Home>Garden Essentials>Why Can I See Infill Through Outer Layer

Garden Essentials

Why Can I See Infill Through Outer Layer

Modified: April 22, 2024

Discover why you can see infill through the outer layer of your garden. Uncover the secrets behind this intriguing phenomenon.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Why Can I See Infill Through Outer Layer

Introduction

In the world of 3D printing, infill refers to the internal structure or pattern that is printed within the solid outer layers of an object. It serves the purpose of providing support and stability to the overall print. However, one common issue that many 3D printing enthusiasts encounter is the visibility of infill through the outer layer of the print.

This phenomenon can be quite frustrating, especially when you have put time and effort into creating a detailed and visually appealing print. In this article, we will delve into the factors that contribute to the visibility of infill through the outer layers of a 3D print and explore techniques to minimize this issue.

Understanding the reasons behind this problem is crucial for achieving high-quality prints. So let’s dive in and explore why infill can sometimes be seen through the outer layers of a 3D print, and how we can address this issue effectively.

Why Can I See Infill Through Outer Layer

Key Takeaways:

- Choosing the right filament material and infill density can hide the infill pattern, creating a smoother appearance. Experiment with different materials and densities to achieve the desired print quality.

- Adjusting printing speed and cooling settings can reduce the visibility of infill. Finding the right balance between speed and cooling can help produce high-quality and visually pleasing prints.

Read more: Bumps Where Infill Meets Outer Wall

Understanding Infill and Outer Layers

Before we discuss the factors influencing the visibility of infill through the outer layers, it’s important to understand what infill and outer layers are in the context of 3D printing.

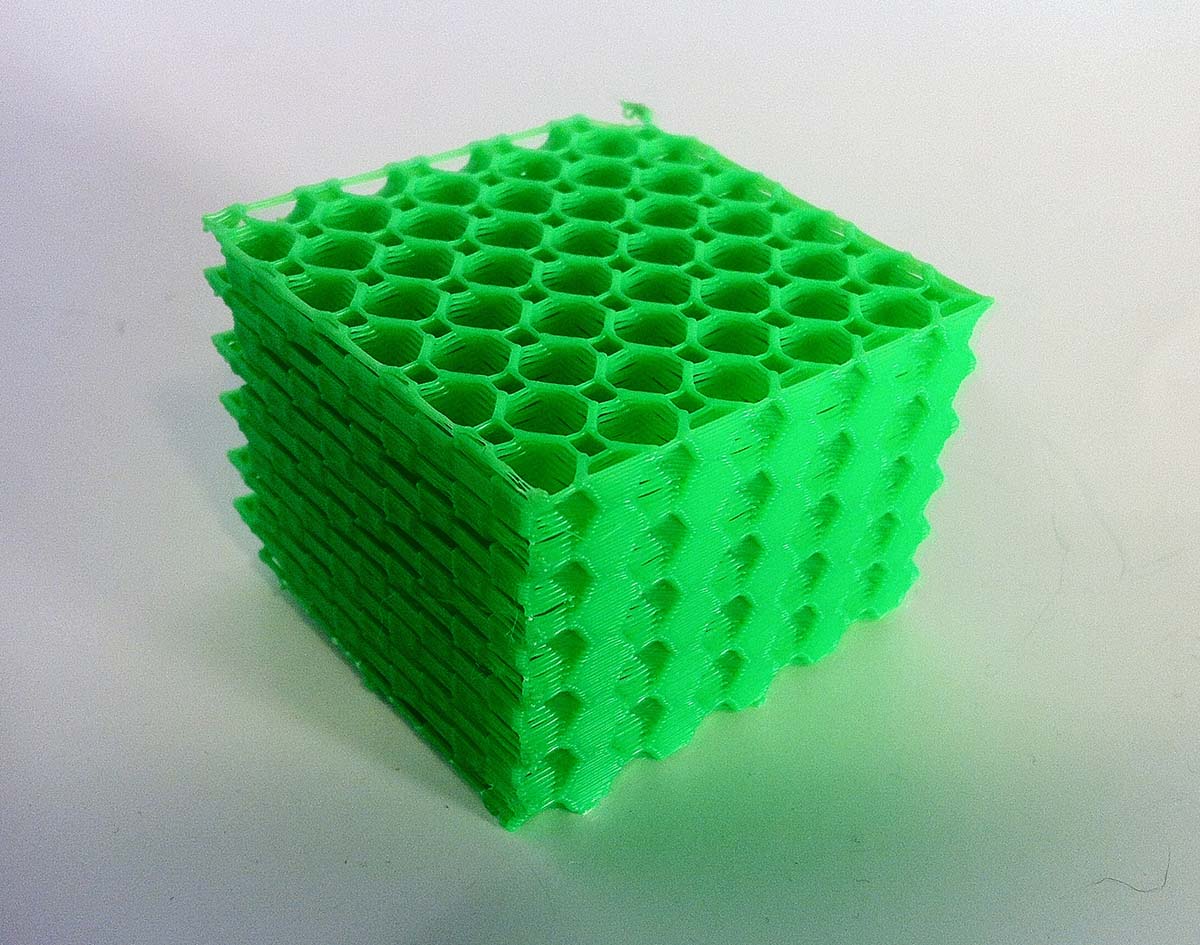

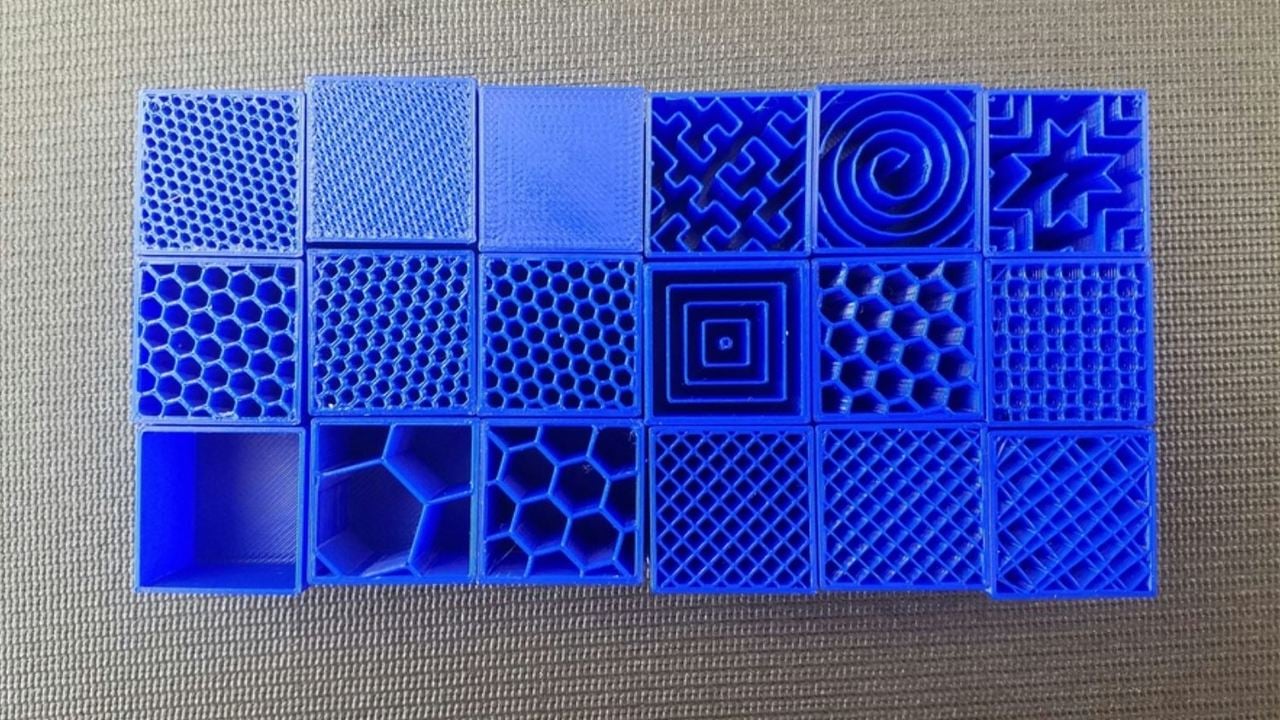

Infill refers to the internal structure of a 3D print. It is composed of a series of interconnected lines, patterns, or grids that occupy the interior volume of the print. The main purpose of infill is to provide support and add strength to the overall structure of the print, while minimizing material usage and print time.

On the other hand, outer layers are the solid, dense shells that enclose the infill and give the 3D print its final shape and appearance. These outer layers are what we see and touch when looking at a completed print.

The visibility of infill through the outer layers can be attributed to various factors, such as the material selection and density, extrusion settings and calibration, top and bottom layer thickness, and printing speed and cooling. Let’s take a closer look at each of these factors to gain a better understanding.

Why Can I See Infill Through Outer Layer

Factors Affecting Visibility of Infill through Outer Layer

There are several factors that can influence the visibility of infill through the outer layers of a 3D print. By understanding these factors, you can make adjustments to your printing parameters and minimize the visibility of infill. Let’s explore these factors in detail:

1. Material Selection and Density

The type of filament you choose for your 3D print plays a significant role in the visibility of infill. Some materials, like transparent or semi-transparent filaments, allow light to pass through, making the infill more apparent. Additionally, the infill density can also affect its visibility. Lower density infill will have more gaps, making it easier to see through the outer layers.

2. Extrusion Settings and Calibration

Proper extrusion settings and calibration are essential for achieving a well-balanced and consistent flow of filament. Inadequate extrusion settings or incorrect calibration can lead to gaps or over-extrusion, resulting in a more visible infill through the outer layers.

Read more: Why Can You See Someone Clearly Through A Clear Glass Window But Not Through A Frosted Glass Window?

3. Top and Bottom Layer Thickness

The thickness of the top and bottom layers can impact the visibility of infill. Thicker top and bottom layers provide more coverage and can help conceal the infill, while thinner layers may result in a more visible infill pattern.

4. Printing Speed and Cooling

The printing speed and cooling settings during the 3D printing process can affect infill visibility. Higher printing speeds and inadequate cooling can result in less time for the material to solidify, leading to a more visible infill pattern.

By considering these factors and making the necessary adjustments to your printing settings, you can significantly reduce the visibility of infill through the outer layers of your 3D prints. Experimenting with different combinations of materials, densities, and settings can help you achieve the desired results.

Why Can I See Infill Through Outer Layer

Material Selection and Density

The choice of filament material and infill density can significantly impact the visibility of infill through the outer layers of a 3D print. Let’s explore how these factors can affect the outcome of your prints:

1. Filament Material

The transparency or translucency of the filament material can make a difference in how visible the infill is through the outer layers. Transparent or semi-transparent filaments, such as clear or translucent PLA, PETG, or ABS, allow light to pass through them, making the infill more apparent. On the other hand, opaque filaments like solid color PLA or ABS tend to hide the infill better.

It’s important to consider the intended purpose of your print when selecting the filament material. If you want a solid, opaque appearance with minimal visibility of infill, choose a filament with a solid color or low transparency. If you don’t mind the infill being slightly visible and are going for a more decorative or artistic effect, transparent or semi-transparent filaments can be a great choice.

Read more: What Is A Good Infill Layer Thickness

2. Infill Density

The density of the infill plays a significant role in its visibility through the outer layers. Higher infill densities create a more solid internal structure, making it less visible through the outer layers. Conversely, lower infill densities have more gaps, which can result in a more visible infill pattern.

When selecting the infill density, consider the balance between strength, material usage, and the desired appearance. If the primary goal of the print is functional strength, higher infill densities are recommended. However, if you are primarily concerned with reducing material usage and printing time, lower infill densities can be suitable.

Experimenting with different filament materials and infill densities can help you find the optimal combination to achieve your desired print quality. It’s important to keep in mind that the visibility of infill through the outer layers will vary depending on the filament material, infill pattern, and specific printing parameters.

Why Can I See Infill Through Outer Layer

Extrusion Settings and Calibration

Proper extrusion settings and calibration are crucial in achieving high-quality 3D prints with minimal visibility of infill through the outer layers. Let’s explore how these factors can affect the outcome of your prints:

1. Extrusion Settings

Accurate extrusion settings are essential to ensure a consistent flow of filament during the printing process. When the extrusion settings are not properly calibrated, it can lead to under-extrusion or over-extrusion, which can impact the visibility of the infill.

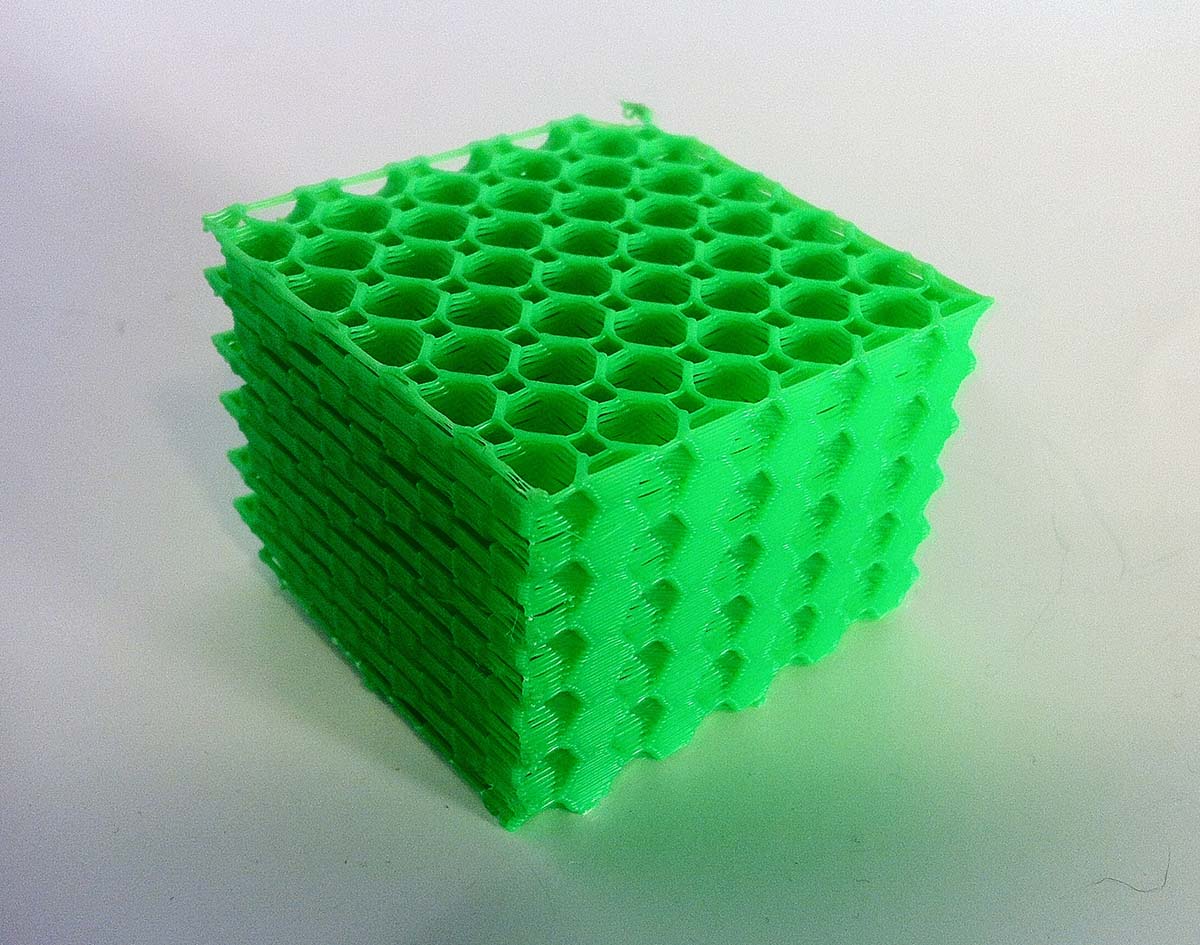

Under-extrusion occurs when the extruder fails to push out enough filament, resulting in gaps or an inconsistent infill pattern. This can make the infill more visible through the outer layers. Over-extrusion, on the other hand, leads to excess material being deposited, which can distort the infill pattern and affect its visibility. Calibrating the extrusion steps/mm and ensuring a consistent flow can help minimize these issues.

2. Calibration

Proper calibration of your 3D printer is vital for achieving accurate prints. This includes calibrating the bed level, nozzle height, and extruder steps/mm. An uneven or incorrectly calibrated bed can cause issues with layer adhesion, resulting in gaps and visibility of the infill. A misaligned nozzle height can also lead to inconsistent extrusion and visible infill lines.

Regularly calibrating your printer and ensuring proper leveling and alignment will help minimize the visibility of infill through the outer layers. This can be done using calibration prints, such as bed level tests, first layer calibration, and extruder calibration cubes.

By paying attention to these extrusion settings and performing regular calibrations, you can achieve better overall print quality, reducing the visibility of infill through the outer layers. It is important to note that different 3D printers may require specific calibration procedures, so consult your printer’s documentation or online resources for detailed instructions.

Why Can I See Infill Through Outer Layer

Read more: Why Can’t Birds See Glass

Top and Bottom Layer Thickness

The thickness of the top and bottom layers in a 3D print can impact the visibility of infill through the outer layers. Let’s explore how adjusting these layer thicknesses can affect your prints:

1. Top Layer Thickness

The top layer of a 3D print is the solid layer that forms the uppermost surface of the print. Increasing the thickness of the top layer can help conceal the infill beneath it, reducing its visibility. With a thicker top layer, the infill pattern is less likely to show through, resulting in a smoother and more solid appearance.

However, it’s important to find the right balance when increasing the top layer thickness. Very thick top layers may result in longer print times and increased material usage, so it’s essential to consider the trade-off between print quality and efficiency.

2. Bottom Layer Thickness

The bottom layer of a 3D print is similar to the top layer but forms the base of the print. Adjusting the thickness of the bottom layer can also impact the infill visibility. By increasing the thickness of the bottom layer, you provide a solid foundation for the print, which can help minimize the visibility of the infill pattern from the bottom.

Similarly to the top layer, it’s important to strike a balance between print quality and efficiency when adjusting the bottom layer thickness. Find the optimal thickness that provides sufficient stability and minimizes the visibility of infill without causing excessive print times or material usage.

Experimenting with different top and bottom layer thicknesses can help you find the ideal configuration that suits your specific print requirements. Keep in mind that the layer thickness settings may also affect other aspects of the print, such as overall print time and surface finish.

By considering the top and bottom layer thicknesses and finding the right balance, you can achieve prints with reduced visibility of infill through the outer layers, resulting in a more aesthetically pleasing appearance.

Why Can I See Infill Through Outer Layer

Printing Speed and Cooling

The printing speed and cooling settings during the 3D printing process can greatly affect the visibility of infill through the outer layers. Let’s dive into these factors and how they can impact your prints:

Read more: How To See Through Frosted Glass

1. Printing Speed

The speed at which the printer head moves during the printing process can influence the visibility of the infill. High printing speeds may result in a shorter time for the filament to solidify, leading to a more visible infill pattern through the outer layers. On the other hand, slower speeds provide more time for the filament to cool and bond, reducing the visibility of infill.

It’s important to find a balance when it comes to printing speed. Too high, and you may sacrifice print quality and increase the visibility of infill. Too low, and it can significantly lengthen the printing time. Adjusting the printing speed based on the specific print and desired quality can help minimize the visibility of infill while maintaining a reasonable print time.

2. Cooling

Cooling plays a vital role in the 3D printing process. It helps the molten filament solidify quickly and maintain its shape. Proper cooling is essential for reducing the visibility of infill through the outer layers. Insufficient cooling can result in a longer “plastic state” for the filament, allowing the infill pattern to be more visible as the layers are stacked on top of each other.

Many 3D printers have built-in cooling fans or cooling settings that can be customized. Ensuring adequate cooling airflow over the print can help the layers solidify faster, reducing the visibility of infill. It’s recommended to test different cooling settings and observe the impact on the print quality.

By adjusting the printing speed and cooling settings appropriately, you can achieve prints with reduced visibility of infill through the outer layers. Finding the optimal balance between speed and cooling can help you produce high-quality and visually pleasing prints.

Why Can I See Infill Through Outer Layer

Techniques to Minimize Infill Visibility

While it’s challenging to completely eliminate the visibility of infill through the outer layers, there are several techniques you can implement to minimize its appearance. Let’s explore these techniques:

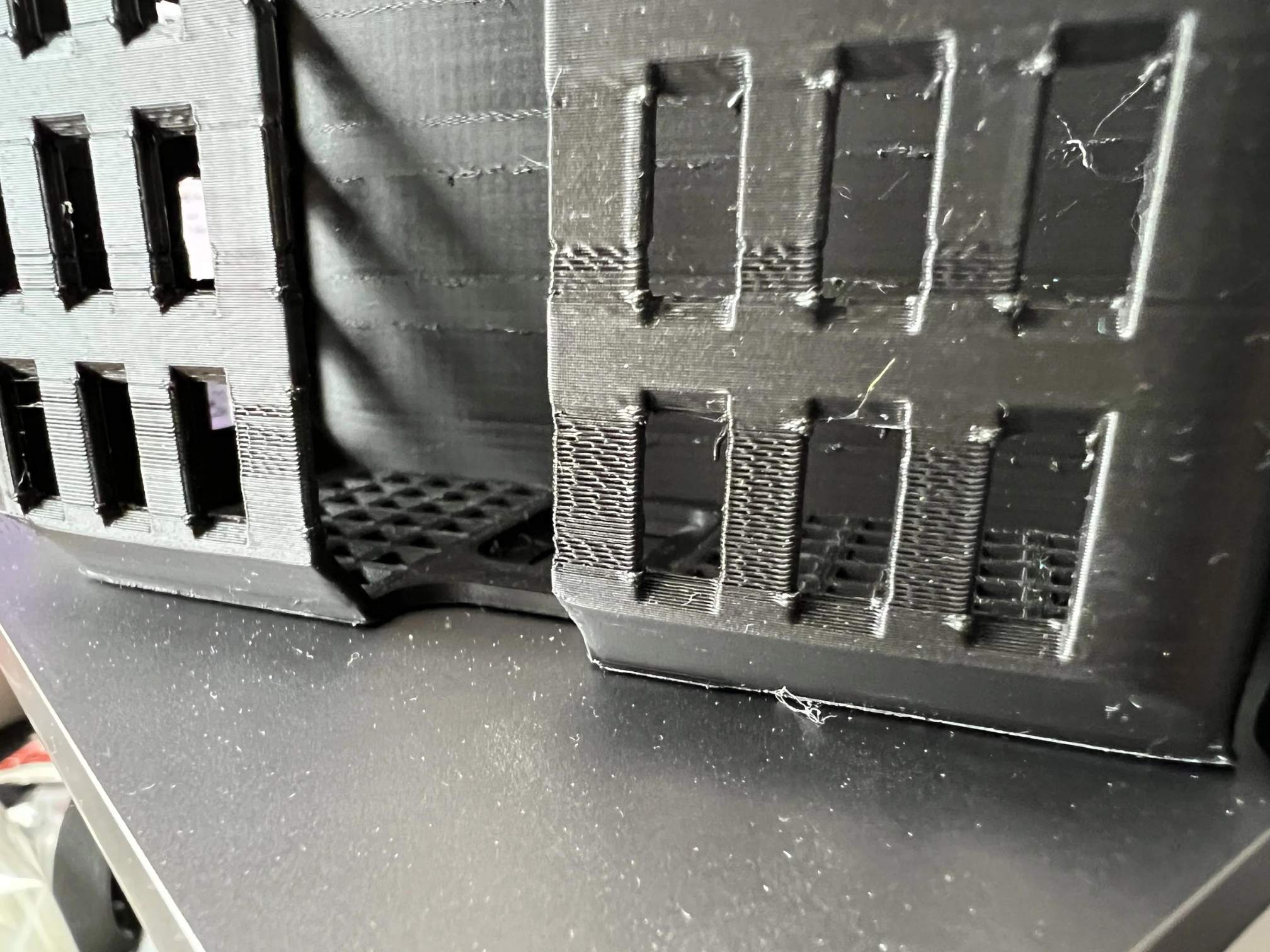

1. Infill Pattern Selection

Choosing the right infill pattern can have a significant impact on the visibility of infill. Some patterns, such as rectilinear or grid, tend to be more visible as they create distinct lines. On the other hand, patterns like cubic or gyroid can help distribute the infill more evenly, reducing its visibility. Experimenting with different infill patterns can help you find the one that best suits your desired appearance.

2. Gradual Infill Transition

Gradually transitioning the infill density from the inner layers to the outer layers can help minimize its visibility. You can achieve this by adjusting the infill density settings in your slicing software. By reducing the density as you approach the outer layers, you create a smoother transition with less pronounced infill lines.

3. Strategic Layer Thickness Changes

Another technique to minimize infill visibility is to strategically change the layer thickness for specific sections of your print. Increasing the layer thickness for the outermost layers can help create a thicker, more solid shell that conceals the infill. This technique can be particularly useful for prints where the outer appearance is a priority.

4. Post-Processing and Finishing Techniques

Post-processing and finishing techniques can also help reduce the visibility of infill. Sanding, filling, and smoothing the outer surface of the print can help hide the infill lines and create a more seamless look. Additionally, applying a coat of primer and painting the print can further enhance its appearance and hide any remaining infill visibility.

It’s important to remember that the effectiveness of these techniques may vary depending on factors like filament material, print design, and specific printing parameters. It may require some experimentation and fine-tuning to achieve the desired results.

By implementing these techniques, you can significantly reduce the visibility of infill through the outer layers, resulting in prints with a more polished and professional appearance.

Why Can I See Infill Through Outer Layer

Conclusion

The visibility of infill through the outer layers is a common challenge faced by 3D printing enthusiasts. However, by understanding the factors that contribute to this issue and implementing the right techniques, you can minimize the appearance of infill and achieve high-quality prints with a seamless outer layer.

Factors such as material selection and density, extrusion settings and calibration, top and bottom layer thickness, and printing speed and cooling all play a role in the visibility of infill. By carefully considering and adjusting these factors, you can achieve better print quality, conceal the infill, and enhance the overall appearance of your prints.

Furthermore, techniques such as infill pattern selection, gradual infill transition, strategic layer thickness changes, and post-processing and finishing techniques can further minimize the visibility of infill. These techniques enable you to create smoother and more solid outer layers, achieving a more professional and visually appealing print.

It’s important to note that finding the right balance between print quality, time, and material usage may require some experimentation and adjustment based on your specific print requirements. Each 3D printer and filament material may have its own unique set of considerations, so don’t be afraid to test different settings and techniques to achieve the desired results.

In conclusion, with a deep understanding of the factors influencing infill visibility and the implementation of effective techniques, you can overcome the challenge of infill visibility and create beautiful, high-quality 3D prints with seamless outer layers.

Frequently Asked Questions about Why Can I See Infill Through Outer Layer

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “Why Can I See Infill Through Outer Layer”