Articles

How To Rebuild A Pressure Washer Pump

Modified: August 28, 2024

Learn how to rebuild a pressure washer pump with our informative articles. Gain expert knowledge and save money on repairs.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to this comprehensive guide on how to rebuild a pressure washer pump. Pressure washers are an essential tool for outdoor cleaning, providing powerful water pressure to tackle even the toughest grime and dirt. However, over time, the pump can wear out or develop issues that affect its performance. Instead of shelling out for a new pump, rebuilding the existing one can save you time and money.

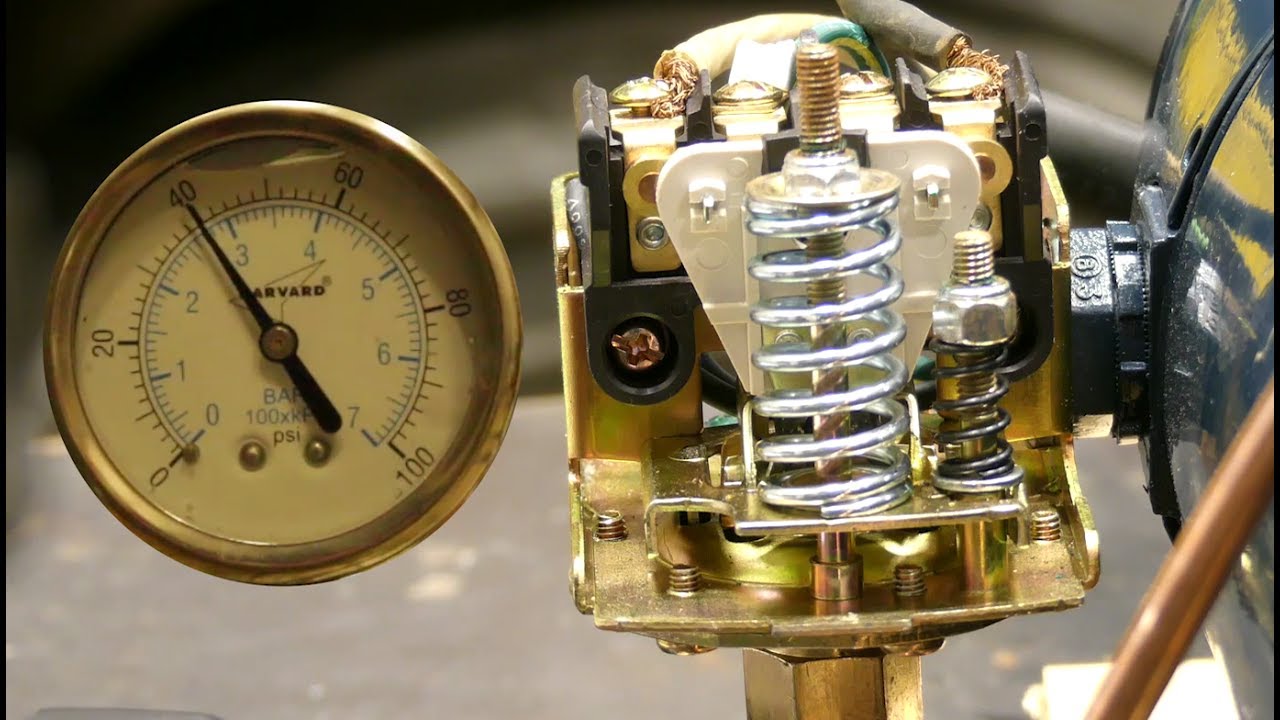

Understanding the inner workings of a pressure washer pump is crucial before attempting a rebuild. A pressure washer pump consists of various components, including seals, valves, pistons, and bearings, all working together to deliver high-pressure water. Over time, these parts can wear out or become damaged, resulting in decreased performance or even pump failure.

To successfully rebuild a pressure washer pump, you’ll need a set of tools and equipment specifically designed for this task. Having the right tools helps make the process more efficient and ensures that you can properly dismantle, diagnose, and rebuild the pump. We’ll cover the necessary tools in detail shortly.

Before we dive into the step-by-step guide on how to rebuild a pressure washer pump, it’s important to prioritize safety. Working with high-pressure equipment can be dangerous, so taking proper safety precautions is essential. We’ll outline some safety measures to follow throughout the rebuilding process to keep you and others around you safe.

In this guide, we’ll provide a detailed step-by-step process for rebuilding a pressure washer pump. Each step will be explained thoroughly, ensuring that even beginners in pressure washer maintenance can follow along. Additionally, we’ll address some common troubleshooting issues and maintenance tips to help extend the life of your pump.

By the end of this article, you’ll have the knowledge and confidence to successfully rebuild your pressure washer pump, saving you money and ensuring that your pressure washer continues to deliver optimal cleaning performance. So let’s get started and explore the fascinating world of pressure washer pump rebuilding!

Key Takeaways:

- Rebuilding a pressure washer pump requires understanding its components, gathering the right tools, prioritizing safety, and following a step-by-step process. With patience and attention to detail, you can successfully restore your pump’s performance and save money.

- Regular maintenance, troubleshooting common issues, and following proper start-up and shutdown procedures are essential for extending the life of your pressure washer pump. By incorporating these maintenance tips, you can enjoy consistent performance and prevent major issues.

Read more: How To Rebuild A Water Pump

Understanding Pressure Washer Pumps

Before diving into the process of rebuilding a pressure washer pump, it’s crucial to have a solid understanding of how it works. A pressure washer pump is the heart and soul of the machine, responsible for generating the high-pressure water needed for effective cleaning.

Pressure washer pumps come in different types: axial cam, triplex, and axial piston. While they may have slight variations in design and operation, their goal remains the same – to pressurize water and deliver it through the spray nozzle.

The pump consists of several key components that work together to create the high-pressure output:

- Pump Housing: The outer casing that houses all the pump components and provides structural support.

- Seals and O-rings: These are crucial for keeping the water contained within the pump and preventing leaks.

- Pistons: These reciprocating components create the pressure by pushing water through the system.

- Valves: Pressure washer pumps typically have inlet and outlet valves that control the flow of water. These valves ensure that water only moves in one direction, increasing efficiency and pressure.

- Bearings: Bearings provide support and help reduce friction between moving parts.

Understanding the components of a pressure washer pump is essential when it comes to diagnosing problems. By knowing how each part interacts, you can better identify the cause of any performance issues or failures.

It’s also important to note that pressure washer pumps require regular maintenance to ensure optimal performance and longevity. This includes routine checks for leaks, lubrication of moving parts, and cleaning or replacing filters. By keeping up with maintenance tasks, you can prevent major issues and extend the lifespan of your pump.

In the next section, we will explore the tools and equipment you’ll need to rebuild your pressure washer pump. Equipping yourself with the right tools is vital for a successful rebuild process and will save you time and frustration. Let’s continue!

Tools and Equipment Needed

Before embarking on the process of rebuilding a pressure washer pump, it’s essential to gather the necessary tools and equipment. Having the right tools not only makes the task easier but also ensures that you can properly dismantle, diagnose, and rebuild the pump. Here’s a list of the tools and equipment you’ll need:

- Screwdrivers: You’ll need both flathead and Phillips head screwdrivers to remove screws and detach various components of the pump.

- Wrenches: Adjustable wrenches and socket wrenches will come in handy for loosening and tightening nuts and bolts.

- Pliers: Needle-nose pliers and adjustable pliers can help with gripping and maneuvering smaller parts or removing retaining clips.

- Allen Wrenches: Also known as hex keys, these tools are useful for loosening or tightening hexagonal screws or bolts.

- Pump Rebuild Kit: This kit typically includes all the necessary seals, O-rings, valves, and other components required to rebuild your specific pressure washer pump model.

- Grease: Use a high-quality pump grease to lubricate bearings and other moving parts during the rebuild process.

- Cleaning Solution: A mild detergent or specific pump cleaning solution can help remove dirt, debris, and residue from the pump components.

- Safety Equipment: Ensure you have safety goggles, gloves, and hearing protection to protect yourself during the rebuilding process.

Having these tools and equipment readily available will save you time and frustration during the rebuilding process. It’s important to note that the specific tools needed may vary depending on the make and model of your pressure washer pump.

Before beginning the rebuild, make sure to read the manufacturer’s instructions or consult an online guide for your specific pump model. This will provide you with any additional tools or special instructions required for a successful rebuild.

Now that you’ve gathered the necessary tools and equipment, it’s time to move on to the safety precautions you should take when working with pressure washer pumps. Safety should always be a top priority to prevent accidents or injuries. Let’s proceed!

Safety Precautions

When working with pressure washer pumps, it’s crucial to prioritize safety to prevent accidents and injuries. The high pressure and mechanical components involved in rebuilding a pump can pose potential hazards if not handled properly. Here are some important safety precautions to follow:

- Wear Protective Gear: Always wear safety goggles to protect your eyes from debris or pressurized water. Additionally, use gloves to protect your hands and hearing protection to reduce noise-induced hearing damage.

- Disconnect Power: Before starting any work on the pressure washer, ensure that it is completely turned off and disconnected from any power source. This will prevent any accidental starts or electrical shocks.

- Depressurize the System: Release any built-up pressure by pulling the trigger on the spray gun or wand. This should be done before disassembling any components to avoid sudden releases of pressurized water.

- Proper Ventilation: Work in a well-ventilated area to prevent the buildup of fumes or carbon monoxide from exhaust gases. If working indoors, ensure proper ventilation or use exhaust fans to maintain a safe working environment.

- Secure the Pressure Washer: Place the pressure washer on a stable and level surface during the rebuilding process. This will prevent any accidental tipping or movement that could lead to injury.

- Follow Manufacturer’s Instructions: Always refer to the manufacturer’s instructions or user manual for your specific pressure washer pump model. This will provide you with any specific safety recommendations or precautions that you need to be aware of.

- Work in a Clean and Organized Area: Keep your work area clean and free of any clutter or obstructions. This will minimize the risk of tripping or falling during the rebuild process.

- Take Breaks: Rebuilding a pressure washer pump can be a time-consuming task. Take regular breaks to prevent fatigue, maintain focus, and ensure that you’re working safely and efficiently.

By following these safety precautions, you can minimize the risk of accidents or injuries while rebuilding your pressure washer pump. It’s important to prioritize safety at all times to ensure a successful and incident-free rebuild process.

Now that you’re aware of the necessary safety precautions, let’s dive into the step-by-step guide on how to rebuild a pressure washer pump. This will provide you with a detailed understanding of the rebuilding process and the necessary steps to restore your pump’s performance. Let’s proceed!

Regular maintenance of your pressure washer pump is crucial to ensure its longevity. Be sure to check and replace any worn or damaged seals, valves, or O-rings to prevent leaks and maintain optimal performance.

Step-by-Step Guide to Rebuilding a Pressure Washer Pump

Rebuilding a pressure washer pump may seem like a daunting task, but with the right guidance and a methodical approach, it can be accomplished successfully. Follow these step-by-step instructions to rebuild your pressure washer pump:

- Gather Your Tools and Equipment: Make sure you have all the necessary tools and equipment mentioned earlier in this guide. Having everything readily available will make the process smoother.

- Disconnect Power: Before starting the rebuild, disconnect the pressure washer from any power source to ensure your safety.

- Remove Pump from Pressure Washer: Depending on the design of your pressure washer, you may need to remove the pump from the machine. Refer to the manufacturer’s instructions for guidance on how to do this properly.

- Depressurize and Drain the Pump: Release any built-up pressure by triggering the spray gun or wand. Then, drain any remaining water from the pump by tilting it or using a drainage plug if applicable.

- Dismantle the Pump: Carefully disassemble the pump, starting with the outer housing and removing screws or bolts. Take pictures or make notes of how the components are arranged for easier reassembly later.

- Inspect and Clean the Components: Thoroughly inspect each component for any signs of damage or wear. Clean all parts with a mild detergent or specific pump cleaning solution to remove dirt, debris, and residue.

- Replace Seals, O-rings, and Valves: Using the rebuild kit, replace any worn-out or damaged seals, O-rings, and valves with the new ones provided. Follow the manufacturer’s instructions for proper installation.

- Lubricate Moving Parts: Apply a small amount of pump grease to bearings and other moving parts to ensure smooth operation. Avoid using excessive grease, as it can cause clogs or other issues.

- Reassemble the Pump: Refer to your notes or pictures taken during disassembly to guide you in putting the pump back together. Pay attention to the correct placement and alignment of each component.

- Reinstall the Pump: Once the pump is reassembled, reinstall it into the pressure washer following the manufacturer’s instructions. Ensure proper connections of hoses and fittings.

- Test the Pump: Before using the pressure washer, test the rebuilt pump by running it without the high-pressure nozzle attached. Check for any leaks, unusual noises, or other issues.

- Perform a Test Run: Once you’re satisfied that the pump is functioning properly, perform a test run with water to ensure optimal performance and pressure output.

Following these steps will guide you through the process of rebuilding your pressure washer pump. Remember to exercise patience and attention to detail to ensure a successful rebuild. If you encounter any difficulties or have specific questions, consult the manufacturer’s instructions or reach out to a professional for assistance. Congratulations on rebuilding your pressure washer pump!

In the next section, we will address some common troubleshooting issues and provide maintenance tips to help extend the life of your pressure washer pump. Let’s continue!

Read more: How To Adjust Pressure On Pressure Washer

Troubleshooting and Common Issues

While rebuilding your pressure washer pump can significantly improve its performance, there may still be instances when troubleshooting is necessary. Here are some common issues you may encounter and some troubleshooting tips:

- Low Pressure: If your pressure washer is experiencing low pressure, first check the inlet filter screen for any clogs or debris. Clean or replace it if necessary. Inspect the seals and O-rings for leaks or damage and replace them if needed. Finally, ensure that the nozzle or spray tip is free from any obstructions.

- No Pressure: If you’re not getting any pressure from your pressure washer, check the inlet water supply first. Ensure that the water source is turned on and providing sufficient flow rate. Inspect the pump components for any signs of damage or wear, especially the valves and pistons. Replace any faulty components as necessary.

- Leaking Water: If you notice water leaking from your pump, check the seals, O-rings, and connections for any damage or improper installation. Make sure these components are correctly seated and tightened. If the issue persists, consider replacing the affected seals or O-rings.

- Excessive Noise: Unusual or excessive noise coming from your pressure washer pump may indicate a problem. Inspect the bearings and other moving parts for any signs of damage. Lubricate them properly with pump grease or replace them if necessary.

- Pump Not Priming: If the pump fails to prime and draw in water, check the inlet hose for any blockages or kinks. Ensure that the inlet valve is free from debris and properly functioning. If the problem persists, consider replacing the inlet valve.

- Overheating: If your pressure washer pump is overheating, it may be due to excessive use or insufficient water flow. Check that the water supply is adequate and that the intake hose is not obstructed. Allow the pump to cool down between uses or consider using a higher flow rate nozzle to reduce strain on the pump.

If you encounter any issues with your pressure washer pump that are beyond your troubleshooting abilities, it’s advisable to consult the manufacturer’s instructions or seek assistance from a professional. Regular maintenance and proper care can help prevent many of these common issues and extend the life of your pressure washer pump.

In the next section, we will provide you with some maintenance tips to keep your pressure washer pump in optimal condition. Let’s proceed!

Maintenance Tips for Extending Pump Life

Maintaining your pressure washer pump is essential for ensuring its longevity and optimal performance. By following these simple maintenance tips, you can extend the life of your pump:

- Check and Clean the Inlet Filter: Regularly inspect the inlet filter screen for any debris or clogs. Clean or replace the filter to ensure proper water flow and prevent damage to the pump.

- Monitor Water Supply: Ensure that your pressure washer is receiving an adequate and consistent water supply. Insufficient water flow can put strain on the pump and lead to overheating or other issues.

- Lubricate Moving Parts: Keep the bearings, pistons, and other moving parts properly lubricated with pump grease. This reduces friction and extends the life of these components.

- Store Properly: When not in use, store your pressure washer in a dry and clean environment. Protect it from extreme temperatures, direct sunlight, and any potential damage or impacts.

- Flush and Drain the System: After each use, flush the pump system with clean water to remove any dirt or debris. Once flushed, drain any remaining water to prevent freezing or corrosion.

- Inspect and Replace Seals: Regularly inspect the seals and O-rings for any signs of wear, leaks, or damage. Replace them promptly to prevent water leaks and maintain optimal pressure.

- Perform Regular Maintenance Checks: Regularly check the pump components, hoses, and connections for any signs of damage, leaks, or wear. Address any issues promptly to prevent further damage or performance decline.

- Follow Proper Start-Up and Shutdown Procedures: Always follow the manufacturer’s instructions for starting up and shutting down your pressure washer. This ensures that the pump is properly primed and decompressed, prolonging its life.

- Use the Recommended Cleaning Solutions: Ensure that you use the appropriate cleaning solutions and chemicals recommended for your pressure washer pump. Using improper chemicals can cause damage and affect performance.

- Keep a Maintenance Schedule: Create a regular maintenance schedule to perform routine checks, cleanings, and replacements as needed. This helps you stay on top of maintenance tasks and ensures the longevity of your pump.

By following these maintenance tips, you can keep your pressure washer pump in optimal condition, prolonging its life and enjoying consistent performance. Regular maintenance is key to preventing major issues and saving you time and money on costly repairs.

Now that you have a better understanding of pressure washer pump maintenance, let’s conclude our guide in the next section.

Conclusion

Congratulations! You have reached the end of our comprehensive guide on how to rebuild a pressure washer pump. We have covered everything from understanding pressure washer pumps to the step-by-step process of rebuilding, troubleshooting common issues, and maintenance tips to extend the life of your pump.

Rebuilding a pressure washer pump can save you time and money by restoring its performance and avoiding the need for a new pump. Understanding the inner workings of the pump, gathering the right tools and equipment, and following safety precautions are crucial for a successful rebuild.

By following our step-by-step guide, you can confidently dismantle, diagnose, and rebuild your pressure washer pump. Remember to take your time, inspect and clean the components, replace any worn-out parts with the ones from the rebuild kit, and properly lubricate the moving parts. With careful assembly and testing, your pump should be back in action!

In case you encounter any issues or need assistance beyond your expertise, it’s always advisable to consult the manufacturer’s instructions or seek help from a professional. Safety should be prioritized throughout the rebuild process, and regular maintenance checks should be performed to prolong the life of your pump.

We hope that this guide has been informative and helpful in equipping you with the knowledge and confidence to tackle a pressure washer pump rebuild. By following the steps and tips outlined here, you can keep your pressure washer running smoothly and efficiently for years to come.

Thank you for reading, and happy pressure washer pump rebuilding!

Frequently Asked Questions about How To Rebuild A Pressure Washer Pump

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Rebuild A Pressure Washer Pump”