Articles

How To Set Up A Woodworking Shop

Modified: January 19, 2024

Learn how to set up a woodworking shop with our helpful articles. From tools to layout, we have everything you need to get started on your woodworking projects.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to the exciting world of woodworking! Whether you are a beginner looking to embark on a new hobby or a seasoned woodworker wanting to set up a dedicated space, designing and organizing your woodworking shop is crucial for optimal productivity and enjoyment.

Having a well-equipped woodworking shop allows you to unleash your creativity and turn raw materials into beautiful and functional pieces. But where do you begin? In this article, we’ll guide you through the essential steps to help you set up a woodworking shop that is tailored to your needs.

From planning the layout and selecting the right tools to optimizing storage space and ensuring safety, we will cover all the key aspects that go into creating a functional and efficient woodworking shop.

So, let’s dive in and discover the steps to transform your workshop into a woodworking haven!

Key Takeaways:

- Planning and organizing your woodworking shop is crucial for creating a space that inspires creativity and productivity. Consider factors such as layout, location, and safety to optimize your woodworking experience.

- Prioritize safety by implementing proper tool storage, wearing protective gear, and following best practices for machinery operation. By creating a safe and organized workspace, you can reduce the risk of accidents and injuries.

Read more: Where Do Landscapers Shop For Hand Tools

Planning Your Woodworking Shop

Before you start setting up your woodworking shop, it is crucial to invest time in the planning phase. Proper planning will help you make the most of your available space and ensure that your shop is organized and efficient.

Begin by assessing your needs and goals. Consider the type of projects you intend to work on and the tools and equipment you will require. This will help determine the size of your shop and the specific features it should have.

Next, create a detailed floor plan of your woodworking shop. Measure the dimensions of the space and sketch out where each item will be placed, including workbenches, tools, and storage areas. This plan will serve as a blueprint for your shop layout and help you visualize the optimal arrangement.

Think about the flow of your workspace. Keep in mind that you’ll want easy access to your tools and materials, as well as plenty of maneuvering space to work on your projects. Consider both the functional and ergonomic aspects of your shop design.

Additionally, think about any specific requirements related to noise, ventilation, and natural light. If possible, place your workstation near windows to benefit from natural light, and ensure you have proper ventilation to keep the air in your shop clean and safe.

Finally, establish a budget for your woodworking shop. Determine how much you are willing to spend on equipment, tools, and storage solutions. By establishing a budget from the beginning, you can make more informed decisions when purchasing items for your shop.

Overall, the key to planning your woodworking shop is to prioritize efficiency, functionality, and comfort. By thoroughly planning the layout and considering your specific needs, you will be able to create a workspace that is conducive to creativity and productivity.

Selecting the Right Location

Choosing the right location for your woodworking shop is essential for creating a productive and enjoyable workspace. Here are some factors to consider when selecting the location:

1. Space: Assess the amount of space you have available for your woodworking shop. Consider the size of your projects and the equipment you will be using. Ensure that the location can accommodate your needs comfortably and provide enough room for storage and maneuvering.

2. Accessibility: Opt for a location that is easily accessible. If possible, choose a space that is close to your home or has convenient access to highways or main roads. This will make it easier for you to transport materials and equipment to and from your shop.

3. Noise Considerations: Woodworking can be noisy, especially if power tools are involved. Take into account your neighbors and the noise restrictions in your area. If you anticipate noise being an issue, select a location that is more isolated or consider soundproofing the walls to minimize disruption.

4. Utilities: Ensure that your chosen location has access to electrical power and adequate lighting. Depending on the types of tools and machinery you plan to use, you may also need access to water for cleaning or cooling purposes.

5. Ventilation: Woodworking can create dust and fumes, so good air ventilation is crucial. Choose a location that allows for proper airflow to keep your workspace clean and safe. If necessary, you can install a ventilation system or consider opening windows or using fans to improve air circulation.

6. Safety Considerations: Assess the safety of the location. Look for any potential hazards, such as overhead pipes or electrical wiring, that could interfere with your operations. Additionally, ensure that there are fire prevention measures in place, such as fire extinguishers or smoke detectors.

Remember, the location of your woodworking shop will have a significant impact on your overall experience. Take the time to carefully evaluate different options and choose a location that best suits your needs, while also considering the practicality and potential limitations of the space.

Essential Tools for Your Woodworking Shop

Setting up a woodworking shop requires having the right tools to complete your projects with precision and efficiency. While the specific tools you need may vary depending on the type of woodworking you plan to pursue, here are some essential tools that every woodworking shop should have:

- Workbench: A sturdy and well-built workbench is the foundation of any woodworking shop. Look for a workbench that is large enough to accommodate your projects and has a durable surface for cutting, drilling, and assembling.

- Power Tools: Power tools are essential for fast and accurate woodworking. Some must-have power tools include a table saw, miter saw, router, drill press, and power sander. These tools will help you cut, shape, and finish your workpieces effectively.

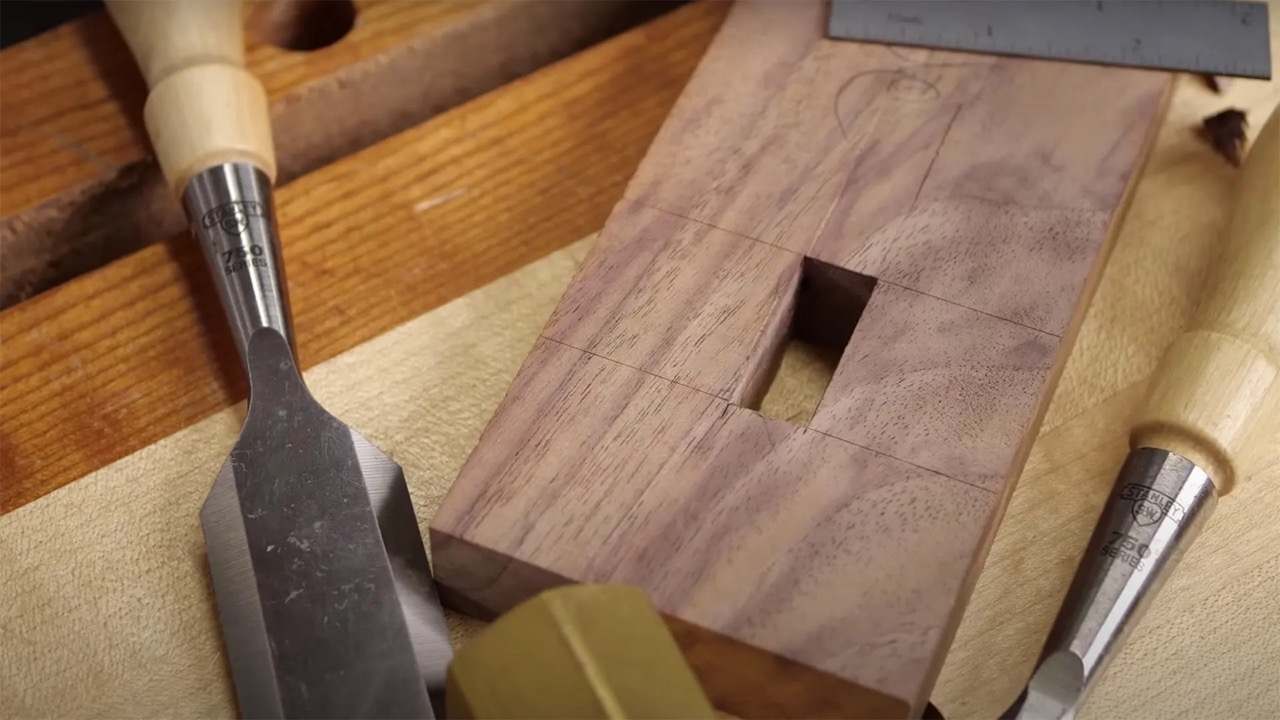

- Hand Tools: While power tools are convenient, hand tools are equally important for finer and more delicate woodworking tasks. Invest in quality hand tools such as chisels, hand planes, screwdrivers, mallets, and layout tools like a combination square and tape measure.

- Clamps: Clamps are indispensable for holding workpieces together while the glue dries or when you need extra support during assembly. Having a variety of clamps in different sizes and types, such as bar clamps, pipe clamps, and spring clamps, will greatly enhance your woodworking capabilities.

- Safety Equipment: Prioritize safety in your woodworking shop by having the necessary protective equipment, including safety glasses, dust masks or respirators, ear protection, and gloves. These items will help keep you safe from potential hazards and ensure a healthy working environment.

- Measuring and Marking Tools: Accurate measurements are crucial in woodworking. Invest in a good quality tape measure, combination square, marking gauge, and marking knife to ensure precision in your work.

- Sharpening Tools: Sharp tools are essential for clean and precise woodworking. Have sharpening tools like sharpening stones or honing guides to keep your chisels, planes, and other cutting tools sharp and ready to use.

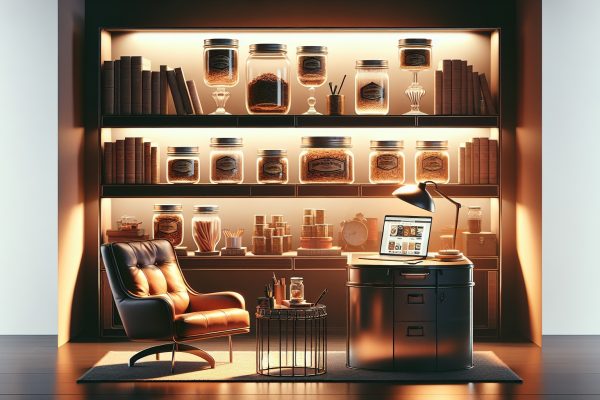

- Storage and Organization: To keep your woodworking shop tidy and efficient, invest in storage solutions such as drawers, shelves, and tool cabinets. Proper organization will save you time and ensure that your tools and materials are easily accessible.

Remember that the tools mentioned above are just the basics. Depending on your woodworking projects, you may require additional specialized tools. It’s always a good idea to research and consult with experienced woodworkers to determine the specific tools you need for your desired woodworking endeavors.

Setting Up Your Workbench

Your workbench is the heart of your woodworking shop, where you’ll spend a significant amount of time crafting and assembling your projects. Here are some key considerations when setting up your workbench:

Workbench Height: The height of your workbench is crucial for comfortable and efficient working. Consider your own height and preferences when determining the ideal height. As a general guideline, the workbench should be at a height that allows you to work without straining your back or arms.

Sturdiness and Stability: A sturdy and stable workbench is essential for accurate and safe woodworking. Choose a workbench that is built from high-quality materials and has a solid construction. This will ensure that your workbench can withstand the weight of your projects and the pressure applied during tasks such as sawing or chiseling.

Workbench Size: The size of your workbench will depend on the available space in your woodworking shop and the type of projects you plan to undertake. Seek a workbench that provides ample surface area for your projects, as well as enough storage space for tools, materials, and accessories.

Workbench Vise: Consider adding a vise to your workbench. A vise will allow you to securely hold your workpieces in place while you work on them, providing stability and accuracy. Look for a vise that is easy to adjust and has a strong grip to accommodate various sizes and shapes of workpieces.

Lighting: Adequate lighting is essential for ensuring clear visibility of your work. Install task lighting above or near your workbench to illuminate your projects. Consider using adjustable lighting options to direct light exactly where you need it.

Power Outlets: Having power outlets conveniently placed near your workbench will allow you to easily plug in and operate power tools without the hassle of extension cords. Consider installing multiple outlets to accommodate various tools and accessories.

Organization: Keep your workbench organized to maximize efficiency. Utilize drawers, shelves, and pegboards to store and access your frequently used tools and accessories. Consider using tool holders and dividers to keep everything neat and easily accessible.

Covering or Protection: Protect your workbench surface by using a sacrificial cover such as a hardboard or plywood sheet. This will prevent damage to the workbench surface when cutting or drilling into your workpieces.

By taking the time to set up your workbench properly, you’ll create a functional and comfortable workspace where you can tackle your woodworking projects with ease and precision. Remember to regularly maintain and clean your workbench to ensure its longevity and optimal performance.

When setting up a woodworking shop, prioritize safety by ensuring proper ventilation, good lighting, and a clear, organized layout to minimize hazards.

Read more: How Home Decor Shops Fill Up Their Walls

Organizing Your Shop Layout

Creating an organized layout for your woodworking shop is essential for maximizing productivity and efficiency. A well-organized shop allows you to easily locate and access tools, materials, and equipment, saving you time and reducing frustration. Here are some tips to help you organize your shop layout:

Zoning: Divide your woodworking shop into functional zones to create a logical flow. Some common zones to consider include a work area, assembly area, tool storage area, and finishing area. This zoning will help you keep similar activities and tools together, making it easier to find what you need when you need it.

Clear Pathways: Ensure there are clear and unobstructed pathways between the different zones in your shop. This will allow you to move around freely without any potential trip hazards. Keep in mind the size of your projects and the space required for maneuvering.

Workbench Placement: Position your workbench in a central location that provides easy access to tools and materials. This will serve as your primary workstation and should be within reach of your frequently used tools and storage areas.

Tool Storage: Properly storing and organizing your tools is crucial for efficiency. Utilize tool cabinets, pegboards, or wall-mounted racks to keep your tools well-organized and easily accessible. Consider organizing them by type or frequency of use to further streamline your workflow.

Material Storage: Invest in storage solutions, such as shelves or racks, to keep your materials neatly stored and readily available. Organize them by type and size to make it easy to locate the materials you need for your projects.

Labeling and Inventory: Labeling your storage areas and containers can save you time and effort when searching for specific items. Consider using color-coded labels or clear containers for easy identification. Additionally, maintaining an inventory of your supplies and materials can help you keep track of what you have and when it needs replenishing.

Workspace Organization: Keep your work area clutter-free to create a focused and safe workspace. Clear away unnecessary tools and materials, and periodically clean up wood chips and sawdust. Use bins or containers to collect scraps and dispose of them properly.

Flexibility: Your shop layout should be adaptable to accommodate different project sizes and types. Consider incorporating mobile or adjustable workstations and storage units that can be easily reconfigured when needed.

Remember, organizing your shop layout is an ongoing process. Regularly evaluate and refine your organization methods to ensure they continue to meet your needs as your woodworking skills and projects evolve.

Maximizing Storage Space

Having ample storage space in your woodworking shop is crucial for keeping your tools, materials, and supplies organized and easily accessible. Proper storage not only helps optimize workflow but also ensures the longevity of your tools and equipment. Here are some tips to maximize storage space in your shop:

Utilize Vertical Space: Take advantage of the vertical space in your shop by installing wall-mounted shelves, racks, or cabinets. This will free up valuable floor space and provide additional storage options for tools, containers, and materials.

Modular Storage Systems: Invest in modular storage systems that can be customized and adjusted to fit your specific needs. These systems often include adjustable shelving, drawers, and wall panels with various accessory attachments, allowing you to create a flexible and efficient storage solution.

Overhead Storage: Consider installing overhead storage racks or shelves to utilize the often underutilized space near the ceiling. This is an ideal location for storing less frequently used items or long and bulky materials like lumber.

Drawer Organizers: Use drawer organizers or divider trays to keep small tools and accessories neatly organized and easily accessible. This will help prevent cluttered drawers and make it quicker to find the items you need.

Pegboards: Install pegboards on your shop walls for efficient tool storage. Arrange hooks and holders on the pegboard to hang tools such as wrenches, pliers, and screwdrivers. This allows for easy visibility and accessibility of your frequently used hand tools.

Rolling Tool Carts: Invest in rolling tool carts or utility carts with multiple drawers and shelves. These carts provide mobile storage and can be easily moved around your shop, maximizing convenience and flexibility.

Bins and Containers: Use bins and containers to group and store similar items together. Label the containers to clearly identify their contents, making it easier to locate specific items when needed. Opt for stackable containers to save space and keep your shop organized.

Under-Bench Storage: Make use of the space under your workbench by adding shelves or drawers. This allows you to store tools or materials that you frequently use during your projects, keeping them within reach but out of the way when not in use.

Optimize Corner Space: Corner spaces can often be overlooked, but they offer excellent storage potential. Consider installing corner shelves or utilizing corner cabinets to maximize storage in these areas.

Regular Purging: Regularly assess and purge items that are no longer needed or used. This will help declutter your shop and create more available storage space for essential tools and materials.

By implementing these storage strategies, you can effectively utilize the available space in your woodworking shop and create a clean, organized, and efficient workspace.

Electrical Considerations for Your Shop

When setting up your woodworking shop, it’s important to consider the electrical requirements to power your tools and equipment safely and efficiently. Here are some key electrical considerations to keep in mind:

Adequate Power Supply: Assess the electrical capacity of your shop and determine if it can support the power requirements of your tools and machinery. Consult with a licensed electrician to ensure that your electrical system can handle the load and make any necessary upgrades if needed.

Dedicated Circuits: Allocate dedicated circuits for large power-consuming tools such as table saws, jointers, and planers. This helps prevent overloading and tripping breakers, ensuring consistent power supply to these important tools.

Multiple Outlets: Install multiple outlets throughout your shop to conveniently power different tools and equipment. This avoids the need for excessive use of extension cords, reducing clutter and potential tripping hazards.

Ground Fault Circuit Interrupter (GFCI) Outlets: Use GFCI outlets in areas where the risk of electrical shock is higher, such as near water sources or in damp environments. GFCI outlets are designed to quickly shut off power in the event of a ground fault, providing an added layer of safety.

Proper Wiring and Insulation: Ensure that all electrical wiring and connections are properly installed and insulated. This reduces the risk of electrical malfunctions and potential fire hazards. It is advisable to hire a professional electrician to handle all wiring installations and modifications.

Convenient Switch Placement: Position light switches and power switches in easily accessible locations near the entrance of your shop or at key workstations. This allows for quick and convenient control of the lighting and power supply as you enter or exit your shop or while working on specific projects.

Task Lighting: Install ample task lighting above your workbenches and other work areas. This ensures proper illumination for detailed and precise woodworking tasks. Consider using LED lights for energy efficiency and reduced heat emission.

Emergency Power Backup: Consider having an emergency power backup system, such as a generator or uninterruptible power supply (UPS), to keep essential tools and equipment running during power outages. This prevents work disruptions and protects unfinished projects.

Electrical Safety Measures: Educate yourself about electrical safety practices, such as avoiding overloading outlets, properly grounding equipment, and using surge protectors. Follow manufacturer’s instructions for the safe use of your tools and machinery, and always unplug equipment when not in use or during maintenance.

Remember, electrical safety is of utmost importance in your woodworking shop. If you are unsure about any electrical installations or modifications, consult with a qualified electrician to ensure compliance with local electrical codes and best practices.

Safety Measures in Your Woodworking Shop

Creating a safe working environment is crucial when setting up your woodworking shop. Woodworking involves the use of sharp tools, power machinery, and potentially hazardous materials. Here are some important safety measures to implement:

Protective Gear: Wear appropriate personal protective equipment (PPE) when working in your shop. This includes safety glasses or goggles, hearing protection, a dust mask or respirator, and sturdy footwear. PPE helps protect your eyes, ears, lungs, and body from potential injuries or exposure to hazardous materials.

Sharp Tool Handling: Handle sharp tools with care. Keep blades properly sharpened and securely fastened in their respective tools. Always cut away from your body and maintain a firm grip on tools to prevent slips or accidents. When not in use, store your tools in a designated area or with protective covers to avoid accidental injuries.

Dust Collection: Woodworking generates a significant amount of dust. Install a dust collection system or use a shop vacuum with proper attachments to effectively remove and contain sawdust and debris. Regularly clean your shop and empty the dust collection system to maintain a clean and healthy working environment.

Machinery Safety: Follow manufacturer guidelines and instructions for the safe operation and maintenance of all power tools and machinery. Ensure that guards and safety features are in place and functional. Avoid wearing loose clothing or jewelry that can become entangled in moving parts. Disconnect power sources or lockout/tagout machinery when making adjustments or performing maintenance.

Fire Safety: Implement fire safety measures in your shop. Keep a fire extinguisher accessible and ensure it is regularly inspected and charged. Store flammable materials in designated cabinets or away from heat sources. Install smoke detectors and consider having a fire escape plan in place.

Proper Material Handling: When handling and moving materials, use proper lifting techniques to avoid strain or injury. Additionally, be cautious when working with heavy or awkwardly shaped materials to maintain balance and prevent accidents. Use appropriate tools such as dollies or forklifts to assist in moving larger pieces.

Clear Work Area: Maintain a clutter-free work area to prevent tripping hazards. Keep your shop organized and ensure that tools, materials, and cords are properly stored when not in use. Sweep up sawdust and clean up spills promptly to maintain a safe and clean working environment.

Training and Education: Continuously educate yourself on woodworking safety practices and techniques. Attend workshops, classes, or seek guidance from experienced woodworkers to enhance your knowledge and skills. Stay informed about any updates or recalls related to your tools and equipment.

Remember, safety should always be a top priority in your woodworking shop. By implementing these safety measures and maintaining awareness of potential hazards, you can create a secure and enjoyable working environment for yourself and others.

Conclusion

Setting up a woodworking shop is an exciting venture that allows you to turn your creative ideas into tangible pieces of art. By carefully planning your shop layout, selecting the right location, and organizing your tools and materials, you can create a workspace that is efficient, comfortable, and safe.

Remember to consider important factors such as adequate space, accessibility, and electrical requirements when designing your shop. Maximize storage space and prioritize safety by implementing proper tool and material storage, utilizing safety gear, and following best practices for tool handling and machinery operation.

Your workbench serves as the centerpiece of your shop, so ensure it is sturdy, properly set up, and well-lit to facilitate your woodworking projects effectively. Additionally, maintaining a clean and organized workspace not only enhances your workflow but also ensures a clutter-free and safe environment.

Always prioritize safety in your woodworking shop. Wear the appropriate protective gear, ensure your tools are in good condition, and practice safe working habits. By following these safety measures, you can reduce the risk of accidents and injuries.

Ultimately, the key to a successful woodworking shop lies in your ability to create a space that inspires creativity, efficiency, and enjoyment. Whether you are a beginner or an experienced woodworker, taking the time to plan, organize, and optimize your shop will enable you to embark on woodworking projects with confidence.

So, go ahead and set up your woodworking shop with care and attention to detail. Let your imagination run wild as you embark on this woodworking journey, creating beautiful and functional pieces that will bring joy to yourself and others.

Frequently Asked Questions about How To Set Up A Woodworking Shop

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Set Up A Woodworking Shop”