Home>Renovation & DIY>Tools & Equipment>What Grit Sandpaper For Glass

Tools & Equipment

What Grit Sandpaper For Glass

Modified: May 6, 2024

Discover the best grit sandpaper for glass in our comprehensive guide. Find the right tools and equipment for your glass sanding projects.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of glass sanding, where precision meets creativity. Whether you’re a seasoned artisan or a DIY enthusiast exploring the art of glasswork, understanding the nuances of grit sandpaper for glass is crucial. This often-overlooked tool plays a pivotal role in refining, shaping, and polishing glass surfaces to achieve that coveted pristine finish.

Sanding glass may seem like a daunting task, but armed with the right knowledge and tools, you can elevate your glasswork to new heights. In this comprehensive guide, we’ll delve into the intricacies of grit sandpaper for glass, exploring the various types, recommended grit levels, and invaluable tips for achieving impeccable results. So, grab your safety goggles and let’s embark on this enlightening journey into the world of glass sanding.

Key Takeaways:

- Choose the right grit sandpaper for glass based on your project needs, from coarse for shaping to fine for a smooth finish. Understanding grit levels is key to achieving impeccable results in glass sanding.

- Safety, preparation, and progressive grit sequence are crucial for successful glass sanding. Incorporate even pressure, fluid motions, and wet sanding for optimal results.

Read more: What Grit Sandpaper For Glass Edge

Understanding Grit Levels

Before delving into the specifics of sanding glass, it’s essential to grasp the significance of grit levels. Grit refers to the coarseness or fineness of the abrasive particles embedded in the sandpaper. The grit size directly impacts the sanding process, determining the level of abrasion and the resulting surface texture.

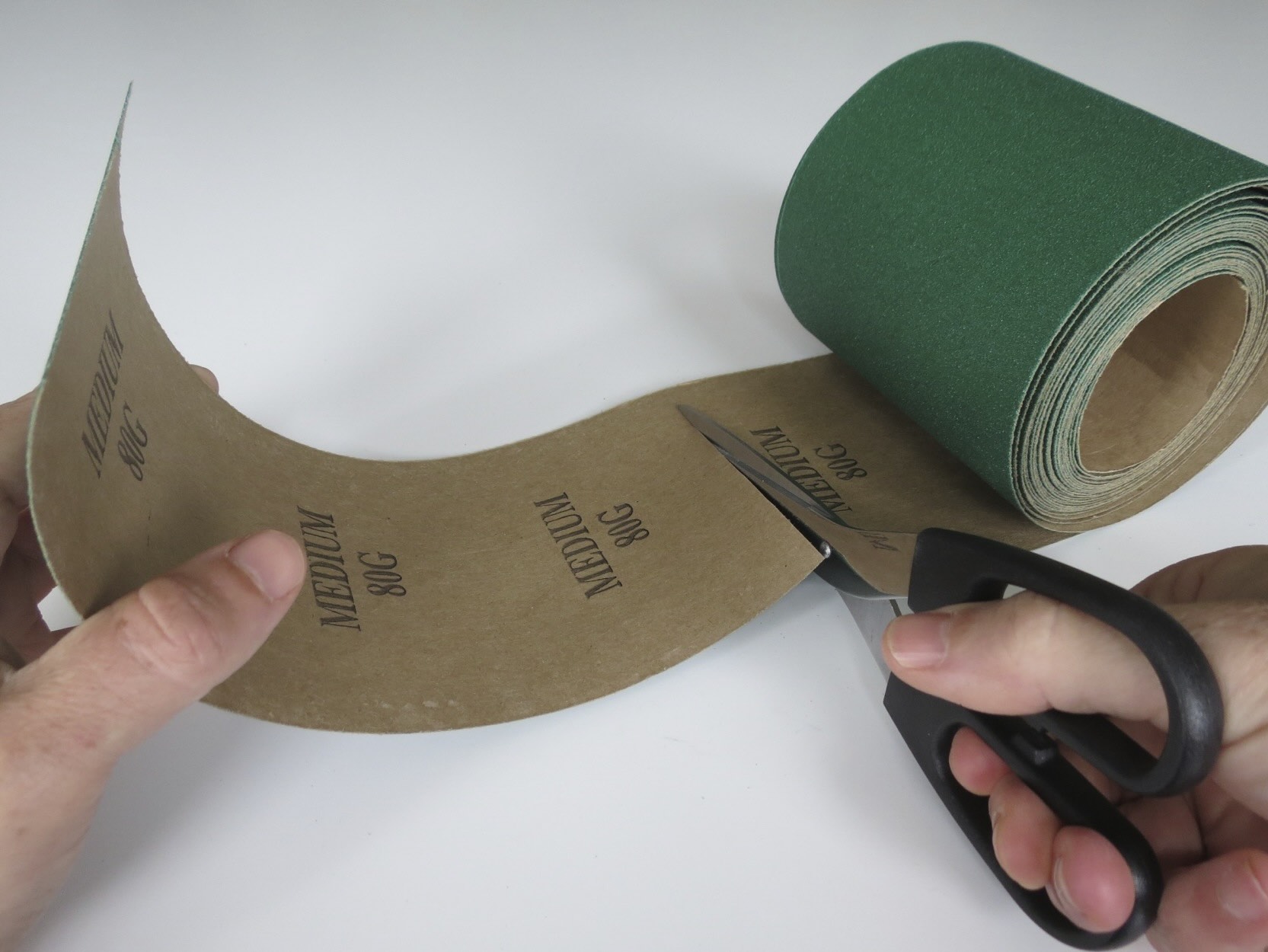

Sandpaper is categorized based on grit levels, which are denoted by a numerical value. Lower grit numbers indicate coarser particles, ideal for aggressive material removal and shaping. Conversely, higher grit numbers signify finer particles, suitable for smoothing and polishing surfaces.

Understanding the correlation between grit levels and the desired outcome is pivotal in achieving precision and finesse when sanding glass. Coarse grits, such as 60 to 100, are adept at swiftly removing imperfections and shaping glass, making them indispensable during the initial stages of sanding. As the process progresses, transitioning to medium grits, typically ranging from 120 to 240, facilitates refining the surface and eliminating coarse scratches.

For the final stages of glass sanding, finer grits come into play, with ranges spanning from 320 to 1500 and beyond. These high-grit sandpapers excel in imparting a smooth, lustrous finish to the glass, effectively eradicating any remaining blemishes and achieving optical clarity. The selection of grit levels is contingent upon the specific requirements of the glasswork, with each grit contributing to the gradual transformation of the glass surface.

By comprehending the nuances of grit levels and their impact on the sanding process, artisans and enthusiasts can navigate the realm of glasswork with confidence, harnessing the power of different grit sandpapers to achieve impeccable results.

Types of Sandpaper for Glass

When it comes to sanding glass, utilizing the appropriate type of sandpaper is paramount for achieving optimal results. Various types of sandpaper are designed to address specific aspects of the glass sanding process, catering to different stages and requirements. Understanding the distinct characteristics of each type enables artisans and enthusiasts to make informed choices, ensuring the seamless execution of their glasswork endeavors.

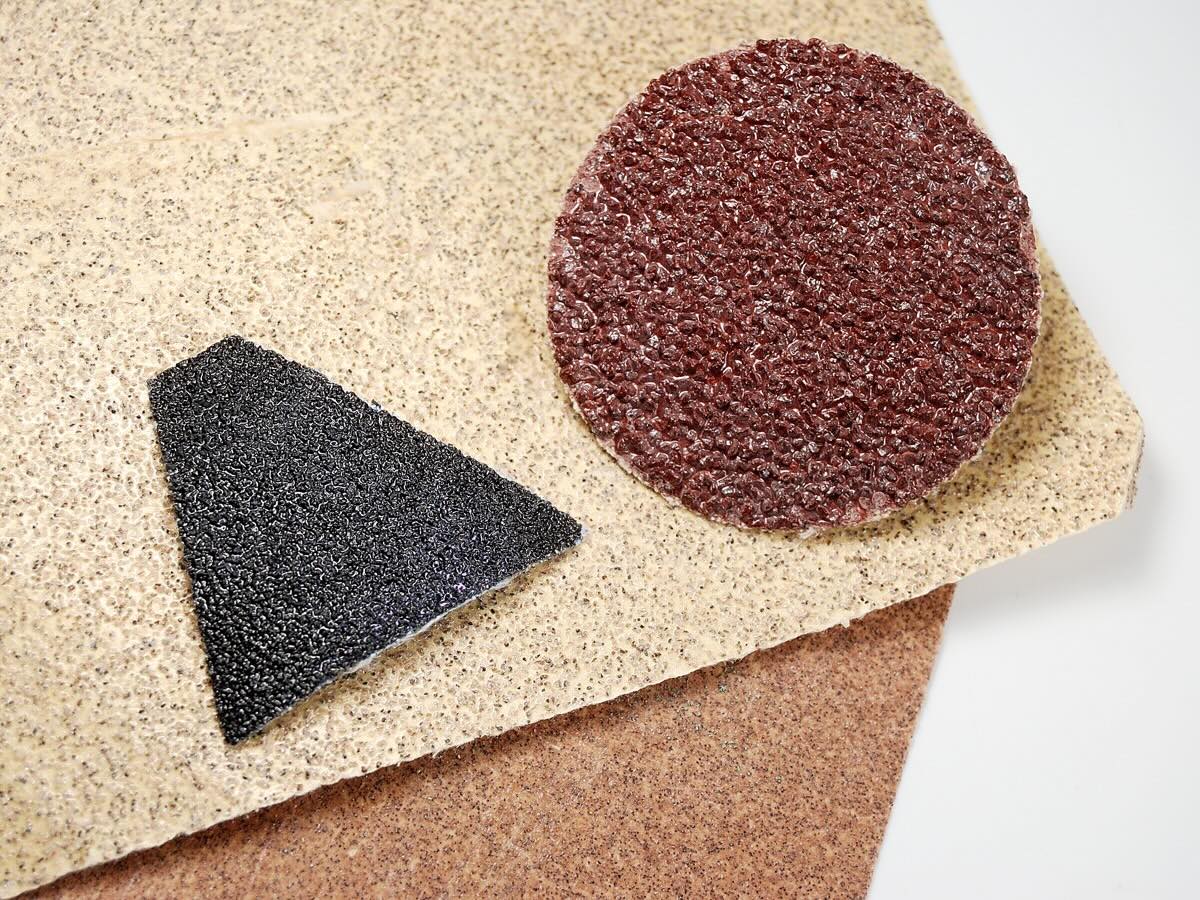

1. Aluminum Oxide Sandpaper: Widely utilized for sanding and shaping glass, aluminum oxide sandpaper boasts exceptional durability and versatility. Its abrasive composition makes it adept at swiftly removing imperfections and shaping glass surfaces during the initial stages of the sanding process. Available in various grit levels, this type of sandpaper is a staple in the arsenal of glass artisans.

2. Silicon Carbide Sandpaper: Renowned for its superior performance in wet sanding applications, silicon carbide sandpaper is a go-to choice for refining and polishing glass surfaces. Its waterproof properties make it ideal for achieving smooth finishes and precise detailing, particularly when working on intricate glass designs that necessitate meticulous attention to detail.

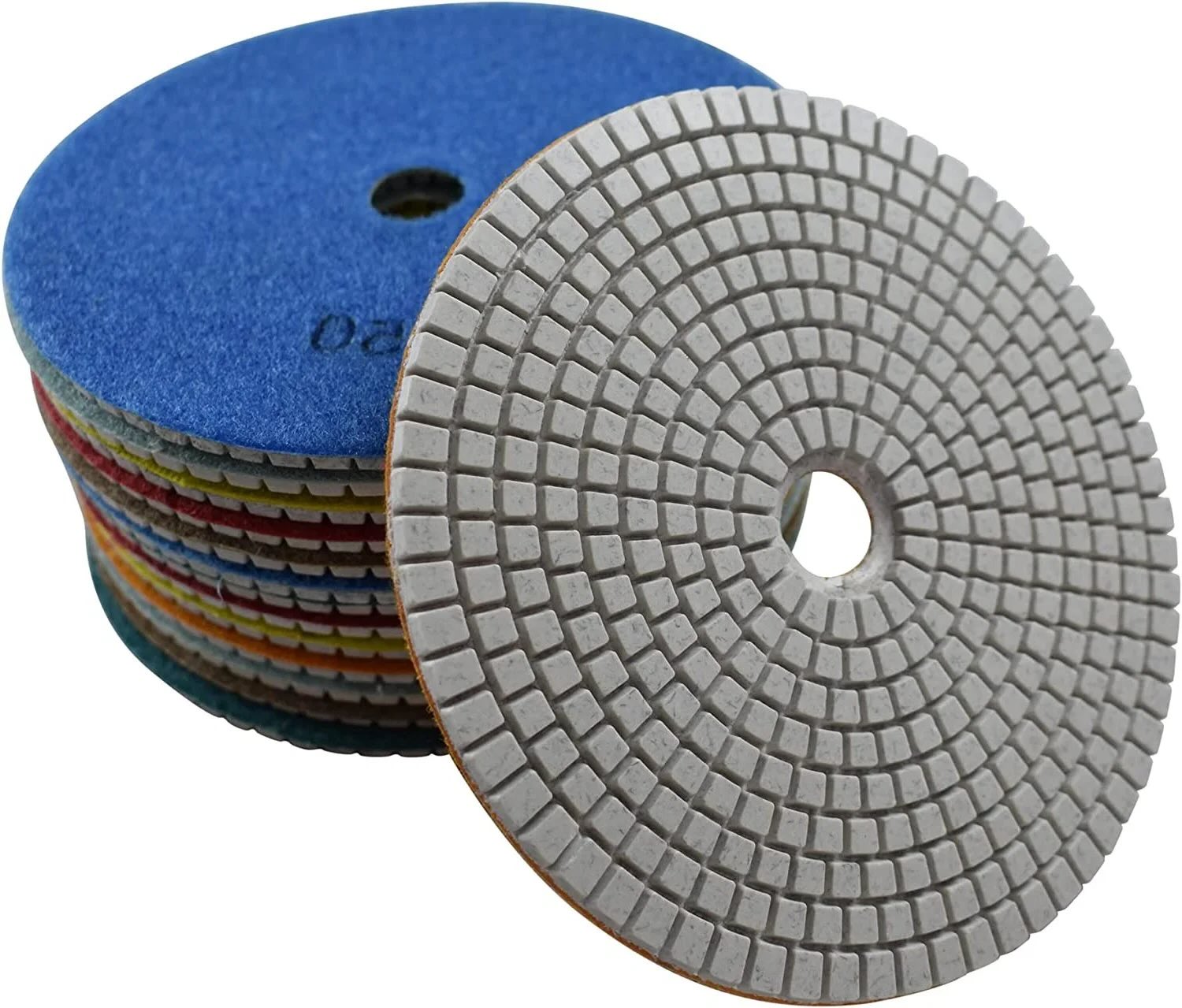

3. Diamond Sandpaper: Leveraging the unparalleled hardness and durability of diamond particles, diamond sandpaper is engineered for precision and longevity. This specialized sandpaper excels in polishing glass to a brilliant, mirror-like sheen, making it indispensable for achieving exceptional optical clarity and flawless finishes.

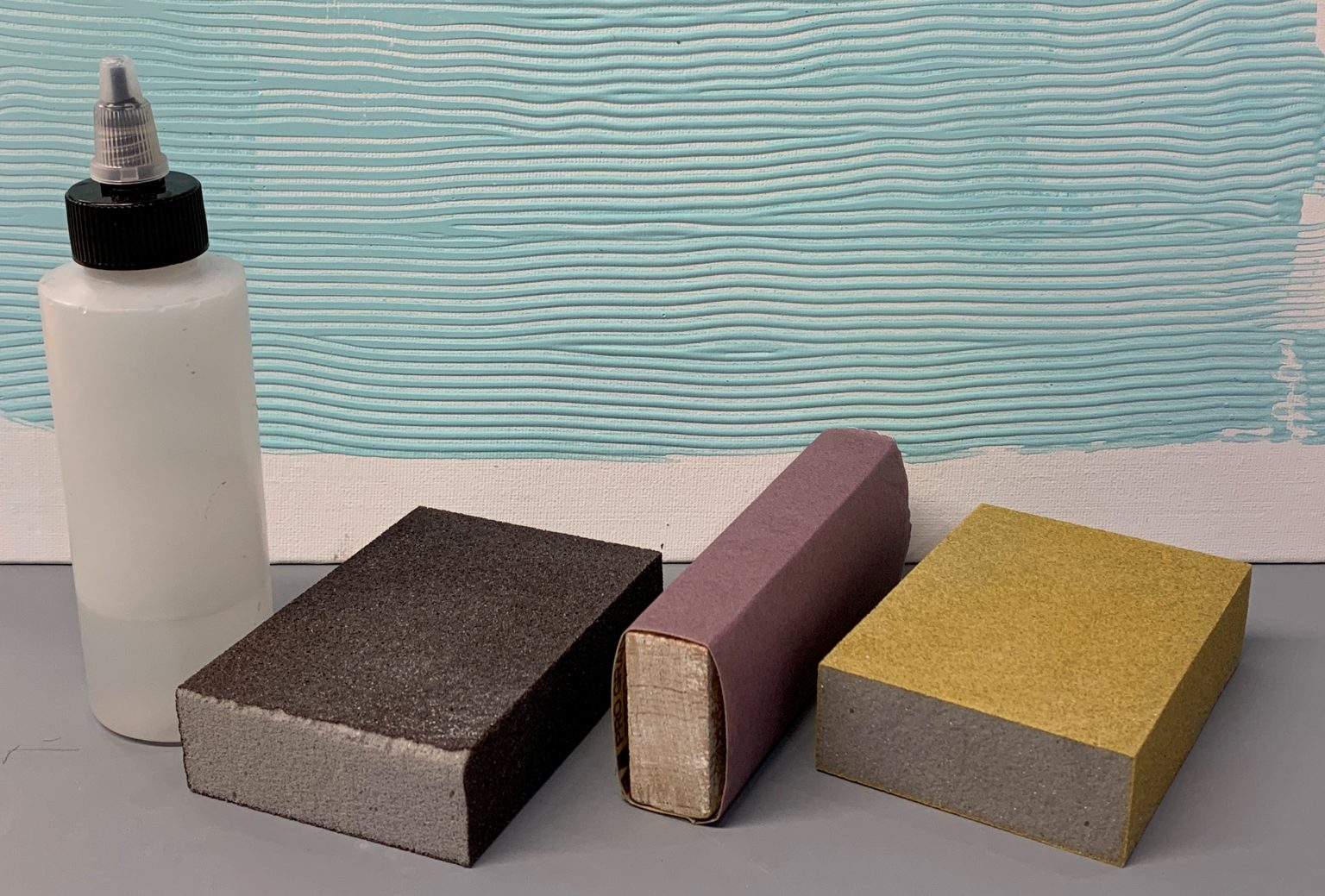

4. Cerium Oxide Sandpaper: Specifically tailored for the final stages of glass polishing, cerium oxide sandpaper is revered for its ability to impart a pristine, glass-like luster. This type of sandpaper is instrumental in refining glass surfaces to perfection, eliminating any remaining imperfections and ensuring a dazzling, professional-grade finish.

By acquainting themselves with the diverse types of sandpaper tailored for glasswork, artisans and enthusiasts can strategically leverage these tools to navigate the intricacies of the sanding process, elevating their glasswork to new levels of refinement and visual allure.

When sanding glass, use a fine grit sandpaper such as 400 or 600 grit to avoid scratching or damaging the surface. Wet the glass before sanding to reduce dust and achieve a smoother finish.

Recommended Grit Sandpaper for Glass

Choosing the right grit sandpaper is pivotal for achieving impeccable results when sanding glass. The selection of grit levels is contingent upon the specific requirements of the glasswork, encompassing the desired surface texture, the extent of imperfections to be addressed, and the ultimate finish to be achieved. By aligning the grit selection with these considerations, artisans and enthusiasts can optimize the sanding process, ensuring the attainment of pristine, professional-grade results.

1. Coarse Grits (60 to 100): During the initial stages of glass sanding, coarse grit sandpapers ranging from 60 to 100 are indispensable for swiftly removing imperfections and shaping the glass surface. These grits facilitate efficient material removal, enabling artisans to address rough edges and irregularities, laying the foundation for subsequent refinement.

2. Medium Grits (120 to 240): As the sanding process progresses, transitioning to medium grit sandpapers within the range of 120 to 240 allows for refining the glass surface and eliminating coarse scratches. This stage is instrumental in smoothing out imperfections and preparing the glass for the subsequent polishing phase.

3. Fine Grits (320 to 1500 and beyond): For achieving a smooth, lustrous finish and impeccable optical clarity, fine grit sandpapers ranging from 320 to 1500 and beyond are employed during the final stages of glass sanding. These high-grit sandpapers excel in eradicating remaining blemishes and imparting a pristine, mirror-like sheen to the glass, culminating in a flawless, professional finish.

While the recommended grit sandpaper for glass varies based on the specific project requirements and the intricacies of the glass surface, this comprehensive approach enables artisans and enthusiasts to navigate the sanding process with precision and finesse, harnessing the power of different grit levels to achieve exceptional results.

Tips for Sanding Glass

Sanding glass demands meticulous attention to detail and a strategic approach to achieve exemplary results. Whether you’re embarking on a glasswork project or refining a cherished glass creation, incorporating these invaluable tips can elevate your sanding endeavors, ensuring precision, finesse, and a flawless finish.

1. Safety First: Prioritize safety by wearing protective gear, including safety goggles and a dust mask, to shield your eyes and respiratory system from glass particles and abrasive dust generated during the sanding process.

2. Surface Preparation: Thoroughly clean the glass surface to remove any debris, oils, or contaminants that may impede the sanding process. This ensures optimal adhesion and abrasion during sanding, facilitating seamless material removal and surface refinement.

3. Progressive Grit Sequence: Adhere to a progressive grit sequence, commencing with coarse grits for material removal and shaping, transitioning to medium grits for refining the surface, and culminating with fine grits for achieving a smooth, lustrous finish.

4. Even Pressure and Motion: Apply even pressure and utilize consistent, fluid motions during sanding to ensure uniform material removal and avoid creating uneven surfaces or scratches. This promotes a seamless transition between grit levels and contributes to the attainment of a pristine finish.

5. Wet Sanding Technique: For enhanced precision and surface refinement, consider employing the wet sanding technique, particularly when using silicon carbide or diamond sandpapers. Wet sanding minimizes heat buildup, reduces friction, and facilitates superior polishing, resulting in impeccable finishes and optical clarity.

6. Frequent Inspection: Periodically inspect the glass surface during the sanding process to assess the progress and identify areas that require additional attention. This proactive approach enables targeted refinement and ensures consistent results across the entire glass surface.

7. Final Polishing: Conclude the sanding process with a meticulous polishing phase using cerium oxide sandpaper or a specialized glass polishing compound. This step enhances the luster and clarity of the glass, elevating the visual appeal and professional-grade finish.

By integrating these tips into your glass sanding endeavors, you can navigate the intricacies of the process with confidence and precision, elevating your glasswork to new levels of refinement and visual allure.

Read more: What Grit Sandpaper For Polyurethane

Conclusion

As we conclude our exploration of grit sandpaper for glass, it becomes evident that this often-underestimated tool holds immense significance in the realm of glasswork. From shaping and refining to polishing and perfecting, the strategic selection and utilization of grit sandpaper are pivotal in achieving impeccable results that elevate glass creations to new heights of visual allure and professional-grade finesse.

By understanding the nuances of grit levels and their impact on the sanding process, artisans and enthusiasts can navigate the intricacies of glasswork with confidence, harnessing the power of different grit sandpapers to achieve exceptional results. The progressive sequence of grits, ranging from coarse to fine, facilitates a methodical approach to glass sanding, ensuring seamless material removal, surface refinement, and the attainment of a flawless, mirror-like finish.

Furthermore, familiarizing oneself with the diverse types of sandpaper tailored for glasswork empowers individuals to make informed choices, strategically leveraging these tools to address specific aspects of the sanding process. Whether it’s aluminum oxide for swift material removal, silicon carbide for meticulous wet sanding, diamond sandpaper for precision polishing, or cerium oxide for the final lustrous finish, each type plays a distinctive role in refining and perfecting glass surfaces.

Armed with a repertoire of invaluable tips for sanding glass, including safety precautions, progressive grit sequences, and meticulous surface preparation, artisans and enthusiasts can embark on their glasswork endeavors with a heightened sense of precision and finesse. The incorporation of even pressure, fluid motions, and the wet sanding technique further contributes to the attainment of exemplary results, culminating in glass creations that exude unparalleled clarity, brilliance, and visual allure.

As you venture into the realm of glass sanding, may these insights serve as guiding beacons, illuminating the path to exceptional craftsmanship and the realization of your glasswork aspirations. Embrace the artistry and precision of glass sanding, and let your creations shimmer with the timeless elegance and captivating allure that only meticulously-sanded glass can embody.

Curious about achieving even smoother surfaces on your glass projects? Our next guide on fine grit sandpaper dives deeper into selecting ultra-fine abrasives that ensure a flawless finish. Whether you're refining a craft or handling delicate glass repairs, understanding these finer specifics will arm you with knowledge to perform with precision. Don’t miss out on mastering these essential sanding skills!

Frequently Asked Questions about What Grit Sandpaper For Glass

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Grit Sandpaper For Glass”