Home>Technology>Smart Home Devices>How To Print Labels On A Thermal Printer

Smart Home Devices

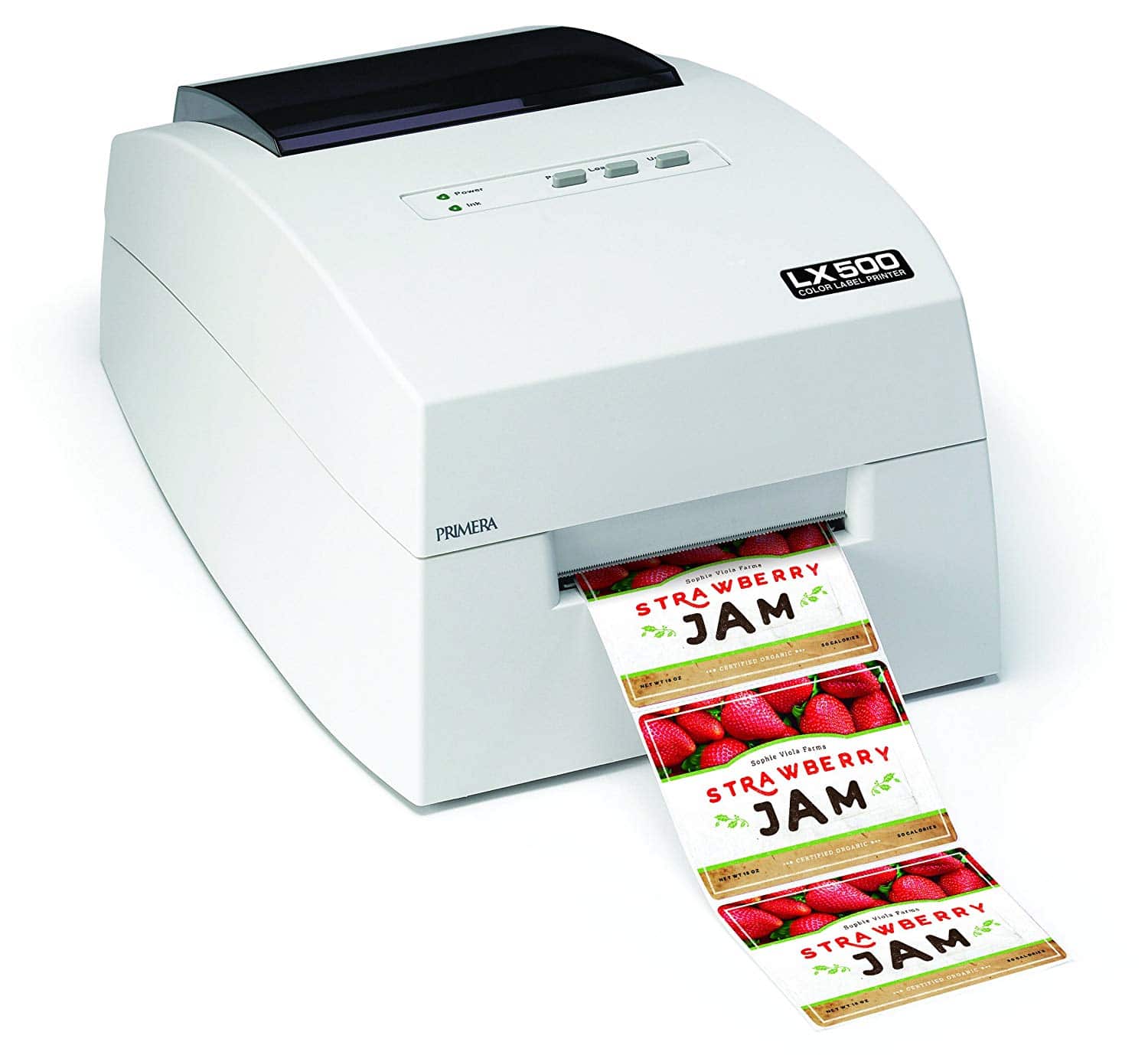

How To Print Labels On A Thermal Printer

Modified: August 16, 2024

Learn how to print labels on a thermal printer for your smart home devices with our step-by-step guide. Streamline your labeling process today!

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

**

Introduction

**

Welcome to the world of thermal printing! In today's digital age, the demand for efficient and high-quality printing solutions is ever-growing, and thermal printers have emerged as a popular choice for a wide range of applications. Whether you are a small business owner looking to streamline your labeling process or a home user seeking a convenient way to print shipping labels, understanding how to print labels on a thermal printer can significantly enhance your efficiency and productivity.

Thermal printing technology offers numerous advantages, including fast printing speeds, low maintenance requirements, and the ability to produce durable, high-resolution labels. By harnessing the power of heat to create images on specially coated paper, thermal printers eliminate the need for ink or toner, resulting in cost-effective and hassle-free printing.

In this comprehensive guide, we will delve into the intricacies of thermal printing, from setting up your thermal printer to designing and formatting your labels. We will explore the key considerations for choosing the right label and provide practical insights into troubleshooting common issues that may arise during the printing process. By the end of this journey, you will be equipped with the knowledge and skills to harness the full potential of your thermal printer, unlocking a world of seamless label printing possibilities.

So, let's embark on this enlightening exploration of thermal printing and discover the art of effortlessly producing professional-quality labels with precision and ease. Whether you are a novice or a seasoned user, this guide is designed to empower you with the expertise needed to make the most of your thermal printing experience. Let's dive in and unravel the secrets of printing labels on a thermal printer! **

**

**

Key Takeaways:

- Thermal printing uses heat to create images on paper, making it cost-effective and efficient. It’s great for businesses and home users looking for high-quality label printing without the hassle of ink or toner.

- To print labels on a thermal printer, it’s important to choose the right label material, design, and troubleshoot common issues. With the right setup and knowledge, anyone can create professional-quality labels with ease.

Read more: How To Print Ebay Labels On Thermal Printer

Understanding Thermal Printing

Thermal printing is a revolutionary technology that utilizes heat to create images on paper, eliminating the need for traditional ink or toner. This innovative printing method relies on two primary types of thermal printing: direct thermal and thermal transfer.

Direct Thermal Printing:

Direct thermal printing involves the direct application of heat to a chemically treated paper, known as direct thermal paper, which darkens in response to the heat. This process is ideal for producing receipts, shipping labels, and other short-term applications. Direct thermal printers are renowned for their simplicity and cost-effectiveness, making them a popular choice for businesses seeking efficient and economical label printing solutions.

Thermal Transfer Printing:

Thermal transfer printing, on the other hand, employs a thermal print head to transfer ink from a ribbon onto the label material. This method is commonly used for producing durable, long-lasting labels that are resistant to environmental factors such as moisture, heat, and chemicals. Thermal transfer printing is well-suited for applications requiring high-quality, smudge-resistant labels, making it a preferred choice for industries such as manufacturing, healthcare, and logistics.

Advantages of Thermal Printing:

Thermal printing offers a myriad of benefits that contribute to its widespread adoption across diverse industries. Some of the key advantages include:

- Rapid Printing Speeds: Thermal printers are renowned for their high-speed printing capabilities, facilitating swift and efficient label production.

- Cost-Effective Operation: With no need for ink or toner cartridges, thermal printing minimizes ongoing operational expenses, making it an economical choice for businesses of all sizes.

- Low Maintenance Requirements: Thermal printers are relatively low-maintenance, reducing downtime and ensuring consistent performance.

- High-Quality Output: Whether producing text, barcodes, or graphics, thermal printers deliver crisp, legible images with exceptional clarity and precision.

- Durable Labels: Thermal printing yields durable labels that are resistant to fading, smudging, and abrasion, ensuring long-lasting readability.

By harnessing the power of thermal printing technology, businesses and individuals can achieve seamless, reliable, and professional-quality label printing, enhancing their operational efficiency and brand image.

Now that we have gained a deeper understanding of thermal printing, let's proceed to the next phase of our journey: setting up your thermal printer for optimal performance. **

Setting Up Your Thermal Printer

**

Before diving into the world of label printing, it is crucial to ensure that your thermal printer is properly set up and configured for seamless operation. Whether you have just acquired a new thermal printer or are looking to optimize the performance of an existing device, the setup process involves several key steps to guarantee smooth and efficient printing.

Step 1: Unboxing and Inspection

Upon receiving your thermal printer, carefully unbox the device and inspect it for any signs of damage that may have occurred during shipping. Verify that all components, including the power cable, interface cables, and accessories, are present and in good condition. It is essential to handle the printer with care and follow the manufacturer’s guidelines for unpacking and handling to prevent any potential damage.

Step 2: Power and Connectivity

Connect the power cable to the thermal printer and plug it into a suitable power source. Depending on the model of your printer, you may also need to establish a connection to your computer or network using the appropriate interface cables, such as USB, Ethernet, or Wi-Fi. Ensure that the connections are secure and that the printer is positioned within reach of the power source and communication interfaces for convenient access during operation.

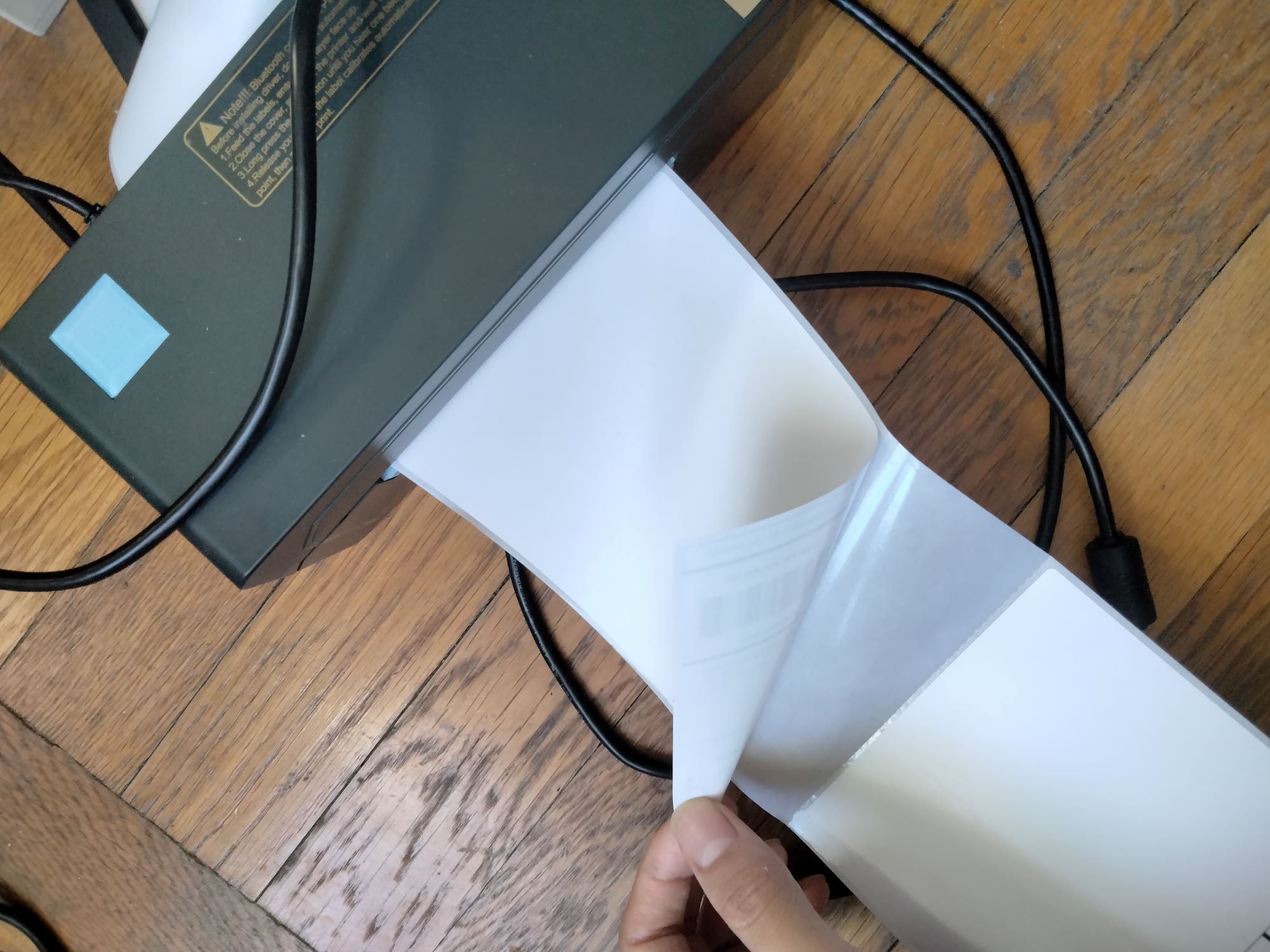

Step 3: Paper Roll Installation

Load the appropriate thermal label roll into the printer, following the manufacturer’s instructions for proper installation. Pay attention to the orientation of the label roll and ensure that it is inserted securely to prevent any feeding or alignment issues during printing. It is important to select label rolls that are compatible with your specific printer model and are suitable for the intended application to achieve optimal printing results.

Step 4: Software Installation and Configuration

Install the necessary printer drivers and software on your computer to enable seamless communication with the thermal printer. Follow the provided instructions to configure the printer settings, including label dimensions, print quality, and other relevant parameters. Familiarize yourself with the printer’s control panel or software interface to customize settings according to your preferences and printing requirements.

Step 5: Calibration and Testing

After completing the initial setup, perform a calibration and test print to ensure that the printer is functioning correctly and producing accurate output. Adjust the print head and sensor settings as needed to achieve optimal print alignment and quality. Conduct thorough testing of various label designs and content to validate the printer’s performance across different print jobs.

By meticulously following these steps, you can establish a solid foundation for your thermal printer, paving the way for seamless label printing and operational efficiency. With the setup process complete, you are now ready to explore the next crucial aspect of thermal label printing: choosing the right label for your specific needs.

Choosing the Right Label

When it comes to thermal printing, selecting the appropriate label is a critical decision that directly impacts the quality, durability, and functionality of the printed output. With a myriad of label options available, it is essential to consider various factors to ensure that the chosen labels align with your specific application requirements and deliver optimal performance.

Label Material:

The material composition of the label plays a pivotal role in determining its suitability for different environments and applications. Common label materials for thermal printing include paper, synthetic materials such as polypropylene and polyester, and specialized options such as tamper-evident and weather-resistant labels. Consider the environmental conditions, handling requirements, and longevity of the labels to select a material that aligns with the intended use case.

Adhesive Properties:

The adhesive backing of the label is a crucial consideration, especially when the labels will be applied to various surfaces. Different adhesives offer varying levels of tackiness, removability, and resistance to factors such as moisture and temperature. Assess the surface characteristics of the items to be labeled and choose an adhesive that ensures secure adhesion without leaving residue or compromising the label’s integrity.

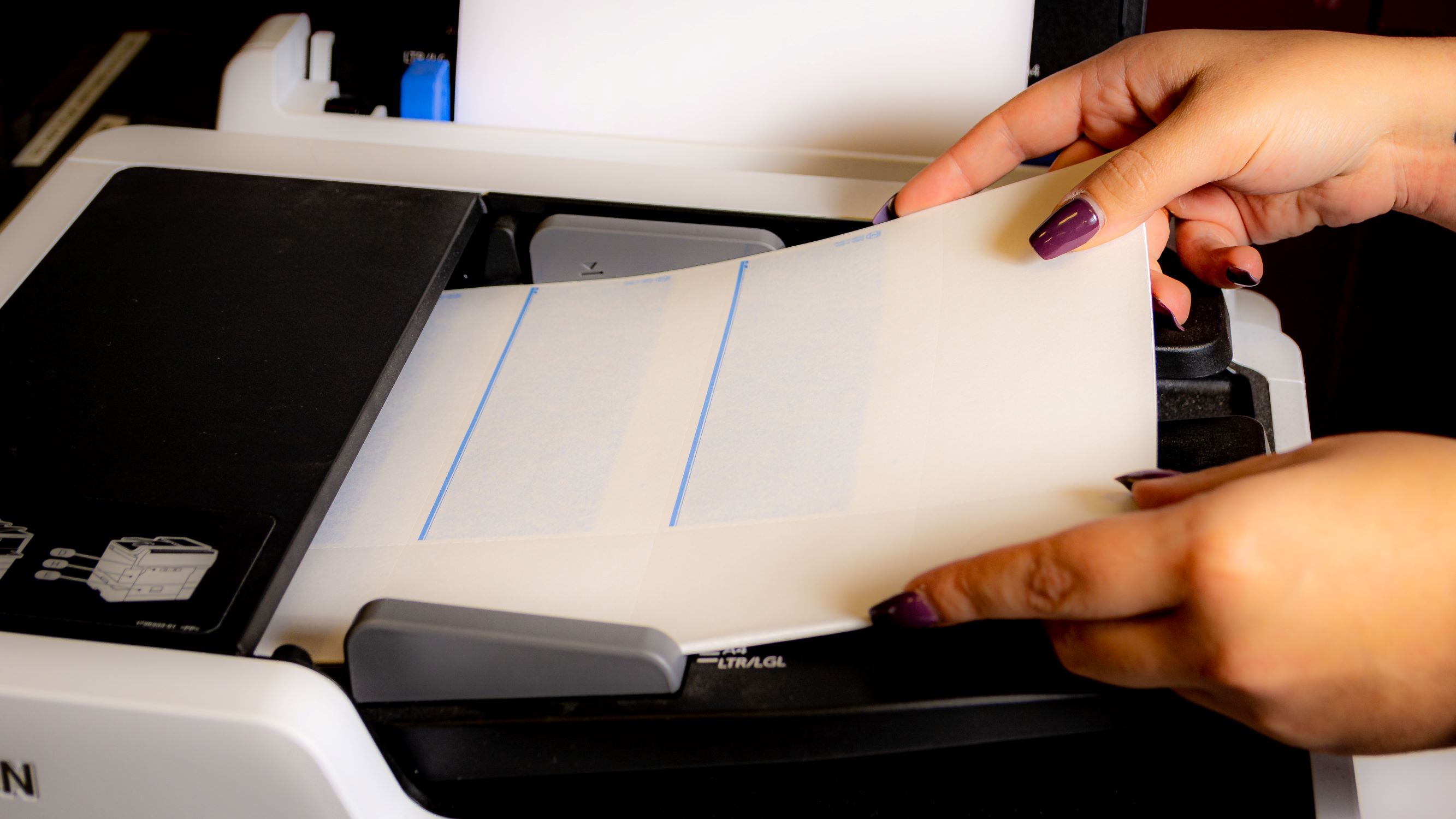

Label Size and Format:

The dimensions and format of the label should be tailored to accommodate the content and design elements of the intended label application. Whether printing shipping labels, product identifiers, or barcode labels, ensure that the label size and format align with industry standards, regulatory requirements, and the capabilities of your thermal printer. Consider the readability and scanability of barcodes and text when determining the optimal label size.

Specialized Features:

Certain applications may necessitate specialized label features, such as tamper-evident constructions, color coding, or pre-printed elements. Evaluate the specific needs of your labeling tasks and explore label options that offer enhanced security, visual identification, or pre-printed content to streamline the printing process and convey essential information effectively.

Compatibility with Printer:

Verify that the selected labels are compatible with your thermal printer in terms of size, material thickness, and core size. Consult the printer’s specifications and guidelines to ensure that the chosen labels align with the printer’s capabilities and do not cause feeding, alignment, or print quality issues.

By carefully evaluating these considerations, you can make informed decisions when choosing the right label for your thermal printing needs. Selecting labels that are well-suited to your application requirements and compatible with your printer sets the stage for producing professional-quality, durable labels that meet the demands of your business or personal endeavors.

With the optimal label selection in mind, our journey through the realm of thermal label printing leads us to the next crucial phase: designing and formatting your labels for visually appealing and informative output. **

Make sure to use the correct label size and type for your thermal printer. Adjust the printer settings to match the label specifications to ensure clear and accurate printing.

Designing and Formatting Your Labels

Effective label design and formatting are essential elements in leveraging the full potential of thermal printing to create visually appealing, informative, and functional labels. Whether you are crafting product labels, shipping identifiers, or barcode tags, the design and layout of your labels play a pivotal role in conveying information, enhancing brand identity, and facilitating efficient label utilization.

Content and Layout:

Begin by conceptualizing the content and layout of your labels, considering the essential information to be included, such as product details, barcodes, logos, and compliance elements. Prioritize clarity and readability, ensuring that the text and graphical elements are strategically positioned for optimal visibility and comprehension. Utilize industry-standard fonts and sizes to enhance legibility, especially for barcode and alphanumeric data.

Branding and Visual Elements:

Incorporate your brand elements, such as logos, color schemes, and visual motifs, to infuse your labels with a distinct brand identity. Consistent branding across labels fosters brand recognition and reinforces your business’s image, making it easier for customers and stakeholders to associate the labels with your products or services.

Compliance and Informational Elements:

For labels requiring compliance information, such as regulatory symbols, safety instructions, or product specifications, ensure that these elements are prominently featured and adhere to relevant industry standards. Informational elements should be clear, concise, and positioned to attract attention without overshadowing other critical label content.

Barcode and Variable Data Integration:

If your labels incorporate barcodes, serial numbers, or variable data, ensure that these elements are accurately generated and formatted to align with industry standards and scanning requirements. Test the readability and scannability of barcodes to verify their accuracy and consistency across different label designs and printing runs.

Software Tools and Templates:

Leverage specialized label design software or templates provided by your thermal printer manufacturer to streamline the design process. These tools offer intuitive interfaces, design elements, and label templates tailored for thermal printing, empowering you to create professional-quality labels with ease and precision.

Print Quality and Testing:

Before proceeding with large-scale label printing, conduct thorough testing of your label designs to evaluate print quality, color accuracy, and overall visual appeal. Adjust design elements and printer settings as needed to achieve optimal results, ensuring that your labels meet your expectations and align with industry standards for visual and informational clarity.

By investing time and attention into the design and formatting of your labels, you can elevate the visual impact, functionality, and professionalism of your thermal printed labels. With a well-crafted label design in place, you are poised to embark on the final phase of our thermal printing journey: printing your labels with precision and confidence. **

Printing Your Labels

As you venture into the realm of thermal label printing, the process of printing your labels with precision and efficiency becomes a pivotal stage in bringing your designs to life. Whether you are producing shipping labels, product identifiers, or barcode tags, mastering the art of printing your labels is essential for achieving consistent, high-quality output that meets your operational and branding needs.

Printer Settings and Calibration:

Before initiating the printing process, ensure that your thermal printer is configured with the appropriate settings for label dimensions, print quality, and media type. Calibration of the print head and sensor alignment is crucial for achieving accurate and consistent print placement, especially when producing labels with barcodes or graphical elements that demand precise positioning.

Test Printing and Quality Assurance:

Conduct test prints of your label designs to verify print quality, color accuracy, and overall visual appeal. Assess the readability of text and barcodes, ensuring that all elements are rendered with clarity and precision. If discrepancies or inconsistencies are observed, refine your designs and adjust printer settings to achieve the desired print output before proceeding with full-scale label production.

Print Batch Management:

When printing labels in batches, organize your print jobs to optimize efficiency and minimize material waste. Utilize batch printing features offered by your thermal printer to streamline the printing process, allowing for sequential printing of multiple labels without the need for manual intervention between each label. This approach enhances productivity and ensures uniform print quality across the entire label batch.

Media Handling and Loading:

Proper handling and loading of label rolls are essential to prevent feeding issues, misalignments, or print errors during the printing process. Follow the manufacturer’s guidelines for loading label rolls into your thermal printer, ensuring that the media is securely seated and aligned for smooth and consistent feeding. Regularly inspect the label path for any debris or adhesive residue that may impact print quality and printer performance.

Maintenance and Cleaning:

Maintain the cleanliness and operational integrity of your thermal printer by adhering to recommended maintenance practices. Regularly clean the print head, platen roller, and label path to remove debris, adhesive buildup, and contaminants that can compromise print quality and lead to premature wear of printer components. By upholding proper maintenance, you can prolong the lifespan of your printer and sustain reliable label printing performance.

Print Monitoring and Verification:

During the printing process, monitor the output for any anomalies, such as smudging, misprints, or incomplete images. Inspect the printed labels for adherence to design specifications, color consistency, and overall print quality. Conduct periodic verifications of printed barcodes to ensure readability and compliance with industry standards for scanning and data capture.

By mastering the intricacies of printing your labels on a thermal printer, you can harness the full potential of thermal printing technology to produce professional-quality labels with precision and confidence. With your labels seamlessly brought to life, you are well-equipped to navigate the final phase of our thermal printing journey: troubleshooting common issues that may arise during the label printing process. **

Troubleshooting Common Issues

While thermal printing offers numerous advantages, occasional challenges may arise during the label printing process. Understanding and addressing common issues that can affect print quality and operational efficiency is essential for maintaining seamless label production and minimizing disruptions. By familiarizing yourself with troubleshooting techniques, you can swiftly resolve issues and optimize the performance of your thermal printer.

Print Quality Issues:

If you encounter issues such as faded print, streaks, or inconsistent darkness on your labels, the print head may require cleaning or calibration. Inspect the print head for debris, adhesive residue, or wear, and perform a thorough cleaning using approved cleaning materials and techniques. Additionally, recalibrate the print head and adjust printer settings to enhance print quality and consistency.

Label Feeding Problems:

Misfeeds, label jams, or skewed printing can be attributed to improper label loading, media misalignment, or debris obstructing the label path. Ensure that label rolls are loaded securely and aligned correctly within the printer. Clear any debris or adhesive buildup from the label path, platen roller, and sensors, and verify that the media sensors are functioning correctly to facilitate smooth label feeding.

Barcode Readability Issues:

In cases where barcodes exhibit poor readability or scanning performance, review the barcode design and printing parameters to ensure compliance with industry standards. Adjust the print density, label material, and printer settings to optimize barcode clarity and contrast. Conduct thorough testing of barcodes across various label designs to validate their scannability and adherence to encoding standards.

Communication and Connectivity Problems:

Issues related to printer connectivity, communication errors, or print job interruptions may stem from interface cable faults, driver conflicts, or network connectivity issues. Verify the integrity of interface cables, USB or network connections, and power sources to eliminate potential communication disruptions. Update printer drivers and firmware to ensure compatibility and stability across different printing environments.

Print Head and Component Maintenance:

Regular maintenance of the print head, platen roller, and label path is essential for preventing print quality issues and prolonging the operational lifespan of your thermal printer. Adhere to recommended cleaning schedules and procedures provided by the printer manufacturer to remove debris, adhesive residue, and contaminants that can impact print performance and component longevity.

Environmental Factors and Label Storage:

Environmental conditions, such as excessive heat, humidity, or exposure to contaminants, can affect label quality and printer performance. Store label rolls in a controlled environment to prevent moisture absorption, adhesive degradation, or curling of label stock. Shield the printer from dust, direct sunlight, and other environmental factors that can compromise print quality and operational integrity.

By addressing common issues and implementing proactive maintenance practices, you can uphold the reliability and performance of your thermal printer, ensuring consistent and high-quality label printing. With the knowledge and skills to troubleshoot common challenges, you are well-prepared to navigate the dynamic landscape of thermal label printing with confidence and proficiency. As we conclude our exploration of thermal printing, let’s reflect on the transformative potential of this technology and its impact on modern labeling practices. **

Conclusion

Embarking on the journey of thermal label printing has unveiled a realm of innovation, efficiency, and boundless possibilities. From understanding the intricacies of thermal printing technology to mastering the art of designing, formatting, and printing labels with precision, this comprehensive guide has empowered you with the knowledge and skills to harness the full potential of thermal printing technology.

As you navigate the multifaceted landscape of thermal printing, you have gained insights into the advantages of thermal printing, the critical considerations for selecting the right label, and the nuances of troubleshooting common issues that may impact print quality and operational performance. By embracing these insights, you are well-equipped to embark on a seamless label printing journey, whether for business, personal, or creative endeavors.

With the ability to optimize your thermal printer’s performance, create visually captivating label designs, and troubleshoot common challenges, you stand poised to revolutionize your labeling practices and elevate the efficiency and professionalism of your printed output. Whether you are producing shipping labels for a burgeoning e-commerce venture, crafting product identifiers for a manufacturing enterprise, or adding a personal touch to your creative projects, thermal label printing empowers you to bring your designs to life with precision and confidence.

As you continue to explore the dynamic landscape of thermal label printing, remember the transformative impact of this technology on streamlining operations, enhancing brand identity, and facilitating seamless communication of essential information. Embrace the versatility and reliability of thermal printing as you embark on your label printing endeavors, and leverage the knowledge gained from this guide to propel your printing prowess to new heights.

With each label that emerges from your thermal printer, you have the opportunity to make a lasting impression, convey vital information, and elevate the visual appeal of your products, packages, or creations. As you harness the power of thermal printing, let your labels become a testament to your dedication to precision, quality, and innovation.

In the ever-evolving landscape of labeling and printing, your mastery of thermal label printing serves as a testament to your commitment to excellence and your ability to adapt to the dynamic demands of the modern world. With the knowledge and expertise acquired from this guide, you are poised to embark on a transformative journey of thermal label printing, unlocking a world of seamless, efficient, and visually captivating label production.

So, as you venture forth into the realm of thermal label printing, armed with the insights and skills acquired from this guide, may each label that emerges from your thermal printer be a testament to your commitment to precision, professionalism, and the seamless fusion of art and technology.

**

Frequently Asked Questions about How To Print Labels On A Thermal Printer

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Print Labels On A Thermal Printer”