Home>Renovation & DIY>Tools & Equipment>What Sandpaper To Use On Concrete

Tools & Equipment

What Sandpaper To Use On Concrete

Published: December 20, 2023

Discover the best tools and equipment for sanding concrete surfaces. Learn which sandpaper grits are most effective for achieving a smooth finish.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to our comprehensive guide on choosing the right sandpaper for concrete surfaces. Whether you’re a DIY enthusiast or a professional contractor, knowing the right tools and equipment to use on concrete is essential for achieving the desired results. Concrete surfaces can be rough, uneven, or in need of polishing, and using the correct sandpaper is crucial to smooth and refine the surface.

Concrete is a versatile and durable material commonly used in various construction applications, such as driveways, sidewalks, patios, and floors. Over time, concrete can become worn, stained, or develop imperfections that need to be addressed. Sanding is a process that helps to smooth out the surface, eliminate scratches, and prepare it for further treatment or finishing.

In this guide, we will explore different factors to consider before choosing sandpaper for concrete surfaces. We will discuss various grit options, the difference between wet and dry sanding, the use of sandpaper for concrete polishing, and important safety precautions you need to be aware of. Let’s dive in!

Key Takeaways:

- Choose the right sandpaper grit based on the concrete surface condition and desired finish. Consider wet vs. dry sanding for dust control and surface cooling, and prioritize safety with protective gear and proper ventilation.

- Progressively use coarse to extra fine grit sandpapers for concrete polishing, enhancing smoothness and shine. Prioritize safety, work in sections, and follow local regulations for waste management.

Read more: What Is Sandpaper Used For

Understanding Concrete Surfaces

Before delving into the world of sandpaper for concrete, it’s important to understand the nature of concrete surfaces. Concrete is a composite material made up of a mixture of cement, aggregates, water, and sometimes additives. When freshly poured, concrete is semi-fluid and can be shaped into various forms. As it cures, it hardens and becomes a solid, strong surface.

Concrete surfaces can vary in texture, depending on factors such as the finishing method used during installation, the type of aggregate used, and any additional treatments applied. Some common types of concrete finishes include smooth finishes, broom finishes, stamped finishes, and exposed aggregate finishes.

When it comes to sanding concrete, the main objective is to achieve a smooth and even surface. This can be particularly challenging because of concrete’s inherent hardness. In addition, concrete might have imperfections like ridges, uneven surfaces, and small cracks that require attention. Understanding the specific requirements of your concrete surface will help you choose the right sandpaper and achieve the desired results.

It’s also important to note that not all concrete surfaces are suitable for sanding. Some special finishes, such as polished concrete, may require specific polishing techniques rather than traditional sanding methods. It’s crucial to evaluate the condition of your concrete surface and identify any specific requirements or limitations before proceeding with sanding.

Next, let’s explore the factors you should consider before choosing sandpaper for concrete surfaces.

Factors to Consider Before Choosing Sandpaper

Choosing the right sandpaper for concrete surfaces involves considering a few important factors. By understanding these factors, you can make an informed decision and achieve the best results. Let’s explore the key considerations:

- Grit Size: One of the primary factors to consider is the grit size of the sandpaper. The grit size refers to the coarseness or fineness of the abrasive particles on the sandpaper. Common grit sizes for sanding concrete range from 40 to 1200, with lower numbers representing coarser grits and higher numbers representing finer grits. The specific grit size you need will depend on the surface condition and the level of smoothing or polishing required.

- Surface Condition: Assessing the condition of your concrete surface is crucial in determining the appropriate sandpaper. For rough surfaces with deep imperfections or previous coatings, a coarser grit may be needed initially to remove any uneven areas. On the other hand, if the surface is relatively smooth and you’re looking to achieve a polished finish, a finer grit sandpaper will be more suitable.

- Material Compatibility: Ensure that the sandpaper you choose is compatible with concrete surfaces. Not all sandpapers are designed for use on concrete, and using the wrong sandpaper can result in inefficiency or damage to the surface. Look for sandpaper specifically labeled for use on concrete or masonry materials.

- Wet vs. Dry Sanding: Consider whether you’ll be wet or dry sanding. Wet sanding involves using water as a lubricant to minimize dust and keep the surface cool. Dry sanding, on the other hand, is performed without water and produces more dust. The choice between wet and dry sanding will depend on personal preference, the type of sandpaper, and the specific concrete surface being worked on.

- Project Size: Take into account the size and scope of your sanding project. For small DIY projects or spot treatments, you may opt for hand sanding using sandpaper sheets or sponges. For larger areas, power sanding tools such as orbital sanders or concrete grinders may be more efficient. Consider the right sanding tools for your project to ensure optimal results.

By considering these factors, you can narrow down your options and choose the most appropriate sandpaper for your concrete surface. In the next section, we will discuss the different grit options available for sanding concrete.

Different Grit Options for Sanding Concrete

When it comes to sanding concrete, the grit size of the sandpaper plays a crucial role in achieving the desired results. Different grit options are available, each designed for specific purposes. Let’s explore the various grit options for sanding concrete:

- Coarse Grit (40-80): Coarse grit sandpaper is used for initial rough sanding on concrete surfaces. It is effective in removing thick coatings, leveling out uneven areas, and smoothing rough surfaces.

- Medium Grit (100-150): Medium grit sandpaper is suitable for further refinement of the surface after initial rough sanding. It helps to smooth out scratches, remove minor imperfections, and prepare the surface for finer grit sanding.

- Fine Grit (180-240): Fine grit sandpaper is used for intermediate sanding to achieve a smoother surface. It is effective in removing finer imperfections, refining the surface, and preparing it for polishing or coating.

- Very Fine Grit (320-400): Very fine grit sandpaper is used for final sanding before polishing or applying a coating. It helps to achieve a smooth and polished finish on the concrete surface.

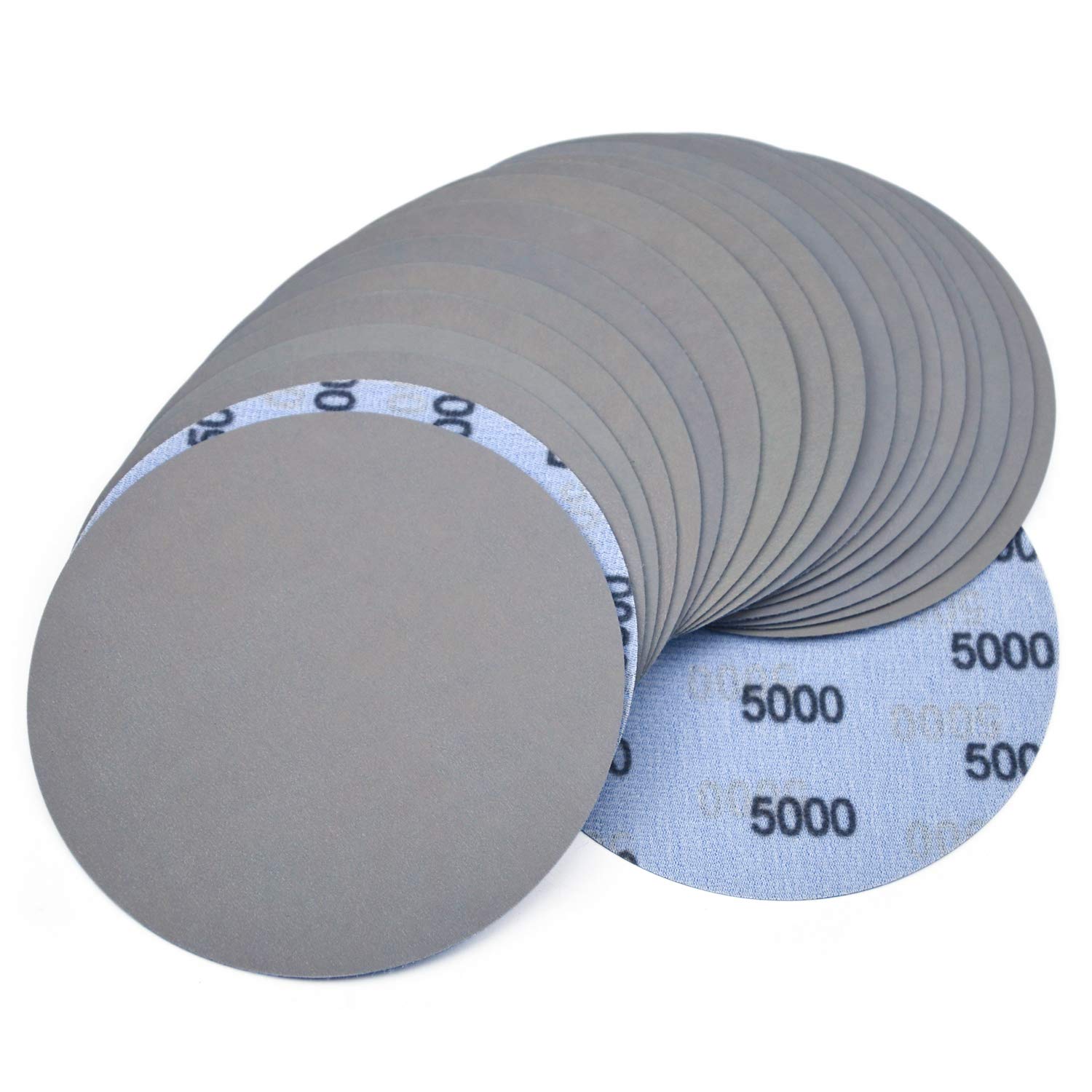

- Extra Fine Grit (600-1200): Extra fine grit sandpaper is used for ultra-smooth finishes, such as polishing concrete surfaces. It is typically used in conjunction with polishing compounds to achieve a high level of shine and reflectivity.

It’s important to note that the specific grit size required will depend on the condition of the concrete surface, the level of smoothing or polishing desired, and the specific project requirements. In general, start with a coarse grit to remove any major imperfections, gradually move to finer grits to achieve a smoother surface, and finish with extra fine grits for polishing and achieving a refined finish.

Additionally, consider the type of sandpaper you’re using. Some abrasive materials, such as silicon carbide or diamond, are highly effective for sanding concrete surfaces and offer long-lasting durability.

Now that we have explored different grit options, let’s discuss the difference between wet and dry sanding for concrete surfaces.

When sanding concrete, use silicon carbide sandpaper for the best results. It is durable and can handle the hardness of concrete without wearing out quickly.

Wet vs. Dry Sanding

When it comes to sanding concrete surfaces, you have the option to choose between wet sanding and dry sanding methods. Each method has its own advantages and considerations. Let’s take a closer look at wet and dry sanding for concrete:

Wet Sanding: Wet sanding involves using water as a lubricant during the sanding process. This method offers several benefits:

- Dust Control: Wet sanding minimizes the amount of dust produced during the sanding process. This can be particularly advantageous when working indoors or in areas with poor ventilation.

- Cooler Surface: The water used in wet sanding helps to cool down the concrete surface, preventing overheating and potential damage caused by excessive friction.

- Smooth Finish: Wet sanding tends to achieve a smoother finish due to the lubrication provided by water. It helps to reduce the visibility of scratches and creates a more polished appearance.

However, wet sanding also has its considerations:

- Mess and Clean-up: Working with water can create a mess, especially when sanding larger areas. You will need to account for proper drainage and take precautions to protect surrounding areas from water damage.

- Drying Time: After wet sanding, the concrete surface will need time to dry completely before any further treatment or finishing can be applied.

Dry Sanding: Dry sanding involves sanding the concrete surface without using water. This method has its own advantages and considerations:

- Convenience: Dry sanding is often more convenient and easier to perform, especially for smaller projects or areas that are not easily accessible with water.

- No Drying Time: Unlike wet sanding, you can proceed directly with further treatment or finishing after dry sanding since there is no moisture to dry out.

However, dry sanding also has some considerations:

- Dust Control: Dry sanding generates a significant amount of dust that can be hazardous to your health if inhaled. It’s vital to wear appropriate respiratory protection and ensure proper ventilation when dry sanding.

- Heat Build-up: Dry sanding can generate heat due to friction, potentially leading to overheating of the concrete surface. This heat can cause damage if not managed properly, so it’s important to monitor the surface temperature and take necessary breaks to prevent overheating.

Ultimately, the choice between wet and dry sanding depends on personal preference, the nature of the project, and the specific requirements of the concrete surface. Consider these factors to determine which method suits your needs best.

Next, we will explore the use of sandpaper for concrete polishing.

Read more: What Is Sandpaper Used For In Art

Using Sandpaper for Concrete Polishing

While sandpaper is commonly used for sanding rough concrete surfaces, it can also be used for concrete polishing to achieve a smooth and glossy finish. Polishing concrete involves progressively refining the surface through a series of sanding steps. Here’s how you can use sandpaper for concrete polishing:

- Starting Grit: Begin the concrete polishing process by using a relatively low grit sandpaper, such as 80 or 100. This coarse grit will help remove any remaining imperfections and roughen the surface for further polishing.

- Progressive Grits: Gradually work your way up to higher grit sandpapers, such as 200, 400, and 800. Each subsequent grit will refine the surface and help remove the scratches left by the previous grit. This step-by-step process will result in a smoother and more polished finish.

- Finer Grits: Once you have reached a desired level of smoothness, continue using even finer grits, such as 1000 or 1500. These finer grit sandpapers will further refine the surface and enhance its shine and reflectivity.

- Polishing Compounds: In conjunction with the finer grit sandpapers, you can also apply polishing compounds to aid in the polishing process. Polishing compounds are abrasive materials mixed with a binder that helps create a high-gloss finish on the concrete surface. Follow the manufacturer’s instructions when applying the polishing compounds.

- Buffing: After the final polishing step, you can use a buffing pad or polishing bonnet attached to a polishing machine or floor buffer to achieve an even higher level of shine. This step helps to further enhance the smoothness and reflectivity of the polished concrete surface.

It’s important to note that concrete polishing requires patience and attention to detail. Take your time with each grit and ensure that all scratches from the previous grit are removed before moving on to the next. Proper technique and maintaining consistent pressure during the sanding process will result in the best polishing results.

Additionally, keep in mind that concrete polishing can be a labor-intensive process, especially for larger areas. Consider using power sanding tools such as floor buffers or concrete polishers to make the process more efficient and manageable.

Remember to always follow safety precautions and wear protective equipment like goggles, a dust mask, and gloves during the sanding and polishing process.

Now that you understand how to use sandpaper for concrete polishing, let’s discuss some important safety precautions and tips to keep in mind.

Safety Precautions and Tips for Sanding Concrete

When sanding concrete surfaces, it’s important to prioritize safety to protect yourself and ensure a successful outcome. Here are some essential safety precautions and tips to keep in mind:

- Protective Gear: Always wear appropriate protective gear, including safety goggles, a dust mask or respirator, and gloves. Concrete dust can be harmful if inhaled, so it’s crucial to protect your respiratory system. Gloves will also help protect your hands from rough concrete surfaces.

- Ventilation: Ensure proper ventilation when sanding concrete, especially in enclosed or poorly ventilated areas. Open windows, use fans, or consider using a dust collection system to minimize dust and maintain air quality.

- Power Tool Safety: If using power sanding tools, carefully read and follow the manufacturer’s instructions. Ensure that the tools are in good working condition, and use them according to their intended purpose. Do not force the sanding tool, and always use a secure grip.

- Work Area Preparation: Before starting the sanding process, clear the work area of any debris, objects, or furniture that could interfere with your work. Protect nearby surfaces and objects by covering them with plastic sheets or drop cloths to prevent any damage or contamination.

- Proper Technique: Maintain a firm grip on the sandpaper or sanding tool, and use consistent pressure during sanding. Avoid applying excessive force, as this can lead to uneven results or damage to the concrete surface.

- Work in Sections: When sanding larger concrete surfaces, it’s advisable to work in smaller sections. This allows you to focus on one area at a time and ensures a more even and thorough sanding process.

- Regular Inspections: Periodically inspect the sandpaper or sanding tool during the sanding process. If the sandpaper becomes clogged or worn out, replace it with a fresh piece to maintain optimal sanding results.

- Take Breaks: Take breaks as needed to prevent fatigue and maintain concentration. Sanding concrete surfaces can be physically demanding, so it’s important to give yourself adequate rest when necessary.

- Clean-Up: After completing the sanding process, properly dispose of any dust or debris generated. Use a vacuum cleaner equipped with a HEPA filter or dampen the area with water before sweeping to minimize dust dispersion.

- Follow Local Regulations: Familiarize yourself with any local regulations or guidelines regarding the handling and disposal of concrete dust and debris. Adhere to proper waste management practices to protect the environment.

By following these safety precautions and tips, you can minimize the risks associated with sanding concrete surfaces and ensure a safe and successful project.

Now that you have a comprehensive understanding of sandpaper options, techniques, and safety measures, you can confidently tackle your concrete sanding projects. Remember to always prioritize safety, choose the right sandpaper for the job, and approach each project with patience and attention to detail.

Good luck with your concrete sanding endeavors!

Conclusion

Choosing the right sandpaper for concrete surfaces is essential for achieving smooth and polished results. By considering factors such as grit size, surface condition, material compatibility, and the choice between wet and dry sanding, you can make an informed decision and ensure the best outcome for your project.

Understanding the nature of concrete surfaces and their specific requirements is crucial before embarking on any sanding or polishing endeavor. Whether you’re working on rough patches, leveling uneven areas, or aiming for a glossy finish, using the appropriate sandpaper and following the proper techniques will help you achieve the desired results.

From coarse grits for initial sanding to finer grits for polishing, the progression of sandpaper helps refine and transform the concrete surface. Consider the use of polishing compounds in conjunction with finer grit sandpapers to enhance the smoothness and shine of the surface.

It’s important to prioritize safety during the sanding process. Wear protective gear, ensure proper ventilation, and follow safety guidelines for power tools. By taking these precautions, you can minimize health risks and avoid accidents.

Remember to work in smaller sections, maintain proper technique, and inspect your sandpaper regularly for optimal results. Take breaks when needed and properly clean up dust and debris after completing the sanding process.

Sanding concrete surfaces can be a labor-intensive endeavor, but with the right tools, techniques, and safety measures, you can achieve remarkable results. Whether you’re a DIY enthusiast or a professional contractor, this guide has provided you with the knowledge and insights necessary to choose the right sandpaper and approach your concrete sanding projects with confidence.

So, equip yourself with the appropriate sandpaper, unleash your creativity, and transform your concrete surfaces into smooth, polished, and visually appealing masterpieces.

Frequently Asked Questions about What Sandpaper To Use On Concrete

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Sandpaper To Use On Concrete”