Home>Home Maintenance>How To Fix Air Conditioner Compressor

Home Maintenance

How To Fix Air Conditioner Compressor

Modified: March 7, 2024

Learn how to fix your air conditioner compressor with these simple home maintenance tips. Keep your AC running smoothly and avoid costly repairs.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to our comprehensive guide on how to fix an air conditioner compressor. As homeowners, we understand the importance of maintaining a comfortable indoor environment, especially during the hot summer months. The air conditioner compressor plays a crucial role in cooling your home by compressing and circulating refrigerant, allowing for efficient heat transfer.

Unfortunately, like any mechanical component, the air conditioner compressor can experience issues over time. These issues can range from minor malfunctions to major failures, resulting in a breakdown of your cooling system. However, with the right knowledge and tools, many common compressor problems can be diagnosed and repaired, saving you money on costly professional repairs or replacements.

In this guide, we will delve into the various aspects of the air conditioner compressor and provide you with step-by-step instructions to fix common issues. We will also discuss the necessary tools and materials you’ll need, as well as important safety precautions to ensure your well-being throughout the repair process.

Whether your air conditioner is not blowing cold air, making strange noises, or failing to turn on altogether, this guide will equip you with the skills and knowledge to tackle the compressor repair yourself. So, roll up your sleeves and let’s dive into this handy guide on how to fix an air conditioner compressor!

Key Takeaways:

- Fixing your air conditioner compressor is possible with the right tools and knowledge. By following safety precautions and step-by-step instructions, you can save money on repairs and keep your home cool.

- Regular maintenance, testing, and monitoring are essential for ensuring your repaired compressor works efficiently. Stay informed, stay proactive, and enjoy a comfortable indoor environment.

Read more: How To Check An Air Conditioner Compressor

Understanding the Air Conditioner Compressor

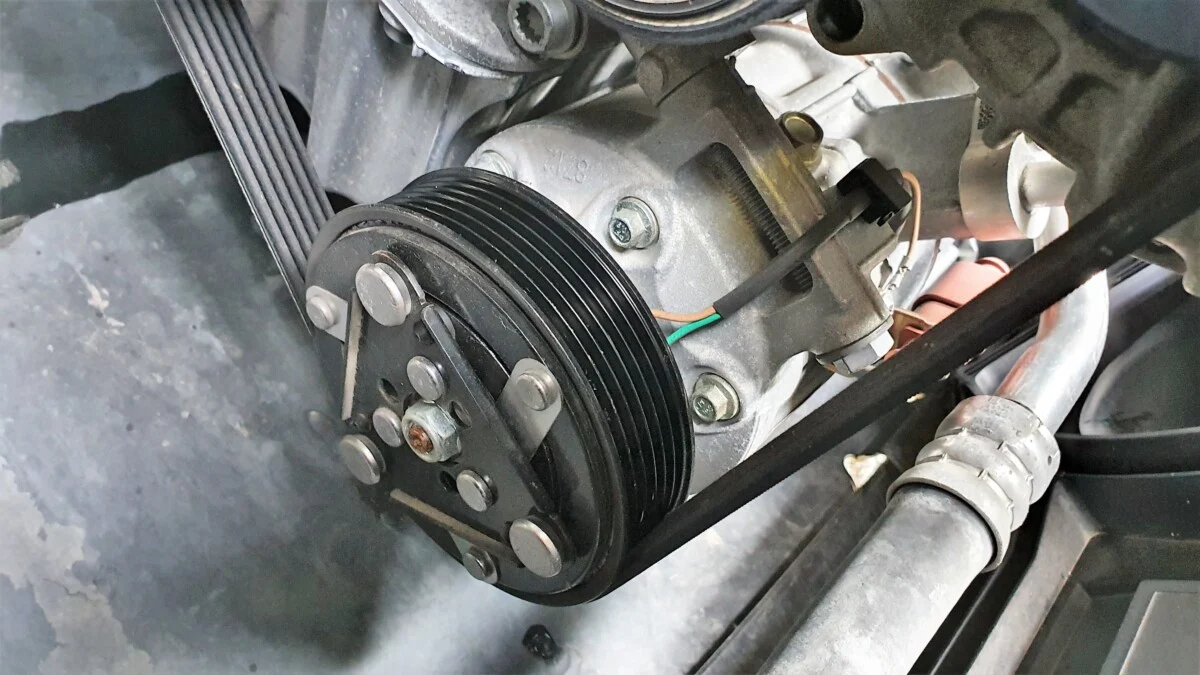

Before we jump into the process of fixing the air conditioner compressor, it’s important to have a solid understanding of how this vital component works. The compressor is essentially the heart of the air conditioning system, responsible for pressurizing the refrigerant and circulating it through the system to facilitate the transfer of heat.

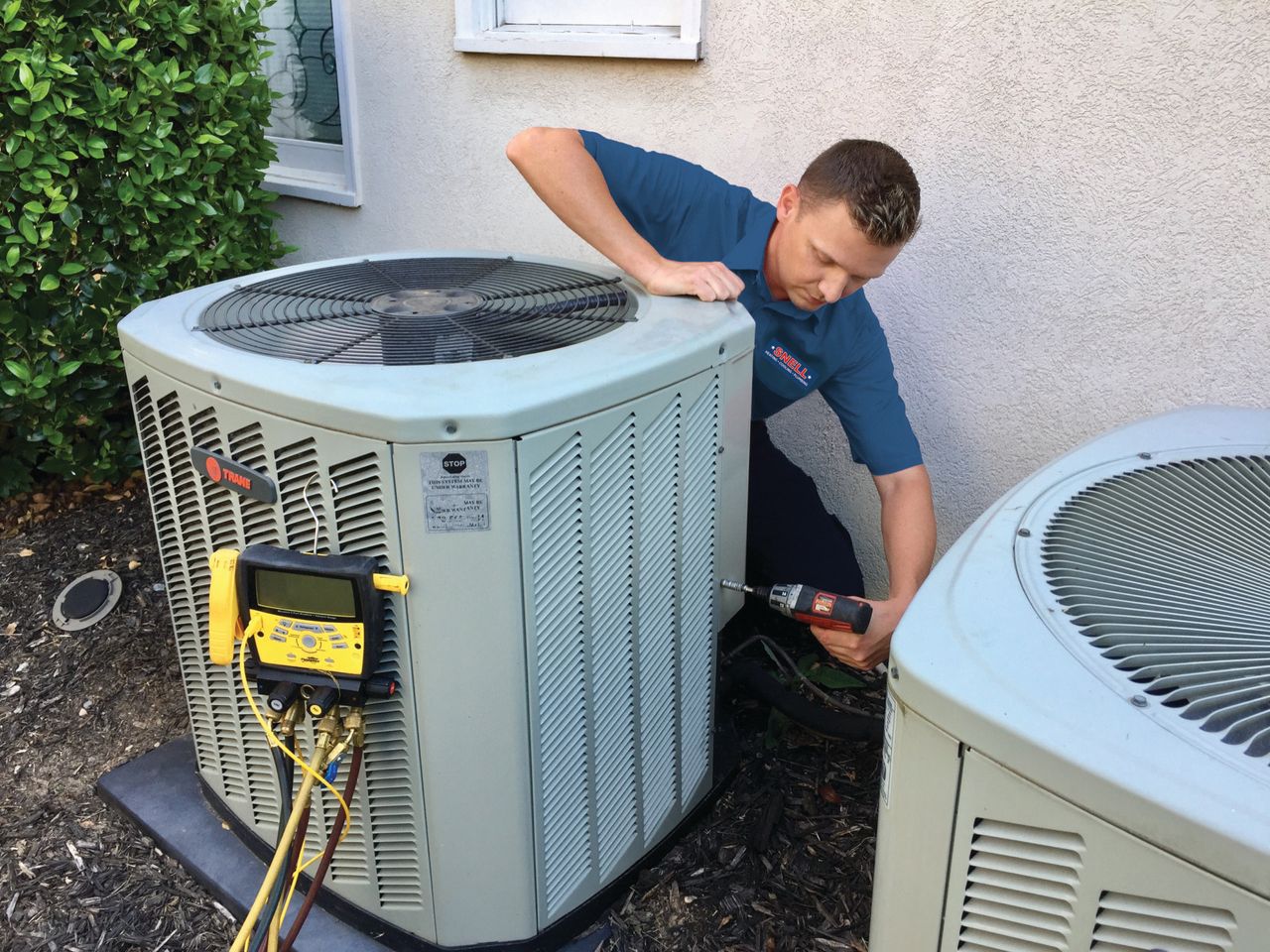

The compressor is typically located on the exterior unit of your air conditioner, known as the condenser unit, and is powered by an electric motor. It works by compressing low-pressure, low-temperature refrigerant vapor from the evaporator coil, raising its temperature and pressure.

Once the refrigerant is compressed, it moves to the condenser coil where it releases heat to the surrounding air, causing it to condense into a high-pressure liquid. This process ensures efficient cooling inside your home.

Compressor issues can arise due to various factors, including electrical problems, refrigerant leaks, and mechanical failures. These issues can lead to inadequate cooling, reduced energy efficiency, and even complete system failure.

By understanding the workings of the air conditioner compressor, you’ll be better equipped to diagnose and fix any problems that may arise. However, please note that some compressor issues may require professional assistance, especially those involving refrigerant leaks or complex electrical problems.

In the next sections, we will discuss common issues that can affect the compressor and guide you through the necessary steps to fix them. Remember, it’s always a good idea to consult your air conditioner’s user manual or seek professional help if you are unsure about any aspect of the repair process.

Common Issues with the Compressor

The air conditioner compressor can experience a range of problems, which can impact its efficiency and overall performance. Here are some of the most common issues you may encounter:

- Electrical Problems: Faulty wiring, tripped circuit breakers, or damaged capacitors can affect the compressor’s ability to receive the necessary electrical power and function properly.

- Refrigerant Leaks: Refrigerant leaks can cause a drop in the refrigerant level, resulting in reduced cooling capacity and potential damage to the compressor.

- Compressor Overheating: Inadequate airflow, dirty coils, or a malfunctioning fan can cause the compressor to overheat, leading to system shutdown or a decrease in efficiency.

- Compressor Won’t Start: If the compressor fails to start when the air conditioner is turned on, it could be due to a faulty start capacitor, a malfunctioning compressor motor, or an issue with the control board.

- Loud Noises: Unusual noises, such as grinding, squealing, or banging sounds, may indicate a mechanical problem with the compressor, such as worn bearings or damaged internal components.

It’s important to note that some of these issues may require professional assistance, especially if they involve complex repairs or the handling of refrigerant. However, there are certain troubleshooting steps you can take to address these common issues, which we will cover in the upcoming sections of this guide.

Remember to exercise caution and prioritize safety throughout the repair process. If you’re unsure about any aspect of the repair or feel uncomfortable performing the troubleshooting steps, it’s always best to consult a qualified HVAC technician.

Tools and Materials Required

Before you begin the process of fixing the air conditioner compressor, it’s essential to gather the necessary tools and materials. Having these items on hand will help ensure a smooth and efficient repair process. Here’s a list of the tools and materials you’ll likely need:

- Screwdriver Set: A set of both Phillips and flathead screwdrivers will come in handy for removing access panels and securing components.

- Multimeter: This device allows you to measure voltage, resistance, and continuity, making it essential for diagnosing electrical issues.

- Adjustable Wrench: An adjustable wrench is useful for tightening or loosening nuts and bolts.

- Pliers: A pair of locking pliers and needle-nose pliers can assist in gripping and manipulating small components.

- Refrigerant Leak Detector: If you suspect a refrigerant leak, a leak detector can help identify the source of the leak for repair.

- Refrigerant Recovery System: If you need to handle refrigerant, it’s crucial to have a recovery system to safely remove and store the refrigerant before making any repairs.

- Replacement Parts: Depending on the specific issue with your compressor, you may need to have replacement parts on hand, such as capacitors, relays, or fan motors.

- Cleaning Supplies: It’s important to have cleaning supplies like a brush, compress air, and coil cleaner to remove dirt, debris, and dust from the condenser coils and other components.

- Safety Equipment: Don’t forget to prioritize safety. Wear protective gloves, safety goggles, and a face mask to protect yourself from potential hazards like electrical shock, refrigerant exposure, and debris.

Ensure that you have the appropriate tools and materials for your specific air conditioner model. Consult your air conditioner’s user manual or seek professional advice if you are uncertain about any specific requirements.

By having the necessary tools and materials ready, you can save time and frustration during the repair process, and increase the chances of successfully fixing your air conditioner compressor.

Safety Precautions

When working with the air conditioner compressor or any other electrical components of your cooling system, it’s essential to prioritize safety. Follow these safety precautions to ensure a safe repair process:

- Turn Off Power: Before starting any repairs, make sure to turn off the power to your air conditioner. This can typically be done by switching off the circuit breaker or disconnecting the power supply at the main electrical panel.

- Wear Protective Gear: It’s essential to protect yourself from potential hazards. Wear safety goggles, gloves, and a face mask to shield yourself from electrical shock, refrigerant exposure, and debris.

- Work in a Well-Ventilated Area: If you’re working with refrigerant or cleaning solutions, ensure that you’re in a well-ventilated area to avoid inhaling potentially harmful fumes.

- Use Proper Lifting Techniques: Compressor components can be heavy, so use proper lifting techniques to avoid injuries. When possible, enlist the help of a second person to assist with lifting and maneuvering components.

- Follow Manufacturer’s Instructions: Always refer to your air conditioner’s user manual for specific safety instructions and guidelines. Different models may have unique requirements, so it’s important to follow the manufacturer’s instructions.

- Avoid Working on Live Wires: Never attempt to work on live electrical wires or components. Ensure that the power is completely turned off and use a multimeter to verify the absence of voltage before proceeding.

- Properly Dispose of Refrigerant and Packaging: If you handle refrigerant, be sure to follow proper disposal guidelines and regulations. Additionally, dispose of packaging materials and any other debris responsibly.

- Know Your Limits: While it’s admirable to take on DIY repairs, it’s important to recognize your limits. If at any point you feel uncomfortable or unsure about a specific repair task, it’s best to seek professional assistance.

By adhering to these safety precautions, you can minimize the risk of accidents or injuries and ensure a safe repair process. If you are uncertain about any step or lack the necessary experience, it’s always best to consult a qualified HVAC technician.

Regularly clean and replace the air filters in your air conditioner to prevent clogging and strain on the compressor. This can help improve the efficiency and lifespan of the compressor.

Read more: What Does An Air Conditioner Compressor Do

Step-by-Step Guide to Fixing the Air Conditioner Compressor

Now that you have a good understanding of the air conditioner compressor, common issues, and the necessary tools and safety precautions, let’s dive into the step-by-step process of fixing the compressor. Remember to consult your air conditioner’s user manual and verify the specific requirements and recommendations for your model before proceeding.

- Turn Off Power: Begin by turning off the power to your air conditioner at the circuit breaker or main electrical panel.

- Remove Access Panel: Locate the access panel on the condenser unit. Use a screwdriver to remove any screws securing the panel and carefully remove it to gain access to the compressor.

- Inspect Electrical Connections: Inspect the electrical connections for any loose wires or signs of damage. Use a multimeter to check for continuity and ensure proper electrical connections.

- Test Start Capacitor: If your compressor fails to start, a faulty start capacitor may be the issue. Use a multimeter to test the capacitor for continuity and compare the readings with the manufacturer’s specifications. Replace the capacitor if it is defective.

- Check Control Board: Examine the control board for any signs of damage or burnt components. If you notice any issues, it may be necessary to replace the control board.

- Inspect Compressor Motor: Conduct a visual inspection of the compressor motor for any visible damage or signs of wear. Check the motor windings using a multimeter to ensure they are not open or shorted. Replace the motor if necessary.

- Clean Condenser Coils: Use a soft brush and coil cleaner to remove dirt, debris, and dust from the condenser coils. Ensure that the coils are clean and free of any obstructions that may impede airflow to the compressor.

- Test Refrigerant Levels: If you suspect a refrigerant leak, use a refrigerant leak detector to locate the source of the leak. Once found, repair the leak and recharge the system with the appropriate refrigerant following manufacturer guidelines.

- Replace Faulty Components: If you have identified any faulty components during your inspection, such as capacitors, relays, or fan motors, replace them with new ones that are compatible with your air conditioner model.

- Reassemble and Power Up: Once you have completed the necessary repairs and replacements, reassemble the access panel and securely fasten it with screws. Turn on the power to your air conditioner and test its operation to ensure the compressor is functioning correctly.

Remember to take your time and carefully follow each step. If you encounter any difficulties or are unsure about any aspect of the repair process, it’s best to seek professional assistance.

Following these step-by-step instructions, you’ll be well on your way to fixing common issues with your air conditioner compressor and restoring efficient and reliable cooling performance to your home.

Testing the Repaired Compressor

Once you have completed the necessary repairs on your air conditioner compressor, it’s crucial to test the unit to ensure that it is functioning correctly. Testing the repaired compressor will help you verify the effectiveness of your repairs and confirm that your cooling system is operating efficiently. Here’s how to test the repaired compressor:

- Power Up: Turn on the power to your air conditioner at the circuit breaker or main electrical panel.

- Set Thermostat: Set the thermostat to a desired temperature setting that will prompt the air conditioner to start running and engage the compressor.

- Observe Operation: Listen for any unusual noises coming from the compressor and pay attention to the airflow and cooling performance. The air blowing from the vents should be cool and steady.

- Monitor Temperature: Use a thermometer to measure the air temperature at the supply vents. It should be within the expected range based on the thermostat settings. If the air is not cooling properly, there may still be an issue with the compressor or other components.

- Check for Proper Cycling: Observe the compressor’s cycling behavior. It should turn on and off as needed to maintain the desired temperature. If the compressor continuously runs non-stop or frequently cycles on and off rapidly, there may be an issue that needs further attention.

- Inspect Refrigerant Lines: Examine the refrigerant lines for any signs of leaks, such as oil spots or frost buildup. Ensure that the refrigerant levels are stable and within the appropriate range.

- Monitor Energy Consumption: Keep an eye on your electricity usage and compare it to your typical energy consumption. If there is a significant increase in energy usage, it may indicate an ongoing issue or inefficient compressor operation.

By carefully testing the repaired compressor, you can evaluate the effectiveness of your repairs and address any lingering issues promptly. If you notice any problems during the testing phase or are unsure about the results, it’s best to consult a professional HVAC technician who can provide further assistance and guidance.

Your goal is to achieve optimal cooling performance while ensuring energy efficiency and a comfortable indoor environment. Regular maintenance and monitoring can help prolong the lifespan of your compressor and prevent potential problems from escalating.

Additional Tips and Troubleshooting

While the step-by-step guide and testing process covered the basics of fixing an air conditioner compressor, there are additional tips and troubleshooting steps that can help you address common issues and ensure optimal performance. Here are some additional tips to consider:

- Regular Maintenance: Keep up with routine maintenance tasks, such as cleaning or replacing air filters, clearing debris around the condenser unit, and scheduling professional tune-ups. Regular maintenance helps prevent future problems and keeps your compressor running efficiently.

- Check for Proper Airflow: Verify that there is adequate airflow around the condenser unit. Clear any obstructions, such as overgrown vegetation, debris, or furniture, to allow for proper air circulation.

- Monitor Thermostat Settings: Make sure the thermostat settings are appropriate for the desired comfort level, and ensure that it is functioning correctly. Clean the thermostat periodically to remove dust and debris that can affect its accuracy.

- Address Ductwork Issues: Inspect your ductwork for leaks, gaps, or obstructions. Sealing ductwork and ensuring proper insulation can help improve airflow and prevent energy loss.

- Consider Insulation: Proper insulation in your home can help prevent heat gain, reducing strain on your air conditioner compressor. Insulate walls, attics, and windows to maintain a more comfortable indoor temperature.

- Keep an Eye on Energy Consumption: Monitor your energy bills and compare them to previous months. If there is a significant increase in energy usage, it could indicate an issue with the compressor or other components. Seek professional assistance if necessary.

- Stay Informed: Stay up to date with your air conditioner’s user manual, manufacturer’s recommendations, and any relevant information from reputable sources. Understanding your specific model and its requirements can help you troubleshoot and address problems more efficiently.

If you encounter any issues that are beyond your expertise or the scope of this guide, it’s best to seek professional assistance from a qualified HVAC technician. They have the expertise and specialized tools necessary to diagnose and fix complex problems, ensuring the optimal functioning of your air conditioner compressor.

Remember, proper maintenance, timely repairs, and proactive troubleshooting go a long way in preventing major issues and maximizing the lifespan of your air conditioner compressor. By taking care of your cooling system, you can enjoy a comfortable and efficient indoor environment for years to come.

Conclusion

Fixing an air conditioner compressor may seem like a daunting task, but with the right knowledge and tools, many common issues can be tackled successfully. By understanding the workings of the compressor, identifying common problems, and following a systematic repair process, you can save money on professional repairs and ensure a comfortable indoor environment.

In this comprehensive guide, we covered various aspects of fixing the air conditioner compressor. We started with an introduction to the importance of the compressor and its role in cooling your home. Then, we explored common issues that can arise, such as electrical problems, refrigerant leaks, and compressor overheating.

We provided a list of tools and materials necessary for the repairs, as well as important safety precautions to keep in mind throughout the process. The step-by-step guide walked you through assessing and addressing issues with the compressor, ensuring proper cleaning, and testing the repaired compressor for optimal performance.

We also provided additional tips for regular maintenance, troubleshooting, and energy efficiency, emphasizing the importance of staying informed and seeking professional assistance when needed.

Remember, if at any point you feel uncomfortable or unsure about a certain repair task, it’s best to consult a qualified HVAC technician. They have the expertise and experience to handle more complex issues and ensure the safe functioning of your air conditioner compressor.

By following the guidelines outlined in this guide, you can have the confidence to take on compressor repairs, enhance the efficiency of your cooling system, and enjoy a comfortable and cool indoor environment for years to come.

Stay proactive, stay informed, and enjoy the benefits of a properly functioning air conditioner compressor!

Frequently Asked Questions about How To Fix Air Conditioner Compressor

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.