Articles

How To Fill Refrigerant In HVAC

Modified: October 20, 2024

Learn how to properly fill refrigerant in your HVAC system with our informative articles. Get expert tips and step-by-step instructions for a smooth process.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the world of HVAC (Heating, Ventilation, and Air Conditioning)! In today’s article, we will delve into the topic of filling refrigerant in HVAC systems. Refrigerant plays a vital role in the cooling process, helping to transfer heat from the indoor air to the outdoor environment and keeping our living spaces comfortable.

Understanding how to fill refrigerant in HVAC systems is crucial for maintaining optimal performance and efficiency. When the refrigerant levels are too low, the system may not cool properly, resulting in discomfort for occupants and potential damage to the HVAC unit.

Throughout this article, we will explore the different types of refrigerants used in HVAC systems, the importance of maintaining proper refrigerant levels, and the signs that indicate low refrigerant levels. We will also discuss the tools and equipment needed to fill refrigerant and the necessary safety precautions to undertake.

Whether you are a homeowner with a basic understanding of HVAC systems or a technician looking to enhance your skills, this article aims to provide you with comprehensive knowledge on how to fill refrigerant in HVAC systems. So, let’s dive in and explore the fascinating world of HVAC refrigerants!

Key Takeaways:

- Proper refrigerant levels are crucial for efficient cooling, energy savings, system longevity, indoor air quality, and warranty compliance. Regular maintenance and professional inspection are essential for optimal HVAC performance.

- Filling refrigerant in HVAC systems requires precision, adherence to safety precautions, and the right tools. When in doubt, consult a professional technician to ensure safe and effective system operation.

Read more: How To Fix HVAC Refrigerant Leak

Understanding HVAC Refrigerant

Before we delve into the process of filling refrigerant in HVAC systems, it’s essential to have a clear understanding of what refrigerant is and how it functions within the system.

Refrigerant is a specialized fluid that absorbs heat from indoor spaces and transfers it to the outdoor environment. It undergoes a continuous cycle of evaporation and condensation, absorbing heat energy in the evaporator coil and releasing it in the condenser coil. This heat transfer process allows the HVAC system to cool the indoor air effectively.

Refrigerants are designed to have low boiling points, enabling them to change from a liquid to a gas state at low temperatures. As they evaporate in the indoor coil, they absorb heat from the air, cooling it down. The now-heated refrigerant gas is then compressed by the compressor, which increases its temperature and pressure.

The high-pressure, high-temperature gas then moves to the condenser coil, where it is cooled down by the surrounding air or a separate cooling mechanism, causing it to condense back into a liquid state. During this condensation process, the refrigerant releases the absorbed heat energy into the outdoor environment.

The condensed liquid refrigerant is then sent back to the evaporator coil, and the cycle repeats.

It’s important to note that HVAC systems are designed to operate with a specific type of refrigerant, as different refrigerants have varying temperature ranges and pressure requirements. Manufacturers specify the appropriate refrigerant for each system, and it’s essential to adhere to their guidelines to ensure proper performance and avoid equipment damage.

Additionally, refrigerants have evolved over the years due to environmental concerns and regulations. Older refrigerants such as R-22 (commonly known as Freon) are being phased out due to their ozone depletion potential. Newer refrigerants like R-410A, known as Puron, are more environmentally friendly and have become the standard for residential and commercial HVAC systems.

By understanding the role of refrigerant in the HVAC system and the importance of using the correct type, we can proceed with confidence in filling refrigerant and maintaining optimal system performance.

Types of Refrigerants Used in HVAC Systems

There are several types of refrigerants used in HVAC systems, each with its own unique characteristics and applications. In this section, we will explore the most common types of refrigerants used in residential and commercial HVAC systems.

- R-410A (Puron): R-410A is a hydrofluorocarbon (HFC) refrigerant that has become the industry standard for new HVAC installations. It has replaced R-22 due to its lower environmental impact and higher energy efficiency. R-410A operates at higher pressures than R-22, requiring specially designed systems and equipment.

- R-22 (Freon): R-22 is a hydrochlorofluorocarbon (HCFC) refrigerant that has been widely used in HVAC systems for many years. However, due to its harmful impact on the ozone layer, it is being phased out and will no longer be produced or imported. Existing systems can still be serviced with reclaimed or recycled R-22, but finding it may become more challenging in the future.

- R-134a: R-134a is a hydrofluorocarbon (HFC) refrigerant commonly used in automotive air conditioning systems. It is not used in residential or commercial HVAC systems with air-cooled condensers.

- R-407C: R-407C is a hydrofluorocarbon (HFC) refrigerant that is widely used as a replacement for R-22 in existing systems. It provides similar cooling capacity and performance but operates at higher pressures. R-407C is considered a transitional refrigerant as the industry moves away from R-22.

- R-404A: R-404A is a hydrofluorocarbon (HFC) refrigerant commonly used in commercial refrigeration applications such as walk-in coolers and freezers. It has a high cooling capacity and is known for its low energy consumption.

These are just a few examples of the refrigerants used in HVAC systems. It’s important to consult the manufacturer’s guidelines and specifications for your particular system to determine the appropriate refrigerant to use.

As the industry continues to prioritize environmental sustainability, new refrigerants with even lower global warming potential (GWP) are being developed and introduced. It is crucial for HVAC professionals to stay updated on the latest regulations and advancements in refrigerant technology to ensure compliance and maximize system efficiency.

Importance of Proper Refrigerant Levels

Maintaining proper refrigerant levels in an HVAC system is crucial for optimal performance and efficiency. When the refrigerant levels are incorrect, it can have a significant impact on the system’s ability to cool effectively and can lead to various issues. Let’s explore the importance of maintaining proper refrigerant levels:

- Efficient Cooling: Refrigerant is the lifeblood of an HVAC system. It is responsible for absorbing heat from the indoor air and releasing it outside. When refrigerant levels are too low, it hampers the system’s ability to absorb sufficient heat, resulting in reduced cooling capacity. This can lead to inadequate temperature control and discomfort for occupants.

- Energy Efficiency: An HVAC system that operates with improper refrigerant levels consumes more energy to achieve the desired cooling output. When the refrigerant charge is low, the system must work harder and for longer periods to meet the cooling demands, resulting in higher energy bills. Proper refrigerant levels help the system operate at its designed efficiency, reducing energy consumption and saving on utility costs.

- System Lifespan: When the refrigerant charge is too low, the HVAC system works harder than necessary, causing additional wear and tear on components like the compressor. This can lead to premature system failure and the need for costly repairs or even replacement. By maintaining proper refrigerant levels, you can help extend the lifespan of your HVAC system and avoid expensive repairs.

- Preserving Indoor Air Quality: Adequate refrigerant levels are important for maintaining proper humidity control in the indoor environment. When the refrigerant charge is incorrect, the system may not dehumidify the air effectively. This can contribute to excessive moisture, creating a breeding ground for mold, mildew, and other indoor air quality problems. Proper refrigerant levels help ensure a comfortable and healthy indoor environment.

- Manufacturer Warranty Compliance: HVAC systems typically come with manufacturer warranties that protect against defects and faulty equipment. However, these warranties often require proper maintenance, which includes maintaining the correct refrigerant charge. Failing to adhere to manufacturer guidelines regarding refrigerant levels can void the warranty, leaving you responsible for any repairs or replacements.

Overall, maintaining proper refrigerant levels is essential for optimal cooling performance, energy efficiency, system longevity, indoor air quality, and manufacturer warranty compliance. Regular maintenance and professional inspection can help ensure that your HVAC system operates with the correct refrigerant charge, providing you with the comfort and efficiency you expect.

Signs of Low Refrigerant Levels

Low refrigerant levels in an HVAC system can cause a range of problems, affecting its performance and efficiency. It’s important to be aware of the signs that indicate low refrigerant levels so that you can take appropriate action. Here are some common signs to look out for:

- Insufficient Cooling: One of the primary indicators of low refrigerant levels is inadequate cooling. If you notice that your HVAC system is struggling to cool your space as effectively as it used to, it may be due to a refrigerant leak or insufficient refrigerant charge. Poor cooling performance may result in inconsistent temperatures, warm air blowing from the vents, or an inability to reach the desired temperature.

- Increased Energy Bills: Low refrigerant levels force the HVAC system to work harder and longer to achieve the desired cooling output. As a result, the system consumes more energy, leading to higher electricity bills. If you notice a sudden increase in your energy bills without any other explanation, it could be a sign of low refrigerant levels.

- Frozen Evaporator Coil: Inadequate refrigerant levels can cause the evaporator coil to freeze over. When the refrigerant charge is low, the evaporator coil may become excessively cold, causing the moisture in the air to freeze on the coil’s surface. If you notice ice forming on the evaporator coil or water leakage around the indoor unit, it could be an indication of low refrigerant levels.

- Longer Cooling Cycles: HVAC systems with low refrigerant levels often have longer cooling cycles. The system needs to run for extended periods to compensate for the decreased cooling capacity. If you notice that your HVAC unit is frequently running for prolonged periods without achieving the desired temperature, it may be due to low refrigerant levels.

- Audible Hissing or Bubbling Noises: A refrigerant leak can produce audible hissing or bubbling sounds near the indoor or outdoor unit of the HVAC system. If you hear unusual noises while the system is running, it’s advisable to contact a professional technician to inspect for potential refrigerant leaks.

If you notice any of these signs, it’s important to have a qualified HVAC technician inspect your system. They will be able to diagnose the issue, identify any refrigerant leaks, and recharge the system with the appropriate amount of refrigerant. Ignoring low refrigerant levels can lead to further damage to the system and result in costly repairs.

Regular maintenance and timely detection of low refrigerant levels are crucial for maintaining the efficiency and proper functioning of your HVAC system. It’s recommended to schedule routine maintenance checks to ensure that your refrigerant levels remain optimal.

When filling refrigerant in HVAC, always use the manufacturer’s recommended type and amount of refrigerant. Overfilling can damage the system and underfilling can lead to poor performance.

Read more: How To Check Refrigerant Level In HVAC

Tools and Equipment Needed for Filling Refrigerant

When it comes to filling refrigerant in an HVAC system, having the right tools and equipment is essential for a safe and effective process. Here are the key tools and equipment needed for filling refrigerant:

- Refrigerant: The first and most obvious requirement is the refrigerant itself. The type of refrigerant needed will depend on the specific HVAC system and its manufacturer guidelines. Make sure to check the system specifications and purchase the appropriate refrigerant.

- Refrigerant Recovery Machine: Before filling refrigerant, it’s crucial to properly recover any existing refrigerant in the system. A refrigerant recovery machine is designed to safely collect and store the refrigerant for reuse or disposal. This machine helps maintain environmental compliance and prevents the release of harmful substances into the atmosphere.

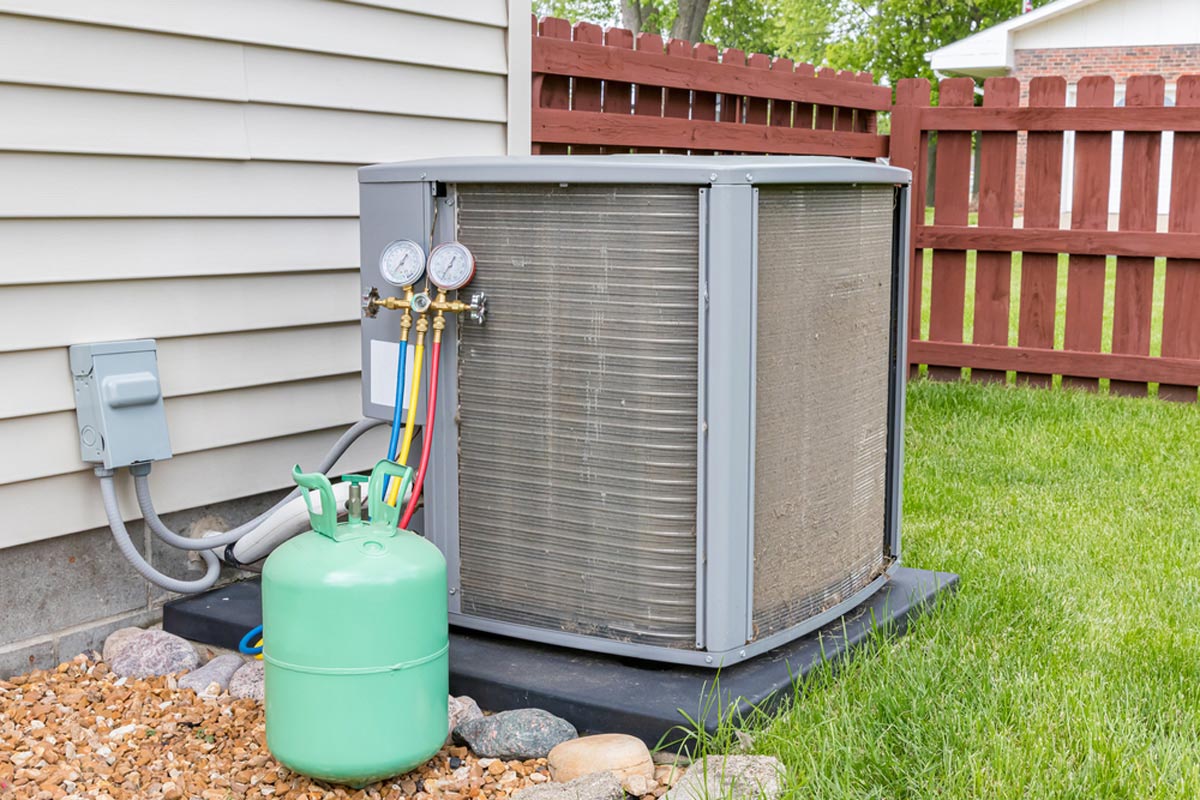

- Manifold Gauge Set: A manifold gauge set allows for accurate measurement of refrigerant pressure and temperature levels. It consists of high and low-pressure gauges, as well as hoses and connectors for connecting to the HVAC system’s service ports. The manifold gauge set helps determine the existing refrigerant levels in the system and enables precise charging.

- Electronic Leak Detector: To identify refrigerant leaks, an electronic leak detector is an invaluable tool. It can detect even the smallest leaks in the HVAC system, helping to pinpoint the source of the problem and prevent further refrigerant loss. Electronic leak detectors offer high sensitivity and reliability in detecting refrigerant leaks.

- Refrigerant Scale: A refrigerant scale is used to accurately measure and monitor the amount of refrigerant being added to the system. This ensures that the correct amount is added, avoiding overcharging or undercharging the system. The scale helps maintain the proper refrigerant charge, which is essential for optimal system performance.

- Refrigerant Charging Hose: A refrigerant charging hose is used to connect the refrigerant canister or recovery machine to the HVAC system. It allows for the controlled transfer of refrigerant into the system. The charging hose should be compatible with the refrigerant being used and in good condition to prevent any leaks or contamination.

- Safety Equipment: It’s important to prioritize safety when working with refrigerants. Safety equipment such as gloves, safety glasses, and a respirator or mask should be worn to protect against potential refrigerant leaks or fumes. Additionally, it’s recommended to have a fire extinguisher nearby in case of any emergencies.

It’s crucial to note that filling refrigerant in an HVAC system should generally be left to trained professionals who are properly certified to handle refrigerants. They have the necessary knowledge, experience, and equipment to perform the task safely and effectively.

However, if you are a homeowner and have a basic understanding of HVAC systems, you can perform simple maintenance tasks such as checking the refrigerant levels and ensuring there are no visible leaks. If you encounter any issues or are unsure, it’s always best to consult a professional technician to avoid any damage to your HVAC system or potential safety hazards.

Safety Precautions

When filling refrigerant in an HVAC system, it’s important to prioritize safety to prevent accidents, injuries, and damage to the system. Here are some essential safety precautions to adhere to:

- Observe Proper Ventilation: Ensure that the area where you are working is well-ventilated. If possible, open windows and doors to allow fresh air to circulate. Proper ventilation helps prevent the accumulation of refrigerant fumes, which can be hazardous if inhaled in high concentrations.

- Wear Personal Protective Equipment (PPE): Always wear the appropriate personal protective equipment to protect yourself from potential hazards. This includes safety glasses or goggles to protect your eyes from refrigerant leaks or splashes, gloves to protect your hands, and a respirator or mask to prevent inhalation of refrigerant fumes.

- Handle Refrigerant Canisters Carefully: When handling refrigerant canisters, ensure that they are not damaged or leaking. Follow the manufacturer’s instructions for storage and handling. Do not drop, puncture, or expose refrigerant canisters to extreme heat or flames.

- Use Proper Tools and Equipment: Use the appropriate tools and equipment specified for handling refrigerant. This includes refrigerant recovery machines, manifold gauge sets, and electronic leak detectors. Regularly inspect and maintain your tools to ensure they are in optimal working condition.

- Avoid Open Flames and Spark-Producing Devices: Do not smoke or use open flames near the refrigerant filling area, as refrigerants can be flammable. Ensure that all spark-producing devices such as electric drills or metal tools are kept away from the refrigerant canisters or system components to prevent accidental ignition.

- Follow Manufacturer Guidelines: Always adhere to the manufacturer’s guidelines and instructions for your HVAC system and the specific refrigerant being used. This includes proper refrigerant type, recommended charging procedures, and appropriate quantities. Failure to follow these guidelines can result in system damage or personal injury.

- Properly Dispose of Refrigerant: If you are removing and replacing refrigerant, follow proper disposal procedures. Refrigerants should not be released into the atmosphere as they are harmful to the environment. Contact a certified refrigerant disposal company or HVAC professional for safe and responsible refrigerant disposal.

- Consult a Professional: If you are uncertain about any aspect of filling refrigerant or if you encounter a complex issue, it is best to consult a qualified HVAC professional. They have the knowledge, experience, and expertise to handle refrigerants safely and effectively.

By following these safety precautions, you can ensure a safe working environment and reduce the risk of accidents or injuries when filling refrigerant in an HVAC system.

Remember, working with refrigerant can be dangerous, and it is typically best left to trained professionals who have the necessary certifications and expertise. If you are unsure or uncomfortable with the process, it is always recommended to seek professional assistance to avoid any potential dangers or costly mistakes.

Step-by-Step Guide to Filling Refrigerant in HVAC Systems

Filling refrigerant in an HVAC system requires precision and adherence to proper procedures. Here is a step-by-step guide to help you navigate the process:

- Prepare the HVAC System: Ensure that the HVAC system is turned off and the power supply is disconnected. This will prevent any accidents or electrical hazards during the refrigerant filling process.

- Inspect for Leaks: Before adding refrigerant, carefully inspect the system for any visible refrigerant leaks. Check the connections, fittings, and hoses for signs of damage or leaks. If you detect any leaks, it’s important to address them before proceeding with the refrigerant filling.

- Recover Existing Refrigerant: If there is existing refrigerant in the system, recover it using a refrigerant recovery machine. Follow the manufacturer’s instructions for proper operation and ensure that the refrigerant is collected and stored safely.

- Connect the Manifold Gauge Set: Attach the high and low-pressure hoses from the manifold gauge set to the service ports of the HVAC system. The high-pressure side corresponds to the smaller refrigerant line and the low-pressure side to the larger refrigerant line.

- Check System Pressure: Turn on the HVAC system and allow it to run for a few minutes. Use the manifold gauge set to check the system’s pressure levels. Compare the readings to the manufacturer’s specifications to determine if the refrigerant charge is too low.

- Locate the Refrigerant Service Ports: Identify the refrigerant service ports on the HVAC system. These ports are where the refrigerant will be injected into the system. They are typically labeled as “H” (high-pressure side) and “L” (low-pressure side).

- Add Refrigerant: Consult the manufacturer’s guidelines to determine the appropriate amount of refrigerant to add. Connect the refrigerant canister to the charging hose, ensuring that the connection is secure and leak-free. Slowly introduce the refrigerant into the system, monitoring the manifold gauge set for pressure and temperature changes.

- Monitor System Operation: As you add refrigerant, monitor the system’s operation and performance. Pay attention to the pressure and temperature readings on the manifold gauge set. Aim to achieve the recommended pressure levels specified by the manufacturer.

- Check for Proper Cooling: After adding refrigerant, allow the system to run for a sufficient period to ensure proper cooling. Observe the airflow and temperature output from the vents. Ensure that the system is cooling effectively and maintaining the desired indoor temperature.

- Finalize and Test: Once the desired pressure and cooling levels are achieved, close the refrigerant canister valve and disconnect the charging hose from the service ports. Double-check for any leaks and ensure that all connections are secure. Finally, test the system’s operation to verify that it is functioning correctly.

Remember, filling refrigerant in an HVAC system can be a complex task and may require professional expertise. If you are unsure or uncomfortable with any step of the process, it is recommended to consult a qualified HVAC technician to ensure safety and proper system performance.

By following this step-by-step guide and taking the necessary precautions, you can contribute to the proper functioning and efficiency of your HVAC system.

Conclusion

Filling refrigerant in an HVAC system is a critical maintenance task that ensures optimal cooling performance and energy efficiency. Understanding the importance of maintaining proper refrigerant levels and knowing the signs of low refrigerant allows you to take proactive measures to address any issues. By following the step-by-step guide and adhering to safety precautions, you can successfully fill refrigerant in your HVAC system.

Remember, the type of refrigerant used in your system may vary, and it’s crucial to comply with manufacturer guidelines to ensure proper system operation. Consult a professional technician if you are uncertain or uncomfortable with the process, as they have the expertise and equipment to handle refrigerant safely.

Regular maintenance and inspections play a vital role in maintaining optimal refrigerant levels. Monitoring the performance of your HVAC system, checking for leaks, and scheduling professional maintenance and servicing are essential practices that can help extend the lifespan of your system and prevent costly repairs.

As advancements in refrigerant technology continue, keep abreast of the latest industry regulations and guidelines regarding refrigerant types and disposal procedures. Maintaining compliance will help protect the environment and ensure you are using the most efficient and environmentally friendly refrigerant options available.

By understanding the ins and outs of filling refrigerant in HVAC systems, you are equipped with the knowledge to keep your system running smoothly and efficiently. A well-maintained and properly charged HVAC system will not only provide comfortable indoor temperatures but also help you save on energy costs and support environmental sustainability.

Remember, when it comes to handling refrigerant, safety should always be a top priority. Take the necessary precautions, use the proper tools and equipment, and consult professionals when in doubt. With these practices in place, you can confidently maintain and fill refrigerant in your HVAC system, ensuring optimal performance and comfort for years to come.

Frequently Asked Questions about How To Fill Refrigerant In HVAC

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Fill Refrigerant In HVAC”