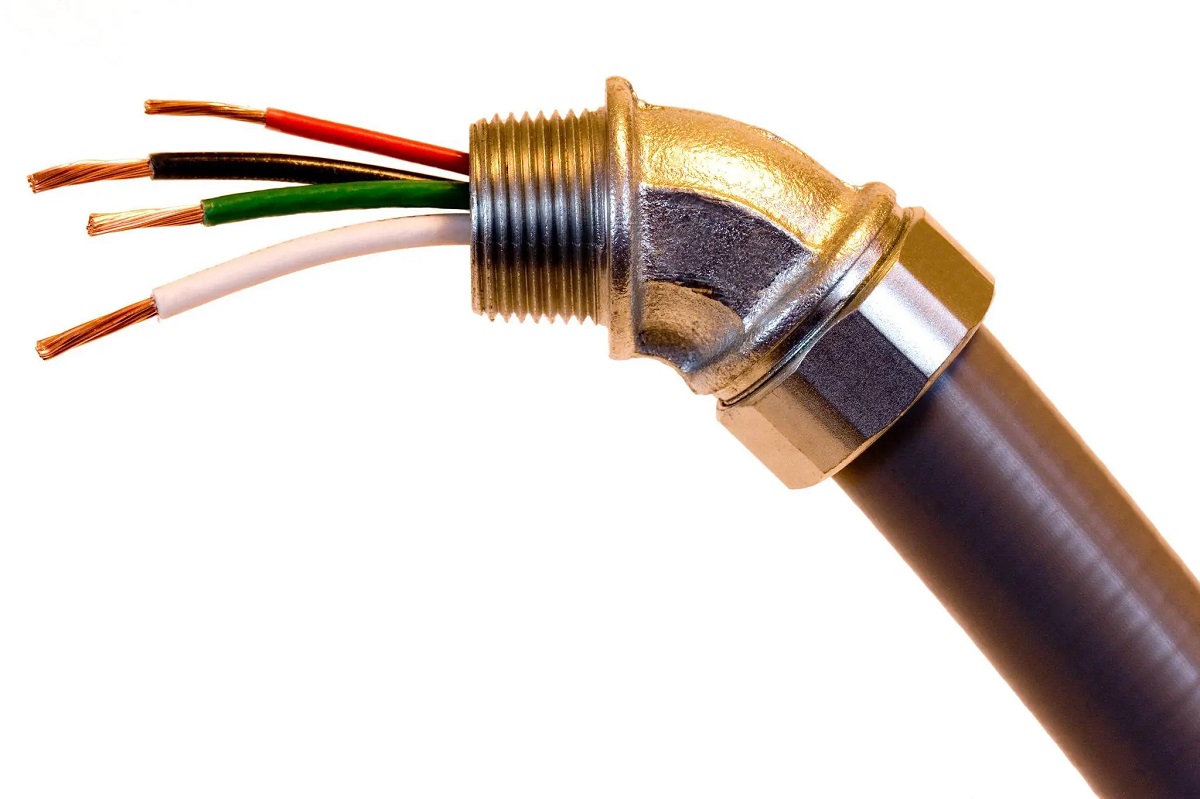

- Flexible Metal Conduit: Flexible metal conduit, often abbreviated as FMC or “Greenfield,” is a flexible type of conduit suitable for both indoor and outdoor applications. It is made of a spiral-wound metal strip with a plastic or metal core, providing flexibility and ease of installation. FMC is commonly used in areas where the wiring needs to be flexible, such as when routing wires through walls, ceilings, or areas with limited space. Note that some jurisdictions require FMC to be protected with an additional layer of conduit for extra safety.

- Liquidtight Flexible Metal Conduit (LFMC): LFMC, also known as sealed conduit, is a type of flexible conduit designed for use in areas where the conduit may be exposed to moisture, oil, dirt, or chemicals. It is made of a liquid-tight outer jacket and a flexible metal core, providing protection against these elements. LFMC is commonly used in outdoor and industrial applications, such as in wet locations or where the conduit needs to be submerged in water.

These are some of the commonly used types of conduit for a 100 amp service. Each type has its own advantages and considerations, so it is important to choose the appropriate conduit based on your specific needs and the requirements of your electrical system. Consulting with a qualified electrician or reviewing local building codes can help ensure the correct choice of conduit for your 100 amp service installation.

Read more: How Many Breakers In 100 Amp Panel

Conduit Installation Guidelines

Installing conduit for a 100 amp service requires careful planning and adherence to installation guidelines to ensure a safe and efficient electrical system. Here are some important guidelines to consider when installing conduit:

- Plan and Design: Before beginning the installation process, it is essential to carefully plan and design the conduit layout. Consider factors such as the location of electrical panels, outlets, and switches, as well as the path of the conduit runs. Create a detailed diagram to guide the installation process and ensure proper conduit sizing and routing.

- Observe Electrical Codes: Familiarize yourself with the electrical codes and regulations applicable to your area. Different jurisdictions may have specific requirements regarding conduit installation, such as minimum burial depth, grounding methods, and specific conduit types allowed for certain applications. It is vital to adhere to the local codes to ensure compliance and safety.

- Correct Conduit Sizing: Select the appropriate conduit size based on the wire size and number of wires being installed. Follow the guidelines provided by the National Electrical Code (NEC) to ensure the conduit can accommodate the wires comfortably and provide proper insulation and protection. Avoid overfilling the conduit, as this can lead to overheating and reduced performance.

- Secure and Support: Install conduit securely and provide adequate support along the entire length. Use approved straps, hangers, or clamps to secure the conduit at regular intervals, typically every 3-4 feet. This ensures the conduit remains in place and prevents unnecessary movement or sagging.

- Bend Radius: When bending conduit, follow the recommended minimum bend radius specified for the conduit and wire size. Exceeding the bend radius can damage the wires and affect the overall performance of the electrical system. Use specialized tools, such as conduit benders or a pre-fabricated conduit with factory-made bends, to achieve accurate and safe bends.

- Junction Boxes: Install junction boxes at appropriate intervals along the conduit run, particularly at points where wires need to be spliced or where there is a change in direction or termination. Junction boxes provide access for future maintenance and allow for safe and organized wire connections.

- Grounding and Bonding: Follow proper grounding and bonding techniques as outlined in the electrical codes. Ensure that the conduit is adequately grounded and bonded to prevent electrical shocks and protect against electrical faults. Use approved grounding fittings and connectors to establish a reliable grounding system.

- Consider Environmental Factors: Take into account the environmental conditions where the conduit will be installed. If the conduit is exposed to moisture, extreme temperatures, or corrosive substances, choose a conduit material that is resistant to these elements. Consider using additional protective measures, such as weatherproof fittings or conduit seals, for outdoor installations.

- Work with a Qualified Electrician: If you are not familiar with electrical installations or if the project is complex, it is highly recommended to seek the assistance of a qualified electrician. They have the expertise and knowledge to ensure that the conduit installation is done correctly and in compliance with the applicable codes and regulations.

Following these guidelines will help ensure a successful conduit installation for your 100 amp service. Proper planning, adherence to electrical codes, and attention to detail are essential for a safe and efficient electrical system.

Conclusion

Choosing the right conduit size for a 100 amp service is essential to ensure the safe and efficient operation of your electrical system. By considering factors such as wire size, number of wires, bend radius, conduit material, conduit length, and environmental conditions, you can make an informed decision regarding the appropriate conduit size.

Remember to follow the guidelines provided by the National Electrical Code (NEC) and local electrical codes to ensure compliance and safety. It is crucial to plan and design the conduit layout, secure and support the conduit properly, and follow recommended bending techniques to avoid damage to the wires or reduction in performance.

Among the various types of conduit available, such as PVC, EMT, RMC, flexible metal conduit, and LFMC, choose the one that best suits your specific needs and meets the requirements of your electrical system. Take into account factors such as durability, compatibility with the environment, and local building codes.

When it comes to the installation process, it is important to observe electrical codes, provide secure support for the conduit, use appropriate junction boxes, and ensure proper grounding and bonding. Consider environmental factors and take additional protective measures when needed.

Ultimately, it is recommended to seek the assistance of a qualified electrician, especially if you are unfamiliar with electrical installations or if the project is complex. Their expertise and knowledge will ensure that the conduit is installed correctly and in accordance with the applicable codes and regulations.

By following these guidelines and considering all the necessary factors, you can confidently select and install the right conduit size for your 100 amp service. This will result in a safe, organized, and efficient electrical system that meets your needs for years to come.

Excited to enhance your home's electrical setup further? If you've just figured out the right conduit size for your 100 amp service, why stop there? Rolling up your sleeves for more DIY projects can lead to significant improvements. For instance, learning how to run overhead electrical wire to a garage could expand your workspace capabilities or allow for new lighting and power tool options. Check out our detailed guide on safely and effectively extending your electrical reach.

Frequently Asked Questions about What Size Conduit For 100 Amp Service

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Size Conduit For 100 Amp Service”