Articles

How Many PSI Concrete Needed For Driveway

Modified: January 24, 2024

Discover how many PSI of concrete you need for your driveway in our informative articles. Achieve the perfect strength and durability for your project.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

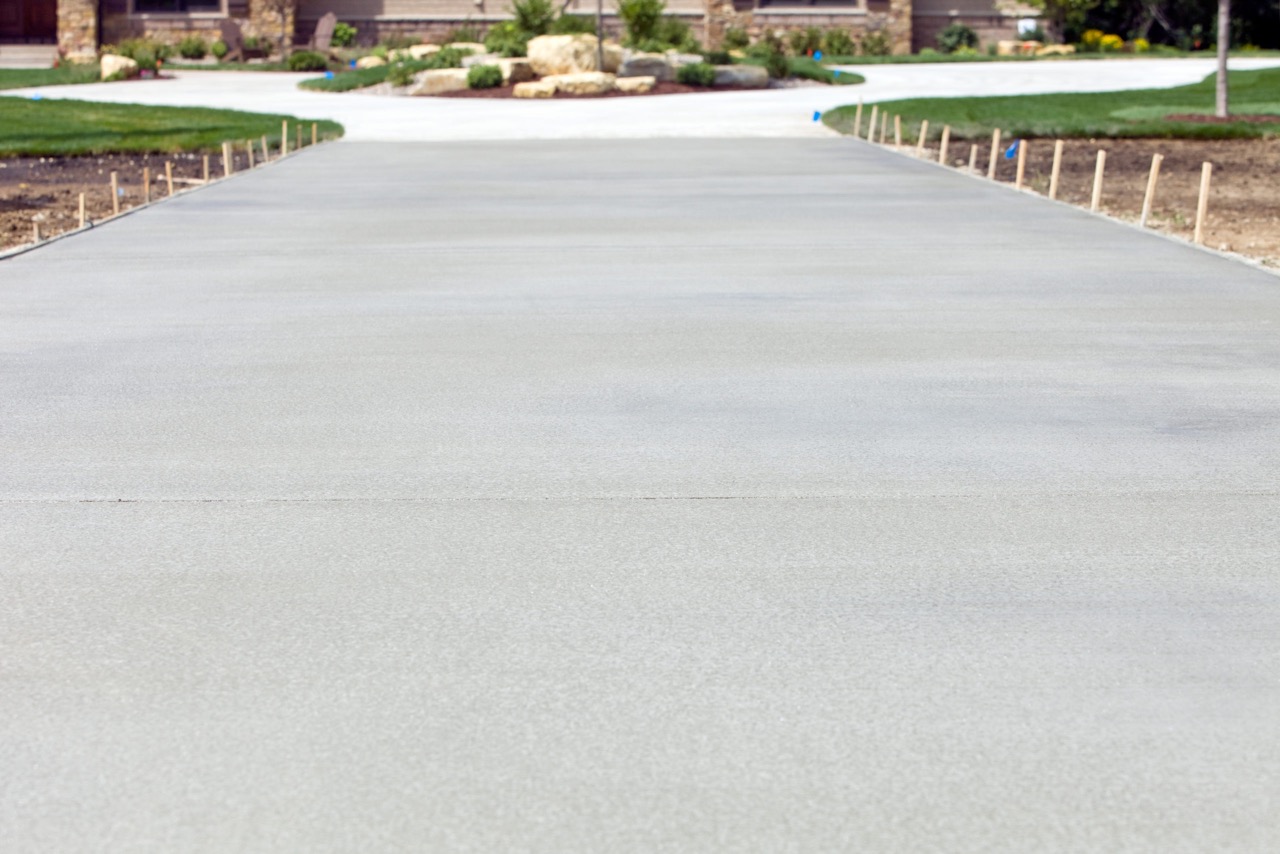

When it comes to installing a new driveway or replacing an existing one, choosing the right type of concrete is crucial for its durability and longevity. One important factor to consider when selecting the concrete for your driveway is the PSI, or pounds per square inch, rating.

PSI is a measurement of the compressive strength of concrete, indicating how much weight it can withstand without breaking or cracking. The higher the PSI, the stronger the concrete. Different applications require different PSI ratings, depending on the expected load-bearing capacity and the specific environment in which the concrete will be placed.

In this article, we will delve into the factors that affect the PSI requirements for driveway concrete, how PSI is measured and determined, as well as common recommendations for PSI in driveway construction. Understanding these factors will help you make an informed decision when it comes to choosing the right PSI rating for your driveway project.

So, let’s dive in and explore the world of PSI and its importance in driveway concrete!

Key Takeaways:

- Choosing the right PSI for your driveway concrete is crucial for durability. Consider factors like expected load, climate, and soil type to ensure your driveway can withstand the test of time.

- Understanding PSI and its significance empowers you to make informed decisions. Achieving the proper PSI ensures strength, resistance to cracking, and long-term cost savings for your driveway.

Factors Affecting PSI Requirements for Driveway Concrete

Several factors come into play when determining the PSI requirements for driveway concrete. These factors include:

- Expected Load: The amount of weight that your driveway will need to support plays a significant role in determining the required PSI. A driveway that will primarily be used for pedestrian traffic will have lower PSI requirements compared to one that will be exposed to heavy vehicles like trucks or RVs.

- Climate and Weather Conditions: The climate and weather conditions in your area can impact the durability of your driveway concrete. Regions with extreme temperatures or frequent freeze-thaw cycles require a higher PSI to withstand the expansion and contraction that occurs due to temperature fluctuations.

- Soil Type and Conditions: The type of soil and its stability can affect the PSI requirements for driveway concrete. Clay-based soils, for example, can expand and contract significantly with changes in moisture content, putting additional stress on the concrete. In such cases, a higher PSI may be necessary to ensure the driveway’s structural integrity.

- Thickness of the Concrete: The thickness of the concrete slab also influences the required PSI. Thicker slabs typically require a higher PSI to distribute the weight evenly and prevent cracking or settlement over time.

- Proximity to Trees and Plant Roots: If your driveway will be located near trees or dense vegetation, the presence of tree roots can potentially exert pressure on the concrete. This can lead to cracks and unevenness over time. In such situations, a higher PSI may be necessary to withstand the added stress.

- Drainage and Water Management: Proper drainage is essential in preventing water from pooling on the driveway surface. If water accumulates on the concrete, it can weaken the material and cause it to deteriorate faster. Areas with poor drainage may require a higher PSI to ensure the driveway can withstand water-related issues.

Considering these factors is crucial in determining the appropriate PSI rating for your driveway concrete. Failing to account for these factors may result in premature cracking, settlement, or other structural issues that could lead to costly repairs or replacements.

Understanding PSI (Pounds per Square Inch)

PSI, or pounds per square inch, is a unit of measurement used to indicate the compressive strength of concrete. It measures the amount of force that can be applied to an area of concrete before it breaks or fails. The higher the PSI rating, the stronger the concrete.

The PSI rating of concrete is determined through rigorous testing in a controlled laboratory setting. A sample of concrete is subjected to increasing amounts of pressure until it reaches its breaking point. The maximum amount of pressure the concrete can withstand without failing is recorded as the PSI rating.

For example, if a sample of concrete has a PSI rating of 4,000, it means that it can withstand a force of 4,000 pounds per square inch before it breaks. This information is crucial in determining the appropriate PSI for specific applications, such as driveway construction.

When choosing the PSI rating for your driveway concrete, it’s important to consider the factors we previously discussed. A higher PSI rating may be necessary for driveways subjected to heavy vehicle traffic, extreme weather conditions, or unstable soil types. On the other hand, a lower PSI rating may be sufficient for driveways with light pedestrian use or favorable environmental conditions.

It is essential to note that the PSI rating only measures compressive strength. Other factors, such as tensile strength and flexural strength, also contribute to the overall durability and performance of concrete. However, for driveway applications, compressive strength is typically the primary concern, as driveways primarily deal with compression forces caused by the weight of vehicles.

By understanding PSI and its significance in concrete strength, you can make an informed decision when selecting the appropriate PSI rating for your driveway project. The goal is to choose a PSI rating that adequately meets the requirements of your specific driveway application, ensuring its long-term durability and performance.

Determining the Required PSI for Driveway Concrete

When determining the required PSI for your driveway concrete, it is important to consider the specific factors and requirements of your project. While there are general guidelines and recommendations, it is always best to consult with a professional contractor or engineer to ensure accuracy.

One common method for determining the required PSI is to follow local building codes and regulations. These codes often provide minimum PSI requirements for various types of concrete applications, including driveways. Adhering to these codes helps ensure that your driveway meets the necessary structural standards and is safe for use.

Additionally, taking into account the factors we discussed earlier, such as expected load, climate conditions, soil stability, and drainage, can give you a better idea of the PSI range that will suit your driveway project.

Consider the type of vehicles that will be using the driveway regularly. Heavy vehicles, like trucks or recreational vehicles (RVs), will require a higher PSI due to their increased weight and potential impact on the concrete surface. Lighter vehicles, such as passenger cars, may be suitable for lower PSI ratings.

Climate conditions play a significant role in determining the required PSI as well. If you live in a region with extreme weather variations, such as freezing temperatures, high heat, or frequent freeze-thaw cycles, you may need a higher PSI concrete to withstand the associated stresses.

Soil type and stability also influence the required PSI. Clay-based or expansive soils require a higher PSI to resist the pressures caused by changing moisture levels. If your soil is known to be unstable or has a poor bearing capacity, a higher PSI may be necessary for the longevity of your driveway.

Lastly, consider the importance of proper drainage in preventing water-related issues. If your driveway has inadequate drainage, water can accumulate and put additional stress on the concrete. In such cases, a higher PSI may be required to ensure the driveway can withstand these pressures.

It is crucial to note that while higher PSI concrete generally offers improved strength and durability, it may come at a higher cost. Finding the right balance between the required PSI and your budget is essential.

By considering these factors and consulting with professionals, you can determine the required PSI that is suitable for your driveway concrete. This will ensure that your driveway meets the necessary strength requirements, performs well under expected loads, and lasts for years to come.

For a standard residential driveway, a concrete with a compressive strength of 3000-4000 PSI is recommended. This will provide the necessary durability to withstand vehicle traffic and environmental conditions.

Common PSI Recommendations for Driveway Concrete

While the specific PSI requirements for driveways vary depending on factors such as expected load, climate conditions, and soil stability, there are some common PSI recommendations for driveway concrete. These recommendations serve as a general guide and starting point when determining the appropriate PSI for your project:

- 2,500 to 3,000 PSI: This PSI range is commonly recommended for residential driveways with light to moderate vehicle traffic, such as passenger cars and pickup trucks. It is suitable for areas with stable soils, moderate climate conditions, and minimal exposure to freeze-thaw cycles. Driveways with this PSI rating can provide sufficient durability and longevity with regular maintenance.

- 3,500 to 4,000 PSI: This PSI range is suitable for driveways that anticipate heavier vehicle traffic or exposure to harsher climate conditions. It provides greater strength and durability to withstand the weight and impact of larger vehicles and regions with more extreme weather variations. This range is commonly recommended for driveways in areas with frequent freeze-thaw cycles or heavy clay-based soils.

- Above 4,000 PSI: For driveways subjected to exceptionally heavy loads or extreme conditions, such as commercial driveways or areas with extremely unstable soil, a PSI rating above 4,000 may be necessary. These high-strength concretes offer superior durability and can handle heavy truck traffic, RVs, or areas with exceptionally challenging environmental conditions.

It is important to note that these PSI recommendations are not set in stone and may vary depending on local building codes, engineering specifications, and specific project requirements. Consulting with a professional contractor or engineer is essential to determine the most appropriate PSI rating that meets the unique needs of your driveway.

Remember that the PSI rating is just one aspect of selecting the right concrete mix for your driveway. Other factors, such as aggregate size, air entrainment, and proper curing techniques, also contribute to the overall strength and durability of the concrete. Working with a knowledgeable contractor will ensure that all these factors are considered when selecting the best concrete mix for your driveway project.

By following these common PSI recommendations and seeking expert advice, you can ensure that your driveway concrete has the necessary strength to withstand expected loads, environmental conditions, and provide long-lasting performance.

Read more: How To Resurface A Concrete Driveway

The Importance of Proper PSI for Driveway Durability

Selecting the proper PSI, or pounds per square inch, for driveway concrete is crucial for ensuring its durability and long-term performance. Here are some key reasons why achieving the right PSI is important:

- Strength and Load-Bearing Capacity: The PSI rating directly correlates to the strength and load-bearing capacity of the concrete. Choosing a PSI that aligns with the expected traffic and load on your driveway ensures that it can withstand the weight and impact of vehicles without cracking or showing signs of distress. A higher PSI provides greater structural integrity and can handle heavier loads, making your driveway more durable and resistant to damage.

- Resistance to Cracking and Settlement: Concrete driveways are prone to cracking and settlement over time, especially if they do not have the appropriate PSI for the specific conditions they will face. Properly selected PSI concrete helps minimize the risk of cracks and settlement, ensuring that your driveway remains smooth and even for years to come.

- Weather and Environmental Conditions: Different regions experience varying weather conditions, such as extreme heat, freezing temperatures, or excess moisture. Choosing the right PSI for your driveway concrete based on the climate and environmental factors in your area is essential. For example, a higher PSI is recommended in regions with frequent freeze-thaw cycles, as it can better withstand the expansion and contraction caused by temperature fluctuations.

- Long-Term Cost Savings: Investing in higher PSI concrete upfront may incur a slightly higher cost, but it can lead to significant long-term cost savings. By choosing a PSI that is appropriate for your driveway’s needs, you can reduce the likelihood of damages and the need for repairs or replacements down the line. Proper PSI selection helps maintain the integrity of the driveway, saving you money on potential repairs and extending its lifespan.

- Enhanced Safety: A properly designed and constructed driveway with the right PSI rating ensures a safe environment for both vehicles and pedestrians. It minimizes tripping hazards caused by cracks or uneven surfaces, reducing the risk of accidents or injuries. A stable and durable driveway provides peace of mind and adds value to your property.

It is important to consult with professionals who have expertise in concrete construction when determining the appropriate PSI for your driveway. They can assess the specific factors that impact your project, such as expected load, climate conditions, and soil stability, to recommend the optimal PSI rating.

By placing importance on selecting the proper PSI for your driveway concrete, you can ensure its durability, stability, and longevity. A well-designed and constructed driveway that meets the necessary PSI requirements will not only enhance the appearance and functionality of your property, but also provide peace of mind knowing that it can withstand the demands of daily use and the challenges of the environment.

Conclusion

Choosing the right PSI, or pounds per square inch, for your driveway concrete is a critical decision that impacts its durability and longevity. By considering factors such as expected load, climate conditions, soil stability, and drainage, you can determine the appropriate PSI rating for your project.

Understanding the concept of PSI and its significance in concrete strength empowers you to make informed decisions when selecting the PSI for your driveway. While there are common recommendations based on factors like anticipated traffic and environmental conditions, it is always advisable to consult with professionals to ensure accuracy.

Achieving the proper PSI for your driveway helps ensure its strength and load-bearing capacity, resistance to cracking and settlement, and ability to withstand challenging weather conditions. It also offers long-term cost savings by reducing the need for repairs or replacements. Furthermore, a well-designed and constructed driveway with the right PSI rating enhances safety for both vehicles and pedestrians.

Remember that selecting the right PSI is just one aspect of creating a durable driveway. Proper construction techniques, including appropriate aggregate size, air entrainment, and curing methods, also contribute to the overall performance of the concrete. Working with experienced contractors helps ensure that all these factors are considered for an optimal driveway outcome.

In conclusion, choosing the right PSI for your driveway concrete is vital for its longevity, resilience, and functionality. By carefully evaluating the specific factors impacting your project and seeking professional advice, you can create a driveway that withstands the test of time, adds value to your property, and provides a safe and aesthetically pleasing entrance to your home.

Frequently Asked Questions about How Many PSI Concrete Needed For Driveway

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How Many PSI Concrete Needed For Driveway”