Home>Garden Essentials>What Infill Does Shapeways Print With

Garden Essentials

What Infill Does Shapeways Print With

Modified: March 7, 2024

Discover what infill Shapeways uses to print garden designs and learn how it enhances durability and creativity in gardening.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the fascinating world of 3D printing! The ability to transform digital designs into physical objects has revolutionized various industries, including manufacturing, healthcare, and even the arts. With advancements in technology, 3D printing has become more accessible and affordable, allowing individuals and businesses to bring their ideas to life.

Shapeways is a prominent player in the 3D printing industry, providing a platform for creators to turn their designs into reality. As a leading online marketplace for 3D printed products, Shapeways offers a wide range of materials and printing options to suit diverse needs.

One crucial aspect of 3D printing is the infill, which plays a significant role in determining the structural strength and material usage of the printed object. In this article, we will delve into the materials used by Shapeways and explore the various infill options available, helping you make informed decisions for your 3D printing projects.

Key Takeaways:

- Shapeways offers a variety of materials and infill options for 3D printing, allowing users to customize prints for strength, weight, and cost, making it easy to bring creative ideas to life.

- Understanding the purpose of the print, considering weight restrictions, and evaluating material properties are crucial when choosing the infill percentage and pattern for 3D prints. Shapeways provides the tools to optimize prints for specific project requirements.

Read more: How To Slow Down Infill On Active Print

Overview of Shapeways

Shapeways is a leading online 3D printing service and marketplace that connects designers, creators, and consumers. Founded in 2007, Shapeways has grown to become a prominent player in the industry, providing a platform for people to bring their ideas to life through 3D printing.

The company offers a range of services, including 3D printing, design assistance, and global shipping. With state-of-the-art printing technology and a vast selection of materials, Shapeways enables individuals and businesses to create unique and personalized products.

Shapeways operates on a business model that combines digital manufacturing with e-commerce. Users can upload their 3D models to the platform and choose from various printing materials, finishes, and other customizable options. The platform also allows designers to set up their own storefronts, sell their creations to a global audience, and earn royalties on every sale.

One of the key advantages of Shapeways is its commitment to quality. The company prides itself on delivering high-resolution prints with attention to detail. Whether you need a prototype for product development or a finished piece for artistic purposes, Shapeways ensures that the final product meets your expectations.

Beyond its printing services, Shapeways has built a vibrant community of designers and enthusiasts. The platform encourages collaboration, knowledge sharing, and inspiration through its forums, tutorials, and design challenges. This sense of community fosters creativity and enables individuals to learn from one another, further fueling innovation within the 3D printing space.

As the popularity of 3D printing continues to grow, Shapeways remains at the forefront of the industry, constantly pushing the boundaries of what is possible. With its user-friendly platform, extensive material options, and commitment to quality, Shapeways has become a go-to destination for anyone looking to turn their ideas into tangible 3D printed objects.

Printing Materials Used by Shapeways

Shapeways offers a diverse range of printing materials to cater to different needs and applications. Each material has its own unique properties, allowing users to achieve various levels of detail, strength, and visual appeal in their prints. Here are some of the materials commonly used by Shapeways:

1. Plastic

Shapeways uses a variety of plastic materials for 3D printing, including Nylon, Polyamide, and Polypropylene. These materials are known for their durability, flexibility, and resistance to impact and heat. They are suitable for a wide range of applications, from functional prototypes to consumer products.

2. Resin

Resin is a popular choice for capturing intricate details and achieving high-resolution prints. Shapeways offers different types of resin materials, such as Standard Resin, High-Detail Resin, and Flexible Resin. Resin prints are ideal for jewelry, miniatures, and any design that requires fine details and smooth surfaces.

Read more: What Does Wetland Infill Mean

3. Metal

Shapeways offers a selection of metal materials for 3D printing, including Stainless Steel, Bronze, Brass, and Silver. Metal prints are renowned for their strength, durability, and ability to replicate intricate designs. They are widely used in industries such as jewelry making, aerospace, and engineering.

4. Ceramic

Ceramic materials offer a unique aesthetic and are well-suited for creating pottery, decorative items, and customized tableware. Shapeways utilizes a variety of ceramic materials, such as Porcelain and Earthenware, that can be 3D printed and finished with beautiful glazes and textures.

5. Full-Color Sandstone

Full-Color Sandstone is a material that allows for vibrant colors and intricate details in 3D printed models. It is commonly used to create figurines, architecture models, and artistic sculptures. Shapeways uses a layer-by-layer printing process to build objects with fine powder and binders, resulting in full-color, textured prints.

These are just a few examples of the printing materials offered by Shapeways. The selection continues to grow as new materials and technologies emerge. By providing a wide range of options, Shapeways ensures that users can choose the most suitable material for their specific projects and achieve the desired results.

Types of Infill in 3D Printing

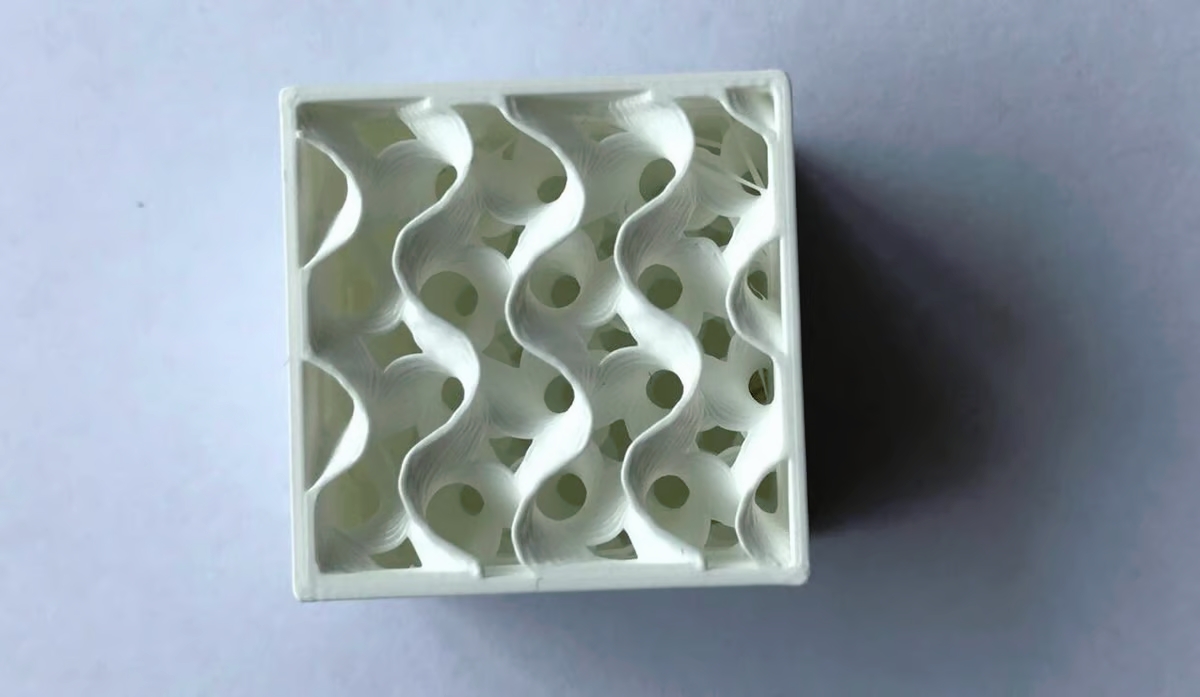

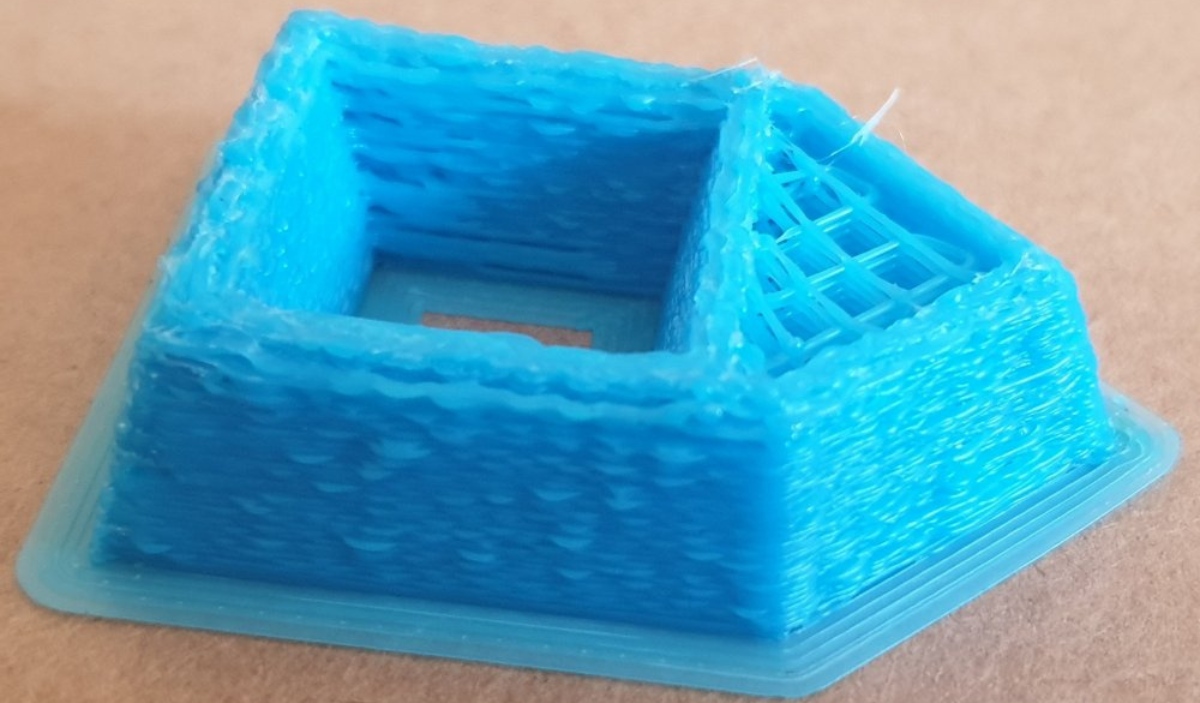

Infill is an essential element of 3D printing that affects the structural integrity and material usage of the printed object. Infill refers to the internal structure or lattice-like pattern that is created inside a solid 3D printed model. This internal structure ensures that the object maintains strength and stability while optimizing material usage and reducing print time.

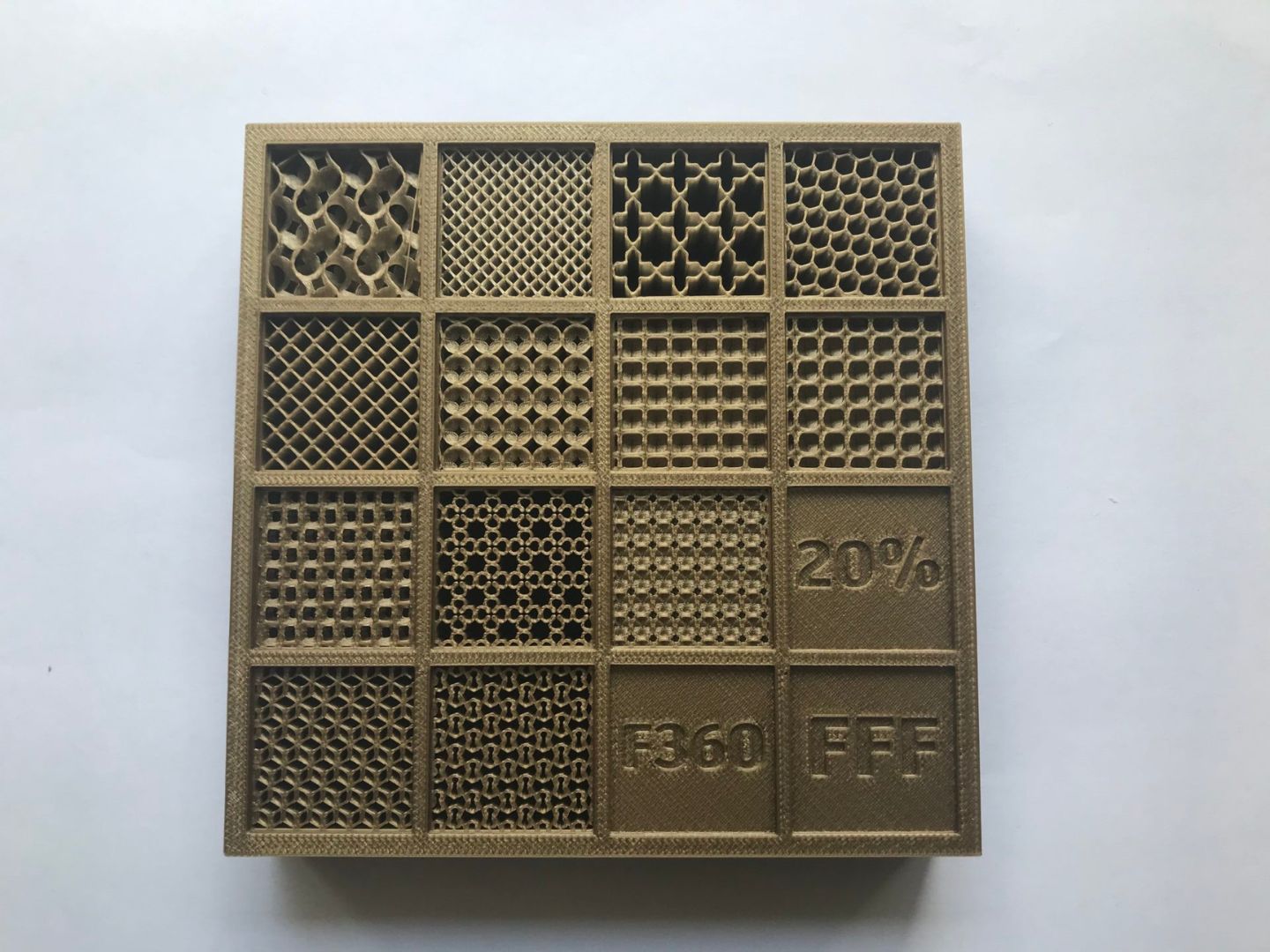

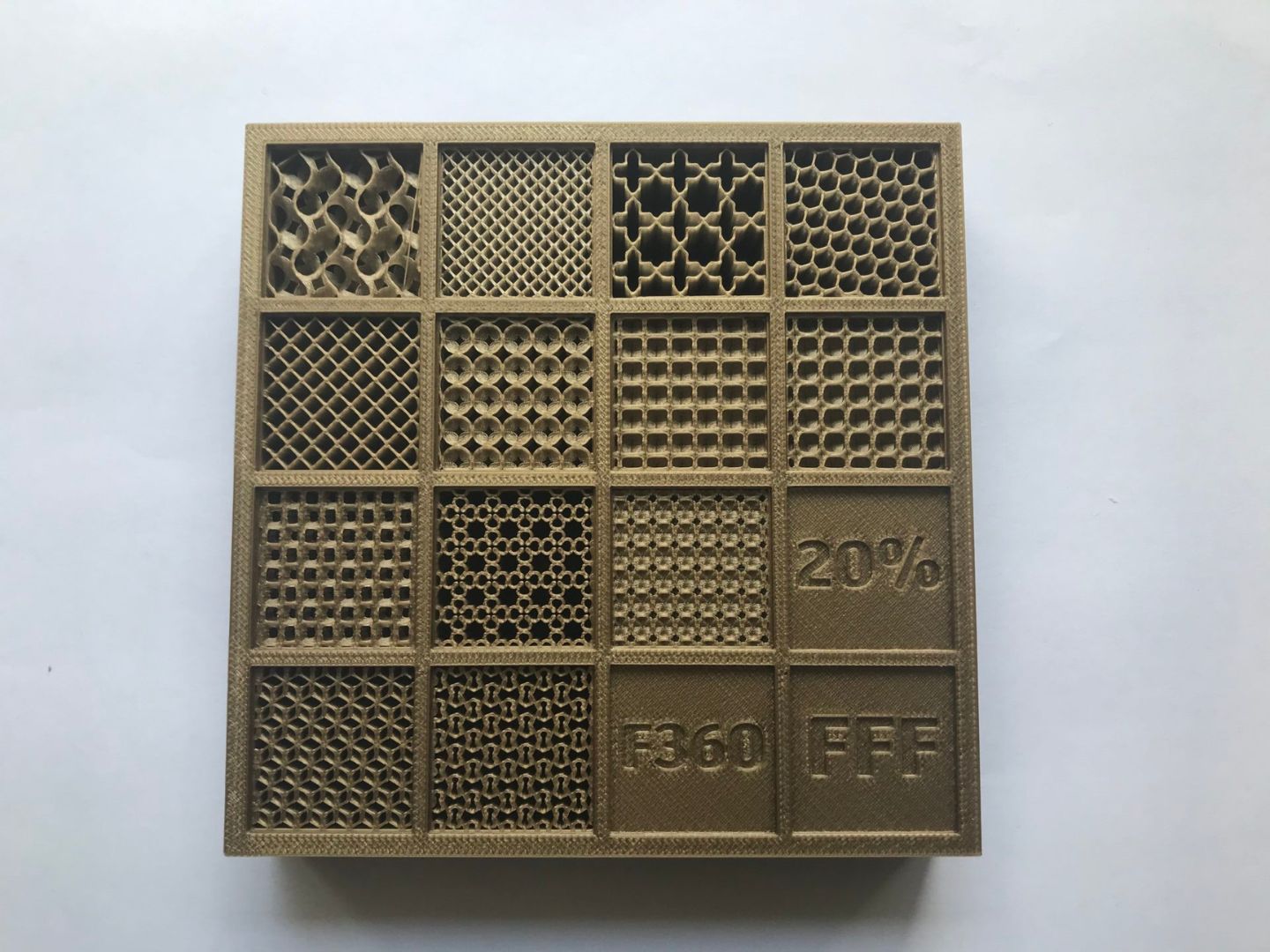

There are several types of infill patterns commonly used in 3D printing. Each pattern has its own advantages and purposes. Let’s explore some of the most popular infill patterns:

Read more: What Does Combine Infill Mean

1. Grid

The grid infill pattern consists of perpendicular lines that intersect to form a series of squares or rectangles. This pattern provides a good balance between structural support and material usage. It is commonly used when a print requires moderate strength and stability.

2. Honeycomb

The honeycomb infill pattern, as the name suggests, resembles the structure of a beehive. It consists of hexagonal cells that interconnect to create a strong yet lightweight internal structure. This pattern is known for its excellent strength-to-weight ratio and is often used for objects that require high structural integrity.

3. Triangular

The triangular infill pattern is created by interconnecting triangular shapes within the model. This pattern provides good strength and rigidity while minimizing material usage. It is commonly used for objects that require a balance between strength and lightweight design.

4. Rectilinear

The rectilinear infill pattern consists of parallel lines running in both the X and Y directions, creating a series of rectangular cells. This pattern offers good structural support and is suitable for objects that require high strength and stability.

Read more: What Is An Infill

5. Concentric

The concentric infill pattern features a series of circular lines or rings that start from the perimeter of the object and move towards the center. This pattern provides good strength and stability while reducing material usage. It is commonly used for objects that require a uniform distribution of internal support.

These are just a few examples of the infill patterns used in 3D printing. The choice of infill pattern depends on the specific requirements of the print, such as structural strength, weight, and material usage. It’s important to consider these factors when selecting the appropriate infill pattern for your 3D printing projects.

Infill Options Offered by Shapeways

Shapeways understands the importance of infill in 3D printing and offers a range of infill options to meet the specific needs of different projects. When uploading a 3D model to the Shapeways platform, users have the option to choose the desired infill percentage, which determines the amount of material used for the internal structure of the print. Here are the infill options typically available on Shapeways:

1. Low Infill Percentage

A low infill percentage, such as 10% or 15%, means that there will be less internal structure in the printed object. This results in a lighter and faster print with less material usage. Low infill percentages are suitable for objects that don’t require high structural strength but still need some internal support.

2. Medium Infill Percentage

A medium infill percentage, such as 20% or 30%, strikes a balance between strength and material usage. This option is commonly used for objects that require moderate structural support, such as functional prototypes or household items.

Read more: What Is An Infill Speed

3. High Infill Percentage

A high infill percentage, typically ranging from 40% to 100%, provides maximum structural strength and stability. This option is ideal for objects that require exceptional durability, such as mechanical parts or load-bearing components.

Aside from selecting the infill percentage, Shapeways also provides the option to choose specific infill patterns, such as grid, honeycomb, or triangular, depending on the desired strength and aesthetic preferences of the printed object. The choice of infill pattern can further enhance the structural integrity and performance of the print.

It’s worth noting that the choice of infill percentage and pattern can impact the final cost and print time of the object. Higher infill percentages and more complex infill patterns require more material and time to print. Therefore, it’s essential to consider the trade-off between strength, cost, and printing efficiency when selecting the infill options on Shapeways.

Shapeways’ flexibility in offering various infill options empowers users to optimize their prints according to their specific needs. Whether you’re creating a delicate, lightweight design or a robust, functional prototype, Shapeways provides the tools to customize the infill to achieve the desired outcome.

Choosing the Right Infill for your 3D Prints

When it comes to 3D printing, selecting the right infill is crucial to ensuring that your prints meet the desired strength, weight, and cost parameters. Here are some factors to consider when choosing the infill for your 3D prints:

1. Purpose of the Print

Consider the intended use of the printed object. If it is purely decorative or doesn’t require high structural integrity, a lower infill percentage may be sufficient. On the other hand, if the print requires strength and durability, a higher infill percentage would be more appropriate.

2. Weight Considerations

Take into account the weight restrictions of your design. If the final product needs to be lightweight, opting for a lower infill percentage or a lighter infill pattern can help achieve that goal. Keep in mind that reducing the infill percentage may sacrifice some structural support.

3. Material Properties

Different materials have varying levels of strength and flexibility. Consider the properties of the material you’re using and choose an appropriate infill percentage to ensure the print achieves the desired mechanical characteristics.

4. Cost and Print Time

Higher infill percentages use more material and may increase the overall cost of the print. Additionally, printing with a higher infill percentage can take longer due to the added layering and internal complexity. Consider your budget and time constraints when selecting the infill percentage.

5. Design Considerations

The geometry and intricate details of your design can also influence the choice of infill. Some infill patterns, such as honeycomb or triangular, can enhance the structural integrity of complex designs, while others may be more suitable for simpler shapes.

It’s important to note that experimenting with different infill percentages and patterns can help fine-tune your prints to achieve the desired results. Consider creating test prints with varying infill options to assess the impact on strength, weight, and overall print quality.

Shapeways provides users with the flexibility to adjust the infill percentage and choose from a variety of infill patterns, allowing for customization based on specific project requirements. By considering these factors and making informed choices, you can optimize your prints for the desired balance of strength, weight, cost, and functionality.

Conclusion

As 3D printing continues to revolutionize the way we create and manufacture objects, infill plays a crucial role in achieving the desired strength, weight, and cost parameters of 3D printed designs. Shapeways, a leading online 3D printing service, offers a wide range of materials and infill options to cater to diverse needs and applications.

By understanding the purpose of your print, considering weight restrictions, and evaluating material properties, you can make informed decisions when selecting the infill percentage and pattern. Whether you need a lightweight and decorative object or a robust functional prototype, Shapeways provides the tools to customize the infill and optimize your prints accordingly.

It’s important to strike a balance between strength, weight, cost, and print time when choosing the infill for your 3D prints. Factors such as the purpose of the print, material properties, and design considerations all come into play. By experimenting with different infill percentages and patterns, you can fine-tune your prints to achieve the desired results.

Shapeways’ commitment to quality, extensive material selection, and user-friendly platform make it an ideal choice for anyone looking to bring their 3D printing projects to life. Whether you’re a designer, entrepreneur, or hobbyist, Shapeways provides the tools and resources to turn your ideas into tangible 3D printed objects.

As technology continues to advance and new materials and infill options emerge, the possibilities for 3D printing are limitless. With Shapeways as your trusted partner, you can delve into the world of 3D printing with confidence, unlock your creativity, and bring your wildest imaginations to life.

Frequently Asked Questions about What Infill Does Shapeways Print With

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Infill Does Shapeways Print With”