Home>Renovation & DIY>Tools & Equipment>What Sandpaper To Use On Wood Filler

Tools & Equipment

What Sandpaper To Use On Wood Filler

Modified: May 6, 2024

Discover the best sandpaper for wood filler and ensure a smooth finish with the right tools and equipment. Learn how to choose the perfect sandpaper grit for your project.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of woodworking, where every project is an opportunity to create something beautiful with your own hands. Whether you're a seasoned carpenter or a DIY enthusiast, working with wood often involves the use of wood filler to achieve a flawless finish. However, applying wood filler is just the first step in the process of achieving a smooth and polished surface. To truly perfect your woodworking project, you need to understand the nuances of sanding wood filler and selecting the right sandpaper for the job.

In this comprehensive guide, we'll delve into the intricacies of sanding wood filler, focusing on the types of sandpaper available and how to choose the most suitable option for your specific woodworking needs. By the end of this journey, you'll be equipped with the knowledge and expertise to take your woodworking skills to the next level. So, grab your tools, put on your creative hat, and let's explore the world of sanding wood filler together.

Key Takeaways:

- Choose the right sandpaper based on wood filler type, imperfections, and wood sensitivity for a flawless finish in woodworking projects.

- Master the art of sanding wood filler with patience and precision, transforming rough surfaces into impeccably smooth canvases for your woodworking endeavors.

Read more: What Sandpaper To Use On Wood Furniture

Understanding Wood Filler

Wood filler, also known as wood putty, is a versatile substance used to fill imperfections, gaps, and cracks in wood surfaces. It is commonly employed in woodworking projects to achieve a smooth, even finish by concealing blemishes and irregularities. Wood filler is available in various formulations, including water-based, solvent-based, and epoxy-based options, each offering unique characteristics suited to different applications.

When applied to a wooden surface, wood filler dries to a hard, sandable consistency, allowing for seamless blending with the surrounding wood. It can be stained, painted, or varnished to match the color and texture of the wood, making it an essential component in achieving a professional-looking result. Additionally, wood filler enhances the structural integrity of the wood by reinforcing weakened areas and preventing further damage.

Understanding the properties and behavior of wood filler is crucial for achieving a flawless finish in woodworking projects. Proper application and sanding techniques can significantly impact the final outcome, making it essential to select the right sandpaper for the job. With this foundational knowledge in mind, let’s explore the world of sandpaper and its role in refining wood filler surfaces.

Types of Sandpaper

Sandpaper, a fundamental tool in woodworking and finishing, comes in various types, each designed for specific purposes and levels of abrasiveness. Understanding the distinctions between these types is crucial for achieving the desired smoothness and finish on wood surfaces, especially when working with wood filler. Here are the primary types of sandpaper:

- Aluminum Oxide Sandpaper: Known for its durability and versatility, aluminum oxide sandpaper is suitable for both hand and machine sanding. It is commonly used for sanding wood filler due to its long-lasting abrasive properties, making it effective for smoothing and refining surfaces.

- Garnet Sandpaper: This natural abrasive is preferred for its fine grit and is often used for finishing wood surfaces. While it may not be as durable as aluminum oxide, garnet sandpaper excels in producing a smooth, polished finish on wood filler.

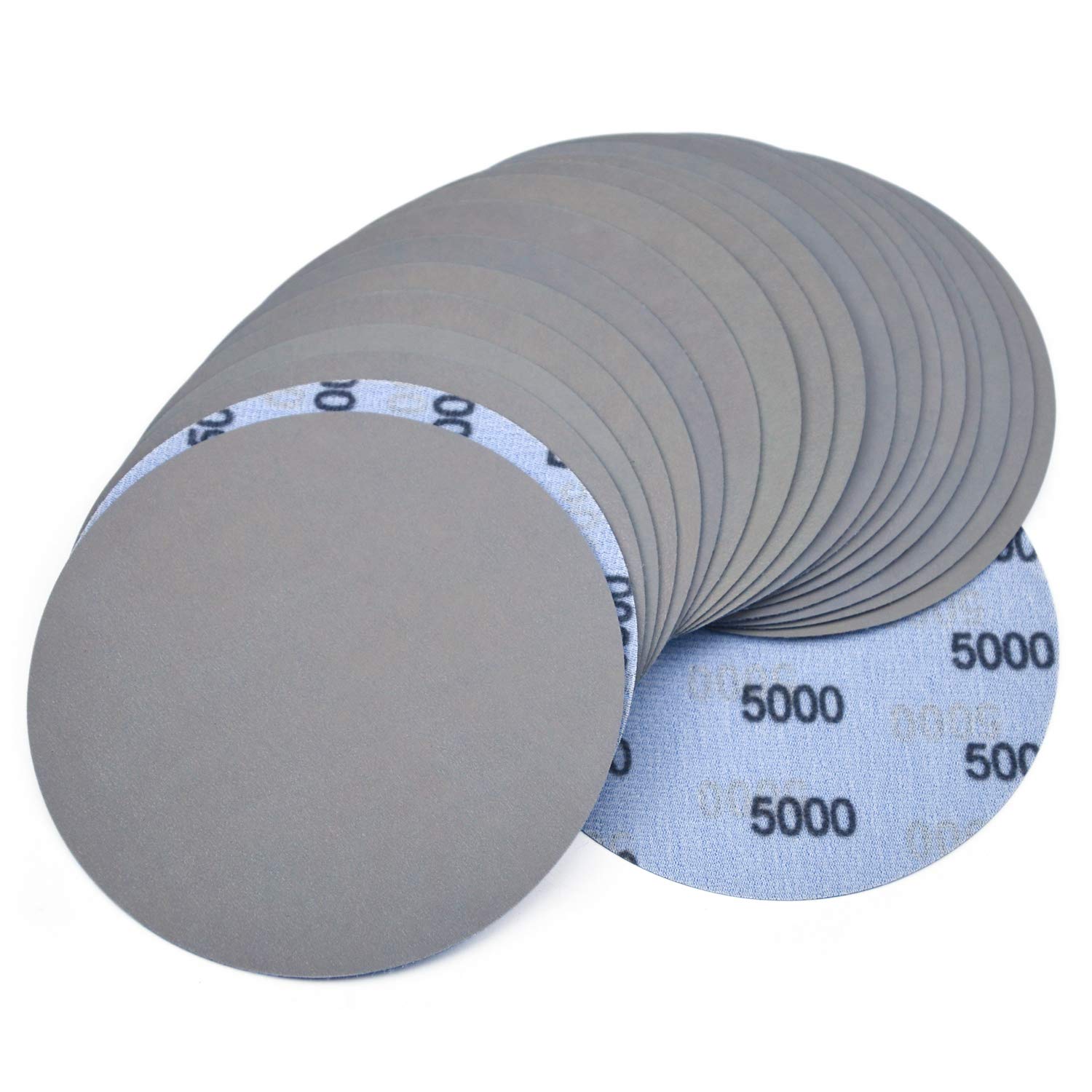

- Silicon Carbide Sandpaper: Ideal for sanding harder materials, such as metal, glass, and ceramics, silicon carbide sandpaper is also suitable for sanding wood filler, especially when a finer finish is desired. It is available in various grits to accommodate different levels of abrasiveness.

- Zirconia Alumina Sandpaper: Recognized for its aggressive cutting action, zirconia alumina sandpaper is well-suited for heavy material removal. When working with wood filler that requires significant leveling or shaping, this type of sandpaper can expedite the process efficiently.

Each type of sandpaper is available in different grits, ranging from coarse to fine, with lower numbers indicating coarser grit and higher numbers representing finer grit. The selection of sandpaper grit depends on the specific requirements of the wood filler surface and the desired level of smoothness.

Now that we’ve explored the types of sandpaper available, let’s delve into the process of choosing the right sandpaper for sanding wood filler to achieve impeccable results in woodworking projects.

When sanding wood filler, it’s best to start with a coarser grit sandpaper, such as 80 or 100, to remove excess filler. Then, switch to a finer grit, like 150 or 180, for a smooth finish.

Choosing the Right Sandpaper for Wood Filler

When it comes to sanding wood filler, selecting the appropriate sandpaper is essential for achieving a flawless finish. The choice of sandpaper depends on the type of wood filler used, the level of smoothing required, and the specific characteristics of the wood surface. Here are the key considerations for choosing the right sandpaper for sanding wood filler:

- Type of Wood Filler: Consider the composition and hardness of the wood filler. For softer wood fillers, such as water-based or solvent-based options, finer grit sandpaper, such as 150-220, is suitable for achieving a smooth finish without removing excessive material. For harder wood fillers, such as epoxy-based formulations, coarser grit sandpaper, such as 80-120, may be necessary to effectively level the surface.

- Surface Imperfections: Assess the nature and extent of imperfections in the wood surface. For shallow imperfections, finer grit sandpaper can effectively smooth the wood filler without causing undue abrasion to the surrounding wood. Deeper imperfections may require the initial use of coarser grit sandpaper to level the surface before progressing to finer grits for refinement.

- Wood Surface Sensitivity: Take into account the sensitivity of the wood surface to abrasion. Softwoods, such as pine, are more susceptible to sanding marks, requiring the use of finer grit sandpaper to minimize visible scratches. Hardwoods, such as oak or maple, can withstand coarser grits for initial sanding to address imperfections.

- Project Requirements: Consider the specific requirements of the woodworking project. If a high-gloss, smooth finish is desired, using progressively finer grits of sandpaper, such as 320-400, in a meticulous sanding process can achieve the desired result. For projects where a more natural, textured finish is acceptable, a coarser grit may be sufficient.

By carefully evaluating these factors, you can determine the most suitable sandpaper for sanding wood filler, ensuring that the surface is impeccably smooth and ready for the next stage of finishing. Now, let’s explore the process of sanding wood filler to achieve professional-quality results in woodworking projects.

Sanding Wood Filler

Now that you’ve selected the appropriate sandpaper for sanding wood filler, it’s time to delve into the process of refining the wood surface to achieve a seamless and polished finish. Whether you’re working on a small craft project or a large-scale woodworking endeavor, the following steps will guide you through the art of sanding wood filler with precision and finesse:

- Prepare the Work Area: Begin by setting up a clean and well-lit workspace. Ensure that the wood surface is free from dust, debris, and any obstructions that may interfere with the sanding process.

- Initial Sanding: If the wood filler has been applied to fill deep voids or gaps, start with coarser grit sandpaper, such as 80-120, to level the surface. Use smooth, even strokes, applying gentle pressure to avoid over-sanding the surrounding wood.

- Progressive Smoothing: As the surface becomes more uniform, transition to finer grit sandpaper, such as 150-220, to refine the wood filler and achieve a smoother texture. Work methodically, moving the sandpaper in the direction of the wood grain to maintain uniformity.

- Detail Sanding: For intricate or detailed areas, utilize sanding sponges or small pieces of sandpaper to reach crevices and contours that may be challenging to access with larger sanding tools. This step ensures that every part of the wood surface receives the necessary attention for a consistent finish.

- Final Finishing: Once the wood filler surface is uniformly smooth, use the finest grit sandpaper available, such as 320-400, to achieve a polished finish. This meticulous sanding process removes any remaining imperfections and prepares the surface for staining, painting, or varnishing.

- Inspect and Clean: After sanding, carefully inspect the wood surface to ensure that the wood filler blends seamlessly with the surrounding wood. Remove any residual dust and debris by wiping the surface with a clean, dry cloth or using a vacuum with a soft brush attachment.

By following these steps and exercising patience and attention to detail, you can master the art of sanding wood filler, transforming rough surfaces into impeccably smooth canvases for your woodworking endeavors.

With the wood filler surface expertly sanded and prepared, you are now ready to apply the finishing touches to your woodworking project, bringing your creative vision to life with finesse and precision.

Read more: How To Sand Wood Using Sandpaper

Conclusion

Congratulations on embarking on a journey through the intricate world of sanding wood filler. By gaining a deeper understanding of wood filler, exploring the nuances of sandpaper, and mastering the art of sanding, you have equipped yourself with the knowledge and expertise to elevate your woodworking projects to new heights of craftsmanship and refinement.

Woodworking is a blend of artistry, precision, and dedication, and the process of sanding wood filler is a crucial step in achieving flawless, professional results. As you venture into future woodworking endeavors, remember the following key takeaways:

- Understanding the Properties of Wood Filler: Appreciate the versatility and structural benefits of wood filler, recognizing its role in achieving seamless finishes and reinforcing wood surfaces.

- Choosing the Right Sandpaper: Select the appropriate type and grit of sandpaper based on the characteristics of the wood filler, the imperfections of the wood surface, and the desired level of smoothness.

- Mastering the Art of Sanding: Embrace the step-by-step process of sanding wood filler, from initial leveling to meticulous finishing, ensuring that every surface is refined to perfection.

As you apply these principles and techniques in your woodworking projects, remember that patience, precision, and attention to detail are the hallmarks of a true craftsman. Each stroke of the sandpaper, each careful inspection, and each moment of creative expression contributes to the transformation of raw materials into works of art.

So, whether you’re crafting furniture, creating intricate designs, or simply indulging in the joy of woodworking, may your journey be filled with inspiration, innovation, and the satisfaction of bringing your creative visions to life. With the knowledge and skills acquired in this guide, you are well-prepared to embark on future woodworking endeavors with confidence and artistry.

Now, armed with the wisdom of wood filler and the art of sanding, go forth and let your woodworking projects shine with the radiance of craftsmanship and creativity.

Now that you've got the hang of selecting the perfect sandpaper for wood filler, why not take your woodworking skills up a notch? Dive into our latest article, where we cover essential tools and innovative techniques that will help you master the craft. Whether you're a seasoned pro or just starting out, you'll find valuable insights and tips to enhance your woodworking projects. Don't miss out on making your next creation your best yet!

Frequently Asked Questions about What Sandpaper To Use On Wood Filler

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Sandpaper To Use On Wood Filler”