Home>Furniture & Design>Interior Design Trends>How To Turn Glass Into A Mirror

Interior Design Trends

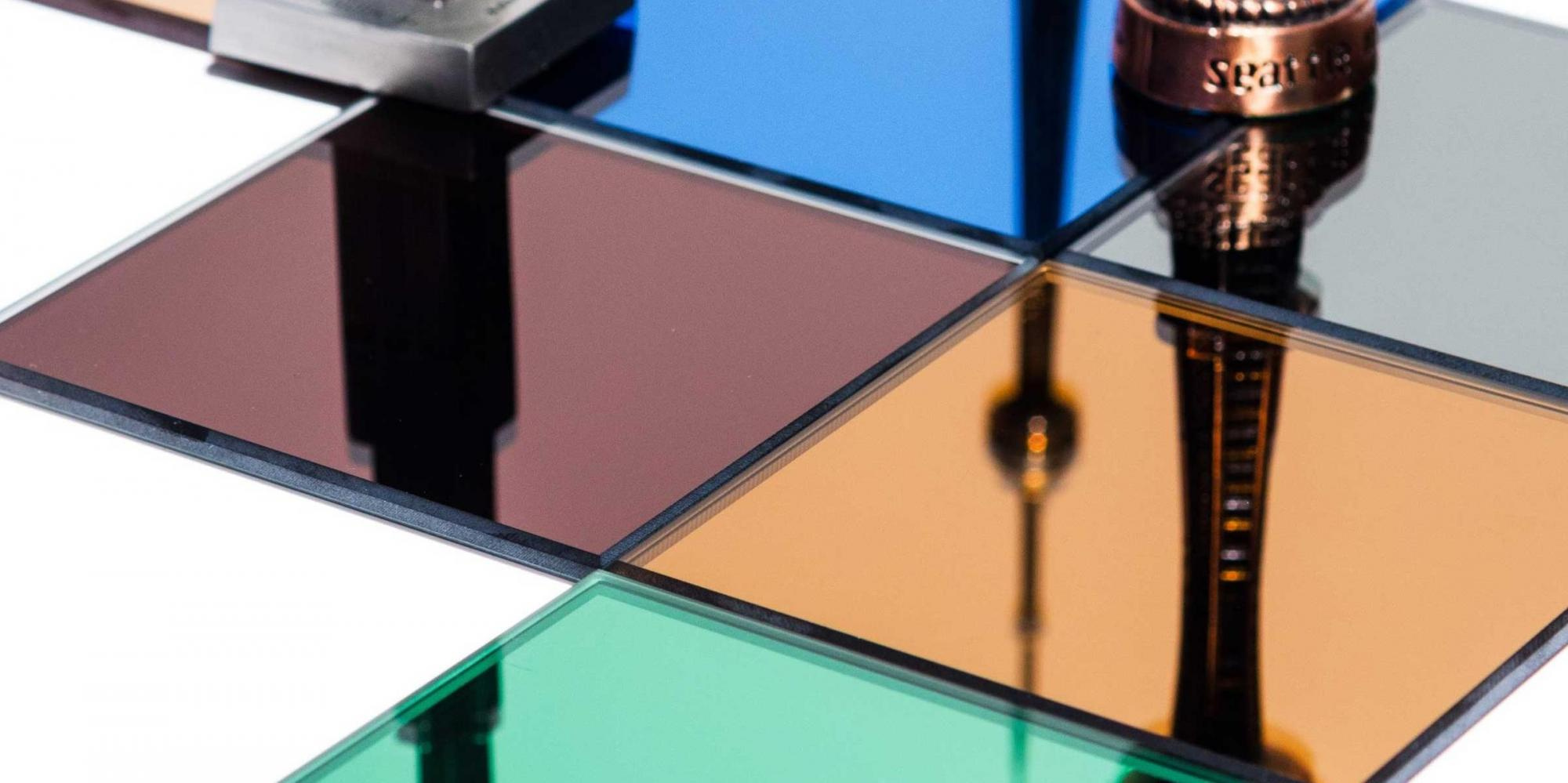

How To Turn Glass Into A Mirror

Modified: February 18, 2024

Learn the latest interior design trends and discover how to turn ordinary glass into a stunning mirror for your home decor. Elevate your space with this innovative DIY project.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Transforming ordinary glass into a stunning mirror is a captivating process that allows you to add a touch of elegance and sophistication to your living space. Whether you're a DIY enthusiast or simply intrigued by the art of mirror-making, this comprehensive guide will walk you through the fascinating journey of turning glass into a mirror. From understanding the science behind this transformation to acquiring the necessary materials and tools, you'll gain valuable insights and practical knowledge to embark on this creative endeavor.

Creating a mirror from glass involves a blend of science, artistry, and precision. The alchemical process of depositing a reflective layer onto the glass surface requires a delicate balance of chemical compounds and meticulous application techniques. As you delve into the intricacies of this craft, you'll discover the magic of turning a transparent pane of glass into a reflective masterpiece that not only serves a practical purpose but also elevates the aesthetic appeal of any room.

Throughout this guide, you'll uncover the secrets behind achieving a flawless mirror finish, learn about the essential materials and tools needed for the transformation, and gain valuable insights into the step-by-step process. Additionally, you'll explore expert tips and tricks to ensure optimal results and discover crucial safety precautions to uphold throughout the mirror-making journey.

Embark on this enchanting exploration of turning glass into a mirror, and unlock the potential to adorn your surroundings with bespoke reflective surfaces that exude charm and allure. Whether you're seeking to revitalize your home decor or delve into the art of mirror-making as a creative pursuit, this guide will equip you with the knowledge and inspiration to embark on this captivating transformation.

Key Takeaways:

- Transforming glass into a mirror is a captivating blend of science and art, requiring precision and attention to detail. It empowers individuals to infuse their living spaces with personalized reflections of beauty and sophistication.

- Prioritizing safety and meticulous attention to detail are essential in the journey of turning glass into mirrors. It’s a celebration of human creativity and the pursuit of timeless elegance.

Read more: How To Install Turn Signal Mirrors

Understanding the Science Behind Turning Glass Into a Mirror

The process of turning glass into a mirror is a captivating fusion of science and artistry. At its core, this transformation revolves around the application of a reflective coating onto the surface of the glass, thereby enabling it to reflect light and create a mirrored effect. To comprehend the science behind this alchemical process, it's essential to explore the fundamental principles that govern the creation of mirrors.

The key component in this transformation is the deposition of a thin, reflective layer onto the glass surface. Traditionally, this is achieved through a process known as silvering, where a thin layer of metallic silver is applied to the glass to create the reflective surface. However, modern techniques often utilize aluminum or other metal alloys to achieve the same effect.

The reflective properties of the mirror stem from the interaction between light and the metallic layer. When light strikes the mirror, it is reflected off the metallic surface, resulting in the creation of a clear and crisp reflection. This phenomenon is rooted in the principles of optics, where the smooth and uniform surface of the metallic layer allows for the efficient reflection of light rays, thereby producing a mirror-like effect.

Furthermore, the chemical composition of the reflective layer plays a crucial role in determining the quality and durability of the mirror. The adhesion of the metallic coating to the glass surface, as well as its resistance to corrosion and degradation, are essential considerations in mirror-making. Through meticulous control of the deposition process and the chemical composition of the reflective layer, artisans and manufacturers can ensure the creation of mirrors that exhibit exceptional clarity and longevity.

In addition to the reflective layer, the glass substrate itself also influences the quality of the mirror. The flatness and smoothness of the glass surface are pivotal in achieving a flawless reflective finish. Imperfections or irregularities in the glass can distort the reflection, underscoring the importance of utilizing high-quality glass as the foundation for creating mirrors.

By delving into the science behind turning glass into a mirror, one gains a profound appreciation for the intricate interplay of materials, light, and chemical processes that culminate in the creation of this ubiquitous yet enchanting object. This understanding serves as the bedrock for mastering the art of mirror-making and paves the way for achieving exceptional results in transforming glass into exquisite mirrors.

Materials and Tools Needed

Embarking on the journey of turning glass into a mirror requires a careful selection of materials and tools to facilitate the transformative process. From the essential components for creating the reflective layer to the specialized tools for precision application, each element plays a crucial role in achieving a flawless mirror finish. Here's a comprehensive list of the materials and tools needed to embark on this captivating endeavor:

Materials:

-

Glass Substrate: High-quality, flat glass serves as the foundation for creating mirrors. Ensure that the glass substrate is free from imperfections and possesses a smooth surface to facilitate optimal reflection.

-

Mirror Coating Solution: The mirror coating solution, often containing metallic compounds such as silver or aluminum, is the key ingredient for creating the reflective layer on the glass surface. It is essential to select a high-quality coating solution that ensures exceptional reflectivity and durability.

-

Protective Coating: A protective layer, such as a clear sealant or varnish, is crucial for safeguarding the reflective coating against corrosion, oxidation, and environmental factors. This protective coating enhances the longevity and resilience of the mirror finish.

-

Cleaning Supplies: To prepare the glass surface for the mirror-making process, gather cleaning supplies such as glass cleaner, lint-free cloths, and alcohol-based solutions to ensure a pristine and debris-free substrate.

-

Masking Tape: Utilize high-quality masking tape to delineate the areas of the glass that will receive the mirror coating. This precision masking ensures clean and defined edges for the reflective surface.

-

Protective Gear: Prioritize safety by acquiring protective gear, including gloves, goggles, and a respirator, to safeguard against potential exposure to chemicals and fumes during the mirror-making process.

Tools:

-

Spray Gun or Applicator: A reliable spray gun or applicator is essential for uniformly applying the mirror coating solution onto the glass surface. Opt for a tool that enables precise and consistent application to achieve an even reflective layer.

-

Squeegee or Soft Cloth: A squeegee or soft cloth is indispensable for smoothing out the mirror coating and removing any air bubbles or imperfections during the application process. This tool ensures a seamless and flawless reflective finish.

-

Precision Cutting Tools: If customization or resizing of the mirror is required, precision cutting tools such as glass cutters or diamond-tipped scoring tools are essential for achieving accurate and clean cuts on the glass substrate.

-

Ventilation System: Given the potential for fumes and airborne particles during the mirror-making process, a well-ventilated workspace or a dedicated ventilation system is crucial to maintain a safe and comfortable working environment.

By assembling these materials and tools, you'll be well-equipped to embark on the captivating journey of turning glass into a mirror, ensuring meticulous attention to detail and exceptional results in creating bespoke reflective surfaces.

Read more: How To Make Glass Into Mirror

Step-by-Step Guide to Turning Glass Into a Mirror

-

Prepare the Glass Surface: Begin by thoroughly cleaning the glass substrate using a glass cleaner and lint-free cloths. Ensure that the surface is free from dust, debris, and any contaminants that may hinder the adhesion of the mirror coating.

-

Masking and Marking: Use high-quality masking tape to delineate the areas of the glass that will receive the mirror coating. Precision masking is essential for achieving clean and defined edges for the reflective surface. Additionally, mark any specific design or pattern if customization is desired.

-

Safety Precautions: Prioritize safety by donning protective gear, including gloves, goggles, and a respirator, to safeguard against potential exposure to chemicals and fumes during the mirror-making process. Ensure that the workspace is well-ventilated to mitigate any risks associated with the application of mirror coating solutions.

-

Application of Mirror Coating: Utilize a reliable spray gun or applicator to uniformly apply the mirror coating solution onto the glass surface. Maintain a steady and consistent motion to achieve an even distribution of the reflective layer. Pay meticulous attention to detail to ensure thorough coverage and a smooth application.

-

Smoothing and Removal of Imperfections: Following the application of the mirror coating, utilize a squeegee or soft cloth to smooth out the coating and eliminate any air bubbles or imperfections. This step is crucial for achieving a seamless and flawless reflective finish.

-

Curing and Drying Process: Allow the mirror coating to cure and dry according to the manufacturer's recommendations. This typically involves a designated period for the reflective layer to set and adhere to the glass surface, ensuring optimal reflectivity and durability.

-

Protective Coating Application: Once the mirror coating has fully cured, apply a protective layer, such as a clear sealant or varnish, to safeguard the reflective coating against corrosion, oxidation, and environmental factors. This protective coating enhances the longevity and resilience of the mirror finish.

-

Final Inspection and Customization: Conduct a thorough inspection of the mirror surface to ensure the absence of any imperfections or blemishes. If desired, proceed with customization or resizing using precision cutting tools to achieve the desired dimensions and aesthetic appeal.

By following this step-by-step guide, you'll embark on a captivating journey of turning glass into a mirror, culminating in the creation of bespoke reflective surfaces that exude elegance and charm. Each stage of the process demands precision, attention to detail, and a commitment to achieving exceptional results, ultimately yielding mirrors that elevate the aesthetic allure of any space.

Tips and Tricks for Achieving the Best Results

Achieving impeccable results when turning glass into a mirror requires a blend of precision, expertise, and attention to detail. Here are invaluable tips and tricks to ensure the creation of stunning mirrors that exude exceptional quality and visual appeal:

-

Optimal Surface Preparation: Prior to applying the mirror coating, meticulously clean and degrease the glass surface to ensure maximum adhesion and a flawless reflective finish. Use lint-free cloths and alcohol-based solutions to eliminate any residues that may compromise the mirror coating's adherence.

-

Uniform Application Technique: When applying the mirror coating solution, maintain a consistent and uniform motion to achieve an even distribution of the reflective layer. Avoid abrupt starts and stops, as they can result in uneven coverage and affect the overall reflectivity of the mirror.

-

Mindful Removal of Air Bubbles: After applying the mirror coating, carefully inspect the surface for any air bubbles or imperfections. Use a squeegee or soft cloth to gently smooth out the coating, ensuring the removal of any trapped air bubbles that may detract from the mirror's clarity.

-

Precision Masking for Clean Edges: Pay meticulous attention to the masking process to delineate the areas of the glass that will receive the mirror coating. Clean and defined edges contribute to the mirror's aesthetic appeal, underscoring the importance of precise masking for a polished finish.

-

Controlled Curing and Drying: Adhere to the recommended curing and drying times for the mirror coating to ensure optimal adhesion and reflectivity. Avoid premature handling or exposure to environmental elements during the curing process to safeguard the integrity of the reflective layer.

-

Strategic Protective Coating Application: When applying the protective layer, ensure thorough coverage to shield the mirror coating from corrosion and environmental factors. Follow the manufacturer's guidelines for the protective coating to enhance the mirror's longevity and resilience.

-

Attention to Workspace Environment: Maintain a clean and well-ventilated workspace to minimize the risk of contaminants or airborne particles compromising the mirror-making process. A controlled environment contributes to the overall quality and integrity of the finished mirror.

-

Thorough Quality Inspection: Conduct a meticulous inspection of the mirror surface to identify and address any imperfections or blemishes. Addressing any irregularities promptly ensures the creation of mirrors that meet the highest standards of quality and visual appeal.

By incorporating these tips and tricks into the mirror-making process, you'll elevate the craftsmanship and artistry involved in turning glass into a mirror, ultimately yielding exquisite reflective surfaces that captivate and enchant. Each nuanced consideration contributes to the creation of mirrors that transcend functionality, emerging as captivating works of art that adorn and elevate any space.

To turn glass into a mirror, you can apply a thin layer of metal, like silver or aluminum, to the back of the glass. This will create a reflective surface and turn the glass into a mirror.

Safety Precautions to Keep in Mind

Ensuring safety throughout the process of turning glass into a mirror is paramount to safeguarding against potential hazards and promoting a secure working environment. From handling chemical compounds to mitigating risks associated with the application of mirror coating solutions, adhering to comprehensive safety precautions is essential. Here's a detailed overview of the critical safety measures to uphold during the mirror-making journey:

-

Protective Gear: Prioritize personal protection by wearing appropriate gear, including chemical-resistant gloves, safety goggles, and a respirator. These essential items shield against potential skin contact with chemicals, eye irritation, and inhalation of fumes, ensuring the well-being of the artisan throughout the mirror-making process.

-

Ventilation: Establish a well-ventilated workspace to mitigate the accumulation of fumes and airborne particles. Adequate ventilation, whether through natural airflow or a dedicated ventilation system, minimizes the risk of inhaling chemical vapors and promotes a comfortable and safe working environment.

-

Chemical Handling: Exercise caution when handling mirror coating solutions and other chemical compounds. Adhere to the manufacturer's guidelines for storage, handling, and disposal of chemicals, preventing accidental spills, exposure, or environmental contamination.

-

Workspace Organization: Maintain a clean and organized workspace, free from clutter and potential tripping hazards. Clear and unobstructed pathways contribute to a safe and efficient working environment, reducing the risk of accidents or injuries during the mirror-making process.

-

Emergency Preparedness: Equip the workspace with essential safety equipment, including a fire extinguisher, a first-aid kit, and an emergency eyewash station. Familiarize yourself with the location and operation of these safety resources to respond promptly to any unforeseen incidents.

-

Handling Glass: Exercise caution when working with glass substrates, as they can pose a risk of breakage and sharp edges. Utilize appropriate handling techniques and consider the use of protective gloves to minimize the risk of cuts or injuries during glass preparation and customization.

-

Chemical Exposure: In the event of accidental chemical exposure, promptly rinse the affected area with water and seek medical attention if necessary. Familiarize yourself with the appropriate first-aid measures for chemical contact and have emergency contact information readily accessible in the workspace.

By prioritizing these safety precautions, artisans and enthusiasts embarking on the captivating journey of turning glass into mirrors can uphold a secure and conscientious approach to the mirror-making process. These measures not only mitigate potential risks but also foster a workspace environment that prioritizes the well-being and safety of all individuals involved in the art of mirror-making.

Conclusion

The art of turning glass into a mirror is a captivating fusion of science, craftsmanship, and creativity. Throughout this comprehensive guide, we've delved into the intricate process of transforming ordinary glass into bespoke reflective surfaces that exude elegance and allure. From understanding the underlying science behind mirror-making to acquiring the essential materials and tools, each facet of this journey embodies a harmonious blend of precision and artistry.

As we conclude this exploration, it's evident that the creation of mirrors transcends mere functionality, emerging as a testament to human ingenuity and the pursuit of aesthetic excellence. The alchemical process of depositing a reflective layer onto the glass surface, coupled with meticulous attention to detail and adherence to safety precautions, underscores the depth of artistry and expertise involved in mirror-making.

The journey of turning glass into a mirror is not merely a technical endeavor; it is a narrative of transformation and creativity. It empowers individuals to infuse their living spaces with personalized reflections of beauty and sophistication, elevating the ambiance and visual allure of any environment. Whether embarking on this journey as a DIY enthusiast, a seasoned artisan, or a creative explorer, the process of mirror-making invites individuals to embrace the intersection of art and science, resulting in the creation of mirrors that resonate with individuality and charm.

As we reflect on the captivating journey of turning glass into mirrors, it becomes evident that this art form is a celebration of human creativity and the pursuit of timeless elegance. Each mirror crafted represents a unique narrative, encapsulating the dedication, expertise, and artistry of its creator. From adorning interior spaces with bespoke mirrors to exploring the art of mirror-making as a creative pursuit, the allure of this craft lies in its ability to transform the ordinary into the extraordinary.

In essence, the journey of turning glass into a mirror is a testament to the enduring allure of craftsmanship and the timeless appeal of reflective surfaces. It invites individuals to embark on a transformative odyssey, where science and art converge to yield mirrors that not only reflect light but also embody the essence of creativity and individual expression. Embrace this enchanting journey, and unlock the potential to adorn your surroundings with bespoke reflective surfaces that captivate the eye and elevate the spirit.

Frequently Asked Questions about How To Turn Glass Into A Mirror

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Turn Glass Into A Mirror”