Articles

How To Store Pump Parts

Modified: January 5, 2024

Learn the best practices on how to properly store pump parts in this informative articles. Keep your pump parts in optimum condition for longer use.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Welcome to this comprehensive guide on how to properly store pump parts. Pump parts are essential components of various industrial and residential systems, and their proper storage is crucial for maintaining their functionality and longevity. Whether you are working with water pumps, gas pumps, or any other type of pump, following the correct storage procedures will help preserve their performance and ensure they are ready for use whenever needed.

Proper storage of pump parts involves a series of steps, from cleaning and drying to organizing and labeling. Storing these parts in the right containers and maintaining a clean and dry storage area are also important factors to consider. By following these steps and guidelines, you can prevent damage, contamination, and other issues that can arise from improper storage of pump parts.

Why is proper storage of pump parts important? Pump parts are often exposed to various elements, including dust, moisture, and corrosive substances. Incorrect storage can result in damage, rust, or contamination, which can lead to pump malfunctions and costly repairs. Moreover, having organized and labeled pump parts makes it easier to locate and retrieve them when needed, ultimately saving time and improving efficiency.

In this guide, we will walk you through step-by-step instructions on how to effectively store pump parts. From cleaning and drying the parts to organizing and labeling them, we will provide you with all the necessary information to ensure the proper storage of your pump parts. So let’s dive in and learn how to store your pump parts the right way!

Key Takeaways:

- Proper storage of pump parts is crucial to prevent damage, ensure functionality, save money on repairs, improve efficiency, and enhance safety. Investing in cleaning, drying, organizing, labeling, and storing pump parts correctly pays off in the long run.

- By following the step-by-step instructions for proper storage of pump parts, you can ensure their longevity, functionality, and convenience of use. Properly stored pump parts will be readily accessible, organized, and protected, allowing you to maximize their lifespan and ensure their reliable performance.

Read more: How To Store Computer Parts

Why Proper Storage of Pump Parts is Important

Proper storage of pump parts is essential for several reasons. By taking the time to store your pump parts correctly, you can avoid unnecessary damage, extend their lifespan, and ensure their optimal performance. Let’s explore the key reasons why proper storage is crucial:

- Prevent damage: Pump parts are often made from delicate materials that can be easily damaged if not stored properly. Exposure to moisture, dust, or corrosive substances can lead to rust, erosion, or deterioration of the parts. By storing them in suitable containers and keeping them away from harmful elements, you can prevent damage and preserve their integrity.

- Ensure functionality: Properly stored pump parts are more likely to maintain their functionality. When parts are exposed to harsh conditions or left untreated for extended periods, they may lose their efficiency or fail to function altogether. By storing them correctly, you protect them from potential issues that could compromise their performance.

- Save money on repairs or replacements: Incorrectly stored pump parts are at a higher risk of damage or contamination, which can lead to costly repairs or the need for replacement parts. By investing time and effort in proper storage, you can avoid unnecessary expenses and ensure that your pump parts remain in good working condition.

- Improve efficiency: When pump parts are organized and labeled in a storage system, it becomes easier to locate and retrieve them when needed. Proper storage allows for quicker access to the required parts, saving time and increasing overall efficiency in maintenance, repairs, or system upgrades.

- Enhance safety: Some pump parts, especially those used in industrial settings, may pose safety risks if mishandled or stored improperly. By following proper storage procedures, you can reduce the likelihood of accidents and injuries associated with pump parts.

Remember, the investment you make in properly storing your pump parts will pay off in the long run. Not only will it prolong the lifespan of your pump parts, but it will also save you time and money in repairs or replacements. So, let’s move on to the step-by-step process of how to store pump parts correctly.

Step 1: Cleaning Pump Parts

Before storing your pump parts, it is crucial to clean them thoroughly to remove any dirt, debris, or residue that may have accumulated during use. Cleaning the parts will help prevent corrosion, contamination, and the buildup of harmful substances that could affect their performance. Follow these steps to ensure effective cleaning:

- Gather the necessary cleaning supplies: You will need a mild detergent or cleaning solution, a soft-bristle brush or cloth, and a bucket or sink to hold the parts during cleaning.

- Dismantle the pump parts: Disassemble the pump parts as much as possible to facilitate thorough cleaning. Refer to the manufacturer’s instructions or documentation if needed.

- Remove visible dirt and debris: Use a soft-bristle brush or cloth to gently remove any dirt or debris from the pump parts. Be careful not to scratch or damage the surfaces.

- Soak the parts: Fill a bucket or sink with warm water and add a mild detergent or cleaning solution. Place the pump parts in the solution and let them soak for a few minutes to loosen any stubborn grime.

- Scrub the parts: Use the soft-bristle brush or cloth to scrub the pump parts thoroughly, paying attention to all surfaces and crevices. Be gentle yet thorough to ensure that all dirt is removed.

- Rinse the parts: After scrubbing, rinse the pump parts with clean water to remove any soap residue or remaining debris. Ensure that all cleaning solution is thoroughly rinsed off.

- Dry the parts: Use a clean, lint-free cloth or allow the pump parts to air dry completely. Make sure there is no moisture left on the parts before proceeding to the next step.

Cleaning your pump parts is an essential first step in proper storage. By removing dirt and contaminants, you are setting a clean foundation for the next steps and ensuring that your pump parts are ready for storage. Once the parts are clean and dry, you can move on to the next step: drying the pump parts.

Step 2: Drying Pump Parts

After cleaning your pump parts, it is crucial to ensure they are completely dry before moving on to the storage process. Moisture left on the parts can lead to corrosion and damage over time. Follow these steps to effectively dry your pump parts:

- Inspect for moisture: After cleaning, visually inspect the pump parts to check for any remaining moisture. Pay attention to small crevices or hidden areas where water might be trapped.

- Use a clean, dry cloth: Take a clean, lint-free cloth and gently pat-dry the pump parts. Make sure to remove any visible moisture on the surfaces.

- Allow air-drying: Place the pump parts in a well-ventilated area or use a fan to circulate air around them. This will help speed up the drying process and ensure that all moisture evaporates.

- Ensure complete dryness: Make sure that all parts, especially those with tight crevices or hard-to-reach areas, are fully dry. Moisture trapped in these areas can cause damage or corrosion over time.

- Consider using compressed air: If available, you can use compressed air to blow-dry the pump parts. This can help remove moisture from hard-to-reach areas and ensure thorough drying.

- Do not rush the drying process: Take your time to ensure that all pump parts are completely dry. Rushing this step could result in moisture being trapped, leading to potential issues when the parts are stored.

Drying your pump parts thoroughly is vital to prevent corrosion and damage during storage. By following these steps, you can ensure that all moisture is removed, providing a clean and dry foundation for the next steps in the storage process. Next, we will discuss how to organize your pump parts for efficient storage.

Step 3: Organizing Pump Parts

Organizing your pump parts plays a significant role in efficient storage and easy accessibility. When properly organized, you can quickly locate the specific parts you need, saving time and ensuring a smooth workflow. Here are some steps to effectively organize your pump parts:

- Sort the pump parts: Start by sorting your pump parts into categories based on their type, size, or usage. This will help create a logical organization system and make it easier to find specific parts when needed.

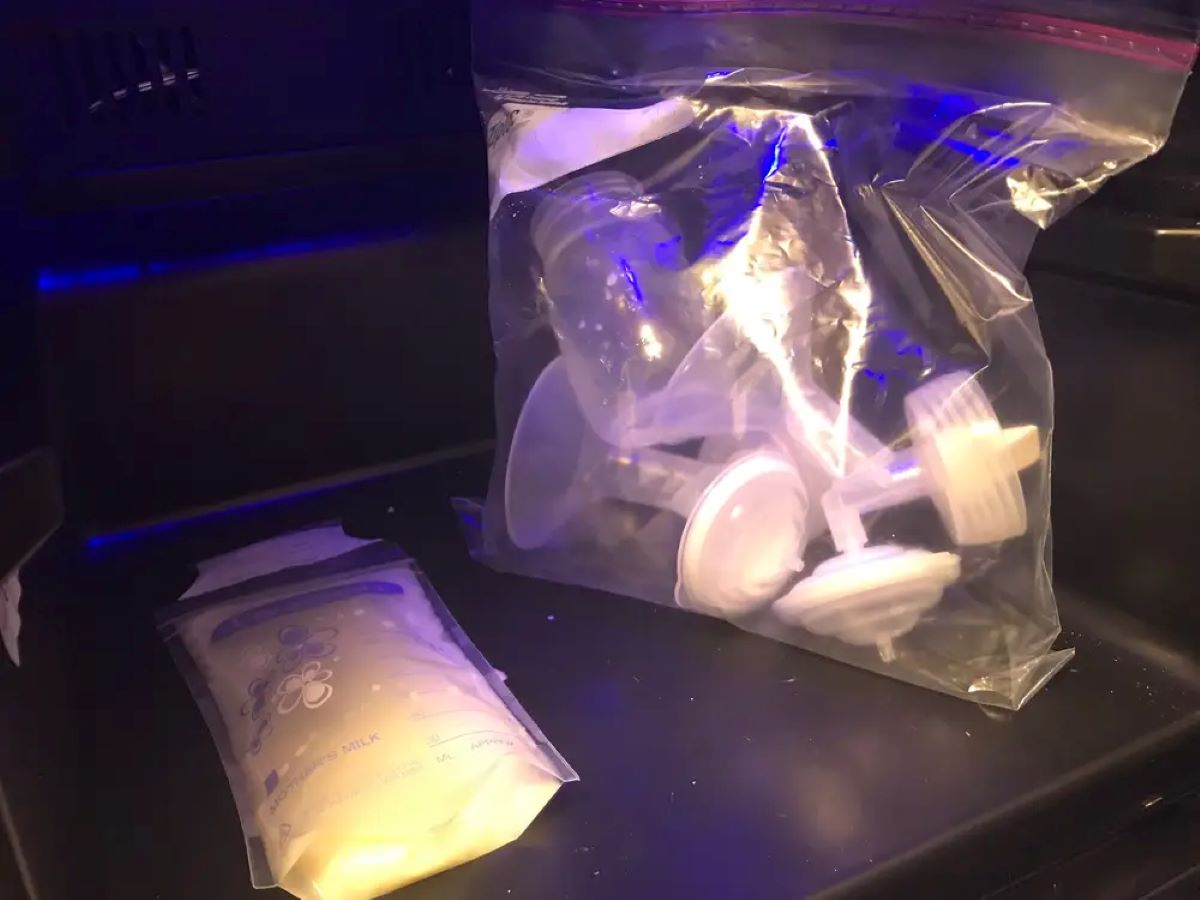

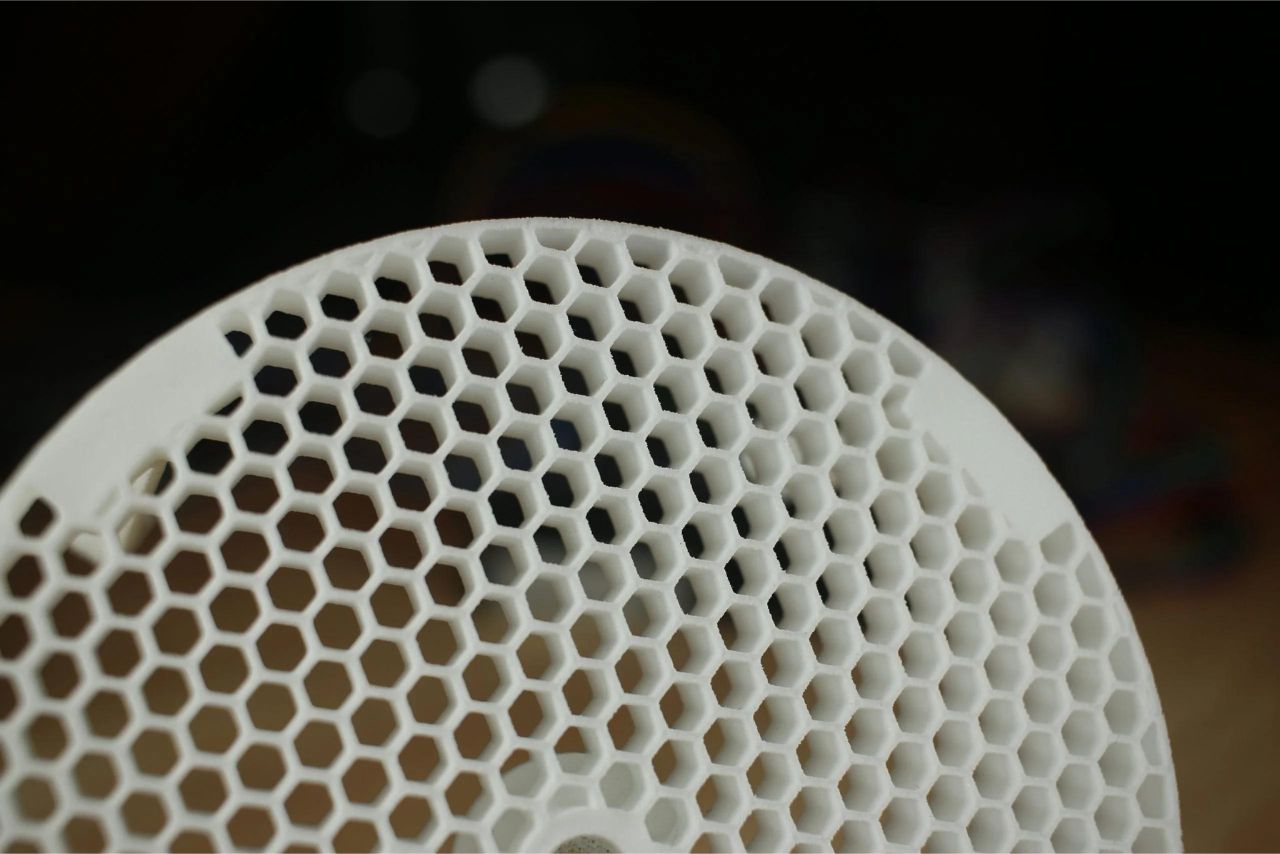

- Use storage containers: Invest in suitable storage containers for your pump parts. Depending on the size and quantity of your parts, you can use plastic bins, toolboxes, or compartmentalized boxes to keep them organized and protected.

- Label the containers: Label each storage container with clear and descriptive labels that indicate the contents. Use waterproof and durable labels to ensure they remain intact over time.

- Create an inventory list: Develop an inventory list that provides detailed information about the pump parts stored in each container. This will serve as a reference and help you keep track of the available parts.

- Consider using a color-coding system: If you have a large collection of pump parts, consider implementing a color-coding system where you assign a specific color to different categories or types of parts. This visual cue can further enhance the organization and ease of retrieval.

- Arrange the containers: Place the storage containers in a designated area that is clean, dry, and easily accessible. Consider factors such as space availability and the frequency of need when deciding on the storage location.

- Maintain the organization: Regularly reassess and update the organization system as needed. Return the pump parts to their designated containers after use to ensure everything remains organized and readily available.

By organizing your pump parts, you will significantly improve your efficiency when it comes to locating and retrieving specific components. Implementing a systematic approach to organization will save you time and streamline your workflow in pump maintenance and repairs. Now that your pump parts are properly organized, let’s move on to the next step: choosing the right storage containers.

After washing pump parts, air dry them on a clean towel or drying rack. Once dry, store them in a clean, covered container or resealable bag in the refrigerator.

Read more: How To Store Sterilized Pump Parts

Step 4: Choosing the Right Storage Containers

Choosing the right storage containers for your pump parts is crucial to ensure their protection and organization. The containers you select should be durable, secure, and suitable for the size and quantity of your parts. Follow these steps to help you choose the right storage containers:

- Determine the size and quantity: Before purchasing storage containers, assess the size and quantity of your pump parts. This will help you determine the appropriate container size and the number of containers needed.

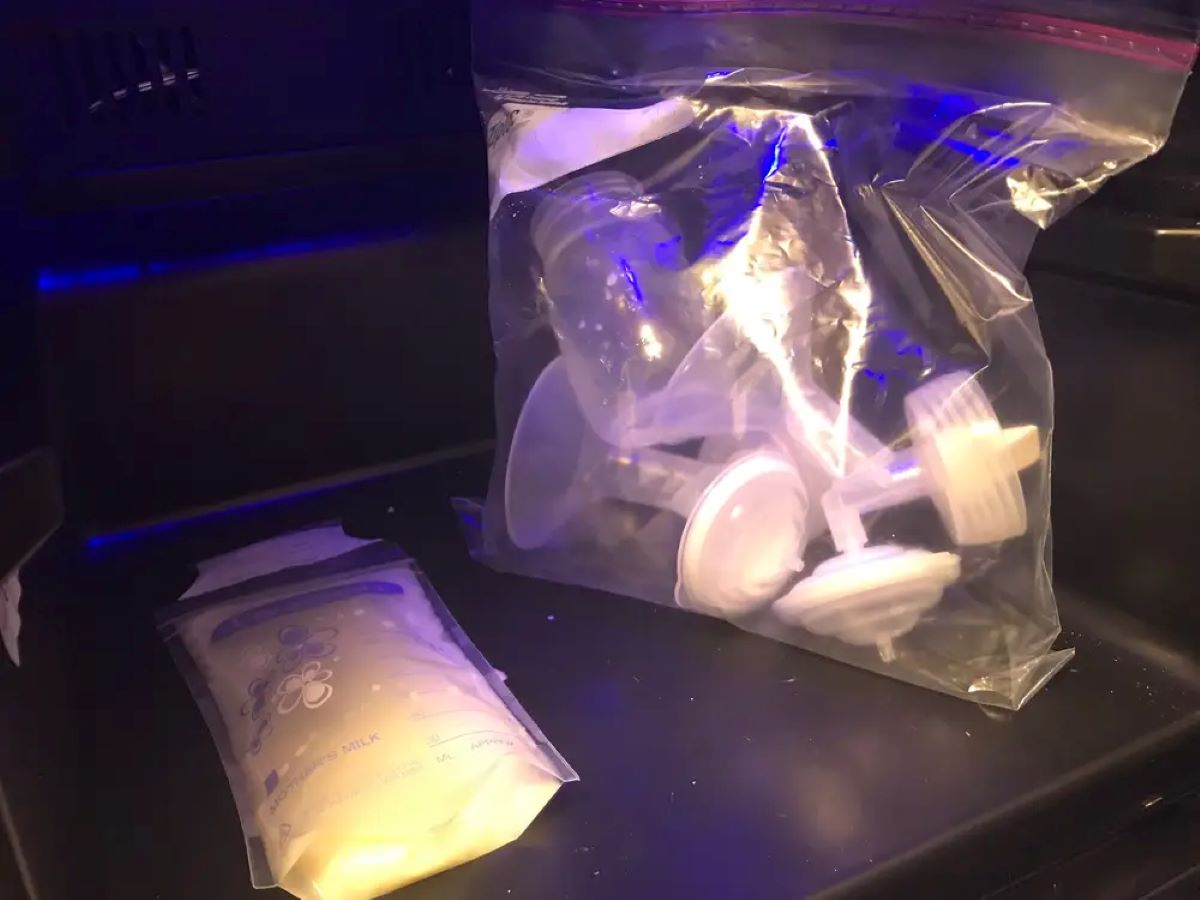

- Opt for sturdy and durable materials: Look for storage containers made from sturdy materials such as plastic or metal. They should be resistant to impact, moisture, and corrosion.

- Consider compartmentalized containers: If you have small or delicate pump parts, consider using compartmentalized containers with dividers or removable trays. This will help keep the parts organized and prevent damage or tangling.

- Ensure secure closures: Look for containers with secure closures, such as latches or locking mechanisms, to keep your pump parts safely stored and protected from dust, moisture, and other potential hazards.

- Transparent or labeled containers: Consider using transparent containers or containers with clear labels. This will make it easier to identify the contents without the need to open each container.

- Stackable containers: If space is a concern, opt for stackable containers that allow you to maximize vertical storage. This will help optimize your storage area and keep your pump parts organized and easily accessible.

- Assess portability: Depending on your needs, consider the portability of the storage containers. If you frequently transport your pump parts, look for containers with handles or wheels for easy movement.

- Account for future expansion: Anticipate potential growth in your pump parts collection and choose storage containers that can accommodate future additions. This will save you from having to invest in additional containers down the line.

By selecting the right storage containers, you can ensure that your pump parts are adequately protected, easily accessible, and organized. Take the time to invest in quality containers that meet your specific storage needs. Once you have chosen the containers, the next step is to label your pump parts for easy identification.

Step 5: Labeling Pump Parts

Labeling your pump parts is an essential step in ensuring easy identification and retrieval. When properly labeled, you can quickly locate the specific parts you need without having to search through multiple containers. Follow these steps to effectively label your pump parts:

- Choose clear and durable labels: Select labels that are clear, legible, and resistant to moisture and wear. Waterproof labels or adhesive labels with a protective coating are ideal to ensure longevity.

- Use descriptive and specific labels: Clearly label each pump part with descriptive information such as its name, model number, size, or specific usage. The labels should provide enough information to identify the part at a glance.

- Apply labels directly to the parts: Depending on the size and nature of the pump part, you can apply the label directly on the part itself. Choose a location that does not obstruct any crucial components or markings on the part.

- Label the storage containers: In addition to labeling the pump parts, make sure to label the storage containers as well. This will help you quickly locate the correct container for a specific pump part.

- Use color-coded labels: If you have implemented a color-coding system for organizing your pump parts, consider using color-coded labels that correspond to the color scheme. This will provide visual cues for easy identification.

- Create an inventory list: Maintain an inventory list or database where you record the pump parts and their corresponding labels. This will serve as a reference and make it easier to track and locate specific parts.

- Regularly check and update labels: Periodically inspect the labels on your pump parts and storage containers to ensure they remain intact and legible. Replace any damaged or faded labels promptly to maintain an efficient and organized system.

By labeling your pump parts, you can ensure that they are easily identifiable and accessible, saving you time and effort in locating specific components. Consistency and accuracy in labeling will go a long way in streamlining your pump maintenance and repair processes. With your pump parts labeled, it’s time to move on to the next step: storing them in a clean and dry area.

Step 6: Storing Pump Parts in a Clean and Dry Area

Once you have cleaned, dried, organized, and labeled your pump parts, it is crucial to store them in a clean and dry area. Proper storage conditions will help protect your pump parts from damage, corrosion, and contamination. Follow these steps to ensure that your pump parts are stored in an optimal environment:

- Select a suitable storage area: Choose a designated area specifically for storing your pump parts. This can be a dedicated shelf, cabinet, or room that is clean, dry, and well-ventilated.

- Clean the storage area: Before placing your pump parts in the storage area, ensure that it is clean and free from dust, dirt, or any other contaminants. Wipe down surfaces and remove any debris or clutter.

- Avoid exposure to moisture: Moisture can cause damage and corrosion to your pump parts. Ensure that the storage area is dry and protected from any potential water leaks or moisture sources. Consider using dehumidifiers or moisture-absorbing products if needed.

- Keep out of direct sunlight: Excessive exposure to sunlight can lead to fading, discoloration, or deterioration of certain pump parts. Store them in an area away from direct sunlight or use light-blocking covers or curtains if necessary.

- Protect from extreme temperatures: Extreme temperatures can also affect the integrity of pump parts. Avoid storing them in areas that experience extreme heat or cold. If possible, maintain a moderate and consistent temperature within the storage area.

- Minimize dust and debris: Take steps to minimize dust and debris in the storage area. Regularly dust surfaces and consider covering the pump parts with protective covers or bags to prevent dust accumulation.

- Avoid overcrowding: Ensure that there is ample space between the pump parts in the storage area to prevent them from rubbing against each other or getting tangled. Overcrowding can increase the risk of damage and make it more challenging to retrieve specific parts when needed.

- Implement security measures: If your pump parts are valuable or require additional security, consider implementing security measures such as locking cabinets, surveillance systems, or restricted access to the storage area.

By storing your pump parts in a clean and dry area, you are taking proactive measures to preserve their functionality and prevent potential damage or contamination. Remember to regularly inspect the storage area and maintain its cleanliness and optimal conditions. Now that you have stored your pump parts in a suitable environment, let’s move on to the final step: regular maintenance of the storage area.

Step 7: Regular Maintenance of Storage Area

Regular maintenance of the storage area for your pump parts is crucial to ensure that they remain in optimal condition and ready for use when needed. By implementing routine maintenance tasks, you can prevent issues such as dust accumulation, moisture buildup, or damage to the storage area itself. Follow these steps to maintain the cleanliness and functionality of your pump parts’ storage area:

- Inspect for cleanliness: Regularly inspect the storage area for any dust, debris, or signs of pests. Clean any dirt or residue found on surfaces, shelves, or containers.

- Dust and wipe down surfaces: Dust the surfaces of the storage area, including shelves, walls, and any equipment or fixtures present. Use a soft cloth or a duster to remove dust particles.

- Check for moisture or leaks: Look for any signs of moisture, water leaks, or condensation within the storage area. Address any sources of moisture promptly and ensure that the area remains dry to prevent damage to your pump parts.

- Inspect containers and labels: Check the storage containers and labels for any wear, damage, or fading. Replace or repair any damaged containers or labels to maintain the organization and readability of the storage system.

- Reorganize if necessary: As your pump parts collection grows or changes, periodically reassess the organization of the storage area. Make adjustments as needed to accommodate new parts or improve the efficiency of the system.

- Monitor temperature and humidity levels: Keep an eye on the temperature and humidity levels within the storage area. Make adjustments or use appropriate measures, such as dehumidifiers or moisture absorbers, to maintain suitable environmental conditions.

- Regularly check inventory: Review your inventory list regularly to ensure that all pump parts are accounted for and properly stored. Update the inventory list as needed to reflect any additions or removals.

- Secure the storage area: Make sure that the storage area remains secure and protected. Ensure that any locking mechanisms or security measures are functioning correctly to safeguard your pump parts.

By implementing regular maintenance tasks, you can prolong the lifespan of your pump parts and maintain an efficient storage system. It is essential to be proactive in addressing any issues to prevent potential damage or complications down the line. With regular maintenance, your pump parts will be well-preserved and readily accessible whenever you need them.

By following these step-by-step instructions for proper storage of pump parts, you can ensure their longevity, functionality, and convenience of use. Remember to clean, dry, organize, label, and store your pump parts in a suitable environment while maintaining regular maintenance. These practices will help protect and preserve your pump parts, saving you time, money, and hassle in the long run. Happy pump part storage!

Read more: How To Store Pump Parts In Fridge

Conclusion

Proper storage of pump parts is essential for maintaining their functionality, longevity, and overall performance. By following the step-by-step guidelines outlined in this comprehensive guide, you can ensure that your pump parts remain in optimal condition and ready for use whenever needed. Let’s recap the key points:

First, cleaning your pump parts thoroughly ensures that they are free from dirt, debris, and contaminants that could lead to damage or reduced performance. Drying the parts completely is equally important to prevent moisture-related issues such as corrosion.

Organizing your pump parts in suitable containers and labeling them provides a systematic and efficient storage system, making it easier to locate and retrieve specific parts when required. Choosing the right storage containers that are durable, secure, and appropriately sized will further protect your pump parts.

Storing your pump parts in a clean and dry area prevents damage from moisture, dust, and extreme temperatures. Regular maintenance of the storage area ensures that it remains in optimal condition and that your pump parts are well-preserved.

By following these steps, you can prevent potential damage, save money on repairs or replacements, and improve overall efficiency in maintenance and repairs. Properly stored pump parts will be readily accessible, organized, and protected, allowing you to maximize their lifespan and ensure their reliable performance.

Remember, the investment you make in proper storage practices will pay off in the long run. Your pump parts are valuable assets that deserve proper care and storage. By taking the time to clean, dry, organize, label, and store them correctly, you are extending their lifespan and ensuring they will be in top-notch condition for future use.

So, implement these storage techniques and maintain regular maintenance of your pump parts’ storage area to reap the benefits of efficient pump maintenance, reduced downtime, and improved operations. Have confidence in knowing that your pump parts are well-protected and readily available for all your pumping needs.

Frequently Asked Questions about How To Store Pump Parts

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Store Pump Parts”