Home>Renovation & DIY>Tools & Equipment>What Grit Sandpaper For Fiberglass Boat

Tools & Equipment

What Grit Sandpaper For Fiberglass Boat

Modified: January 4, 2024

Discover the best grit sandpaper for your fiberglass boat with our comprehensive guide. Find the right tools and equipment for a smooth and successful project.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Fiberglass boats are a popular choice among boating enthusiasts due to their durability, versatility, and sleek appearance. However, as with any vessel, fiberglass boats require regular maintenance to keep them in optimal condition. One essential aspect of boat maintenance is properly sanding the fiberglass surfaces. Sanding helps to remove imperfections, smooth out rough areas, and prepare the surface for painting or refinishing.

In this article, we will delve into the importance of sanding fiberglass boats and provide valuable insights on selecting the right grit sandpaper for the job. Whether you are a seasoned boat owner or a novice in the world of boats and equipment, this comprehensive guide will equip you with the knowledge to achieve excellent results.

Key Takeaways:

- Choose the right grit sandpaper for fiberglass boat maintenance by assessing surface condition and using progressive sanding. Consider factors like boat size, safety, and technique for optimal results.

- Regular sanding of fiberglass boats is crucial for maintaining appearance and structural integrity. Use recommended grit sizes, consider boat size and shape, and implement proper techniques for effective and efficient sanding.

Read more: What Grit Sandpaper For Marble

Understanding Fiberglass Boats

Fiberglass boats are constructed using a combination of fiberglass cloth and resin. The fiberglass cloth is saturated with resin and then molded into the desired shape. This construction technique creates a strong and lightweight boat that is resistant to moisture, corrosion, and UV damage.

One of the key benefits of fiberglass boats is their ability to be easily repaired and refinished. Unlike boats made from other materials, such as wood or aluminum, fiberglass boats can be sanded down and re-coated to restore their appearance and integrity.

It is important to note that fiberglass boats may vary in terms of the thickness and quality of the fiberglass layers. Some boats may have a gel coat, which is a protective layer that adds an extra level of smoothness and durability to the surface. Understanding the construction of your particular boat is crucial when it comes to selecting the appropriate sandpaper grit for sanding.

Before proceeding with any sanding on your fiberglass boat, it is recommended to familiarize yourself with its specific construction details. Refer to the manufacturer’s documentation or consult with a boat expert to ensure you approach the sanding process appropriately.

The Importance of Sanding Fiberglass

Sanding fiberglass is a critical step in maintaining and restoring the appearance of your boat. It serves several important purposes in the overall maintenance process:

- Surface Preparation: Sanding removes any wax, dirt, or imperfections on the surface of the fiberglass. This ensures that any new coatings or finishes applied to the boat adhere properly and provide a smooth and even finish.

- Smoothness and Appearance: Over time, fiberglass boats may develop rough areas, scratches, or pits on the surface. By sanding these imperfections, you can achieve a smoother and more aesthetically pleasing result. Additionally, sanding can help to restore the shine and luster of the gel coat or paint on the boat.

- Painting and Refinishing: If you plan to repaint or refinish your boat, proper sanding is crucial. Sanding the surface helps create a suitable canvas for the new paint or finish, allowing it to adhere well and provide a long-lasting and professional-looking result.

- Structural Integrity: Regular sanding and maintenance of your fiberglass boat help prevent the accumulation of moisture, which can lead to delamination and weakening of the fiberglass layers. By keeping the fiberglass in good condition, you ensure the overall structural integrity and longevity of your boat.

By understanding the importance of sanding, you can ensure that your fiberglass boat remains well-maintained and visually appealing for years to come.

Selecting the Right Grit Sandpaper

Choosing the appropriate grit sandpaper for your fiberglass boat is crucial to achieve the desired results. The grit refers to the roughness of the sandpaper, with lower numbers indicating coarser grit and higher numbers indicating finer grit. Here are some factors to consider when selecting the right grit sandpaper:

- Condition of the Surface: Assess the condition of your boat’s fiberglass surface. If it has significant imperfections, such as deep scratches or rough patches, start with a coarser grit sandpaper to remove these flaws. If the surface is already relatively smooth, you can begin with a finer grit sandpaper.

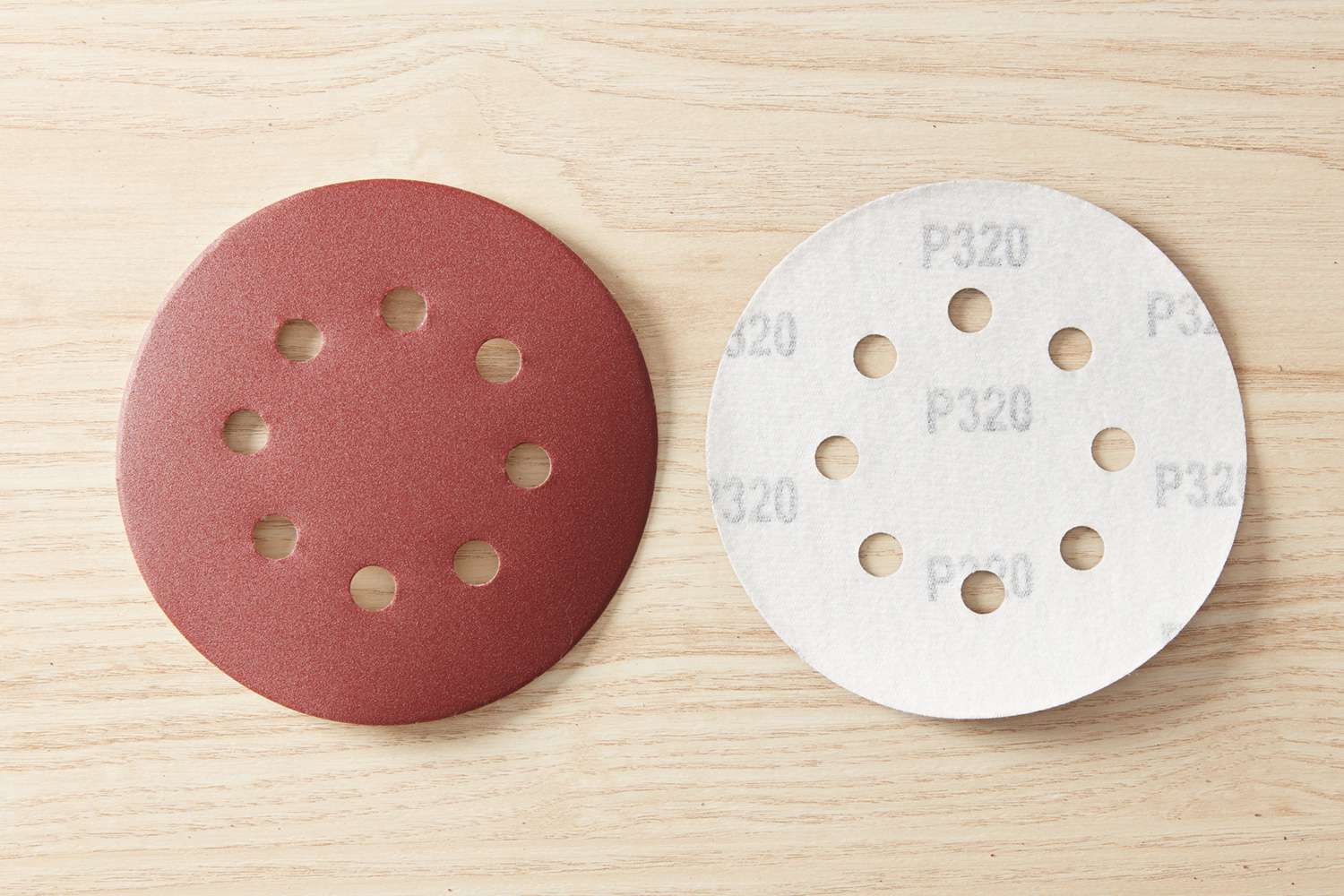

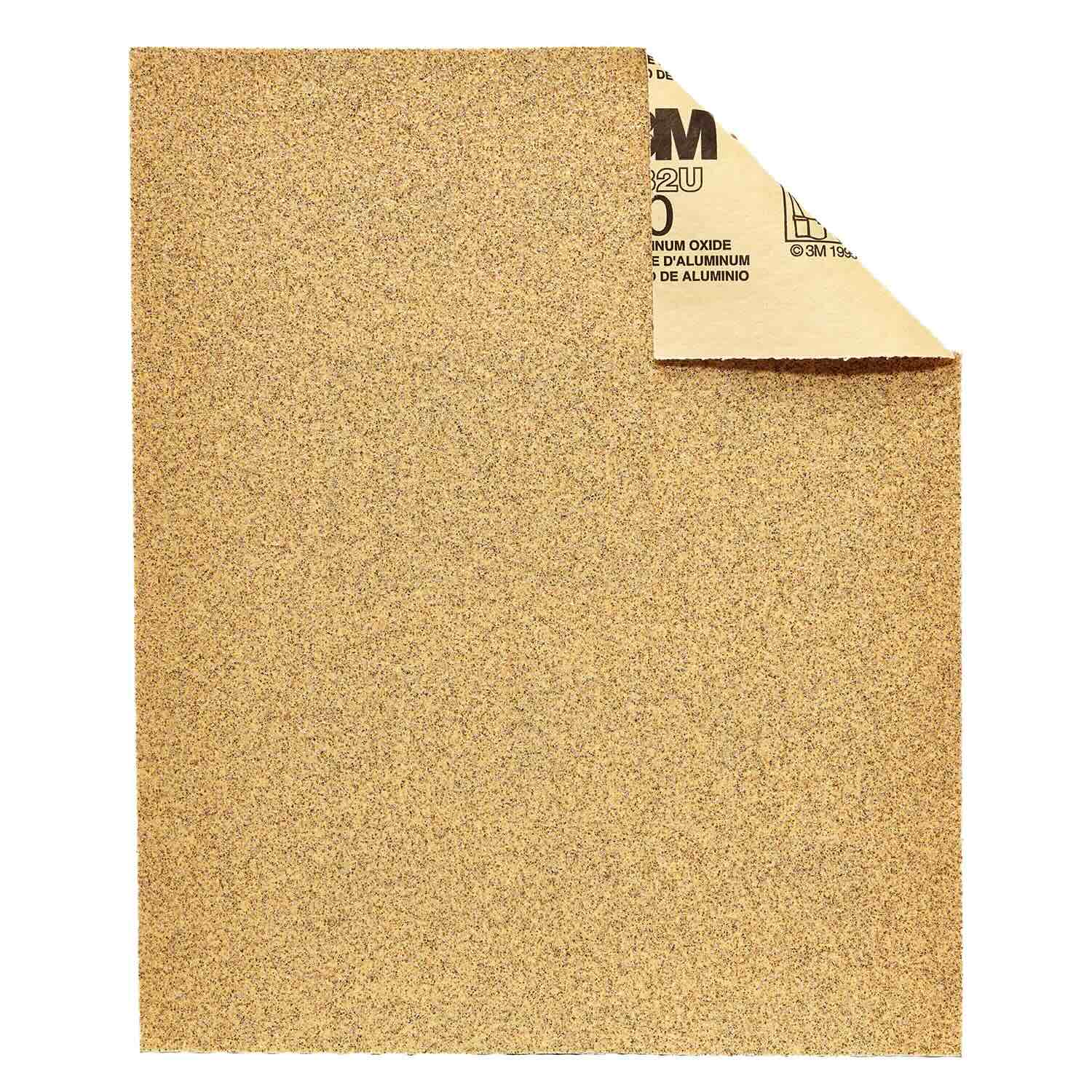

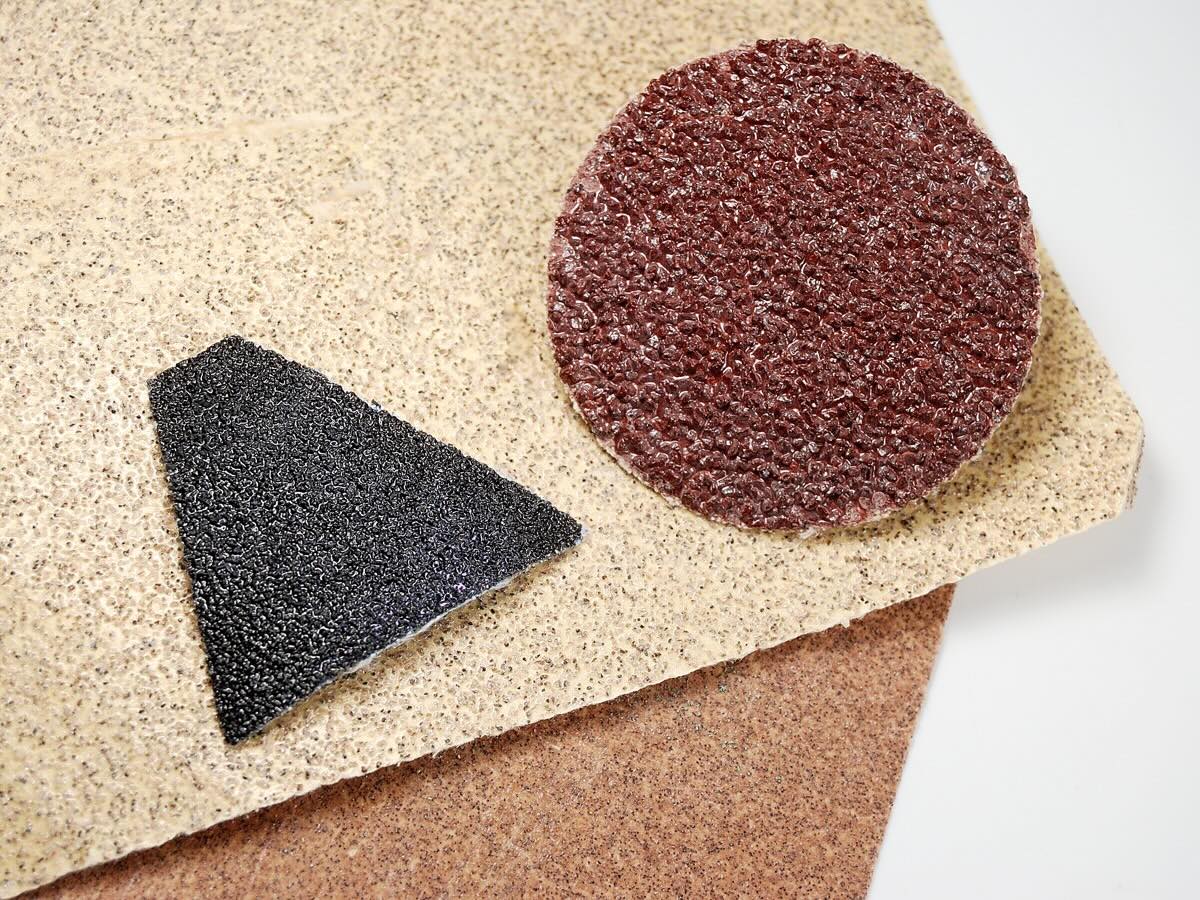

- Types of Sandpaper: There are various types of sandpaper available, including aluminum oxide, silicon carbide, and garnet. It is generally recommended to use aluminum oxide sandpaper for sanding fiberglass. It is durable, long-lasting, and suitable for most applications.

- Grit Size: The appropriate grit size depends on the task at hand. Coarser grits, such as 60 to 80, are suitable for heavy sanding and removing deep scratches. Medium grits, ranging from 120 to 220, are ideal for smoothing the surface and preparing for painting. Finer grits, such as 320 to 600, are used for achieving a polished finish and removing any remaining imperfections.

- Progressive Sanding: It is often necessary to use multiple grit sizes to achieve the desired results. Starting with a coarser grit and gradually moving to finer grits allows for a more consistent and smooth surface. This process, known as progressive sanding, ensures that each stage of sanding removes the marks from the previous grit.

- Sandpaper Grade: Sandpaper is available in various grades, ranging from coarse to fine. The grade is typically indicated by letters such as A, B, C, or D. Lower-grade letters indicate a coarser grit, while higher-grade letters indicate a finer grit. Select the appropriate grade based on the condition of your boat’s surface and the task at hand.

Remember to always follow the manufacturer’s recommendations and guidelines when selecting sandpaper for your fiberglass boat. It is also advisable to test a small area before proceeding with the entire surface to ensure you are achieving the desired results without causing any damage.

Use 80-100 grit sandpaper for initial sanding to remove old paint or gelcoat. Then switch to 220-320 grit for a smoother finish before applying new paint or gelcoat.

Factors to Consider

When it comes to sanding fiberglass boats, there are several additional factors you should consider to ensure a successful and efficient sanding process. These factors can greatly impact the outcome of your sanding efforts:

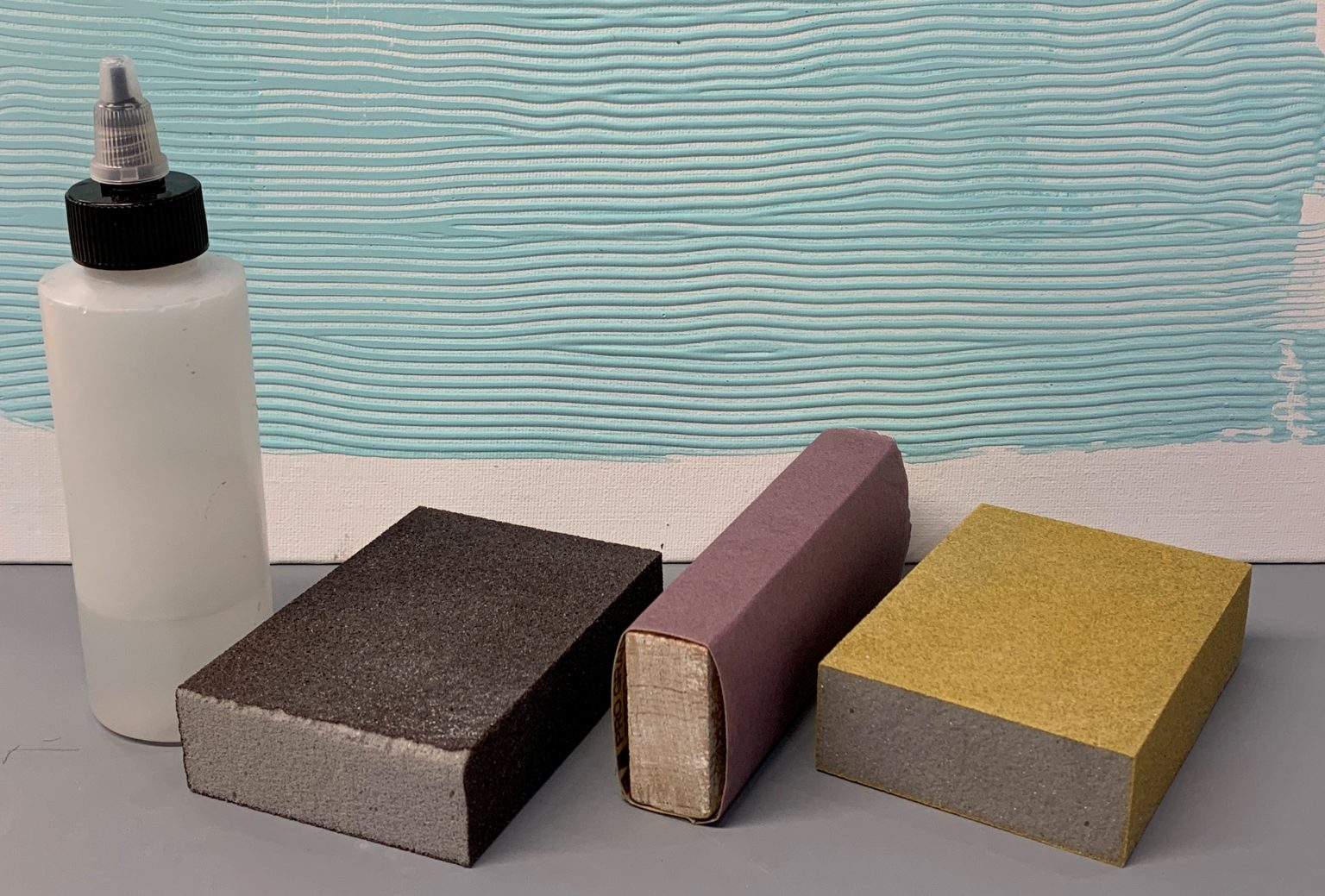

- Boat Size and Shape: The size and shape of your boat may influence the type of sanding equipment you need. For larger boats, consider using a power sander or a sanding block with a handle to cover more surface area efficiently. Smaller boats may allow for more precision with handheld sanding tools.

- Safety Precautions: Protecting yourself during the sanding process is essential. Wear safety goggles to shield your eyes from debris and use a dust mask to prevent inhaling fiberglass particles. Additionally, consider wearing gloves to protect your hands and avoid any cuts or abrasions.

- Sanding Technique: When sanding fiberglass, use light to moderate pressure. Applying excessive force can result in surface damage or create uneven areas on the boat. Keep the sandpaper flat against the surface and move it in a smooth, consistent motion, following the grain of the fiberglass.

- Surface Wetting: When using lower grit sandpaper, you may need to wet the surface to prevent clogging and achieve a smoother sanding action. Lightly wetting the surface with water or a sanding lubricant can help remove debris and provide better results.

- Regular Inspections: As you progress through the sanding process, take breaks to inspect the surface. Check for any remaining imperfections, scratches, or uneven areas. This will help you determine whether you need to continue sanding with the current grit or proceed to a finer grit for a smoother finish.

- Clean and Prep the Surface: After sanding, it is crucial to thoroughly clean and prepare the surface before applying any new coatings, finishes, or wax. Use a clean cloth or tack cloth to remove any sanding residue or dust. This will ensure optimal adhesion and a flawless finished result.

By carefully considering these factors and implementing the appropriate techniques, you can achieve exceptional results when sanding your fiberglass boat.

Read more: What Grit Sandpaper For Stairs

Recommended Grit Sizes for Fiberglass Boat

When it comes to sanding a fiberglass boat, the appropriate grit sizes will depend on the specific condition of the surface and the desired outcome. Here are some recommended grit sizes to consider for different stages of the sanding process:

- Coarse Grit (60 to 80): Start with a coarse grit sandpaper to remove any deep scratches, rough areas, or imperfections on the surface of the fiberglass. This grit size is ideal for heavy sanding and shaping, allowing you to level the surface and provide a smooth foundation for further sanding.

- Medium Grit (120 to 220): Once you have removed the major imperfections, switch to a medium grit sandpaper to further smooth the surface of the fiberglass. This grit size is effective in removing smaller scratches and any remaining roughness. It prepares the surface for finer sanding or the application of paint or coating.

- Fine Grit (320 to 600): For the final sanding stages, use a fine grit sandpaper to achieve a polished finish on the fiberglass. This grit size helps to eliminate any remaining scratches or imperfections left from the previous sanding stages. It creates a smooth and prepped surface, perfect for painting, refinishing, or applying a protective coating.

It is important to note that these recommended grit sizes are not set in stone, and you may need to adjust them based on the specific condition of your fiberglass boat. If you are unsure where to start, it is advisable to begin with a medium grit sandpaper and adjust accordingly based on your observations during the sanding process.

Remember to always work progressively, gradually moving from a coarse to a fine grit sandpaper. This ensures a smooth transition and helps achieve the best possible outcome when sanding your fiberglass boat.

Additional Tips for Sanding Fiberglass Boats

When it comes to sanding fiberglass boats, there are several additional tips and tricks that can help you achieve the best results. Consider implementing these suggestions to enhance your sanding process:

- Use a Sanding Block: To maintain a consistent pressure and ensure even sanding, consider using a sanding block. This tool helps distribute pressure evenly across the surface, preventing any uneven sanding or accidental gouging of the fiberglass.

- Work in Sections: Instead of tackling the entire boat at once, divide the surface into manageable sections. This approach allows you to focus on one area at a time, ensuring thorough sanding and attention to detail. It also helps prevent fatigue and maintains a consistent sanding pattern.

- Keep the Surface Cool: Fiberglass can generate heat when sanded for an extended period. To prevent overheating and potential damage to the boat, periodically stop sanding and allow the surface to cool down. You can use a spray bottle with water to mist the surface and keep it cool during the process.

- Check for Fiberglass Dust Buildup: Fiberglass dust can accumulate quickly during the sanding process. Regularly check for any buildup and clean the area to maintain visibility and prevent the dust from getting into surrounding areas. Use a vacuum cleaner or a damp cloth to remove the dust effectively.

- Experiment with Sanding Techniques: Different sanding techniques, such as circular or back-and-forth motions, can yield various results on the fiberglass surface. Feel free to experiment and find the technique that works best for you, ensuring a smooth and consistent sanding process.

- Take Breaks: Sanding fiberglass can be a time-consuming task, so make sure to take regular breaks to rest and avoid fatigue. This will help maintain focus and ensure that you are consistently providing quality sanding throughout the process.

- Finishing Touches: After completing the sanding process, consider using a wax or polish specifically designed for fiberglass boats. This will help protect the surface and restore its shine, giving your boat a professional and polished look.

Remember, each fiberglass boat is unique, so it’s important to adapt your techniques and approaches based on the specific needs of your boat’s surface. With patience, proper technique, and attention to detail, you can achieve outstanding results when sanding your fiberglass boat.

Conclusion

Sanding fiberglass boats is a crucial aspect of regular maintenance and restoration. By understanding the importance of sanding, selecting the right grit sandpaper, and considering various factors, you can achieve exceptional results and keep your boat looking its best.

Remember to assess the condition of your boat’s surface and choose the appropriate grit size accordingly. Starting with a coarse grit to address deep scratches and rough areas, progressing to a medium grit for further smoothing, and finishing with a fine grit for a polished surface is recommended.

Additionally, consider factors such as boat size and shape, safety precautions, and proper sanding techniques to ensure a smooth and effective sanding process. Take breaks, inspect the surface, and clean the area regularly to maintain visibility and achieve the desired outcome.

Finally, don’t forget that sanding is just one part of the overall maintenance process. After sanding, remember to clean the surface thoroughly and consider applying protective coatings or finishes to maintain the newly achieved smoothness and appearance.

With these tips and techniques in mind, you’ll be well-equipped to confidently sand your fiberglass boat, maintaining its integrity, smoothness, and aesthetic appeal. Regular sanding will not only protect your investment but also enhance your boating experience for years to come.

Frequently Asked Questions about What Grit Sandpaper For Fiberglass Boat

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Grit Sandpaper For Fiberglass Boat”