Articles

How Dangerous Is Laser Level

Modified: March 1, 2024

Discover the potential dangers of using laser levels in this informative article. Learn how to stay safe while working with laser technology.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When it comes to ensuring accurate and precise measurements during construction or DIY projects, a laser level is an indispensable tool. This innovative device projects a laser beam onto a surface, providing a reference point for aligning and leveling. While laser levels offer numerous benefits, it is essential to understand the potential dangers associated with their use and take appropriate safety precautions.

Whether you are a professional contractor or a passionate DIY enthusiast, learning about the different types of laser levels, how they work, and the hazards they may pose is crucial. This article aims to provide a comprehensive overview of laser levels, their applications, and the necessary safety measures to ensure a safe working environment.

So, let’s delve into the world of laser levels and explore the various aspects related to their usage and potential risks.

Key Takeaways:

- Laser levels are essential for precise measurements, but they pose potential hazards such as eye injuries and fire risks. Prioritizing safety precautions and understanding laser classifications is crucial for safe usage.

- Understanding the different types of laser levels and their applications is important for choosing the right tool for specific projects. Safety measures, including protective eyewear and secure work environments, are vital for minimizing risks.

Read more: How To Level A Laser Level Tripod

What is a Laser Level?

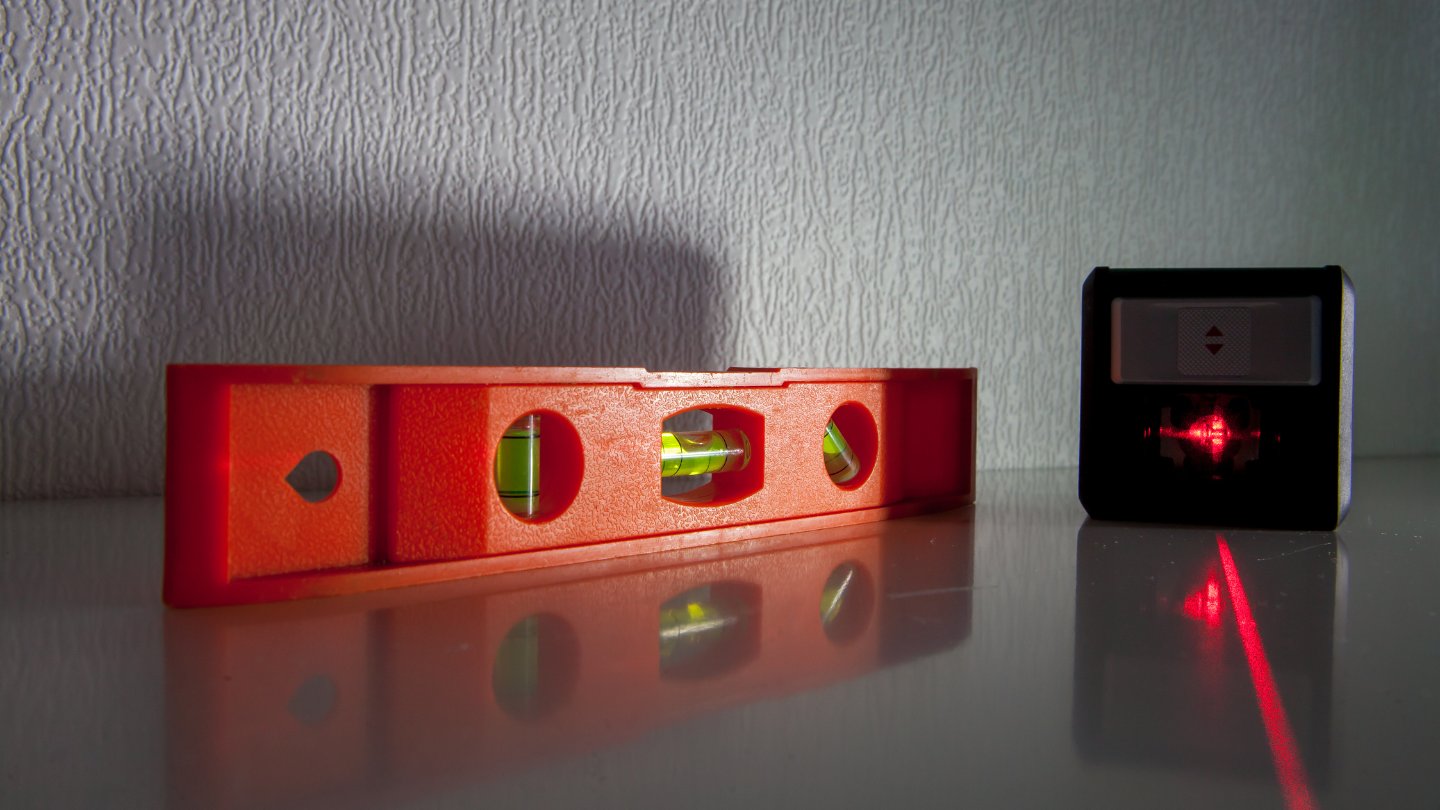

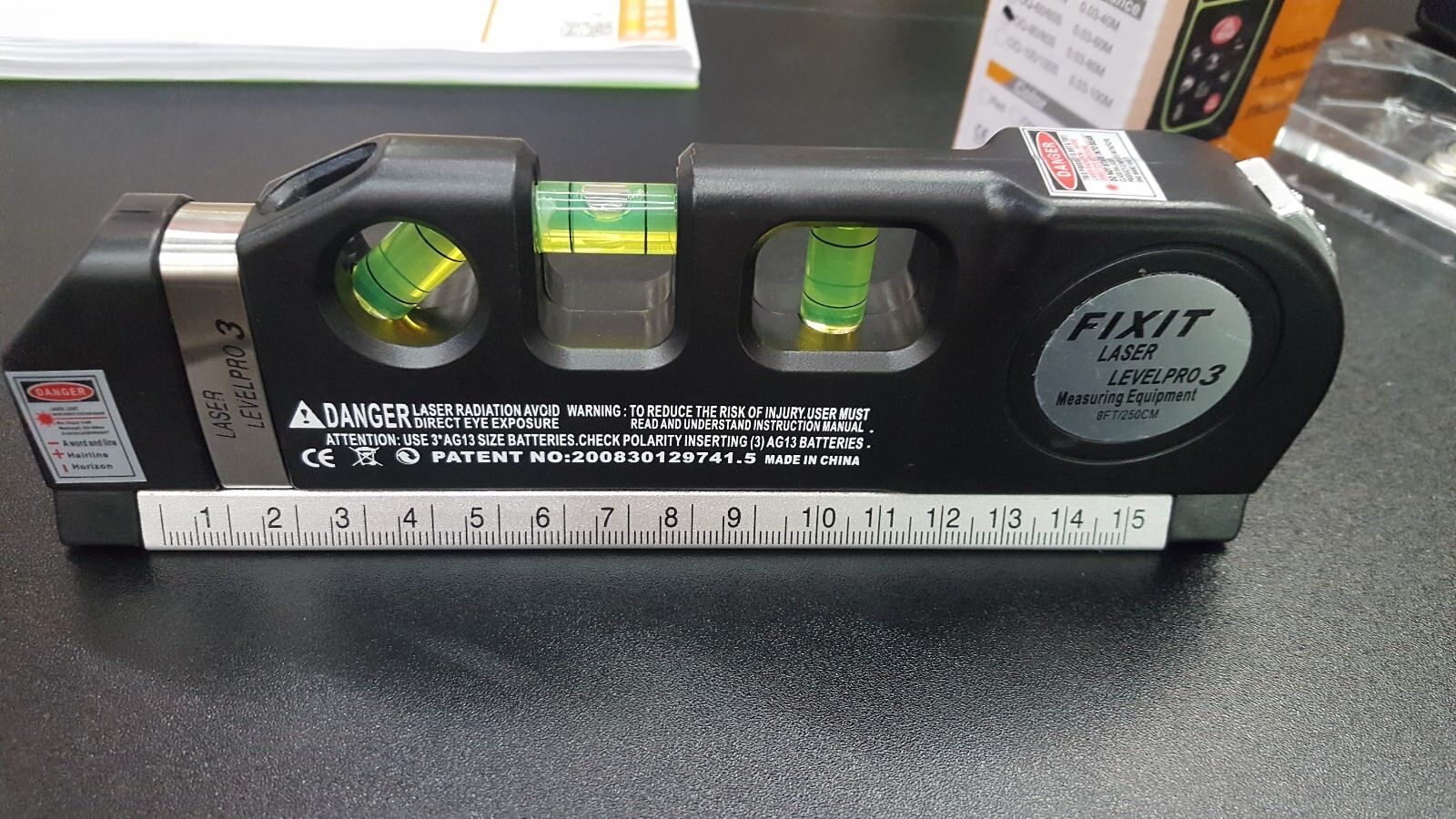

A laser level is a precision tool used to establish a reference line or plane by projecting a laser beam onto a surface. It helps professionals and DIY enthusiasts achieve accuracy and consistency when it comes to leveling, aligning, and measuring in various applications.

Unlike traditional bubble levels, which rely on visual estimation and physical levels, a laser level provides a highly visible beam that serves as a visual guide for creating straight lines and accurate measurements. It revolutionizes the way tasks such as hanging picture frames, installing cabinets, or setting up a drop ceiling are performed.

Laser levels come in various shapes and sizes, from handheld devices to larger, more sophisticated models. They are equipped with advanced features like self-leveling capabilities, remote control operation, and multiple beam options to fulfill different project requirements.

The versatility of laser levels extends to different industries and applications. They are commonly used in construction and surveying, interior design, landscaping, and even by electricians and plumbers. From aligning walls and floors to laying tiles and setting up shelving units, laser levels make these tasks more efficient and accurate.

Overall, a laser level is a powerful tool that simplifies the process of aligning and leveling surfaces. Its precise beam and user-friendly features make it an essential tool for professionals and DIY enthusiasts alike.

How Does a Laser Level Work?

A laser level works on the principle of directing a laser beam to create a perfectly level or straight line reference point. The device consists of a laser diode, a leveling mechanism, and various optics to project the laser beam.

The laser diode is the heart of the laser level. It emits a highly focused laser beam that creates a visible reference line on a surface. The diode is powered by batteries or an external power source and can produce beams of different colors, typically red or green.

The leveling mechanism ensures that the laser beam remains level by compensating for any slight tilt or movement of the device. This is achieved through either a pendulum-based system or an electronic self-leveling mechanism. In a pendulum-based system, the laser level is equipped with a pendulum that swings to maintain a level position. In an electronic self-leveling mechanism, an internal sensor constantly monitors the device’s orientation and adjusts the laser beam accordingly.

Once the laser beam is emitted, it passes through various optics inside the device to shape and project the beam onto a surface. These optics may include lenses, mirrors, or prisms, which help to focus and magnify the laser beam, extending its visibility and range.

When the laser level is turned on and properly leveled, the laser beam projects onto the desired surface, creating a visible line or dot. This line serves as a reference point for aligning objects or measuring distances.

Some laser levels also come with additional features, such as rotating beams for creating 360-degree reference lines, multiple beam options for different applications, or remote control operation for added convenience.

In summary, a laser level uses a laser diode, a leveling mechanism, and optics to emit a highly visible laser beam onto a surface. The device ensures accuracy and precision in creating level or straight reference lines, making it an invaluable tool for a wide range of applications.

The Different Types of Laser Levels

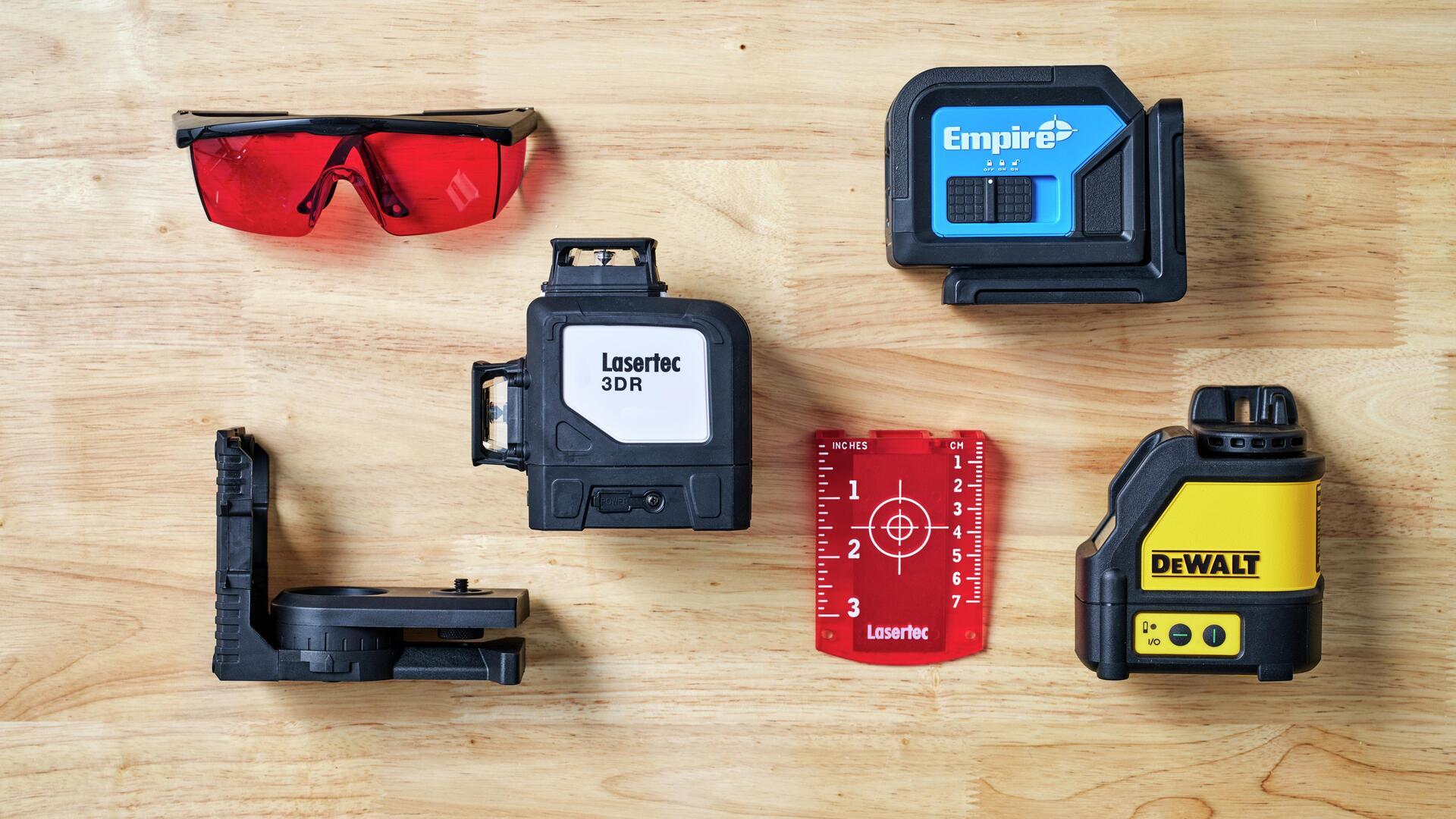

There are several different types of laser levels available on the market, each designed to suit specific applications and project requirements. Understanding the various types can help you choose the right laser level for your needs. Here are some common types of laser levels:

- Point Lasers: Point lasers emit a single laser beam in one direction. They are mainly used for short-range applications, such as plumbing or leveling small surfaces. Point lasers are compact and easy to use, making them popular among DIYers.

- Line Lasers: Line lasers project a straight line or multiple lines in various directions simultaneously. These types of laser levels are ideal for installing cabinets, hanging shelves, or aligning tiles. They allow for accurate horizontal and vertical leveling.

- Cross-Line Lasers: Cross-line lasers emit two perpendicular lines that intersect to form a cross pattern. This type of laser level is beneficial for tasks that require precise right angles, such as installing windows, framing walls, or aligning countertops.

- Rotary Lasers: Rotary lasers create a rotating laser beam that forms a complete 360-degree horizontal plane. They are commonly used in large-scale construction projects, such as laying foundations, grading land, or installing suspended ceilings. Rotary lasers ensure precise leveling over extended distances.

- Rotating Line Lasers: Rotating line lasers combine the functionalities of both line lasers and rotary lasers. They project multiple horizontal and vertical lines that rotate in a complete circle, offering 360-degree coverage. This type of laser level is versatile and suitable for a wide range of applications.

- Plumb Lasers: Plumb lasers emit a laser beam that points vertically, allowing for accurate alignment and plumbing tasks. They are commonly used by electricians, plumbers, and carpenters for installing light fixtures, plumbing pipes, or staircases.

It’s essential to consider the range, accuracy, self-leveling capabilities, and additional features when choosing a laser level. Determine the specific requirements of your project and select the appropriate type of laser level to ensure optimal results.

Applications of Laser Levels

Laser levels have wide-ranging applications across various industries and disciplines. Their accuracy, ease of use, and versatility make them indispensable tools for both professionals and DIY enthusiasts. Here are some common applications of laser levels:

- Construction: Laser levels are extensively used in construction projects for tasks such as establishing level foundation footings, aligning walls, and ensuring accurate elevation and grading. They simplify the process of laying floors, installing ceilings, and setting up framework.

- Surveying and Landscaping: In surveying, laser levels are employed to determine land elevations, layout plots, and establish reference lines for road construction or site grading. Landscapers use laser levels for precise leveling of outdoor features, such as patios, lawns, and gardens.

- Interior Design and Decoration: Laser levels play a crucial role in interior design and decoration. They assist in aligning picture frames, hanging artwork, installing shelves, and positioning furniture. Laser levels ensure a professional and aesthetically pleasing finish to any interior space.

- Electrical and Plumbing: Electricians and plumbers rely on laser levels for accurate installation of fixtures, such as light switches, electrical outlets, and plumbing pipes. Laser levels help ensure precise alignment and positioning, minimizing the risk of errors or malfunctions.

- Tiling and Flooring: When it comes to tiling and flooring projects, laser levels are invaluable. They help achieve straight lines and even spacing between tiles, ensuring a seamless and professional-looking finish. Laser levels also aid in accurately leveling floors before installing hardwood, laminate, or vinyl planks.

- Outdoor Projects: Laser levels find applications in outdoor projects such as installing fences, aligning posts, and building decks. They provide a reliable reference point for accurate measurements and leveling on uneven terrain.

These are just a few examples of the countless applications of laser levels. Whether it’s construction, surveying, interior design, or any other field that requires precise measurements and alignment, a laser level is an essential tool that simplifies the process and ensures accuracy and consistency.

Read more: How To Use A Self Leveling Laser Level

Potential Hazards Associated with Laser Levels

While laser levels offer numerous benefits and enhance work efficiency, it’s important to be aware of the potential hazards they can pose. Understanding these hazards is crucial for taking appropriate safety measures and protecting yourself and others. Here are some potential hazards associated with laser levels:

- Eye Injury: Laser levels produce highly concentrated beams of light that can cause severe eye damage if directly exposed. Looking directly into the laser beam, even for a brief moment, can result in temporary or permanent vision impairment. It’s essential to avoid direct eye contact with laser beams and use protective eyewear when working with laser levels.

- Fire Hazard: Laser levels emit intense beams of light that can ignite flammable materials, such as dry leaves or combustible gases. It’s crucial to keep the laser level away from potential fire hazards and ensure a safe working environment.

- Electrical Hazards: Some laser levels are powered by batteries or external power sources. It’s important to follow proper electrical safety practices, such as avoiding contact with water or wet surfaces, and using appropriate circuit protection when operating laser levels.

- Unsafe Work Environment: Incorrect use of laser levels can create an unsafe work environment. This includes using the laser level on unstable surfaces, not properly securing the device during operation, or not adhering to safety guidelines provided by the manufacturer. It’s important to familiarize yourself with the user manual and follow proper procedures to ensure a safe working environment.

- Classified Laser Hazards: Laser levels are classified based on their power and potential risk to human health. Class 2 laser levels are relatively safe for normal use, while higher-class lasers, such as Class 3 or 4, can cause serious injury if used improperly. It’s crucial to understand the laser classification of your specific device and take appropriate safety precautions.

By being aware of these potential hazards, you can mitigate risks and ensure safe usage of laser levels. Take the time to read the user manual, follow safety guidelines, use appropriate protective equipment, and create a secure work environment to minimize any potential dangers associated with laser level usage.

When using a laser level, always be cautious of the laser beam and avoid direct eye contact. It’s important to follow the manufacturer’s safety guidelines to prevent any potential hazards.

The Importance of Safety Precautions

When working with laser levels, safety should always be a top priority. Taking the necessary safety precautions is crucial to protect yourself and others from potential hazards and ensure a safe working environment. Here are some reasons why safety precautions are of utmost importance:

- Prevention of Accidents: Safety precautions help prevent accidents and injuries. By implementing proper safety measures, such as wearing protective eyewear, securing the laser level properly, and following manufacturer guidelines, you reduce the risk of accidents and create a safer work environment.

- Protection of Vision: The eyes are particularly vulnerable to laser beam exposure. Adhering to safety precautions, such as avoiding direct eye contact with laser beams and wearing appropriate protective eyewear, safeguards your vision and helps prevent eye injuries.

- Minimization of Fire Hazards: Laser beams have the potential to ignite flammable materials. By keeping the laser level away from combustible substances and maintaining a clear work area, you minimize the risk of fire hazards.

- Compliance with Regulations: Safety precautions ensure compliance with regulations and standards set by relevant authorities. By adhering to safety guidelines, you demonstrate your commitment to safety and avoid any legal or regulatory consequences.

- Prolonged Equipment Lifespan: Taking safety precautions also helps prolong the lifespan of your laser level and other equipment. Properly maintaining and handling the device reduces the risk of damage, ensuring its longevity and optimal performance.

- Peace of Mind: Following safety precautions provides peace of mind. Knowing that you have taken the necessary steps to promote a safe working environment allows you to focus on the task at hand, without worrying about potential accidents or injuries.

Remember that safety is a shared responsibility. It’s important to communicate and educate others on safety practices when working with laser levels. Promote a culture of safety by encouraging open discussions, providing proper training, and promoting awareness of potential hazards and safety precautions.

In summary, prioritizing safety precautions when working with laser levels ensures the well-being of yourself and those around you. By maintaining a safe work environment, you can confidently utilize the benefits of laser levels while minimizing the risks associated with their usage.

Understanding Laser Classifications

Laser levels, like all laser devices, are classified based on their power output and the potential risks they pose to human health. Understanding laser classifications is important for assessing the safety precautions required when using a laser level. The classification system follows a standardized approach to categorize lasers into specific classes:

- Class 1: Class 1 lasers are considered safe and pose no significant risk of eye injury. These lasers emit low levels of power and are not known to cause harm, even with direct eye exposure. Most laser levels available for general use fall under this classification.

- Class 2: Class 2 lasers are also considered safe for normal use. However, they can cause eye injuries if the beam is directly stared into for an extended period. These lasers typically have limited power and are commonly used in laser levels that project visible red beams.

- Class 3R: Class 3R lasers are considered safe under normal operating conditions. However, they have a slightly higher power output than Class 2 lasers and can pose a greater risk of eye injury if directly viewed for an extended period. Lasers in this class are often found in higher-end laser levels or laser pointers.

- Class 3B: Class 3B lasers are moderately hazardous and can cause eye injury if viewed directly. These lasers have higher power outputs and should be handled with caution. It’s essential to ensure proper eye protection and follow safety guidelines when working with Class 3B laser levels.

- Class 4: Class 4 lasers are the most hazardous and can cause severe eye and skin injuries. They have high-power outputs and pose the highest risk among all laser classes. Class 4 laser levels are typically used in specialized professional applications and require strict safety protocols, including the use of appropriate protective eyewear and the implementation of safety measures.

It’s important to note that laser level manufacturers provide detailed information regarding the laser classification and associated safety precautions in the product documentation and user manual. It’s crucial to thoroughly read and follow these instructions to ensure safe usage.

When working with laser levels, it’s essential to consider the laser classification, understand the potential risks involved, and take appropriate safety measures. This includes using protective eyewear when necessary, avoiding direct eye exposure, and following the manufacturer’s guidelines and recommended safety practices.

By understanding laser classifications and following safety protocols, you can ensure the safe and responsible use of laser levels, minimizing the risk of eye injuries and creating a safe working environment.

Health Risks Associated with Laser Levels

Laser levels, while extremely useful tools, can also pose certain health risks if not handled properly. It’s important to be aware of these risks and take the necessary precautions to protect yourself. Here are some health risks associated with laser levels:

- Eye Injury: The primary health risk associated with laser levels is eye injury. Direct exposure to the laser beam can cause damage to the retina and other structures of the eye. Even a momentary glance at a laser beam can result in temporary or permanent vision impairment. Laser levels with higher laser classifications, such as Class 3B or Class 4, pose a greater risk of eye injury and require extra caution.

- Flash Blindness: The intense light emitted by laser levels can cause temporary blindness, known as flash blindness, if directly viewed. This effect is similar to staring at a bright light and can temporarily impair vision. Although the blindness is usually temporary, it can still be dangerous, especially in situations where vision is critical for safety, such as working at heights or operating machinery.

- Electrical Shocks: Some laser levels require an external power source or use batteries. Mishandling these power sources can lead to electrical shocks. It’s important to follow proper electrical safety practices, such as using grounded outlets, inspecting power cords for any damage, and avoiding contact with exposed wiring.

- Chemical Hazards: Laser levels often use batteries or emit heat during operation. Mishandling or using incompatible batteries can lead to overheating, leakage, or chemical spills. These incidents can cause skin irritation, burns, or chemical exposure risks. It’s crucial to follow proper battery usage guidelines and dispose of used batteries responsibly.

- Heat and Fire Hazards: Laser levels emit highly concentrated beams of light, which can generate heat when concentrated on certain surfaces. This increased heat can pose a risk of burns or fire if directed onto flammable materials or sensitive surfaces. It’s important to be cautious and avoid placing the laser beam on objects that can heat up quickly or catch fire.

To minimize the health risks associated with laser levels, it’s crucial to adhere to safety guidelines provided by the manufacturer and follow these best practices:

- Always wear appropriate protective eyewear when using laser levels, especially those with higher power outputs.

- Avoid direct eye contact with the laser beam and ensure that others in the vicinity also avoid looking directly at the beam.

- Ensure a clear and safe work environment by keeping flammable materials away from the laser beam.

- Handle batteries and power sources with care, following proper usage and disposal guidelines.

- Inspect the laser level for any damage or malfunctions before use and repair or replace as necessary.

By being aware of the potential health risks and following recommended safety measures, you can mitigate the dangers associated with laser levels and ensure a safe working environment.

Read more: How To Work A Water Level Or Laser Level

Protecting Yourself from Laser Hazards

When working with laser levels, it is crucial to take proactive measures to protect yourself from potential hazards. By following safety guidelines and implementing proper precautions, you can ensure your safety while using these powerful tools. Here are some ways to protect yourself from laser hazards:

- Wear Protective Eyewear: Always wear appropriate laser safety goggles or glasses when operating a laser level. These protective eyewear are designed to block or absorb the specific wavelengths of light produced by the laser level. Make sure to choose eyewear that is specifically rated for the laser class and wavelength emitted by your laser level.

- Avoid Direct Eye Exposure: Never stare directly into the laser beam or point the beam towards anyone’s face or eyes. Even with protective eyewear, it is important to avoid unnecessary exposure to laser light. Direct exposure to the laser beam, even for a short period of time, can cause eye injuries and vision problems.

- Secure the Work Area: Keep the work area clear of any flammable or reflective materials that could pose a fire hazard or redirect the laser beam in unintended directions. Ensure that there are no reflective surfaces, such as mirrors or shiny objects, that could reflect the laser beam into your eyes or other areas where it may cause harm.

- Handle Batteries Properly: If your laser level is battery-powered, handle batteries with care. Follow the manufacturer’s instructions for battery installation and replacement. Avoid using damaged or leaking batteries, and dispose of used batteries according to local regulations.

- Practice Proper Work Techniques: Follow proper work techniques when using a laser level. Ensure that the laser level is securely positioned and not at risk of falling or being knocked over. Be mindful of the laser’s line of sight and avoid crossing the beam with your body or other objects, as this increases the risk of accidental exposure.

- Store and Transport Safely: When not in use, store your laser level in a protective case or bag to prevent damage and maintain proper alignment. During transportation, secure the laser level to prevent any movement or jostling that could affect its accuracy or safety.

It’s essential to familiarize yourself with the specific safety guidelines and recommendations provided by the manufacturer of your laser level. These guidelines may include additional safety measures or considerations tailored to the design and specifications of your particular device.

By following these safety precautions and guidelines, you can protect yourself from potential laser hazards and minimize the risk of eye injuries or other accidents. Always prioritize safety when working with laser levels to ensure a safe and productive work environment.

Conclusion

Laser levels are invaluable tools for achieving precise measurements, accurate alignments, and efficient project outcomes in various industries and applications. However, it is crucial to understand and address the potential hazards that come with their usage.

In this article, we have explored what laser levels are and how they work. We have also delved into the different types of laser levels and their applications in various fields, from construction to interior design. Additionally, we discussed the potential hazards associated with laser levels, including eye injuries, fire hazards, electrical risks, and health concerns.

To ensure a safe working environment, it is important to prioritize safety precautions. This includes understanding laser classifications, using appropriate protective eyewear, following manufacturer guidelines, securing the work area, handling batteries correctly, and implementing best practices for safe operation. By being proactive about safety, you can protect yourself and others from potential accidents and injuries.

Remember, safety is a shared responsibility. It is important to educate others, promote safety awareness, and foster a culture of safety in all laser level-related activities. By doing so, we can create a safer and more efficient working environment for everyone involved.

In conclusion, laser levels are powerful tools that greatly enhance precision and accuracy in a wide range of projects. By understanding the risks associated with laser levels and implementing the necessary safety measures, we can harness their benefits while ensuring the well-being of ourselves and those around us.

Frequently Asked Questions about How Dangerous Is Laser Level

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Dangerous Is Laser Level”