Home>Home Maintenance>What Is An Air Conditioner Compressor

Home Maintenance

What Is An Air Conditioner Compressor

Modified: March 21, 2024

Discover how an air conditioner compressor works and why it is crucial for efficient home maintenance. Get insights on troubleshooting and maintenance tips.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the fascinating world of air conditioner compressors! Whether you are a homeowner looking to learn more about how your cooling system works or a technician seeking a deeper understanding of the machinery you work with, this article is designed to provide you with comprehensive knowledge about air conditioner compressors.

An air conditioner compressor plays a crucial role in the functioning of your cooling system. It is often referred to as the heart of an air conditioner because it is responsible for pressurizing and circulating the refrigerant, which is essential for cooling your home. Understanding how an air conditioner compressor works can help you diagnose and troubleshoot common issues, as well as ensure proper maintenance and care.

In this article, we will delve into the definition, functions, types, working mechanism, common problems, troubleshooting tips, and maintenance practices for air conditioner compressors. So, let’s dive right in and explore the world of air conditioner compressors!

Key Takeaways:

- Air conditioner compressors are like the heart of your cooling system, circulating and pressurizing refrigerant to keep your home cool. Understanding their functions and types can help you troubleshoot issues and ensure proper maintenance.

- Common issues with air conditioner compressors, such as refrigerant leaks and overheating, can be addressed with simple troubleshooting tips like checking power supply and cleaning filters. Regular maintenance and care practices can help extend the lifespan of your compressor.

Read more: What Does An Air Conditioner Compressor Do

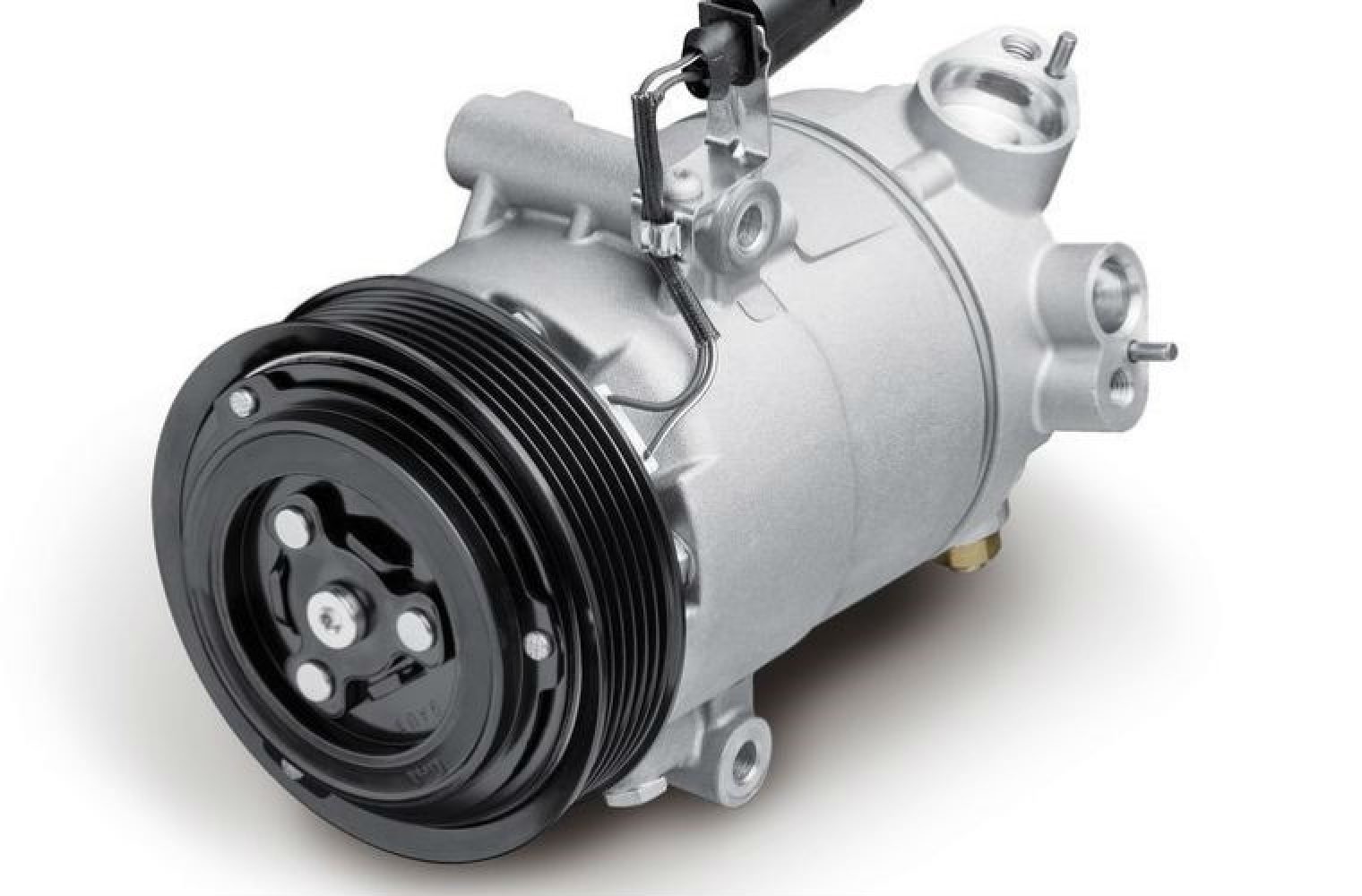

Definition of an Air Conditioner Compressor

An air conditioner compressor is a crucial component of an air conditioning system that is responsible for circulating and pressurizing the refrigerant, allowing the system to cool your home efficiently. It is essentially a mechanical device that compresses low-pressure refrigerant vapor into high-pressure vapor, facilitating heat transfer and cooling.

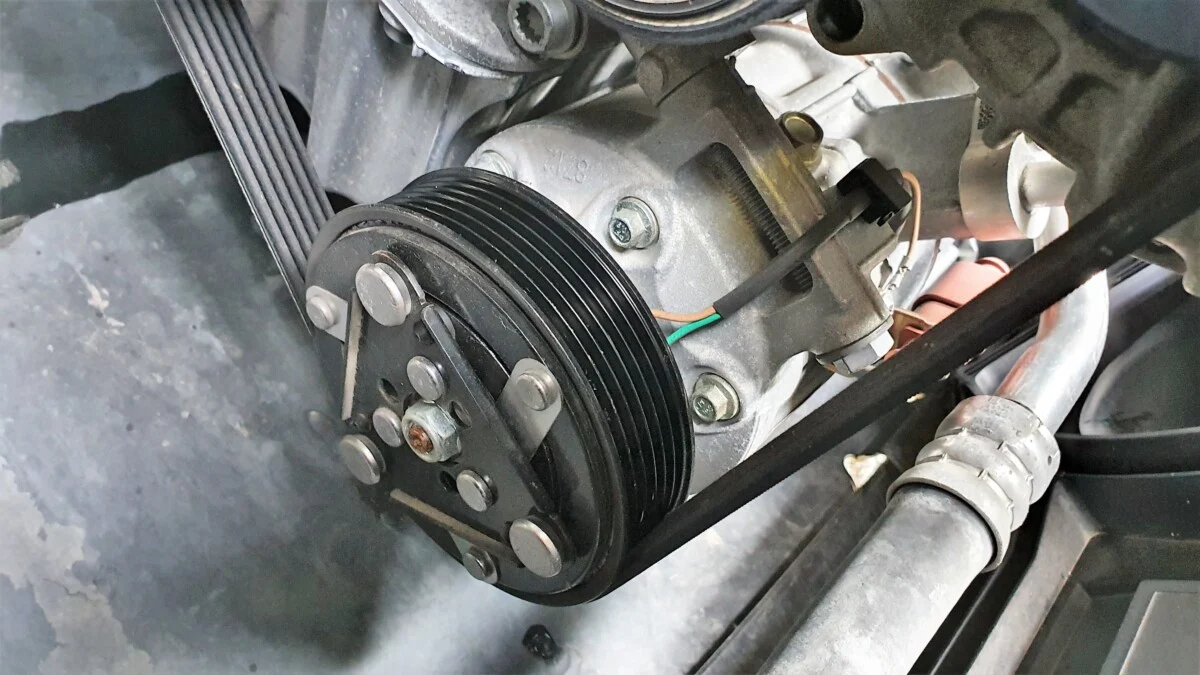

The compressor is typically located in the outdoor unit of the air conditioning system. It is usually a cylindrical or scroll-shaped device with an electric motor and various internal components. The motor drives a piston or a set of scrolled diaphragms, compressing the refrigerant and increasing its pressure and temperature.

The refrigerant, in its gaseous state, enters the compressor at low pressure and temperature. As the piston or diaphragms compress the refrigerant, its pressure and temperature rise significantly. The high-pressure, high-temperature vapor is then sent to the condenser, where it releases heat and transforms back into a liquid state.

Overall, the primary function of an air conditioner compressor is to ensure the proper circulation and pressurization of the refrigerant, allowing the air conditioning system to effectively remove heat from the indoor environment and deliver cool air.

Now that we understand the basic definition of an air conditioner compressor, let’s explore its functions and the different types available in more detail.

Functions of an Air Conditioner Compressor

The air conditioner compressor performs several important functions in the cooling process of an air conditioning system. Let’s take a closer look at these functions:

- Circulation of Refrigerant: One of the primary functions of the compressor is to circulate the refrigerant throughout the air conditioning system. The compressor creates a pressure difference that allows the refrigerant to flow from the evaporator coil to the condenser coil, facilitating the cooling process.

- Pressurization of Refrigerant: The compressor plays a crucial role in pressurizing the low-pressure refrigerant vapor, converting it into high-pressure vapor. By compressing the refrigerant, the compressor increases its temperature and energy level, making it more efficient for heat transfer.

- Heat Transfer: The compressed refrigerant vapor, with high pressure and temperature, moves to the condenser coil. The condenser facilitates heat transfer and releases the heat absorbed from the indoor environment to the outdoor atmosphere. This process cools down the refrigerant, allowing it to transform back into a liquid state.

- Energy Conversion: The compressor transforms electrical energy into mechanical energy to perform its function. The electric motor attached to the compressor drives the piston or diaphragms, which compress the refrigerant. This energy conversion process allows the compressor to generate the necessary pressure to circulate and pressurize the refrigerant.

These functions are essential for the seamless operation of the air conditioning system. Without the compressor, the refrigerant would not be able to circulate or undergo the necessary pressure changes to achieve cooling. It acts as the driving force behind the entire cooling process, ensuring efficient cooling of your home.

Now that we understand the functions of an air conditioner compressor, let’s explore the different types of compressors commonly used in air conditioning systems.

Types of Air Conditioner Compressors

When it comes to air conditioner compressors, there are several different types available, each with its own unique characteristics and advantages. Let’s take a closer look at the most common types of air conditioner compressors:

- Reciprocating Compressor: This type of compressor uses a piston-cylinder mechanism to compress the refrigerant. It operates by reciprocating (back-and-forth) motion, driven by an electric motor. Reciprocating compressors are known for their durability and ability to handle high cooling loads, making them suitable for larger air conditioning systems.

- Scroll Compressor: Scroll compressors have two interleaving spiral-shaped scrolls, one fixed and one orbiting. These scrolls create pockets of decreasing volume, which compress and move the refrigerant. Scroll compressors are known for their reliability, efficiency, and quieter operation. They are widely used in residential and small commercial air conditioning systems.

- Rotary Compressor: Rotary compressors use a rotating vane or blade to compress the refrigerant. They operate with continuous rotary motion and are known for their compact size, simplicity, and high energy efficiency. Rotary compressors are commonly found in window air conditioners and small split-system units.

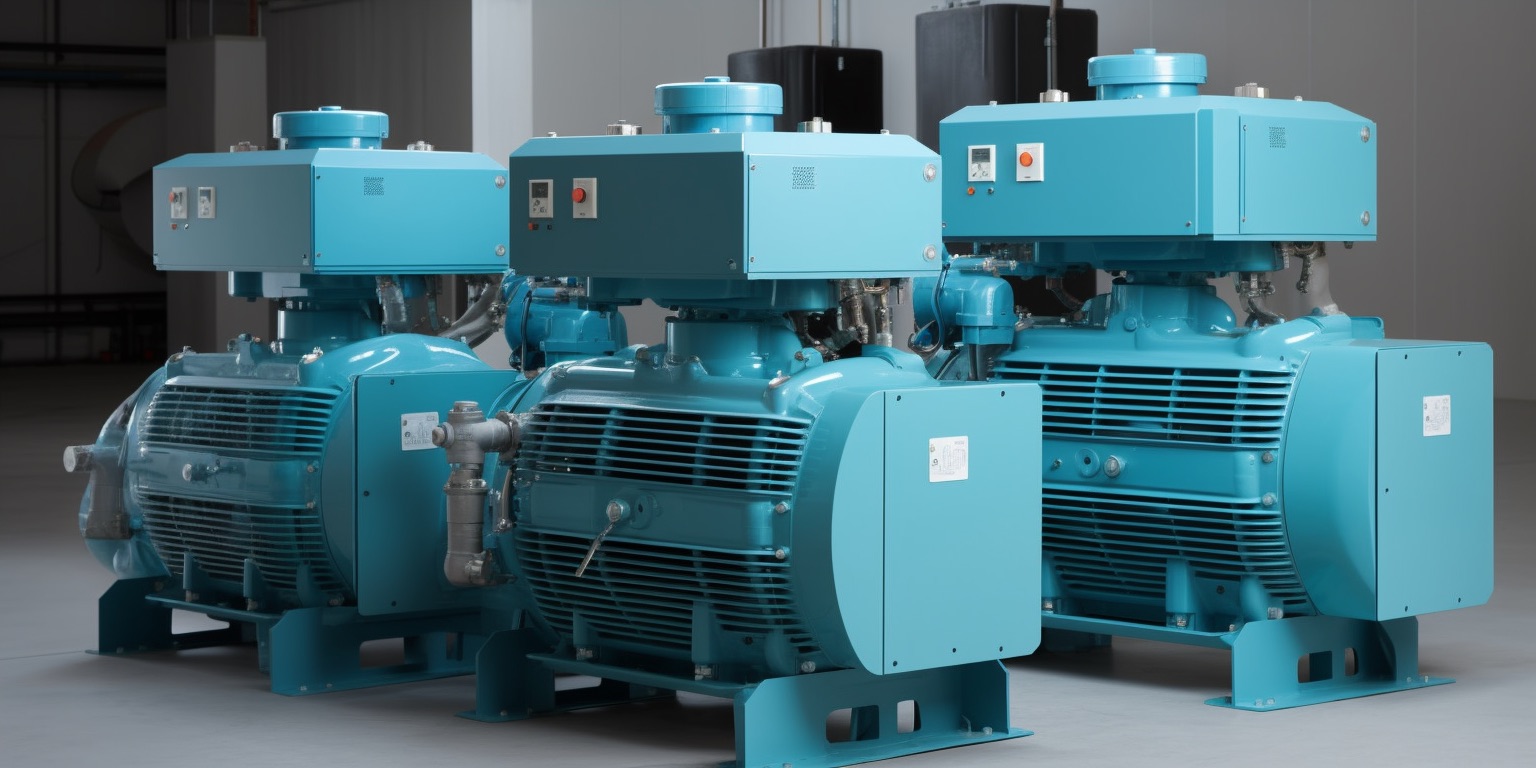

- Screw Compressor: Screw compressors consist of two helical rotors that rotate in opposite directions, compressing the refrigerant. They are known for their high capacity and efficiency, making them suitable for large commercial and industrial air conditioning systems. Screw compressors are often used in central chiller systems.

- Centrifugal Compressor: Centrifugal compressors use centrifugal force to accelerate the refrigerant and then convert its kinetic energy into pressure. They are typically used in very large air conditioning systems, such as central cooling plants. Centrifugal compressors are highly efficient and can handle extremely high cooling capacities.

Each type of air conditioner compressor has its own advantages and is suitable for specific applications. Factors such as cooling requirements, space constraints, noise considerations, and energy efficiency play a role in choosing the right compressor for an air conditioning system.

Now that we have explored the different types of air conditioner compressors, let’s delve deeper into how an air conditioner compressor works.

How an Air Conditioner Compressor Works

Understanding how an air conditioner compressor works is essential for gaining insights into the overall functioning of an air conditioning system. Let’s explore the basic working mechanism of an air conditioner compressor:

1. Circulation of Refrigerant: The process begins with the circulation of the refrigerant, which is a chemical compound responsible for absorbing and releasing heat. The compressor plays a crucial role in facilitating this circulation.

2. Low-Pressure Gas: The refrigerant initially exists in a low-pressure gaseous state. It enters the compressor from the evaporator coil, carrying heat absorbed from the indoor environment.

3. Compression: Once inside the compressor, the refrigerant is compressed. The compressor consists of an electric motor that drives a piston, or in the case of scroll compressors, multiple interleaving scrolls. The compression process increases the pressure and temperature of the refrigerant.

4. High-Pressure Gas: After compression, the refrigerant becomes a high-pressure gas. The high pressure allows the refrigerant to release heat more efficiently during the subsequent stages of the cooling process.

5. Condenser Coil: The high-pressure gas then moves to the condenser coil, located in the outdoor unit of the air conditioning system. In the condenser, the refrigerant releases heat to the surrounding atmosphere, causing it to transform back into a liquid state.

6. Expansion Valve: The liquid refrigerant passes through an expansion valve, which reduces its pressure and temperature.

7. Evaporator Coil: In the evaporator coil, located in the indoor unit, the low-pressure liquid refrigerant absorbs heat from the indoor air, cooling it down.

8. Evaporation: The refrigerant evaporates into a low-pressure gas as it absorbs heat. This completes the cooling cycle.

The air conditioner compressor plays a vital role in this process by compressing the refrigerant and ensuring proper circulation between the indoor and outdoor units. Its ability to increase the pressure and temperature of the refrigerant allows for efficient heat transfer and cooling of the indoor environment.

Understanding the operating principles of an air conditioner compressor can help identify and diagnose issues that may arise during the cooling process, allowing for timely repairs and maintenance.

Now that we have explored the functioning of an air conditioner compressor, let’s move on to discussing common issues that can occur with these compressors.

Regular maintenance, such as cleaning the coils and changing the air filter, can help prolong the life of your air conditioner compressor and ensure it runs efficiently.

Read more: How To Fix Air Conditioner Compressor

Common Issues with Air Conditioner Compressors

Like any mechanical component, air conditioner compressors can experience various issues over time. These issues can affect the performance and efficiency of the air conditioning system. Let’s take a closer look at some common problems that can occur with air conditioner compressors:

- Refrigerant Leaks: One of the most common issues is refrigerant leaks. Leaks can occur due to worn-out seals, cracks in the compressor, or damaged refrigerant lines. Refrigerant leaks not only affect the cooling efficiency but can also lead to further damage to the compressor if not addressed promptly.

- Overheating: Compressors can overheat due to factors like insufficient lubrication, restricted airflow, or electrical issues. Overheating can result in compressor failure and may require professional repairs or replacement.

- Electrical Problems: Faulty electrical components, such as capacitors or wiring connections, can cause issues with the compressor. These electrical problems can hinder the compressor’s performance or lead to motor failure, resulting in a non-functioning air conditioner.

- Starting Problems: Sometimes, compressors may struggle to start or may fail to start altogether. This can be due to a malfunctioning start capacitor or a faulty starting relay. Starting problems need to be addressed promptly to prevent further damage to the compressor.

- Excessive Noise: Unusual noises, such as grinding, squealing, or rattling, coming from the compressor can indicate mechanical issues, such as worn-out bearings or a damaged piston. These noises should be investigated by a professional to prevent further damage.

- Short Cycling: Short cycling refers to a situation where the compressor turns on and off frequently. This can be caused by issues with the thermostat, refrigerant levels, or a malfunctioning pressure switch. Short cycling not only reduces cooling efficiency but can also strain the compressor and lead to premature failure.

It is important to address these issues promptly to prevent further damage to the air conditioner compressor and ensure the longevity of the cooling system. If you encounter any of these problems, it is recommended to consult a professional HVAC technician who can accurately diagnose and repair the issue.

Now that we have identified common problems with air conditioner compressors, let’s move on to the next section where we will discuss troubleshooting tips for compressor problems.

Troubleshooting Tips for Air Conditioner Compressor Problems

If you’re experiencing issues with your air conditioner compressor, there are several troubleshooting steps you can take to identify and potentially resolve the problem. Here are some tips to help you troubleshoot air conditioner compressor problems:

- Check Power Supply: Ensure that the air conditioner is receiving power. Check the circuit breaker and reset it if necessary. Also, verify that the thermostat settings are correct.

- Inspect for Refrigerant Leaks: Look for any signs of refrigerant leaks, such as oily spots or refrigerant odors around the compressor or refrigerant lines. If a leak is suspected, it is best to consult a professional technician for repair.

- Clean or Replace Air Filters: Dirty or clogged air filters can restrict airflow and cause strain on the compressor. Clean or replace the air filters regularly to ensure adequate airflow and proper cooling efficiency.

- Clean Condenser Coils: The condenser coils on the outdoor unit can accumulate dirt and debris over time, affecting the airflow and heat transfer. Clean the condenser coils using a brush or a gentle stream of water to remove any buildup.

- Check for Obstructions: Ensure that there are no obstructions near the outdoor unit, such as plants, furniture, or debris. These obstructions can restrict airflow to the compressor, causing it to overheat or operate inefficiently.

- Inspect Electrical Connections: Examine the electrical connections to the compressor, including wiring and capacitors, for any signs of damage or loose connections. Replace or repair any faulty components as needed.

- Listen for Unusual Noises: Pay attention to any unusual noises coming from the compressor. Grinding, squealing, or rattling sounds can indicate mechanical issues that may require professional attention.

- Check Refrigerant Levels: Low refrigerant levels can cause the compressor to work harder and may indicate a leak. Consult a professional technician to check and recharge the refrigerant if necessary.

While these troubleshooting tips may help resolve minor issues, it is important to note that more complex problems, such as electrical or mechanical failures, may require the expertise of a qualified HVAC technician. Attempting complex repairs without proper knowledge and tools can lead to further damage.

Regular maintenance and professional inspections are recommended to keep your air conditioner compressor in optimal condition and prevent potential problems. Now, let’s move on to discussing maintenance and care practices for air conditioner compressors.

Maintenance and Care for Air Conditioner Compressors

To ensure the longevity and efficient performance of your air conditioner compressor, regular maintenance and care are essential. Here are some tips to help you maintain and care for your air conditioner compressor:

- Regular Cleaning: Keep the outdoor unit clean and free from dirt, debris, and vegetation. Regularly check and clean the condenser coils, fins, and fan blades to ensure proper airflow and heat transfer.

- Change Air Filters: Clean or replace the air filters at least every three months, or as recommended by the manufacturer. This helps maintain proper airflow and prevents dust and debris from entering the air conditioner system.

- Clean Drainage System: Ensure that the condensate drain line is clear of any clogs or blockages. Use a mixture of vinegar and water to clean the drainpipe and prevent the buildup of algae or mold.

- Monitor Refrigerant Levels: Have a professional HVAC technician check the refrigerant levels regularly. If there is a refrigerant leak, it should be repaired promptly, and the system should be recharged with the correct amount of refrigerant.

- Check and Tighten Electrical Connections: Inspect the electrical connections regularly and tighten any loose connections. Faulty electrical connections can hinder the performance of the compressor and may cause overheating or system failure.

- Schedule Professional Maintenance: It is recommended to have a professional HVAC technician perform regular maintenance on your air conditioning system. They can inspect and clean the compressor, check for any potential issues, and ensure optimal performance.

- Protect from Extreme Weather: If your air conditioner is exposed to severe weather conditions, such as hail or strong winds, consider using a protective cover or installing a shelter to shield the outdoor unit from potential damage.

- Follow Manufacturer’s Guidelines: Always refer to the manufacturer’s guidelines and recommendations for maintenance and care. They provide specific instructions that are tailored to your air conditioning system model and can help prolong its lifespan.

Regular maintenance not only ensures the efficient performance of your air conditioner compressor but can also help identify and resolve potential issues before they escalate into major problems. It is important to remember that some maintenance tasks, such as refrigerant adjustments or electrical repairs, should be performed by trained professionals.

By implementing these maintenance and care practices, you can help extend the lifespan of your air conditioner compressor and enjoy cool and comfortable indoor temperatures throughout the hot summer months.

Now, let’s conclude our comprehensive guide to air conditioner compressors.

Conclusion

Understanding the role and operation of an air conditioner compressor is essential for homeowners and technicians alike. As the heart of the air conditioning system, the compressor plays a vital role in circulating and pressurizing the refrigerant to facilitate cooling.

In this article, we have explored the definition and functions of an air conditioner compressor, as well as the various types commonly found in cooling systems. We have also learned about the working mechanism of a compressor, the common issues that can arise, troubleshooting tips, and maintenance practices to keep the compressor in optimal condition.

By being aware of the signs of compressor problems, such as refrigerant leaks, overheating, electrical issues, and unusual noises, you can take appropriate actions in a timely manner and prevent significant damage to the system. Regular maintenance and care, including cleaning, filter replacement, and professional inspections, will help ensure the efficient and reliable operation of your air conditioner compressor.

Remember, while some troubleshooting and maintenance tasks can be performed by homeowners, it is important to consult a professional HVAC technician for complex repairs or when in doubt. Their expertise and knowledge will help identify and resolve issues effectively, minimizing the risk of further damage and optimizing the performance of your air conditioning system.

With proper understanding, care, and maintenance, you can rely on your air conditioner compressor to keep your home cool and comfortable during the hot summer months for years to come. So, take the necessary steps to keep your compressor running efficiently, and enjoy the benefits of a well-functioning cooling system.

Thank you for taking the time to explore the world of air conditioner compressors with us. Stay cool!

Frequently Asked Questions about What Is An Air Conditioner Compressor

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.