Articles

How To Calculate Duct Size For HVAC

Modified: August 27, 2024

Learn how to calculate the perfect duct size for your HVAC system in our comprehensive articles. Get expert tips and techniques for optimal air flow and energy efficiency.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When it comes to heating, ventilation, and air conditioning (HVAC) systems, proper duct sizing plays a crucial role in ensuring optimal performance and energy efficiency. Whether you are designing a new HVAC system or upgrading an existing one, understanding how to calculate duct size is essential.

A well-designed ductwork system ensures that the conditioned air reaches every room evenly and efficiently, allowing the HVAC system to operate at its maximum potential. On the other hand, an improperly sized duct system can result in reduced airflow, uneven temperature distribution, increased energy consumption, and even potential damage to the HVAC equipment.

In this article, we will dive into the importance of proper duct sizing and discuss the factors to consider before calculating the duct size for your HVAC system. We will then provide step-by-step guidance on how to accurately calculate the duct size, ensuring optimal performance and energy efficiency.

By following the guidelines in this article, you will be equipped with the knowledge to design and install a ductwork system that meets the airflow requirements of your HVAC system, enabling it to effectively heat, cool, and ventilate your space.

Key Takeaways:

- Proper duct sizing is crucial for optimal HVAC performance, energy efficiency, and comfort. Factors like airflow requirements, friction rate, and duct material must be considered for accurate calculations.

- Utilizing duct sizing charts or software helps determine the correct duct dimensions based on specific HVAC system requirements, ensuring efficient airflow distribution and optimal performance.

Read more: How To Clean HVAC Ducts

Importance of Proper Duct Sizing

Proper duct sizing is of utmost importance when it comes to HVAC systems. It has a direct impact on the overall efficiency, performance, and comfort of the system. Here are a few key reasons why proper duct sizing is crucial:

- Optimal Airflow: The ductwork is responsible for distributing conditioned air throughout the space. If the ducts are too small, the airflow will be restricted, resulting in inadequate heating or cooling. On the other hand, oversized ducts can lead to excessive airflow, causing uneven temperature distribution and discomfort. Properly sized ducts ensure optimal airflow, allowing the HVAC system to function efficiently.

- Energy Efficiency: HVAC systems that have properly sized ducts operate more efficiently. When the airflow is balanced, the system doesn’t have to work harder to compensate for restricted or excessive airflow. This not only reduces energy consumption but also lowers utility bills.

- Comfort: Properly sized ducts help maintain consistent temperature and humidity levels throughout the space. They prevent hot or cold spots and ensure even distribution of conditioned air, resulting in enhanced comfort for occupants.

- Noise Reduction: Improper duct sizing can cause turbulent airflow, resulting in increased noise levels. Oversized ducts can lead to echoing sounds, while undersized ducts can cause whistling or rattling noises. Properly sized ducts minimize noise disturbances, allowing for a quieter and more peaceful environment.

- Improved HVAC System Performance: When the ducts are sized correctly, the HVAC system can operate at its optimum performance level. Proper airflow ensures that the equipment can deliver the required heating or cooling capacity, extending the lifespan of the system and reducing the need for repairs or replacements.

By understanding the importance of proper duct sizing, you can ensure that your HVAC system operates efficiently, effectively, and reliably for years to come. It not only enhances comfort and indoor air quality but also saves energy and reduces maintenance costs. Now that you understand why duct sizing is essential, let’s explore the factors to consider before calculating the duct size for your HVAC system.

Factors to Consider Before Calculating Duct Size

Before calculating the duct size for your HVAC system, there are several factors that you need to take into consideration. These factors will help determine the appropriate duct size to ensure optimal airflow and performance. Here are the key factors to consider:

- Airflow Requirements: The first step in determining the duct size is to understand the airflow requirements of your HVAC system. This includes the amount of air needed to effectively cool, heat, and ventilate the space. The airflow requirements are typically calculated based on the size of the area, the heat load, and the number of occupants.

- System Efficiency: The efficiency of the HVAC system plays a role in determining the duct size. More efficient systems may require smaller ducts due to their ability to deliver the required airflow with less resistance. On the other hand, less efficient systems may require larger ducts to compensate for higher resistance and lower airflow capacity.

- Static Pressure: Static pressure is the resistance to airflow within the ductwork system. It is influenced by factors such as duct length, bends, fittings, and the type of dampers used. The static pressure of the system should be evaluated to ensure that it falls within the manufacturer-recommended range. This will help determine the appropriate duct size to maintain optimal airflow.

- Space Constraints: The physical constraints within the space, such as ceiling height, wall cavities, and available space for duct installation, must be considered when calculating the duct size. It is essential to design the ductwork in a way that minimizes the disruption to the architectural integrity of the building while maximizing the efficiency of the system.

- Duct Material: The material used for the ductwork can impact its sizing requirements. Different materials have varying resistance to airflow, known as the friction factor. This factor determines the rate of pressure loss as air flows through the ducts. The duct material should be selected based on the specific needs of the HVAC system and its impact on the overall duct sizing.

Considering these factors before calculating the duct size will ensure that you have a comprehensive understanding of the requirements and limitations of your HVAC system. It will help you make informed decisions and design a ductwork system that optimizes airflow, energy efficiency, and comfort. Now that we have covered the factors to consider, let’s move on to the steps involved in calculating the duct size for your HVAC system.

Steps to Calculate Duct Size for HVAC

Calculating the duct size for your HVAC system involves a step-by-step process that takes into account the airflow requirements, system specifications, and other factors. Here are the key steps to follow:

- Determine the Airflow Requirements: Start by determining the required airflow for each room in the space. This can be done by calculating the heat load, considering the room size, number of occupants, and other factors that contribute to the cooling or heating needs. This will give you the total airflow requirement for the entire system.

- Calculate the Total Equivalent Length: The total equivalent length is the total length of the ductwork, including all turns, elbows, and fittings. Each component adds resistance to the airflow, so it is essential to calculate the total equivalent length to determine the pressure drop in the system.

- Determine the Friction Rate: The friction rate is the amount of pressure drop per unit length of the ductwork. It is determined by the duct size, type of material, and air velocity. The friction rate should be selected based on the desired balance between airflow efficiency and pressure drop.

- Select the Appropriate Duct Material: Based on the system requirements and the desired friction rate, select the appropriate duct material. Common duct materials include galvanized steel, fiberglass duct board, and flexible ducts. Each material has its own characteristics and affects the duct sizing.

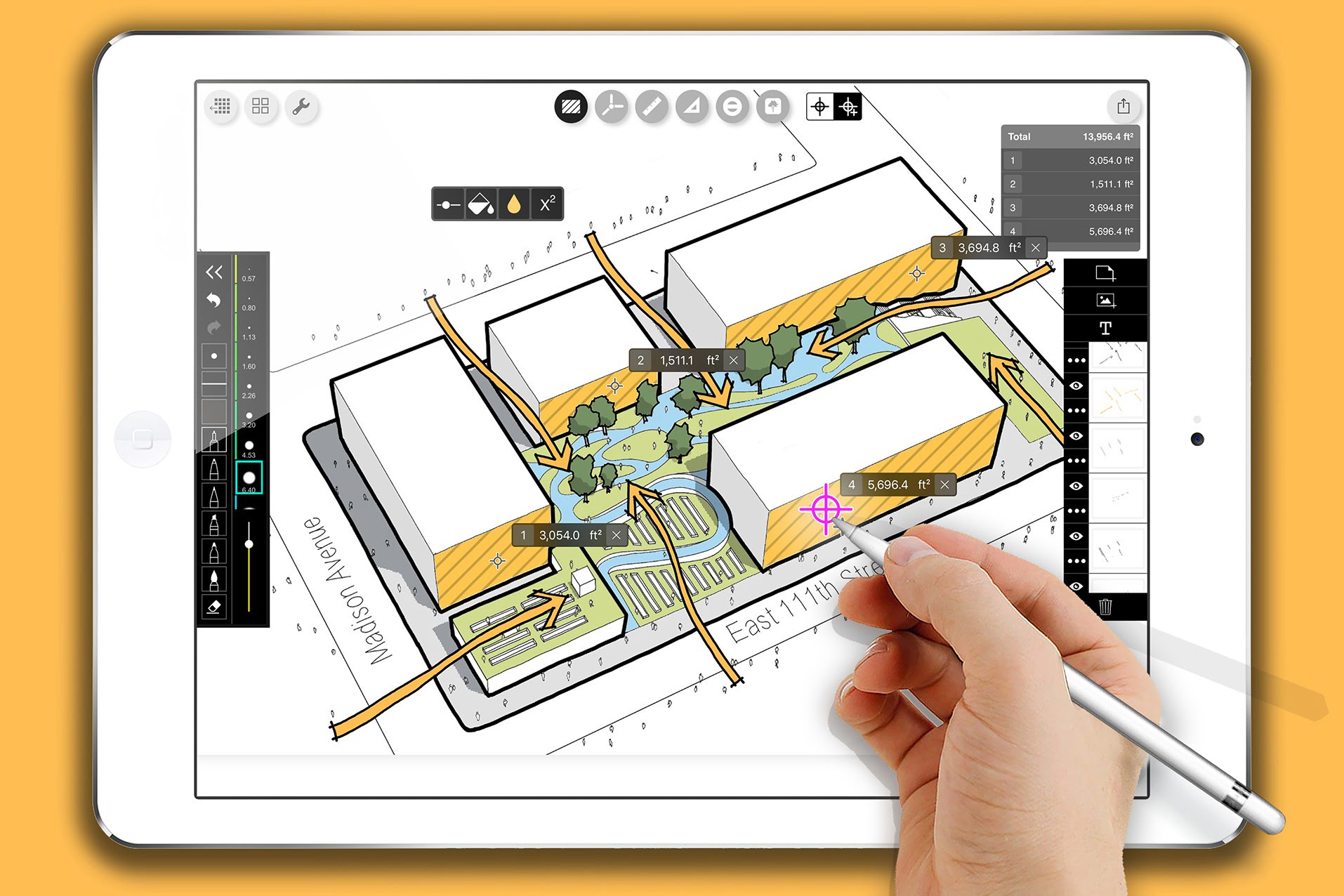

- Use Duct Sizing Charts or Software: Refer to duct sizing charts or use duct sizing software to calculate the appropriate duct size based on the airflow requirements, total equivalent length, and chosen friction rate. These tools provide guidelines and calculations to help determine the correct duct dimensions.

- Check for Velocity and Pressure Drop: After obtaining the initial duct size, verify that the air velocity and pressure drop are within acceptable ranges. The air velocity should not be too high or too low, as it can affect system performance. The pressure drop should also be within the recommended limits to ensure optimal airflow.

It is important to note that duct sizing is a complex process that requires technical knowledge and experience. Consulting with a professional HVAC technician or engineer is recommended to ensure accurate calculations and proper duct sizing for your specific system and space.

By following these steps and considering the factors discussed earlier, you can ensure that your HVAC system has the appropriate duct size to deliver efficient airflow, maintain comfortable indoor conditions, and maximize energy efficiency. Proper duct sizing is essential for the optimal performance and longevity of your HVAC system.

Determine the Airflow Requirements

The first step in calculating the duct size for your HVAC system is to determine the airflow requirements. This involves assessing the cooling, heating, and ventilation needs of the space to ensure that the system can effectively and efficiently meet the desired conditions.

There are several factors to consider when determining the airflow requirements:

- Room Size: The size of each room or area that needs to be conditioned plays a key role in calculating the airflow requirements. Larger rooms typically require more airflow to achieve the desired temperature and comfort level.

- Heat Load: The heat load in each area is another important consideration. Heat load refers to the amount of heat that needs to be removed or added to maintain the desired temperature. Factors that contribute to heat load include the number of occupants, appliances, lighting, insulation, and windows.

- Occupancy: The number of people occupying the space affects the airflow requirements. More occupants generate more body heat and require additional fresh air for ventilation. This needs to be taken into account when estimating the airflow needs.

- Ventilation Requirements: Proper ventilation is crucial for maintaining indoor air quality. The airflow requirements should include the amount of fresh air needed for ventilation, which may be regulated by building codes or standards.

Once you have gathered the necessary information, you can calculate the total airflow requirements for your HVAC system. It is important to note that different spaces may have different airflow needs. For example, areas with higher heat loads or occupancy levels may require more airflow compared to spaces with lower demands.

By accurately determining the airflow requirements, you can ensure that the HVAC system provides sufficient conditioned air to meet the desired comfort levels and ventilation needs. This is the foundation for calculating the appropriate duct size that will allow for the proper distribution of airflow throughout the space.

Now that you understand the importance of determining the airflow requirements, let’s move on to the next step in calculating the duct size: calculating the total equivalent length.

Read more: How To Close Off A HVAC Duct

Calculate the Total Equivalent Length

Calculating the total equivalent length is a crucial step in determining the duct size for your HVAC system. The total equivalent length takes into account all the bends, elbows, fittings, and other components in the ductwork that create resistance to the airflow.

When air flows through a duct, it encounters resistance due to the friction between the air and the duct walls, as well as the obstructions presented by fittings and turns. This resistance results in a pressure drop along the length of the duct. To ensure proper airflow, it is important to calculate the total equivalent length, which accounts for the cumulative effect of all the components.

To calculate the total equivalent length, follow these steps:

- Make a sketch or diagram of the ductwork system, including all the bends, elbows, fittings, and straight sections.

- Assign an equivalent length to each component based on its resistance to airflow. For example, a 90-degree elbow may have an equivalent length of 30 feet, while a straight section may have an equivalent length of 5 feet. Consult industry standards or reference materials for guidance on equivalent lengths.

- Add up the equivalent lengths of all the components to obtain the total equivalent length.

By calculating the total equivalent length, you can determine the amount of resistance to airflow within your ductwork system. This information is crucial for determining the pressure drop and selecting the appropriate duct size to ensure optimal airflow and performance.

It is important to note that different types of duct materials and fittings have varying resistance factors. The equivalent lengths assigned to each component may differ depending on the material and design of the ductwork system. Consulting industry guidelines or seeking the expertise of an HVAC professional can help ensure accurate calculations.

Now that you have calculated the total equivalent length, we can move on to the next step: determining the friction rate.

When calculating duct size for HVAC, consider the airflow requirements for each room, the total airflow needed, and the friction loss in the ductwork. Use a duct sizing calculator to ensure proper sizing for efficient and effective air distribution.

Determine the Friction Rate

After calculating the total equivalent length, the next step in calculating the duct size for your HVAC system is to determine the friction rate. The friction rate refers to the amount of pressure drop per unit length of the ductwork and is influenced by the duct size, type of material, and air velocity.

The friction rate plays a crucial role in determining the appropriate duct size as it affects the resistance to airflow. Higher friction rates result in greater pressure drops, which can impact the system’s performance and efficiency. It is essential to strike a balance between airflow efficiency and pressure drop to ensure optimal HVAC system operation.

To determine the friction rate, consider the following factors:

- Duct Size: The size of the ductwork affects the friction rate. Smaller ducts generally have higher friction rates as the airflow encounters more resistance due to the smaller cross-sectional area.

- Duct Material: Different duct materials have varying friction factors. For example, smooth metal ducts have lower friction factors compared to rougher duct materials. The choice of duct material impacts the friction rate and should be considered when calculating the duct size.

- Air Velocity: The velocity at which the air flows through the ductwork also impacts the friction rate. Higher velocities result in higher pressure drops and increased resistance to airflow. It is important to select a suitable air velocity that balances the desired airflow efficiency and pressure drop.

Industry standards and guidelines provide friction rate charts and tables that help determine the appropriate friction rate based on the duct size, material, and air velocity. These resources serve as references to ensure that the chosen friction rate falls within acceptable ranges for optimal system performance.

By determining the friction rate, you can align the duct size with the desired airflow efficiency and pressure drop. This step is crucial in ensuring that the HVAC system can effectively distribute conditioned air throughout the space without undue strain or energy wastage.

Now that we have determined the friction rate, let’s move on to selecting the appropriate duct material in the next step.

Select the Appropriate Duct Material

Choosing the right duct material is a critical step in calculating the duct size for your HVAC system. The material you select has a significant impact on the efficiency, performance, and durability of the ductwork. It affects factors such as airflow resistance, insulation properties, and cost. Considering the specific needs and requirements of your HVAC system is crucial to make an informed decision.

Here are some common types of duct materials to consider:

- Sheet Metal Ducts: Galvanized steel is a popular choice for ductwork due to its durability and strength. Sheet metal ducts have low friction rates, which allows for efficient airflow. They are also resistant to fire and pests. However, the installation process for sheet metal ducts can be more labor-intensive and costly.

- Fiberglass Duct Board: Fiberglass duct board is an alternative to sheet metal ducts. It consists of insulation material wrapped with a layer of reinforced foil or other protective coatings. Fiberglass duct board offers good thermal insulation properties and helps reduce heat transfer. It is lightweight and relatively easy to install, making it a cost-effective option for certain applications.

- Flexible Ducts: Flexible ducts are made of a wire-reinforced plastic inner core covered with insulation. They are highly flexible and easy to install, making them suitable for tight spaces and areas that require flexibility. However, flexible ducts tend to be more prone to air leakage and may have higher friction rates compared to other duct materials.

- Ductless Mini-Split Systems: In some cases, ductless mini-split systems may be an option to consider. These systems consist of an indoor unit and an outdoor compressor, connected by a refrigerant line. Ductless systems are ideal for spaces where traditional ductwork is not feasible or desirable. They offer flexibility in zoning and can provide efficient heating and cooling.

When selecting the appropriate duct material, consider factors such as the system’s requirements, space constraints, energy efficiency goals, maintenance needs, and budget. It is also important to comply with local building codes and regulations regarding duct materials.

By selecting the right duct material, you can ensure that the ductwork is compatible with your HVAC system and optimizes airflow, energy efficiency, and overall performance.

Now that you have chosen the duct material, let’s move on to the next step: using duct sizing charts or software to calculate the appropriate duct size.

Use Duct Sizing Charts or Software

Once you have determined the airflow requirements, calculated the total equivalent length, determined the friction rate, and selected the appropriate duct material, the next step in calculating the duct size for your HVAC system is to use duct sizing charts or software.

Duct sizing charts and software are valuable tools that help determine the correct duct dimensions based on the specific requirements of your HVAC system. These resources provide guidelines and calculations to ensure that the airflow is efficiently distributed throughout the space, taking into account factors such as airflow volume, pressure drop, and velocity limitations.

Here are the steps to use duct sizing charts or software:

- Refer to duct sizing charts specific to the chosen duct material and the desired airflow rate. These charts provide information on the recommended duct sizes based on various combinations of airflow volume and available static pressure.

- Locate the intersection point on the chart that corresponds to the airflow rate and the total equivalent length. The point where these two values meet will indicate the recommended duct size for your system.

- If using duct sizing software, input the required parameters such as airflow rate, static pressure, total equivalent length, and duct material. The software will then calculate and provide the appropriate duct dimensions.

It is important to note that duct sizing charts and software are based on generalized guidelines and assumptions. Variations in specific system requirements, space conditions, or local building codes may require adjustments to the recommended duct size. Consulting with an HVAC professional or engineer can help ensure accurate calculations and optimal duct sizing for your specific system and space.

By using duct sizing charts or software, you can accurately determine the appropriate duct size to meet the airflow requirements of your HVAC system. This step is crucial to ensure efficient airflow distribution, optimize system performance, and maintain comfort conditions throughout the space.

Now that you have calculated the duct size using charts or software, the final step is to check for velocity and pressure drop, which will be discussed in the next section.

Read more: How To Hide HVAC Ducts In Basement

Check for Velocity and Pressure Drop

Once you have calculated the duct size using duct sizing charts or software, the final step in determining the duct size for your HVAC system is to check for velocity and pressure drop. This step ensures that the selected duct dimensions are suitable for maintaining optimal airflow and system performance.

Here’s how to check for velocity and pressure drop:

Velocity: Verify that the air velocity in the ductwork falls within acceptable limits. High velocity can cause excessive noise, increased turbulence, and reduced system efficiency. On the other hand, low velocity can lead to insufficient airflow and inadequate heating or cooling. Consult industry standards or guidelines to determine the recommended air velocity range for your specific HVAC system and application.

Pressure Drop: Pressure drop refers to the decrease in air pressure as air flows through the ductwork. Excessive pressure drop can result in decreased system performance and increased energy consumption. Ensure that the pressure drop falls within the manufacturer’s recommended limits for optimum airflow and system operation. High-pressure drop may require revisiting the selection of duct material or adjusting the duct dimensions accordingly.

To check for velocity and pressure drop, compare the calculated values with recommended ranges or guidelines provided by industry standards or manufacturers. If the velocity or pressure drop exceeds the recommended limits, it may be necessary to revisit the duct size calculation or make adjustments to the duct dimensions, such as increasing or decreasing the duct size, adjusting the total equivalent length, or changing the duct material.

It is important to strike a balance between airflow efficiency and pressure drop to ensure the optimal performance of your HVAC system. Consulting with an HVAC professional or engineer can provide valuable insight and expertise in assessing the velocity and pressure drop in your specific application.

By checking for velocity and pressure drop, you can confirm that the selected duct size meets the necessary criteria for maintaining efficient and effective airflow. This step ensures that the HVAC system can deliver the desired heating, cooling, and ventilation with minimal resistance and energy consumption.

Now that you have gone through the complete process of calculating the duct size for your HVAC system, you are well-equipped to design and install a ductwork system that optimizes airflow, energy efficiency, and overall system performance.

Conclusion

Proper duct sizing is a crucial aspect of designing and installing an HVAC system that operates efficiently, effectively, and reliably. By following the steps outlined in this article, you can ensure that your ductwork system is accurately sized to meet the airflow requirements of your HVAC system while minimizing pressure drop and energy consumption.

Starting with determining the airflow requirements, you can assess the cooling, heating, and ventilation needs of the space, taking into account factors such as room size, heat load, occupancy, and ventilation requirements. This information serves as the foundation for calculating the duct size.

Calculating the total equivalent length and determining the friction rate help assess the resistance to airflow within the ductwork system. This step is crucial for selecting the appropriate duct size and material that balances airflow efficiency and pressure drop. Consider factors such as space constraints, system efficiency, static pressure, and duct material in this process.

Using duct sizing charts or software, you can accurately determine the recommended duct dimensions based on the calculated airflow requirements, total equivalent length, friction rate, and chosen duct material. These tools provide guidelines and calculations specific to your HVAC system, ensuring efficient airflow distribution.

Finally, checking for velocity and pressure drop confirms that the selected duct size meets the desired airflow and pressure requirements. By staying within the recommended velocity and pressure drop ranges, you can ensure optimal system performance and energy efficiency.

Properly sized ductwork enhances airflow, improves comfort, reduces energy consumption, and extends the life of the HVAC system. However, it is important to note that duct sizing is a complex process, and consulting with an HVAC professional or engineer is recommended to ensure accurate calculations and proper duct sizing for your specific system and space.

By understanding and implementing these steps, you can design and install a ductwork system that optimizes the performance, efficiency, and longevity of your HVAC system. Take the time to properly size your ductwork, and you will enjoy a comfortable and efficient indoor environment for years to come.

Frequently Asked Questions about How To Calculate Duct Size For HVAC

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Calculate Duct Size For HVAC”