Articles

How Far Can You Measure With A Laser Level

Modified: October 27, 2024

Want to know how far you can measure with a laser level? Read our informative articles on laser levels and find out the maximum range they can cover.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

In the world of construction, measurement accuracy is paramount. Whether you are hanging a picture frame or laying the foundation for a skyscraper, having precise measurements is crucial. That is where laser levels come into play.

A laser level is a tool that emits a laser beam to create a straight line or a level reference point. It has become an indispensable tool for professionals in various fields, including construction, carpentry, surveying, and interior design.

Understanding the capabilities and limitations of laser levels is essential for maximizing their effectiveness. One key factor to consider is the maximum measurement range of a laser level.

In this article, we will delve into the world of laser levels and explore how far they can measure. We will also discuss the factors that affect the measurement range and provide tips for accurate measurements.

So, whether you are a professional tradesperson or a DIY enthusiast, join us as we uncover the secrets of laser level measurement range.

Key Takeaways:

- Laser levels offer versatile and efficient measurement capabilities, with ranges varying from a few feet to several hundred feet. Factors such as laser power, atmospheric conditions, and surface reflectivity can impact the effective measurement range.

- Advancements in laser level technology, including improved visibility, wireless connectivity, and self-leveling capabilities, have revolutionized measurement tasks. These advancements have enhanced accuracy, durability, and user experience, making laser levels indispensable tools in various industries.

Read more: How Far Does Laser Level Go?

Understanding Laser Levels

Before we dive into the measurement capabilities of laser levels, let’s first understand what they are and how they work.

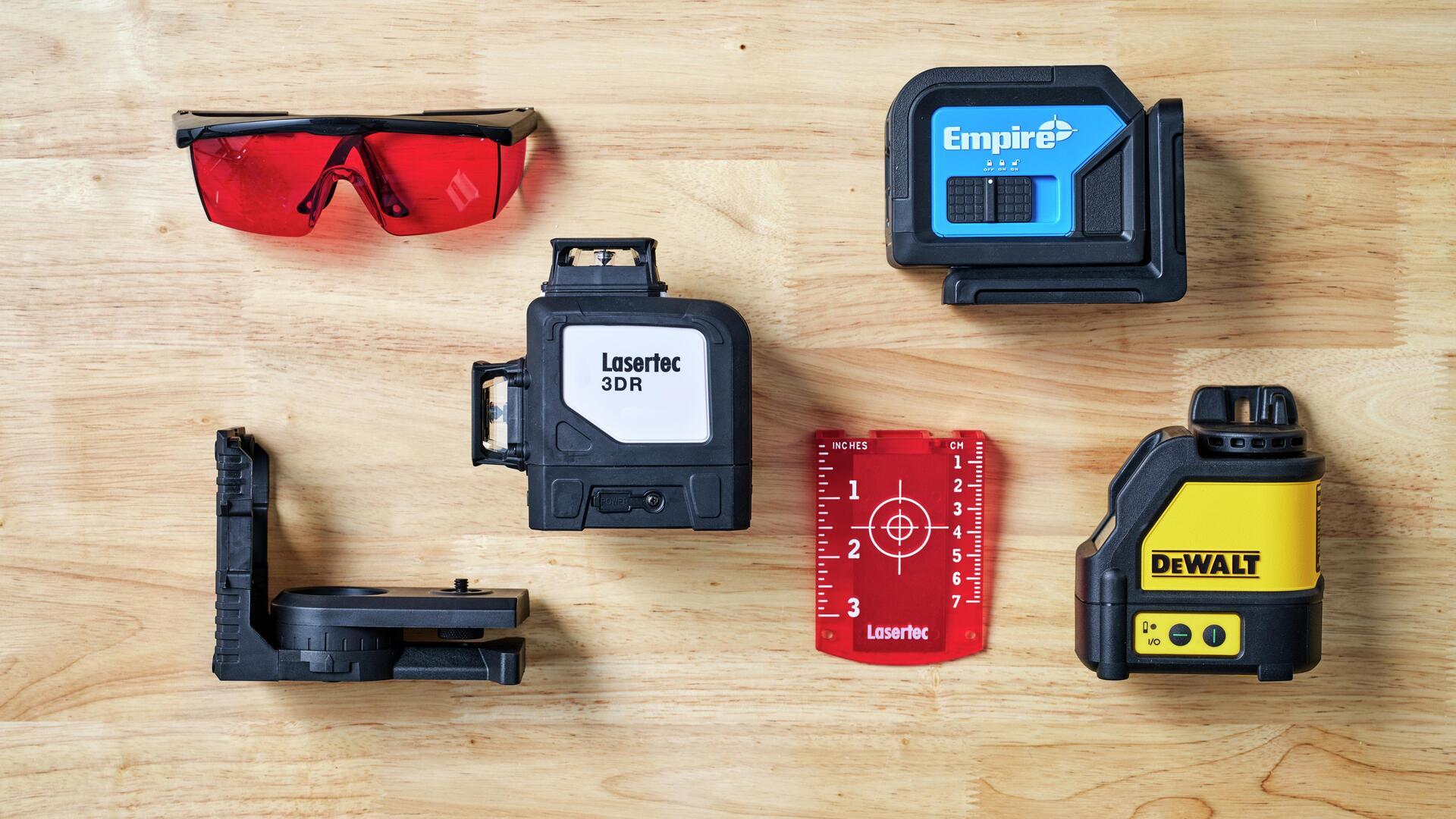

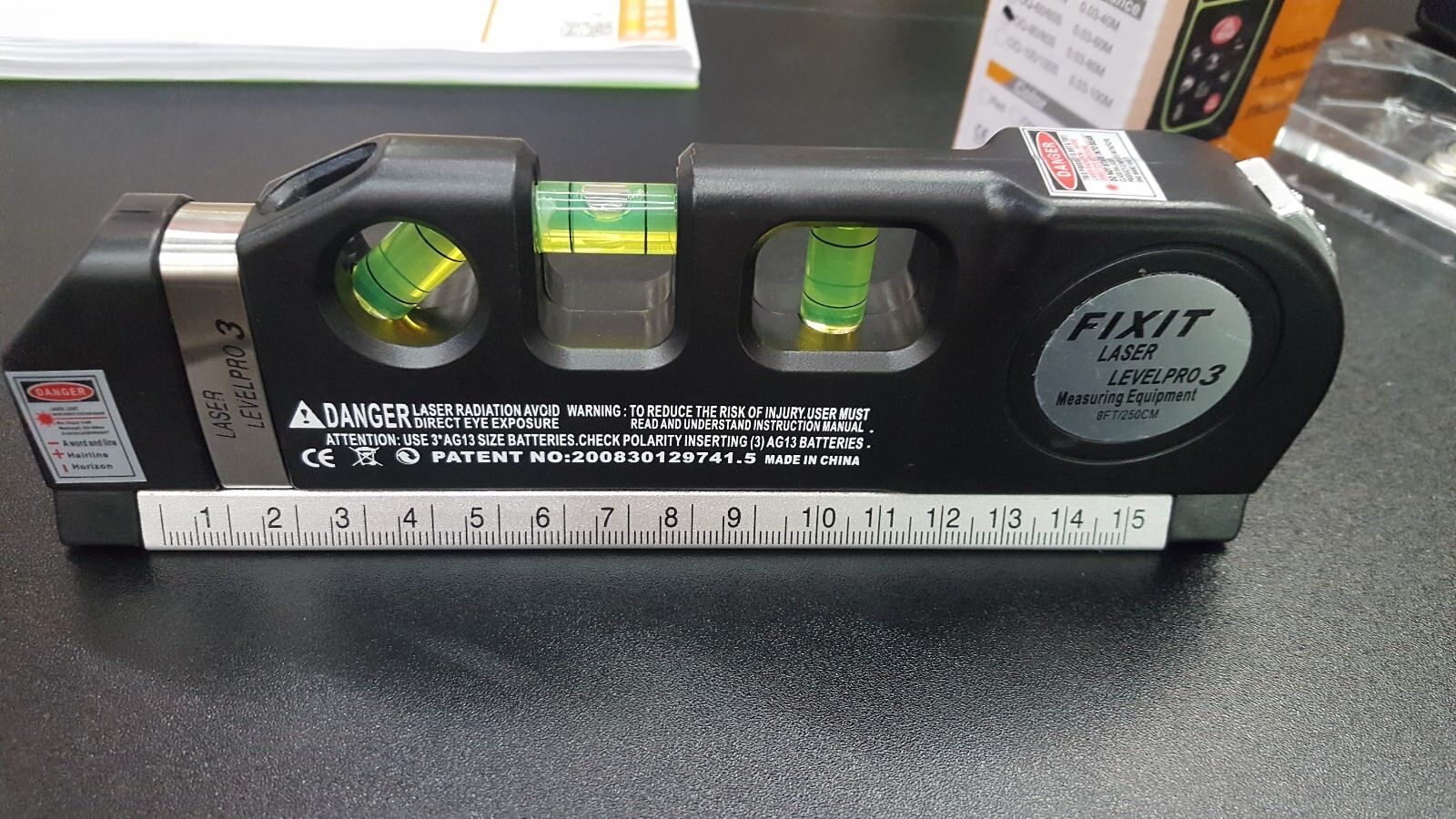

A laser level is a device that uses laser technology to project a straight line or a level reference point onto a surface. It consists of a laser diode, optics, and leveling mechanisms to ensure accuracy. Laser levels are available in various types, including rotary laser levels, line laser levels, and dot laser levels, each with its own specific applications.

Rotary laser levels emit a rotating laser beam in a horizontal or vertical plane, creating a 360-degree level reference. They are commonly used in large-scale construction projects, such as setting foundations and aligning walls. Line laser levels project a straight line onto a surface, ideal for tasks like installing cabinets and tiles. Dot laser levels emit multiple dots to create precise reference points, useful for tasks that require alignment, such as hanging pictures.

Laser levels feature built-in leveling mechanisms that ensure the emitted laser beam is level or plumb. These mechanisms may include pendulum systems, electronic sensors, or self-leveling motors. When the laser level is placed on a stable surface, it automatically adjusts to ensure a level reference point.

To enhance accuracy, laser levels often have additional features such as dual-axis leveling, which allows for both horizontal and vertical leveling, and slope mode, which enables measurements on inclined surfaces. Some laser levels even come equipped with remote controls, digital displays, and Bluetooth connectivity for increased convenience and functionality.

Now that we have a basic understanding of laser levels, let’s explore their measurement capabilities and how far they can reach.

Features and Capabilities of Laser Levels

Laser levels are equipped with a range of features and capabilities that make them versatile and efficient tools for precise measurements. Here are some key features to consider:

- Measurement Range: One of the primary considerations when choosing a laser level is its maximum measurement range. This refers to the distance at which the laser beam remains visible and accurate. The range can vary depending on the type and quality of the laser level, with some models capable of reaching up to hundreds of feet.

- Laser Class: Laser levels are categorized into different classes based on their potential hazard levels. Class 1 lasers are considered safe for all applications, while higher classes may require additional precautions.

- Accuracy: The accuracy of a laser level is an important factor to ensure precise measurements. The accuracy is typically measured in fractions of an inch over a certain distance. Look for a laser level with a high level of accuracy to achieve professional-grade results.

- Visibility: The visibility of the laser beam is crucial, especially in bright environments or on reflective surfaces. Some laser levels feature a highly visible or green laser beam, which is easier to see compared to a traditional red beam.

- Battery Life: Consider the battery life of a laser level, especially if you anticipate using it for extended periods. Look for models with long battery life or ones that offer the option to use rechargeable batteries.

- Durability: Construction sites can be harsh environments, so it’s important to choose a laser level that is built to withstand dust, water, and impacts. Look for models with rugged construction and an IP rating indicating their level of protection.

Aside from these general features, specific types of laser levels may offer additional capabilities. For example, rotary laser levels may have adjustable rotation speeds, remote control operation, or the ability to project lines at various angles. Line laser levels may have the option to project multiple lines or switch between vertical and horizontal lines. Dot laser levels may offer the ability to project dots in different patterns or distances.

By understanding the features and capabilities of laser levels, you can choose the right tool for your specific needs and ensure accurate and efficient measurements in your projects.

Factors Affecting Laser Level Measurement Range

The measurement range of a laser level can be influenced by several factors. Understanding these factors is essential for determining the effective distance at which you can use your laser level. Here are the key factors to consider:

- Laser Power: The power output of the laser diode affects the visibility and range of the emitted laser beam. Laser levels with higher power output tend to have a longer measurement range.

- Atmospheric Conditions: Atmospheric conditions such as dust, humidity, and fog can scatter or absorb the laser beam, reducing its visibility and range. On hazy or foggy days, you may experience a shorter measurement range compared to clear conditions.

- Surface Reflectivity: The reflectivity of the surface onto which the laser beam is projected can affect the visibility and range. Highly reflective surfaces, such as mirrors or polished metals, can reflect more of the laser beam, allowing for a longer measurement range. Conversely, surfaces with low reflectivity, such as matte finishes or dark colors, may limit the measurement range.

- Interference: Other light sources or objects obstructing the laser beam path can interfere with the measurement range. Bright ambient lighting, direct sunlight, or objects blocking the line of sight may decrease the visible range.

- Quality of the Laser Level: The quality and precision of the laser level itself can impact the measurement range. Higher quality laser levels tend to have better optics and more powerful lasers, resulting in a longer measurement range.

- Mounting Stability: Properly mounting the laser level on a stable surface ensures accurate measurements. Any movement or instability during measurements can introduce errors. Using a tripod or a mounting bracket can help maintain stability for extended measurement ranges.

It’s important to note that the measurement range specified by the manufacturer is usually under ideal conditions. Real-world factors such as the ones mentioned above can affect the actual measurement range. It’s always a good practice to test the range in your specific working environment to ensure accurate results.

By considering these factors, you can better understand and optimize the measurement range of your laser level, allowing you to make precise measurements in your projects.

Maximum Measurement Range of Laser Levels

The maximum measurement range of a laser level can vary depending on factors such as the type of laser level, the power output of the laser diode, and the quality of the optics. In general, laser levels are capable of reaching distances ranging from a few feet to several hundred feet. However, it is important to remember that the specified maximum range provided by the manufacturer is often under ideal conditions.

Rotary laser levels, known for their 360-degree coverage, typically have a longer measurement range compared to line or dot laser levels. They can reach distances of up to 100 feet or more, depending on the model. Line laser levels typically have a range of around 30 to 50 feet, while dot laser levels have a more limited range, usually up to 30 feet.

It is worth noting that when considering the measurement range, both the visibility and accuracy of the laser beam play a crucial role. Even if a laser level has a specified range of 100 feet, factors such as atmospheric conditions, surface reflectivity, and interference can affect the actual visible range and the accuracy of measurements.

For outdoor use or in bright environments, laser levels with higher power output or those equipped with a highly visible laser beam, such as a green laser, are often preferred. Green laser beams are more easily visible compared to red laser beams, which can be advantageous for longer measurement distances or when working in conditions with high ambient light.

Furthermore, advancements in laser level technology have led to the development of models that offer extended range capabilities. These advanced laser levels utilize superior optics, more powerful laser diodes, and optimized beam projection techniques to achieve longer measurement ranges and increased accuracy.

When it comes to measurement range, it is important to consider the specific requirements of your projects. Assess factors such as the size and complexity of the job, the distance you need to measure, and any environmental conditions that may impact visibility. By understanding the maximum measurement range of your laser level and factoring in these considerations, you can ensure optimal performance and accurate measurements in your work.

When using a laser level, the maximum distance you can accurately measure will depend on the specific model and its specifications. Be sure to check the maximum range of your laser level before starting your project to ensure accurate measurements.

Read more: How Far Does Laser Level Go For Fence?

Factors to Consider for Accurate Measurements

Accurate measurements are essential when using a laser level to ensure precise work and reliable results. Here are some factors to consider to achieve accurate measurements:

- Leveling and Calibration: Before using a laser level, it is crucial to ensure that it is properly leveled and calibrated. Follow the manufacturer’s instructions to ensure accurate leveling, and regularly calibrate the laser level to maintain accuracy over time.

- Stable Mounting: Mount the laser level on a stable surface or use a tripod for secure placement. Any movement or instability during measurements can introduce errors and affect the accuracy of the results.

- Line-of-Sight: Maintain a clear line-of-sight between the laser level and the target surface. Clear any obstructions, such as furniture or equipment, that may interfere with the laser beam or hinder accurate measurements.

- Surface Preparation: Ensure that the target surface is clean, free from debris, and adequately prepared for measurement. Any dirt, dust, or uneven surfaces can affect the accuracy of the laser level readings.

- Distance and Angle: Consider the distance and angle at which you are measuring. Keep in mind that the accuracy of the laser level may vary at different distances and angles. Refer to the manufacturer’s specifications for the recommended measurement range and accuracy at specific distances.

- Environmental Conditions: Be aware of the environmental conditions that can affect the accuracy of the laser level. Factors such as dust, humidity, temperature changes, and ambient lighting can impact the visibility and stability of the laser beam, thus affecting measurement accuracy.

- Multiple Readings: For critical measurements, it can be beneficial to take multiple readings from different locations to ensure consistency and accuracy. This helps identify any variations and increases confidence in the measured values.

- Regular Maintenance: Regularly inspect and maintain your laser level to ensure it is in proper working condition. Clean the optics, check the battery or power source, and address any necessary repairs or calibrations to maintain accurate measurements.

By considering these factors and adopting best practices, you can maximize the accuracy of your measurements when using a laser level. Remember to always refer to the manufacturer’s instructions and specifications for specific guidance on achieving accurate results with your particular laser level model.

Tips for Using Laser Levels in Various Applications

Laser levels are versatile tools that can be used in a wide range of applications. Whether you are working on construction projects, home improvement tasks, or interior design projects, here are some tips to help you make the most out of your laser level:

- Plan Ahead: Before using a laser level, it’s important to plan your measurements and understand the layout of your project. Identify the areas where you will need level lines or reference points and plan accordingly.

- Use a Laser Detector: In outdoor environments or situations with long distances, a laser detector can be useful for extending the range and ensuring accurate readings. Laser detectors detect the laser beam and emit a signal to indicate when the laser level is aligned.

- Mark Reference Points: When using a laser level to create reference points or lines, mark these points on the surface to provide a visual guide. This can help you align objects or complete tasks accurately.

- Retrace Lines: If you need to extend a line or replicate a line at a different location, retrace the line using the laser level. This ensures consistency and eliminates the need for additional measurements.

- Combine Multiple Functions: Some laser levels have the ability to project horizontal and vertical lines simultaneously. Take advantage of this feature to save time and ensure accuracy when working on projects that require both types of lines.

- Adjust Brightness: If your laser level has adjustable brightness settings, consider adjusting the brightness based on the lighting conditions of your working environment. Increasing the brightness can improve visibility in bright or outdoor settings.

- Check for Interference: Before starting measurements, ensure that there are no objects obstructing the laser beam path. In addition, be aware of elements that may reflect or interfere with the laser beam, such as windows, mirrors, or reflective surfaces.

- Combine with a Tripod or Mounting Bracket: For hands-free and stable operation, consider using a tripod or a mounting bracket. This allows you to position the laser level at the desired height and angle without having to hold it manually.

- Verify Crosshair Alignment: If your laser level features a crosshair function, periodically check the alignment of the crosshairs to ensure accurate measurements. Calibrate or realign the crosshairs as needed.

- Practice and Familiarize: Like any tool, using a laser level effectively takes practice. Familiarize yourself with the features and functions of your specific laser level, and practice using it in different situations to gain confidence and improve accuracy.

By following these tips, you can enhance your productivity and achieve accurate measurements when using a laser level. Always consult the manufacturer’s instructions and recommendations for your specific laser level for the best results.

Advancements in Laser Level Technology

Laser level technology has seen significant advancements in recent years, leading to improved performance, enhanced features, and increased versatility. These advancements have revolutionized the way professionals and homeowners tackle measurement tasks. Here are some notable advancements in laser level technology:

- Improved Visibility: Traditional laser levels often use red laser beams, which can be challenging to see in bright environments or on certain surfaces. However, recent advancements have introduced laser levels with green laser beams that are more visible to the human eye. Green lasers offer increased visibility and allow for more accurate measurements, particularly in outdoor or high ambient light situations.

- Wireless Connectivity: Many modern laser levels are now equipped with wireless connectivity features. Bluetooth technology enables laser levels to connect to smartphones, tablets, or other mobile devices. This connectivity allows for seamless data transfer, remote control operation, and the ability to adjust settings and measurements from a distance.

- Self-Leveling Technology: Self-leveling laser levels have become increasingly common and are highly convenient. These laser levels use internal mechanisms, such as pendulums or electronic sensors, to automatically level the laser beam. This eliminates the need for manual adjustment and ensures accurate measurements even on uneven surfaces or when the tool is placed slightly off-level.

- Multiple Line Projection: Laser levels with the ability to project multiple lines have become popular for various applications. Instead of a single line, these laser levels can project multiple lines, such as vertical, horizontal, and cross lines simultaneously. This feature offers greater flexibility and allows for more precise alignment and leveling across multiple axes.

- High-Precision Accuracy: Laser level technology has made significant strides in terms of accuracy. Advanced models now offer high-precision measurements with accuracy tolerances of fractions of an inch over a specified distance. This level of accuracy ensures more reliable and consistent results in various applications.

- Enhanced Durability: As construction and measurement tasks often involve challenging environments, durability is crucial for laser levels. Recent advancements in materials and construction techniques have led to laser levels that are more rugged, dustproof, and water-resistant. Many laser levels now come with an IP (Ingress Protection) rating to indicate their level of protection against dust and water.

- Intuitive User Interfaces: Laser level interfaces have become more user-friendly and intuitive. Clear and easy-to-navigate controls, digital displays with backlighting, and on-screen guides and indicators provide a seamless user experience. This simplifies operation and allows users to quickly access and adjust settings as needed.

These advancements in laser level technology have made measuring tasks more efficient, accurate, and convenient. Whether for construction, interior design, or DIY projects, these modern laser levels offer improved visibility, wireless connectivity, self-leveling capabilities, and more, making them indispensable tools in various industries.

As technology continues to evolve, we can expect further advancements in laser level technology, with the potential for even greater precision, expanded functionalities, and enhanced user experiences.

Conclusion

Laser levels have become indispensable tools for professionals and DIY enthusiasts alike, providing accurate measurements and precise reference points in a wide range of applications. Understanding the capabilities, features, and factors that affect their measurement range is crucial for maximizing their effectiveness.

From understanding the different types of laser levels to considering factors such as laser power, environmental conditions, and surface reflectivity, users can ensure they achieve accurate measurements and reliable results. Additionally, advancements in laser level technology, such as improved visibility, wireless connectivity, self-leveling capabilities, and enhanced durability, have revolutionized the way measurements are taken and tasks are completed.

Whether measuring distances on a construction site, aligning shelves in a room, or laying out precise points for carpentry work, laser levels provide the accuracy and efficiency needed to make projects successful. By following best practices and utilizing the tips provided, users can make the most out of their laser levels and achieve professional-grade results.

As technology continues to advance, we can anticipate even greater innovations in laser level technology, with improved accuracy, expanded functionalities, and enhanced user experiences.

In conclusion, laser levels are valuable tools for anyone involved in measurement tasks. By understanding their capabilities, considering important factors, and staying up to date with the latest advancements, users can harness the power of laser levels to achieve precise measurements and accurate results in their projects.

Frequently Asked Questions about How Far Can You Measure With A Laser Level

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Far Can You Measure With A Laser Level”