Home>Renovation & DIY>Tools & Equipment>What Is Sandpaper Used For

Tools & Equipment

What Is Sandpaper Used For

Modified: January 19, 2024

Discover the many uses of sandpaper in tools and equipment. Learn how this versatile abrasive material can help you achieve a smooth and polished finish.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Sandpaper is a versatile and essential tool in various industries and DIY projects. It is a type of coated abrasive that consists of abrasive particles bonded to a flexible or semi-rigid backing material. The abrasive particles, typically made of aluminum oxide or silicon carbide, are used for smoothing, polishing, and shaping surfaces.

Whether you’re working on woodworking projects, metalworking, auto body repairs, or even engaging in arts and crafts, sandpaper plays a crucial role in achieving the desired results. With its abrasive properties, sandpaper efficiently removes material and prepares surfaces for further treatment.

In this article, we will explore the different types of sandpaper, understand grit sizes and their uses, learn how to choose the right sandpaper, and explore common applications in various industries and DIY projects.

Key Takeaways:

- Sandpaper is a versatile tool used in woodworking, metalworking, auto body repairs, and arts and crafts. Understanding grit sizes, abrasiveness levels, and proper techniques is crucial for achieving professional results.

- Choosing the right sandpaper for your project is essential. Consider the material, task at hand, grit size, type of sandpaper, and manufacturer’s recommendations to ensure optimal performance and quality finishes.

Read more: What Sandpaper To Use On Concrete

Definition of Sandpaper

Sandpaper is a tool consisting of abrasive particles attached to a backing material that is used for smoothing, polishing, and shaping surfaces. The abrasive particles are typically made of materials like aluminum oxide, silicon carbide, or garnet, which vary in hardness and coarseness.

The backing material of sandpaper can be paper, cloth, or a combination of the two. Paper-backed sandpaper is the most common and economical option. It is suitable for most general-purpose sanding applications. Cloth-backed sandpaper is more durable and tear-resistant, making it ideal for heavy-duty tasks.

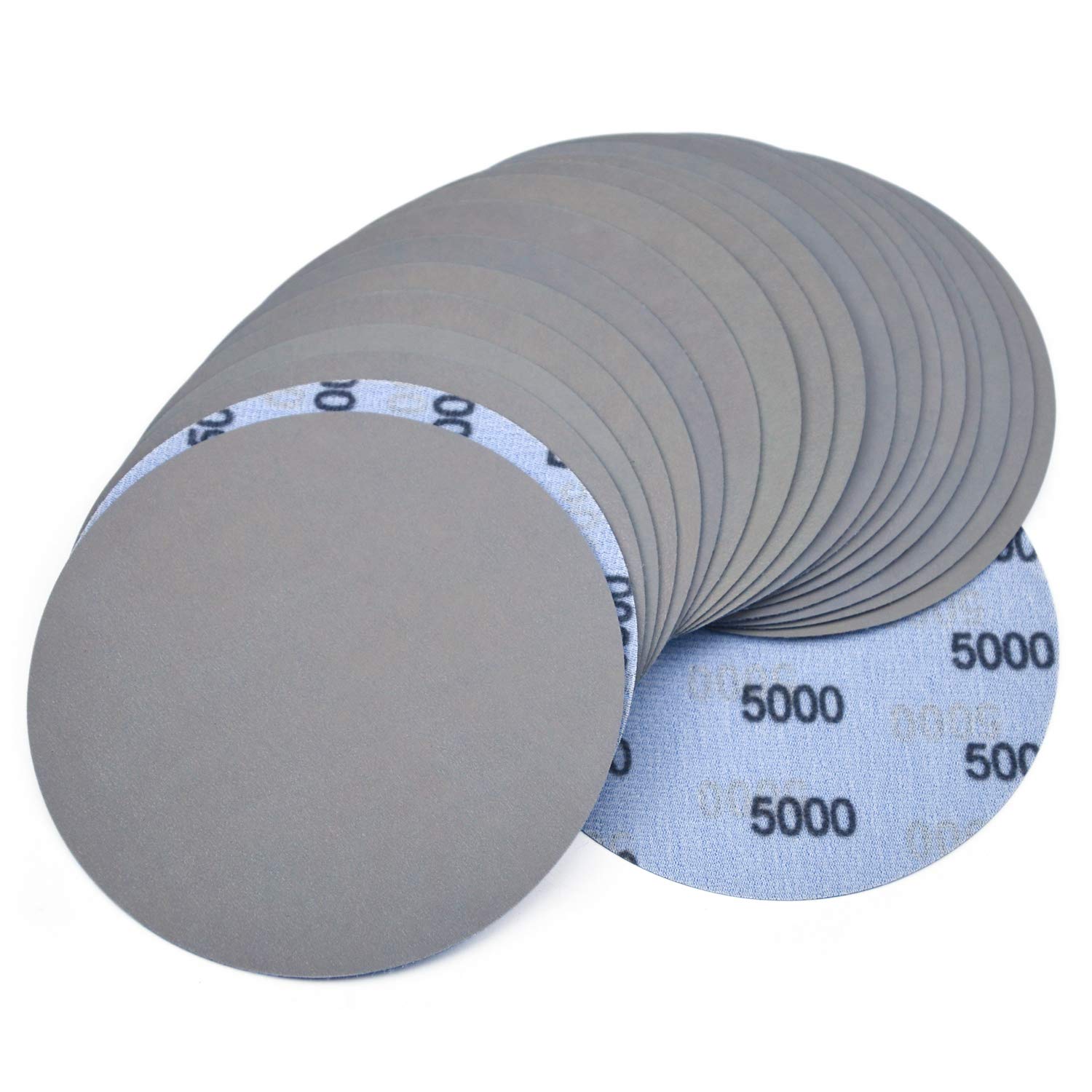

Sandpaper is available in various forms, including sheets, rolls, discs, belts, and pads. The choice of form depends on the specific application, the size of the surface to be sanded, and the equipment being used.

The effectiveness of sandpaper is determined by two important factors: the grit size and the abrasiveness level. Grit size refers to the number of abrasive particles per square inch of sandpaper. The higher the grit number, the finer the particles and the smoother the finish. Abrasiveness level indicates how quickly the sandpaper removes material. Lower abrasiveness levels are used for finer finishing work, while higher levels are used for heavy material removal.

Now that we have a basic understanding of what sandpaper is, let’s take a closer look at the different types available and their specific uses.

Types of Sandpaper

Sandpaper comes in a variety of types, each designed for specific applications and materials. Let’s explore some of the most common types:

- Garnet Sandpaper: Garnet sandpaper is one of the oldest types and is known for its moderate cutting ability. It is commonly used for sanding wood and preparing surfaces for painting or staining.

- Aluminum Oxide Sandpaper: Aluminum oxide sandpaper is the most widely used type. It is available in various grit sizes, making it suitable for both rough shaping and fine finishing of wood, metal, and plastics.

- Silicon Carbide Sandpaper: Silicon carbide sandpaper is highly versatile and ideal for sanding harder materials such as metals, glass, ceramics, and stone. It has a sharp cutting action and is available in both wet and dry forms.

- Zirconia Alumina Sandpaper: Zirconia alumina sandpaper is known for its durability and long-lasting performance. It is commonly used for heavy-duty sanding and grinding applications on metal, fiberglass, and composites.

- Emery Sandpaper: Emery sandpaper is made from natural abrasive minerals and is commonly used for delicate sanding tasks. It is often used for polishing metals and fine woodworking.

In addition to these types, you can also find specialty sandpapers designed for specific purposes. Some examples include sandpapers with anti-clogging properties to prevent the buildup of material, sandpapers with self-adhesive backing for easy application, and sandpapers with additional coatings for improved durability.

Choosing the right type of sandpaper depends on the material being worked on and the desired result. It is always advisable to refer to the manufacturer’s guidelines and recommendations to ensure optimal performance and longevity of the sandpaper.

Grit Sizes and their Uses

Grit size is an important factor to consider when selecting sandpaper. It refers to the number of abrasive particles per square inch of sandpaper. The higher the grit number, the finer the particles and the smoother the finish. Here are some common grit sizes and their uses:

- Coarse Grits (40 – 80): Coarse grit sandpaper is used for heavy material removal and shaping rough surfaces. It is ideal for tasks like removing paint, rust, or corrosion from metal surfaces, or leveling uneven wood surfaces.

- Medium Grits (100 – 150): Medium grit sandpaper is suitable for general-purpose sanding and smoothing of surfaces. It helps to refine the workpiece and prepare it for further treatment, such as applying paint or varnish.

- Fine Grits (180 – 320): Fine grit sandpaper is used for achieving a smooth and polished finish. It is often used for sanding between coats of paint or primer, as well as for final sanding before applying a clear topcoat.

- Extra Fine Grits (400 – 600+): Extra fine grit sandpaper is used for ultra-smooth finishes and polishing delicate materials. It is commonly used in woodworking projects where a high level of precision is required.

It’s important to note that the specific grit sizes may vary slightly between different manufacturers and regions. It’s recommended to use a progression of grits, starting with a coarser grit and gradually moving to finer grits, to achieve the desired surface smoothness.

When working on a project, it is advisable to have a variety of grit sizes available to address different stages of sanding. This allows for efficient material removal in the initial stages and a smooth, refined finish in the later stages.

Understanding the relationship between grit size and surface finish is essential for achieving the desired result. By choosing the appropriate grit size for each stage of your sanding process, you will be able to achieve a professional and polished finish.

Sandpaper Abrasiveness Levels

When selecting sandpaper, it’s important to consider the abrasiveness level, also known as the cutting power or aggressiveness of the sandpaper. Different projects and materials require different levels of abrasiveness to achieve optimal results. Here are some common abrasiveness levels and their uses:

- Low Abrasiveness: Sandpapers with low abrasiveness are designed for fine finishing work. They are used to achieve smooth and polished surfaces without removing a significant amount of material. Low abrasiveness sandpapers are commonly used for sanding between coats of paint or varnish, as well as for preparing surfaces for final finishes.

- Medium Abrasiveness: Sandpapers with medium abrasiveness are suitable for general-purpose sanding tasks. They provide a balance between material removal and surface refinement. Medium abrasiveness sandpapers are commonly used for smoothing rough surfaces, removing minor imperfections, and preparing surfaces for painting or staining.

- High Abrasiveness: Sandpapers with high abrasiveness are designed for heavy material removal and shaping. They are used to remove paint, rust, or corrosion from metal surfaces, as well as to level uneven wood surfaces. High abrasiveness sandpapers are commonly used in the initial stages of a project where significant material removal is required.

It’s important to note that the specific abrasiveness levels may vary between different brands and types of sandpaper. Some manufacturers provide a ranking system or indicate the level of abrasiveness on the package, making it easier to select the appropriate sandpaper for a specific task.

Choosing the right abrasiveness level depends on the material being worked on, the desired amount of material removal, and the surface finish required. It’s recommended to start with a lower abrasiveness sandpaper and gradually move to higher abrasiveness when necessary, especially when smoothing rough surfaces or removing stubborn coatings.

By understanding the different abrasiveness levels and their uses, you can select the appropriate sandpaper that will efficiently and effectively achieve your desired results, whether it’s a smooth finish or heavy material removal.

Read more: What Is Sandpaper Used For In Art

How to Choose the Right Sandpaper

Choosing the right sandpaper for your project can significantly impact the quality and efficiency of your work. Here are some factors to consider when selecting sandpaper:

- Material to be Sanded: Determine the type of material you will be working on. Different materials have different hardness levels and require specific types of sandpaper. For example, wood may require a different type of sandpaper compared to metal or plastic.

- Task at Hand: Consider the task you need to accomplish. Are you looking to remove material, smooth rough surfaces, or achieve a polished finish? This will help you determine the appropriate grit size and abrasiveness level.

- Grit Size: Choose the grit size based on the level of surface smoothness you desire. Coarser grits (lower numbers) are suitable for heavy material removal, while finer grits (higher numbers) are used for a smoother finish. For most projects, it’s recommended to start with a coarser grit and gradually progress to finer grits for a polished result.

- Type of Sandpaper: Consider the type of sandpaper that best suits your needs. Aluminum oxide sandpaper is versatile and commonly used for general-purpose sanding, while silicon carbide is ideal for harder materials like metal or stone. Garnet sandpaper is suitable for woodworking projects, and zirconia alumina sandpaper offers excellent durability for heavy-duty tasks.

- Backing Material: Choose a backing material that suits your project requirements. Paper-backed sandpaper is economical and suitable for most general-purpose applications. Cloth-backed sandpaper offers increased durability for heavy-duty tasks. Additionally, adhesive-backed sandpaper provides convenience for certain applications.

- Manufacturer’s Recommendations: Take into account any specific recommendations provided by the sandpaper manufacturer regarding the material, task, and grit size. These guidelines can help you select the most suitable sandpaper for your project.

- Experiment and Test: If you’re unsure about which sandpaper to use, it’s always a good idea to experiment on a small, inconspicuous area or test different sandpapers on a sample piece of material. This allows you to see the results and determine which sandpaper provides the desired outcome.

Remember, the right sandpaper can make a significant difference in the quality and efficiency of your work. By considering factors such as material, task, grit size, type of sandpaper, and manufacturer’s recommendations, you can choose the most appropriate sandpaper for your specific project and achieve excellent results.

Common Uses of Sandpaper

Sandpaper is an indispensable tool in various industries and DIY projects. Its abrasive nature makes it essential for a wide range of applications. Here are some common uses of sandpaper:

- Woodworking: Sandpaper is extensively used in woodworking projects. It helps smooth rough surfaces, remove imperfections, and prepare wood for painting, staining, or finishing. It can also be used to shape and refine edges and contours.

- Metalworking: Sandpaper is crucial in metalworking tasks. It is used to remove rust, corrosion, and old paint from metal surfaces, providing a clean and smooth base for further treatment. Sandpaper is also used to polish and refine metal surfaces, achieving a bright and reflective finish.

- Auto Body Repair: Sandpaper plays a crucial role in auto body repair. It is used to remove old paint or primer, smooth out dents and imperfections, and prepare the surface for new paint or body filler. Different grit sizes and abrasiveness levels are employed to achieve the desired smoothness and texture.

- DIY/Home Improvement Projects: Sandpaper is a handy tool for various DIY and home improvement tasks. It can be used to sand down surfaces before repainting or refinishing furniture. It is also useful for removing rough edges on materials, such as cutting boards, and preparing surfaces for adhesive applications.

- Arts and Crafts: Sandpaper is often employed in arts and crafts projects. It can be used to distress and age wooden crafts, giving them an antique look. Sandpaper is also useful for smoothing and refining surfaces on sculptures, models, and other art projects.

- Preparing Surfaces: Sandpaper is commonly used to prepare surfaces before applying paint, varnish, or other coatings. It helps create a smooth and clean surface by removing old finishes, rough spots, and imperfections. This ensures better adhesion and a professional-looking final result.

These are just a few examples of the many applications of sandpaper. Its versatility and abrasive characteristics make it an indispensable tool in a wide range of industries and projects. Whether you’re a professional craftsman, a DIY enthusiast, or an artist, sandpaper is sure to play a vital role in achieving the desired results.

When using sandpaper, start with a coarser grit to remove material quickly, then switch to a finer grit for a smoother finish. Always sand in the direction of the wood grain for best results.

Sandpaper in Woodworking

Sandpaper is an essential tool in woodworking projects, helping achieve smooth surfaces and precise finishes. From preparing the wood to the final stages of sanding, sandpaper plays a crucial role in the woodworking process. Here’s how sandpaper is used in woodworking:

- Surface Preparation: Before any sanding takes place, it’s important to prepare the wood surface. Sandpaper is used to remove any rough spots, mill marks, or imperfections on the wood. Coarser grits, such as 80 or 100, are typically used at this stage to level uneven surfaces.

- Smoothing: Once the surface is prepared, finer grit sandpaper is used to achieve a smoother finish. This involves sanding the wood in the direction of the grain using progressively higher grits, such as 150, 220, and beyond. Smoothing the wood surface helps eliminate any remaining scratches or marks left behind by coarser grit sandpaper.

- Removing Stains or Finishes: Sandpaper is also used to remove old stains, finishes, or paint from wood surfaces. Coarser grits can be employed to remove the bulk of the existing finish, followed by finer grits to refine the surface and prepare it for new finishes or staining.

- Shaping and Contouring: Sandpaper is essential for shaping and contouring wood pieces. It allows for the removal of excess material, creating smooth and defined shapes. Sandpaper can be used on various woodworking tools, such as sanding blocks, sanders, or even by hand to achieve the desired contours.

- Final Finishing: In the final stages of woodworking, sandpaper is used to refine the surface for a polished finish. Finer grits, like 320 or 400, are employed to remove any remaining imperfections and create a smooth surface. This prepares the wood for staining, varnishing, or applying a protective finish.

When using sandpaper in woodworking, it’s important to sand with the grain of the wood to avoid causing scratches or damaging the surface. Additionally, it’s recommended to periodically check the sandpaper for clogging and replace it when necessary for optimal performance.

Whether you’re a beginner or experienced woodworker, sandpaper is a tool that you’ll reach for regularly. It helps transform rough lumber into smooth, refined masterpieces, and allows for the precise detailing and finishing that adds beauty to your woodworking projects.

Sandpaper in Metalworking

Sandpaper is a vital tool in metalworking, as it helps prepare and finish metal surfaces to achieve desired results. From removing rust and corrosion to polishing and refining, sandpaper plays a crucial role in the metalworking process. Here’s how sandpaper is used in metalworking:

- Rust and Corrosion Removal: Sandpaper is used to remove rust, corrosion, and old paint from metal surfaces. Coarser grits, such as 80 or 120, are typically used initially to remove the bulk of the rust or corrosion. Sandpaper with higher abrasiveness levels efficiently removes these unwanted substances, revealing a clean metal surface.

- Surface Smoothing: Once the rust or corrosion is removed, finer grit sandpaper is used to smooth the metal surface. This step helps even out any rough areas or imperfections left behind by the initial rust removal stage. Finer grits, such as 220 or 320, are used to achieve a smoother surface.

- Refining and Polishing: Sandpaper is used to refine and polish metal surfaces to achieve a smooth and mirror-like finish. This step involves using even finer grits, such as 400 or higher, to remove any scratches or imperfections and create a highly polished surface. Polishing compounds or buffing wheels may also be used in conjunction with sandpaper for an even greater shine.

- Grinding and Sharpening: In metalworking, sandpaper can be used for grinding and sharpening various metal tools and surfaces. Coarser grits, like 36 or 60, are used to remove material and shape the metal. This is especially useful for reshaping or sharpening blades, chisels, or other cutting tools.

- Deburring: Sandpaper is used to remove burrs, which are rough edges or raised metal created during metalworking processes, such as cutting or drilling. By gently sanding the edges, sandpaper helps smooth and remove any sharp or rough areas, making the metal safer and more aesthetically pleasing.

When using sandpaper for metalworking, it’s important to use it in conjunction with lubricants or coolants to prevent overheating and prolong the life of the sandpaper. Additionally, periodically checking the sandpaper for clogging and replacing it when necessary ensures optimal performance during the metalworking process.

From restoring old metal furniture to polishing intricate metalwork, sandpaper is an indispensable tool in metalworking. It allows for the preparation, refinement, and polishing of metal surfaces, enabling craftsmen to achieve the desired finish and quality in their metal projects.

Read more: What Is Silicon Carbide Sandpaper Used For

Sandpaper in Auto Body Repair

Sandpaper plays a crucial role in auto body repair, helping restore damaged vehicles to their original condition. It is an essential tool used in various stages of the repair process. Here’s how sandpaper is used in auto body repair:

- Paint Removal: Sandpaper is used to remove old paint or primer from the vehicle’s surface. Coarser grit sandpaper, such as 80 or 120, is often used to strip away the existing paint layers. This step prepares the surface for a fresh coat of paint and ensures proper adhesion.

- Surface Smoothing: After removing the paint, sandpaper is used to smooth the surface and level out any imperfections or rough spots. Finer grits, like 180 or 220, are employed to achieve a smoother and more even surface, ensuring optimal paint application and a professional finish.

- Dent and Scratch Repair: Sandpaper is used in conjunction with body filler to repair dents and scratches on the vehicle’s surface. Coarse grits are used initially to shape the body filler, while finer grits are used to smooth and feather the edges for a seamless repair. The sanding process is repeated until the repair area is perfectly blended with the surrounding surface.

- Priming and Sanding: Sandpaper is used to prepare the surface for the application of primer. This involves finer grit sandpaper, usually around 320 or higher, to create a smooth finish. The primer acts as a protective layer and enhances the adhesion of the topcoat. Sanding between primer coats and after the final application helps achieve a flawless surface before painting.

- Final Surface Preparation: Sandpaper is used for the final surface preparation to ensure a smooth and uniform base before applying the topcoat. Finer grits, such as 400 or higher, are used to eliminate any remaining imperfections, scratches, or tiny blemishes. The goal is to create a pristine surface for the paint to adhere to, resulting in a showroom-worthy finish.

When working on auto body repair, it’s important to use the proper grit size and abrasiveness level based on the specific task and the type of repair required. Following proper sanding techniques, such as sanding with the proper motion and applying even pressure, ensures optimal results and avoids unintentional damage to the vehicle’s surface.

Sandpaper is an invaluable tool in auto body repair, allowing for the removal of old paint, the repair of dents and scratches, and the preparation of surfaces for paint and flawless finishes. It plays a significant role in bringing damaged vehicles back to their former glory.

Sandpaper in DIY/Home Improvement Projects

Sandpaper is an essential tool in DIY and home improvement projects, contributing to the successful completion of various tasks. It allows for the preparation, restoration, and finishing of surfaces, ensuring a professional and polished outcome. Here’s how sandpaper is used in DIY and home improvement projects:

- Surface Preparation: Sandpaper is used to prepare surfaces before painting, staining, or applying other finishes. It helps remove old paint, varnish, or coatings, ensuring a clean and smooth surface for better adhesion. Coarser grits are employed initially to remove most of the existing finish, followed by finer grits to refine the surface.

- Woodworking Projects: Sandpaper is extensively used in woodworking projects, both large and small. It helps shape and smooth wooden surfaces, eliminate imperfections, and create a polished finish. From refinishing furniture to building cabinets or shelves, sandpaper is crucial in achieving desired results.

- Repair and Restoration: Sandpaper is used in DIY projects for repairing and restoring various materials. It can smooth rough edges, fix scratches, or remove water stains on wood. Additionally, it can be used to restore old metal furniture, removing rust or tarnish and providing a fresh and attractive appearance.

- Home Renovations: When renovating a home, sandpaper is essential for preparing surfaces to achieve a professional finish. Whether sanding walls before painting or smoothing plaster or drywall patches, sandpaper helps create a smooth and seamless surface for the application of new materials.

- Refinishing or Repurposing Projects: Sandpaper is frequently used when refinishing or repurposing furniture or other items. It allows for the removal of old finishes, smoothing rough surfaces, and providing a fresh canvas for new paint or stain. Sandpaper is also used to distress or create a vintage look on furniture for a more rustic or shabby-chic style.

- Craft and DIY Decor Projects: Sandpaper comes in handy for craft and DIY decor projects. It can be used to distress wooden signs or frames, create texture on surfaces, or prepare materials for adhesion. Sanding can also be used to smooth and polish surfaces of handmade jewelry or decorative pieces.

When using sandpaper for DIY and home improvement projects, it’s important to follow proper sanding techniques. This includes using the appropriate grit size based on the task at hand, sanding with the grain of the material, and finishing with finer grits for a smooth and polished result.

From preparing surfaces to refinishing furniture and tackling various repair projects, sandpaper is a versatile tool in DIY and home improvement endeavors. It allows DIY enthusiasts to achieve professional-quality finishes and transform their homes with a personal touch.

Sandpaper in Arts and Crafts

Sandpaper is a valuable tool in arts and crafts projects, offering artists and crafters a range of creative possibilities. It is particularly useful in shaping, refining, and adding unique textures to various materials. Here’s how sandpaper is used in arts and crafts:

- Woodworking: Sandpaper is often used in woodworking projects in the realm of arts and crafts. It helps shape and smooth wooden surfaces, allowing artists to create intricate details and smooth finishes. Sandpaper can be used to create relief carvings, sculpt wooden figures, or refine wooden objects, such as picture frames or decorative boxes.

- Texture and Distressing: Sandpaper is commonly used to add texture and distressing effects to different materials. By rubbing sandpaper on surfaces, artists can create a weathered or worn appearance on wood, metal, or even paper. This technique can be used to achieve a vintage or aged look on art pieces, mixed media projects, or handmade cards and scrapbooking projects.

- Polishing and Smoothing: In jewelry making and other crafts involving metal or other hard materials, sandpaper is used for polishing and smoothing. It helps remove scratches or imperfections on metal surfaces, providing a polished and shiny finish. Sandpaper can also be used to shape and smooth polymer clay or resin creations, ensuring a professional look.

- Mixed Media Collage: Sandpaper is a valuable tool in creating textured backgrounds for mixed media collages. By sanding and distressing paper or cardboard surfaces, artists can add depth and dimension to their artwork. Sandpaper can also be used for blending colors or removing unwanted paint or ink, allowing for creative experimentation and unique effects.

- Paper Crafts: Sandpaper is useful for various paper crafts, such as making handmade cards or invitations. It can be used to distress paper edges, creating a soft and vintage look. Sandpaper can also be employed to smooth down rough paper surfaces or refine intricate paper cut-outs, ensuring a clean and polished result.

- Model Making and Miniatures: Sandpaper is vital in model making and miniature craft projects. It helps shape and refine small-scale structures, such as model houses, dioramas, or miniature landscapes. Sandpaper allows artists to achieve precise details and smooth finishes, ensuring realistic and visually appealing creations.

In arts and crafts, sandpaper offers artists and crafters a way to add unique textures, create distressed effects, and achieve polished finishes. Whether it’s woodworking, mixed media projects, paper crafts, or miniature creations, sandpaper is a versatile tool that allows for endless creative possibilities.

Conclusion

Sandpaper is a versatile and essential tool in various industries, DIY projects, and creative endeavors. It serves a multitude of purposes, from preparing surfaces to shaping and refining materials. Whether you’re working on woodworking projects, metalworking, auto body repairs, or engaging in arts and crafts, sandpaper plays a crucial role in achieving the desired results.

By understanding the different types of sandpaper available, including garnet, aluminum oxide, silicon carbide, and more, you can choose the most suitable option for your specific application. Considering factors such as grit size, abrasiveness level, and backing material enables you to select the appropriate sandpaper for your project, whether it requires heavy material removal or fine finishing work.

In woodworking, sandpaper aids in surface preparation, smoothing, and achieving refined finishes. In metalworking, it helps remove rust, shape metal, and polish surfaces to a mirror-like shine. In auto body repair, sandpaper is essential for paint removal, dent repair, and creating a seamless finish. In DIY and home improvement projects, it’s indispensable for surface preparation, repair, and refinishing. In arts and crafts, sandpaper allows for texture creation, distressing effects, and polishing.

Proper sanding techniques, including using the correct grit size, sanding with the grain, and progressively moving to finer grits, contribute to the desired outcome. Regularly checking for clogging and replacing sandpaper when necessary ensures optimal performance and efficiency throughout your project.

In summary, sandpaper is a valuable tool that enhances the quality and aesthetics of your work. Whether you’re a professional craftsman, a DIY enthusiast, or an artist, the right sandpaper can make a significant difference in achieving smooth surfaces, polished finishes, and professional-level results.

So, the next time you embark on a project, don’t forget the power of sandpaper. Embrace its versatility and harness its abrasive properties to transform materials, bring creativity to life, and achieve impressive results.

Frequently Asked Questions about What Is Sandpaper Used For

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is Sandpaper Used For”