Home>diy>Building & Construction>What Is A Shop Drawing In Construction

Building & Construction

What Is A Shop Drawing In Construction

Modified: January 9, 2024

Learn about shop drawings in building construction and why they are essential for accurate project execution. Gain insights into their purpose and importance in construction processes.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

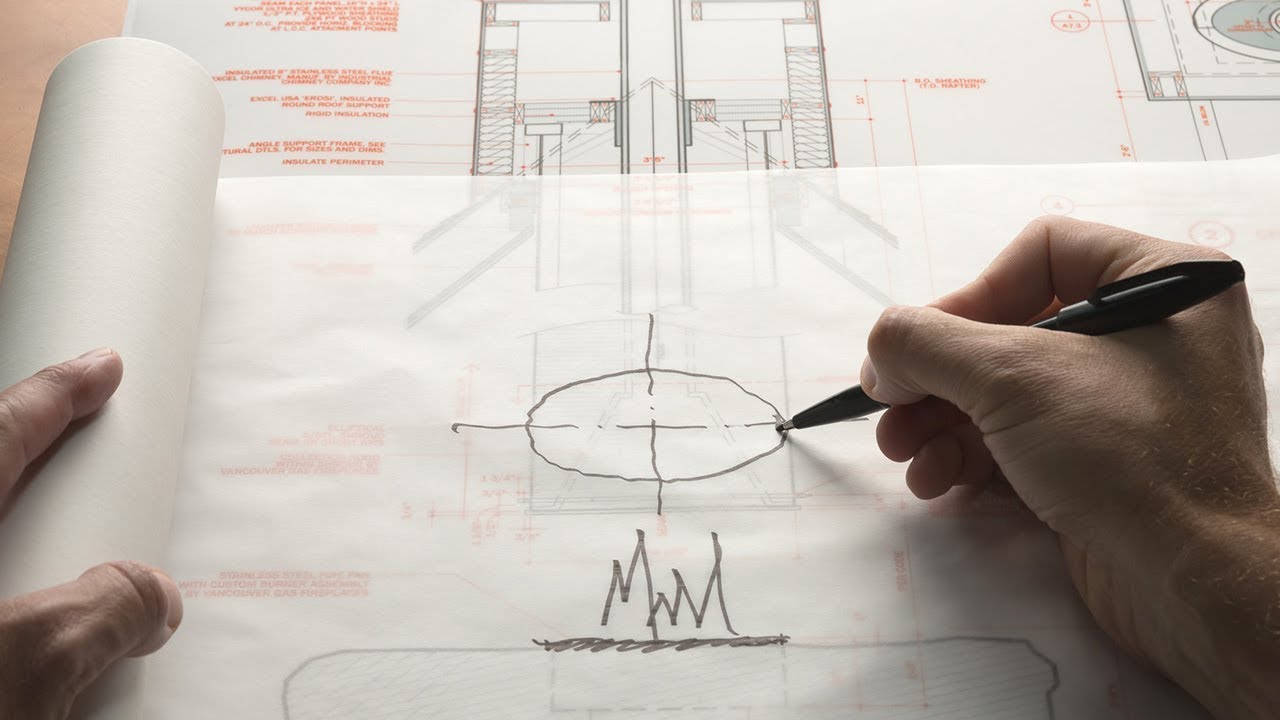

When it comes to construction projects, accuracy and precision are paramount. From engineering to architecture, every aspect of a construction project requires meticulous planning and attention to detail. One crucial element in this process is the creation and utilization of shop drawings.

In this article, we will explore what exactly a shop drawing is, its purpose, the importance of using shop drawings in construction, the process involved in creating them, the different components they include, various types of shop drawings, benefits of using shop drawings, and the challenges that may arise during their creation.

So, let’s delve into the world of shop drawings and discover how they play a vital role in the construction industry.

Key Takeaways:

- Shop drawings are detailed, technical drawings that bridge the gap between design intent and construction implementation. They enhance accuracy, coordination, and communication, contributing to the success of construction projects.

- Despite challenges such as interpretation of design intent and time constraints, effective project management, communication, and technology can overcome hurdles in creating accurate and high-quality shop drawings.

Read more: What Are Construction Drawings

Definition of Shop Drawing

A shop drawing is a detailed, dimensioned, and technical drawing created by contractors, fabricators, or manufacturers that illustrates the specific components, materials, and construction methods for a particular element of a construction project. It provides a visual representation of how various parts or systems in the project will be manufactured, installed, and assembled.

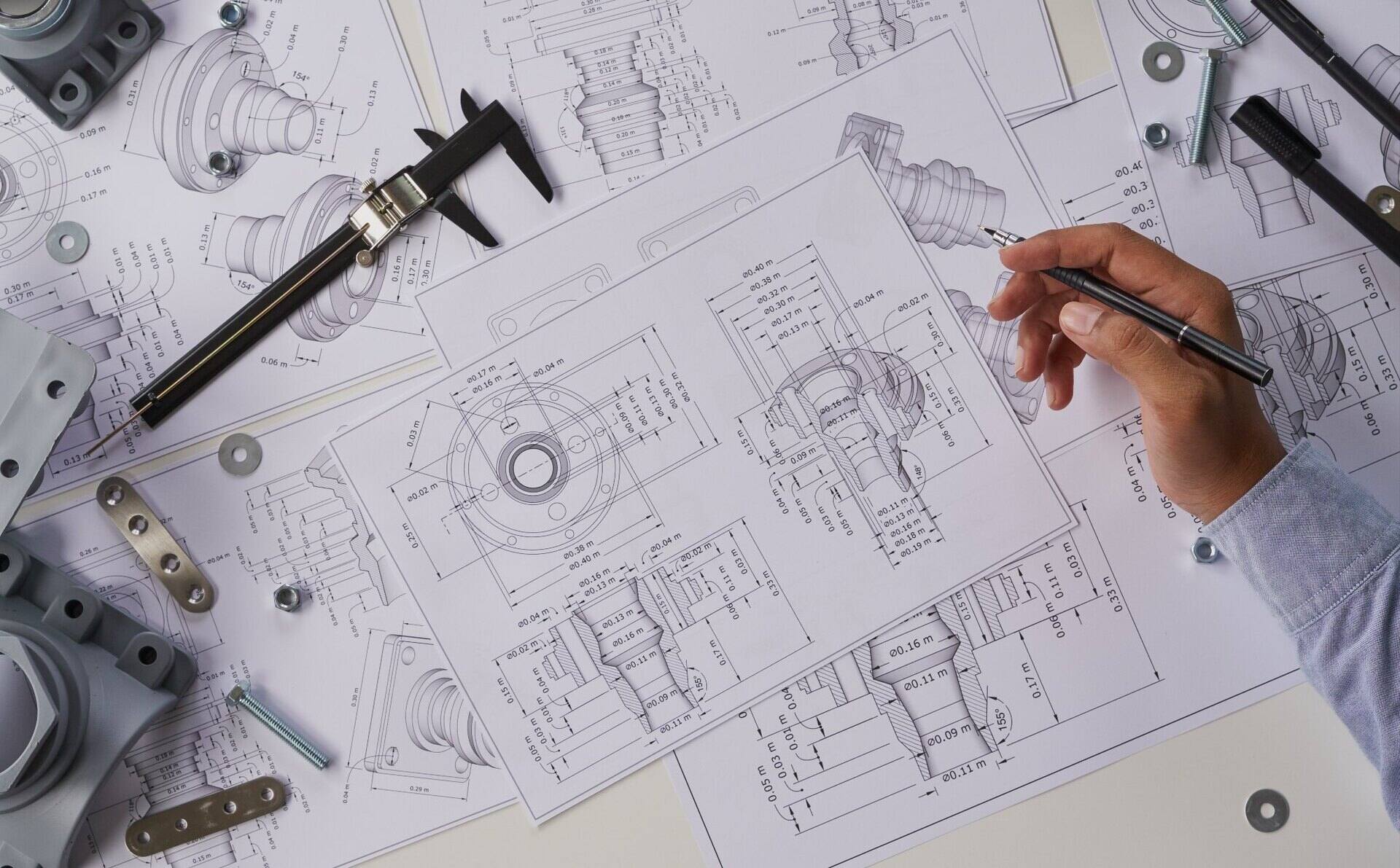

Unlike architectural or engineering drawings that provide a broader overview of the project, shop drawings focus on the specific details of individual items, such as structural elements, mechanical systems, electrical components, or architectural finishes. These drawings serve as a guideline for construction teams and contractors to accurately fabricate, install, and construct the project according to the approved design and specifications.

Shop drawings are typically created using computer-aided design (CAD) software or other drafting tools. They are usually prepared by subcontractors or manufacturers who specialize in their respective trades, such as steel fabricators, MEP (mechanical, electrical, and plumbing) contractors, or millwork shops.

These drawings are typically accompanied by a Bill of Materials (BOM), which lists all the materials required for construction, including quantities and specifications. Additionally, shop drawings may also include fabrication details, assembly instructions, connection details, and other relevant information specific to the item being depicted.

Overall, shop drawings act as a critical communication tool between the design team, contractors, and suppliers, ensuring that everyone involved in the construction process has a clear understanding of how different elements of the project will come together.

Purpose of Shop Drawing

The primary purpose of shop drawings in construction is to bridge the gap between the design intent and the actual implementation of the project. These detailed drawings serve several crucial purposes that contribute to the successful execution of a construction project.

Firstly, shop drawings enable contractors and subcontractors to visualize and understand the specific requirements for each component or system of the project. By providing a detailed representation of the design, shop drawings help ensure that everyone involved is on the same page and can accurately interpret and execute the plans.

Secondly, shop drawings play a vital role in coordination among different trade disciplines. They allow the various subcontractors and suppliers to coordinate their work and ensure that all components fit together smoothly. For example, mechanical shop drawings will show how the HVAC system integrates with other elements, such as ductwork and electrical systems.

Furthermore, shop drawings provide a means for quality control and verification. Contractors can review these drawings to ensure that the proposed materials, dimensions, and construction methods comply with the project’s specifications and codes. This helps identify any potential clashes or conflicts early on, reducing the risk of mistakes or rework during construction.

Another purpose of shop drawings is to assist in obtaining approvals and permits. These detailed drawings provide the necessary documentation and visual representation required for authorities and building inspectors to review and approve the proposed construction details. This is particularly important for complex projects that involve intricate components or custom fabrication.

Additionally, shop drawings serve as a reference for fabrication and installation. Manufacturers and subcontractors can use these drawings to guide the fabrication process, ensuring that components are built to the required specifications. Contractors can also reference the drawings during installation to ensure proper alignment, connection, and overall construction quality.

Overall, the purpose of shop drawings is to facilitate effective communication, coordination, and implementation of the project, ensuring that the design intent is realized accurately and efficiently.

Importance of Shop Drawing in Construction

Shop drawings are an integral part of the construction process, bringing numerous benefits and contributing to the successful completion of a project. The importance of using shop drawings can be seen in several key areas:

1. Accuracy and Precision: Shop drawings provide precise details and measurements for each component and system in the project. By outlining the exact dimensions, materials, and construction methods, shop drawings help ensure that the final product meets the design intent and specifications with utmost accuracy.

2. Coordination and Collaboration: The construction process involves various subcontractors, suppliers, and trades who need to work together seamlessly. Shop drawings facilitate coordination among these different parties, allowing them to understand how their work integrates and interfaces with other components. This collaborative approach helps minimize conflicts and ensures components fit together smoothly on-site.

3. Clarity and Communication: Shop drawings serve as a visual communication tool, helping all stakeholders to understand and visualize the project details. With detailed drawings, misunderstandings and confusion are minimized, enabling everyone involved to have a clear understanding of the expectations and requirements for each element of the project.

4. Quality Assurance: Shop drawings allow for thorough quality control and verification. Contractors and project managers can review the drawings to ensure that the proposed materials, dimensions, and construction methods comply with industry standards, regulations, and project specifications. By catching and rectifying any potential issues beforehand, the use of shop drawings helps maintain high quality throughout the construction process.

5. Efficiency and Time Savings: By providing a detailed plan of each component, shop drawings help streamline the construction process. With clear instructions on fabrication and installation, contractors can work more efficiently, reducing the risk of errors, delays, and rework. The use of shop drawings also helps avoid costly changes or modifications during or after construction.

6. Compliance and Approvals: Authorities and building inspectors often require detailed documentation to review and approve construction plans. Shop drawings provide the necessary visual representation and technical information, facilitating the approval process and ensuring compliance with local building codes and regulations.

In summary, shop drawings play a vital role in construction by enhancing accuracy, coordination, communication, quality control, and project efficiency. Their importance cannot be overstated, as they contribute to the overall success of a construction project, from design to execution.

Process of Creating Shop Drawings

Creating shop drawings requires a systematic and detailed process to ensure accuracy and consistency. While the specific steps may vary depending on the project and the trade involved, the general process of creating shop drawings can be outlined as follows:

- Gather Project Information: The first step in creating shop drawings is to gather all relevant project information, including architectural and engineering drawings, specifications, design plans, and any other necessary documentation. This information serves as the foundation for developing accurate and detailed shop drawings.

- Understanding Design Intent and Specifications: It is crucial to thoroughly review and understand the design intent and project specifications. This involves studying the architectural and engineering drawings, analyzing the materials and dimensions specified, and comprehending any specific requirements or constraints outlined in the project documentation.

- Measurement and Field Survey: If applicable, the next step is to conduct field measurements or surveys to ensure precise dimensions and documentation of existing conditions. This is particularly important for retrofit or renovation projects, where accurate measurements are essential for proper integration of new components with the existing structure.

- Drafting and Detailing: Using Computer-Aided Design (CAD) software or other drafting tools, the next step involves translating the design intent into detailed drawings. This includes creating accurate representations of each component, including dimensions, materials, connections, and any necessary assembly or installation instructions. The level of detail may vary depending on the specific trade and complexity of the project. Attention to detail and accuracy are paramount during this stage.

- Review and Coordination: Once the initial shop drawings are completed, they should be reviewed for accuracy, compliance with project specifications, and coordination with other trade disciplines. Coordination meetings may be held with relevant stakeholders, such as engineers, architects, and subcontractors, to address any conflicts or discrepancies and ensure seamless integration of all components.

- Revisions and Finalization: Based on feedback and coordination meetings, revisions to the shop drawings may be necessary. This iterative process continues until all parties are satisfied with the accuracy, clarity, and completeness of the drawings. Once approved, the shop drawings are considered final and are ready for use during the construction phase.

Throughout the entire process, effective communication and collaboration among stakeholders are essential to address any challenges or changes that may arise. By following a structured and systematic approach, the creation of shop drawings ensures that all critical details and specifications are accurately translated into a comprehensive set of construction documents.

A shop drawing in construction is a detailed drawing that shows the installation and fabrication of materials. It is important to review and approve shop drawings to ensure they align with the design intent and project requirements.

Read more: What Size Are Construction Drawings

Components of a Shop Drawing

Shop drawings consist of several key components that provide a detailed and comprehensive depiction of each element or system in a construction project. These components work together to communicate the necessary information for fabrication, installation, and construction. The main components of a typical shop drawing include:

- Title Block: The title block is located at the top of the drawing and contains essential project information, such as the project name, drawing number, designer/contractor details, date of creation, and revision history. It serves as a reference and helps track the version and status of the shop drawing.

- General Notes: General notes provide important instructions, guidelines, or specific requirements that may apply to the entire drawing or set of shop drawings. These notes include information related to material specifications, construction methods, finishes, coordination requirements, and any other relevant details that need to be communicated to all project stakeholders.

- Plan Views and Elevations: Shop drawings typically include plan views and elevations that provide a detailed representation of the specific component or system being depicted. These views illustrate the dimensions, shape, and placement of the item, showing how it fits within the overall project design. The plan views and elevations are crucial for accurate fabrication and installation.

- Section Views: Section views are used to showcase internal details and structural aspects of the component. By cutting through the object, these views provide a cross-sectional perspective, including details of connections, fasteners, joints, and other integral parts that may not be visible in plan or elevation views.

- Dimensioning: Dimensions are crucial in shop drawings as they provide precise measurements of each element or system depicted. These dimensions indicate the overall size, height, width, thickness, and any other relevant measurements required for fabrication, installation, or coordination with other components.

- Details and Callouts: Details and callouts are used to highlight specific features, connections, or assembly methods of the component. These details provide additional clarity and specific instructions on how the item is to be fabricated and installed. Callouts may reference specific sections or details for further explanation or clarification.

- Bill of Materials (BOM): The Bill of Materials (BOM) is an essential part of shop drawings, listing all the materials required to fabricate and assemble the component. The BOM includes detailed information such as the type of material, quantity, dimensions, grade, finish, and any other relevant specifications to ensure the accurate sourcing and procurement of materials.

- Assembly Instructions: For complex components or systems, shop drawings may include assembly instructions that provide step-by-step guidelines on how to construct or install the item. These instructions ensure proper alignment, positioning, and connection of various parts, ultimately contributing to the successful fabrication and installation of the component.

By incorporating these components into the shop drawings, contractors, fabricators, and installers can effectively communicate and execute the details necessary to bring the construction project to life.

Types of Shop Drawings

Shop drawings come in various types, each serving a specific purpose and focusing on different aspects of a construction project. The following are some common types of shop drawings:

- Architectural Shop Drawings: These drawings provide detailed information about architectural elements such as doors, windows, cabinetry, finishes, and other aesthetic components. They depict the dimensions, materials, and installation details necessary to accurately fabricate and install these architectural features.

- Structural Shop Drawings: Structural shop drawings focus on the structural components of a building, including beams, columns, foundations, slabs, and reinforcement detailing. These drawings show the specific layout, dimensions, and connection details required for the proper fabrication and installation of these critical structural elements.

- Mechanical Shop Drawings: Mechanical shop drawings pertain to the mechanical systems within a building, such as HVAC (heating, ventilation, and air conditioning), plumbing, and fire protection systems. These drawings illustrate the layout, sizing, equipment specifications, and connections of the mechanical components to ensure proper integration and functionality.

- Electrical Shop Drawings: Electrical shop drawings focus on the electrical systems of a building, including lighting, power distribution, communications, and control systems. These drawings depict the specific placement, wiring, connections, and equipment details required for the electrical installations to meet safety and regulatory standards.

- Millwork and Cabinetry Shop Drawings: Millwork and cabinetry shop drawings provide detailed information about custom-built woodwork, including cabinets, shelves, countertops, and other interior finishes. These drawings show the exact dimensions, joinery, hardware, and finishing details required for the fabrication and installation of these custom millwork features.

- Facade and Curtain Wall Shop Drawings: Facade and curtain wall shop drawings focus on the external envelope of a building, including cladding systems, curtain walls, windows, and other façade elements. These drawings illustrate the specific components, connections, and attachment details necessary to achieve the desired aesthetics, weatherproofing, and structural integrity of the building exterior.

- Shop Drawings for Specialized Trades: In addition to the aforementioned types, there are various other specialized shop drawings that cater to specific trades or components. For example, shop drawings for metalwork, glasswork, plumbing fixtures, fire suppression systems, and more, all provide detailed information related to their specific trade requirements.

These types of shop drawings are essential in the construction process, as they provide the necessary details and guidance for the accurate fabrication, installation, and integration of various components and systems within a construction project.

Benefits of Using Shop Drawings in Construction

Shop drawings play a crucial role in the construction industry, offering several benefits that contribute to the overall success of a project. Here are some key advantages of using shop drawings:

- Improved Accuracy: Shop drawings provide precise details and measurements for each component, ensuring accurate fabrication, installation, and construction. By eliminating guesswork and ambiguity, shop drawings help minimize errors and discrepancies during the building process, resulting in a higher level of accuracy.

- Enhanced Coordination: Shop drawings facilitate coordination among different trade disciplines involved in a construction project. By illustrating how various components integrate and interface with each other, these drawings ensure seamless coordination and eliminate conflicts or clashes that may arise on the job site.

- Clear Communication: Shop drawings serve as effective communication tools between project stakeholders, including architects, engineers, contractors, and fabricators. They provide a visual representation of the design intent, helping all parties understand the expectations and requirements for each element of the project. This clear communication minimizes misunderstandings and leads to better collaboration.

- Streamlined Construction Process: With the detailed instructions and specifications provided by shop drawings, the construction process becomes more streamlined and efficient. Contractors and fabricators can fabricate and install components accurately, reducing the risk of errors, delays, or rework. This ultimately saves time and improves overall project productivity.

- Quality Control: Shop drawings enable thorough quality control and verification. Contractors and project managers can review the drawings to ensure compliance with project specifications, codes, and industry standards. By catching discrepancies early on, shop drawings help maintain high-quality construction throughout the project.

- Cost Savings: The use of shop drawings can lead to cost savings in multiple ways. By optimizing material use and minimizing waste, contractors can reduce material costs. Additionally, the accuracy and coordination provided by shop drawings help prevent costly rework or changes during construction.

- Regulatory Compliance: Shop drawings assist in meeting regulatory requirements and obtaining necessary approvals. These drawings provide the required documentation and visual representation for authorities and building inspectors to review and approve construction plans. This ensures compliance with local building codes and regulations.

- Improved Client Satisfaction: Accurate and well-coordinated shop drawings contribute to a smoother construction process and ultimately result in a high-quality finished project. By delivering on time and meeting client expectations, the use of shop drawings enhances client satisfaction, leading to positive reviews and potential future business opportunities.

In summary, the benefits of utilizing shop drawings in construction are numerous. These detailed drawings enhance accuracy, coordination, communication, quality control, and efficiency, resulting in a successful and satisfactory construction project.

Challenges in Creating Shop Drawings

The creation of shop drawings in the construction industry comes with its fair share of challenges. While the specific challenges may vary depending on the project and the trade involved, here are some common hurdles faced in the process:

- Interpretation of Design Intent: Translating the design intent into detailed shop drawings can be challenging. This requires a thorough understanding of the architect’s or engineer’s vision and ensuring that it is accurately represented in the drawings. Effective communication and collaboration among project stakeholders are essential to address any potential misinterpretations or conflicts.

- Coordination Among Trades: Coordinating various trade disciplines is critical to ensure the proper integration of different components. However, conflicting dimensions, specifications, or installation requirements can pose challenges. Collaborative efforts, regular coordination meetings, and clear communication channels are necessary to resolve these conflicts and achieve a cohesive design.

- Complexity and Customization: Projects that involve complex and customized components can present challenges in creating accurate shop drawings. Custom millwork, intricate façades, or unique engineering requirements require meticulous attention to detail and may involve additional research, calculations, or consultations to ensure accurate representation in the drawings.

- Changes and Iterations: Construction projects often involve changes or revisions throughout their lifecycle. These changes can impact previously created shop drawings and require updates or modifications. Managing these iterations and ensuring updated drawings are effectively communicated to all stakeholders can be challenging, requiring efficient document control and revision tracking systems.

- Time Constraints: Shop drawings are typically required within tight project timelines. Meeting deadlines can be challenging, particularly when dealing with large-scale projects or projects with complex components. Efficient resource allocation, effective project management, and leveraging technology can help mitigate these time constraints.

- Integration of Building Information Modeling (BIM): With the increasing adoption of Building Information Modeling (BIM), incorporating BIM data into shop drawings can pose challenges. Ensuring accurate representation of BIM elements, interoperability between different software platforms, and effective collaboration between BIM professionals and shop drawing creators can be complex but crucial for successful implementation.

- Design-Code Compliance: Shop drawings must comply with both design intent and relevant building codes and regulations. Addressing these requirements while maintaining the design intent can sometimes be challenging, especially when specific design elements conflict with certain code provisions. Collaboration between designers and code experts is necessary to find appropriate solutions.

Despite these challenges, utilizing effective project management strategies, proactive communication, continual coordination, and leveraging technology can help overcome these hurdles and ensure the creation of accurate and high-quality shop drawings.

Read more: What Is IFC Drawings In Construction

Conclusion

Shop drawings are a vital component in the construction industry, playing a significant role in ensuring accuracy, coordination, and efficiency throughout the project lifecycle. These detailed drawings bridge the gap between design intent and construction implementation, providing a roadmap for fabricators, contractors, and installers to follow.

Through the definition of shop drawings, we understand that they are detailed and technical drawings that illustrate the specific components, materials, and construction methods for different elements of a construction project. They are created using CAD software or other drafting tools, and they act as a guideline for accurate fabrication, installation, and construction based on the approved design and specifications.

The purpose of shop drawings is to enhance accuracy, coordination, communication, and quality control in construction projects. By utilizing shop drawings, stakeholders can benefit from improved accuracy, streamlined construction processes, cost savings, efficient coordination, and enhanced client satisfaction.

The creation of shop drawings involves a detailed process that includes gathering project information, understanding design intent and specifications, conducting field surveys if necessary, drafting and detailing, review and coordination, and finalization of the drawings. Following this structured process ensures accuracy and clarity in the shop drawings.

Shop drawings consist of various components such as title blocks, general notes, plan views, elevations, section views, dimensioning, details and callouts, bill of materials, and assembly instructions. Each component contributes to the clear and comprehensive communication of the design and construction details.

While there are challenges in creating shop drawings, such as the interpretation of design intent, coordination among trades, complexity and customization, managing changes, time constraints, integration of BIM, and design-code compliance, these hurdles can be overcome with effective communication, collaboration, project management, and leveraging technology.

In conclusion, shop drawings are an indispensable tool in the construction industry, facilitating accuracy, coordination, and effective communication between project stakeholders. They play a significant role in ensuring the successful execution of construction projects and contribute to the overall quality and efficiency of the built environment.

Frequently Asked Questions about What Is A Shop Drawing In Construction

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is A Shop Drawing In Construction”