Articles

How To Use Micrometers And Calipers

Modified: August 16, 2024

Learn how to effectively use micrometers and calipers in this informative article. Become an expert in precision measurements and improve your accuracy today.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

Measurement is an essential part of many industries and professions, from manufacturing and engineering to woodworking and jewelry making. Accurate measurements are crucial for ensuring precision and quality in the final product. Two commonly used tools for precise measurement are micrometers and calipers.

These instruments provide accurate and precise measurements of dimensions, allowing professionals to make precise adjustments and ensure parts fit together perfectly. Whether you’re a machinist, a hobbyist, or someone looking to measure objects with utmost accuracy, understanding how to use micrometers and calipers is essential.

In this article, we will delve into the world of micrometers and calipers, exploring their types, their use, and best practices for accurate measurements. So, let’s dive in and explore these indispensable tools of precision measurement!

Key Takeaways:

- Precision measurement tools like micrometers and calipers are crucial for ensuring accuracy in various industries. Understanding their types, reading techniques, and best practices is essential for achieving precise results.

- Proper care and maintenance of micrometers and calipers are vital for preserving their accuracy and reliability. Following guidelines for cleaning, lubrication, and storage can ensure precise measurements for years to come.

Read more: What Are Calipers Used To Measure

What are Micrometers and Calipers?

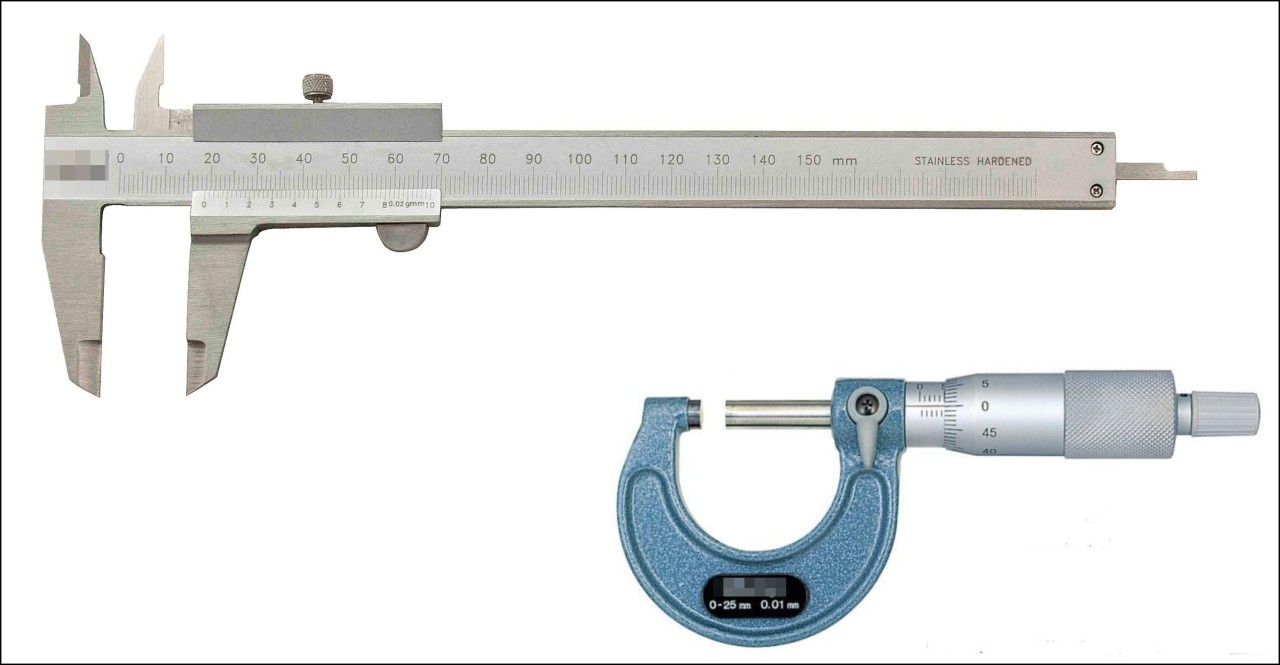

Micrometers and calipers are both handheld measuring tools used to determine the dimensions of an object with high precision. While they serve the same purpose, they differ in their design and application.

A micrometer, also known as a micrometer screw gauge, is a device used to accurately measure the thickness, diameter, or depth of an object. It consists of a U-shaped frame, a movable spindle, a thimble, and a micrometer screw. The spindle moves along the screw, allowing for precise measurements to be taken. Micrometers typically have a range from 0 to 25 millimeters (mm) or 0 to 1 inch (in).

On the other hand, calipers are versatile measuring tools used to measure external or internal dimensions of an object. They come in two main types: inside calipers and outside calipers. Inside calipers are used to measure the inner dimensions, while outside calipers are used to measure the outer dimensions of an object. Calipers consist of two legs or jaws, one fixed and one movable, that can be adjusted to fit the object being measured.

Both micrometers and calipers are available in various types and configurations to suit different measurements and applications. Understanding the different types of micrometers and calipers is crucial for choosing the right tool for the task at hand. Let’s take a closer look at the various types of these measuring instruments.

Types of Micrometers

There are several types of micrometers available, each designed for specific measurement purposes. Here are some common types:

- Outside Micrometer: Also known as a micrometer caliper, this type of micrometer is used to measure the external dimensions of an object. It consists of a U-shaped frame with a spindle and an anvil. The spindle is moved by rotating the thimble, allowing for precise measurements to be taken.

- Inside Micrometer: As the name suggests, inside micrometers are used to measure the internal dimensions of objects such as holes or cylinders. They consist of a measuring head, an extension rod, and a micrometer unit. The extension rod is inserted into the hole being measured, and the micrometer unit provides the measurement.

- Depth Micrometer: This type of micrometer is used to measure the depth of holes, slots, or recesses. It consists of a base, a rod, a measuring head, and a micrometer unit. The rod is placed into the hole or slot, and the measurement is taken using the micrometer unit.

- Screw Thread Micrometer: Screw thread micrometers are specifically designed to measure the pitch diameter of screw threads. They have specially shaped anvils and spindles to accommodate different thread sizes and profiles. They are commonly used in the manufacturing and machining industries.

- Outside Groove Micrometer: These micrometers are used to measure the width, depth, or diameter of grooves or recessed features on objects. They have special anvils and measuring heads that can reach into grooves and provide accurate measurements.

These are just a few examples of the types of micrometers available. It’s important to choose the right type of micrometer for your specific measurement needs to ensure accurate results.

Types of Calipers

Calipers come in various types, each designed for specific measurement purposes. Here are some common types of calipers:

- Vernier Caliper: Vernier calipers are one of the most widely used types of calipers. They consist of a main scale and a sliding Vernier scale that allows for precise measurements. They can measure both internal and external dimensions, as well as depths. Vernier calipers are available in both metric and imperial scales.

- Dial Caliper: Dial calipers operate similarly to Vernier calipers but display measurements on a dial instead of a Vernier scale. They are known for their easy-to-read dial, which eliminates any reading errors due to Vernier scale interpretation. Dial calipers are commonly used in machining and engineering applications.

- Digital Caliper: Digital calipers have a digital readout display that shows the measurements in decimal or fractional form. They provide quick and accurate readings and are easy to use. Digital calipers usually have additional features like zero reset and data output options, making them popular in various industries.

- Inside Caliper: Inside calipers, also known as internal calipers or dividers, are used to measure the internal dimensions of an object, such as the diameter of a hole or the distance between two inside walls. They have two legs that can be adjusted to fit the object being measured.

- Outside Caliper: Outside calipers, also called external calipers, are used to measure the external dimensions of an object, such as the diameter of a shaft or the width of a part. They consist of two legs that can be adjusted to fit the object being measured.

In addition to these types, there are specialized calipers such as depth calipers, step calipers, and gear tooth calipers, which are designed for specific measurement applications. Choosing the right type of caliper is crucial for accurate measurements, so consider the specific requirements of your task when selecting a caliper.

Understanding the Basics: Measurement Units

Before we delve into how to read micrometers and calipers, it’s important to have a basic understanding of measurement units. Micrometers and calipers typically use both metric and imperial units of measurement. Let’s take a closer look at these measurement systems:

- Metric System: The metric system is based on units of length, with the meter being the primary unit. In the metric system, measurements are expressed in millimeters (mm), centimeters (cm), and meters (m). It is the most widely used measurement system worldwide and is known for its simplicity and decimal-based increments.

- Imperial System: The imperial system, also known as the English system, is widely used in the United States and a few other countries. It is based on units of length, with the inch being the primary unit. In the imperial system, measurements are expressed in inches (in) and fractions of an inch. While less commonly used in the scientific and engineering fields, it’s important to be familiar with the imperial units when working with certain industries.

When using micrometers and calipers, it’s essential to be aware of the measurement units being used and ensure consistency throughout your measurements. The tool you are using will typically have a display or scale that indicates the units being measured.

In some cases, you may encounter situations where you need to convert between metric and imperial units. You can use conversion factors or online conversion tools to convert measurements accurately.

Now that we have a basic understanding of measurement units, let’s move on to the practical aspect of how to read micrometers and calipers.

Read more: How To Use Accu Measure Skinfold Calipers

How to Read a Micrometer

Reading a micrometer may seem daunting at first, but with a little practice, it becomes second nature. Here’s a step-by-step guide on how to read a micrometer:

- Zero the micrometer: Before taking any measurements, make sure the micrometer is properly zeroed. Close the jaws or anvils together so that there is no gap between them, and turn the thimble or ratchet until the zero mark on the thimble aligns with the reference line on the barrel.

- Place the object in the micrometer: Open the jaws or anvils of the micrometer and place the object between them. Gently close the jaws until they make light contact with the object.

- Read the whole number: Look at the numbers on the barrel of the micrometer. Each number represents one full unit of measurement (millimeters or inches).

- Read the fractional part: Look at the markings on the thimble. The thimble typically has 25 or 50 equally spaced divisions, each representing a fraction of the full unit. Determine which division on the thimble aligns with the reference line on the barrel.

- Add the whole number and fractional part together: Combine the whole number and the fractional part to determine the final measurement. Be sure to account for any additional measurements indicated by the thimble rotation beyond the zero mark.

For example, if the barrel reading is 5 mm and the thimble reading is on the 0.25 mark, the final measurement would be 5.25 mm.

It’s important to handle the micrometer with care, ensuring that the jaws make proper contact with the object being measured without exerting excessive pressure. This will help ensure accurate and consistent measurements.

With practice, you will become more comfortable and proficient in reading micrometers, enabling you to take precise measurements for your specific application.

When using a micrometer or caliper, always ensure that the measuring faces are clean and free from debris to ensure accurate measurements.

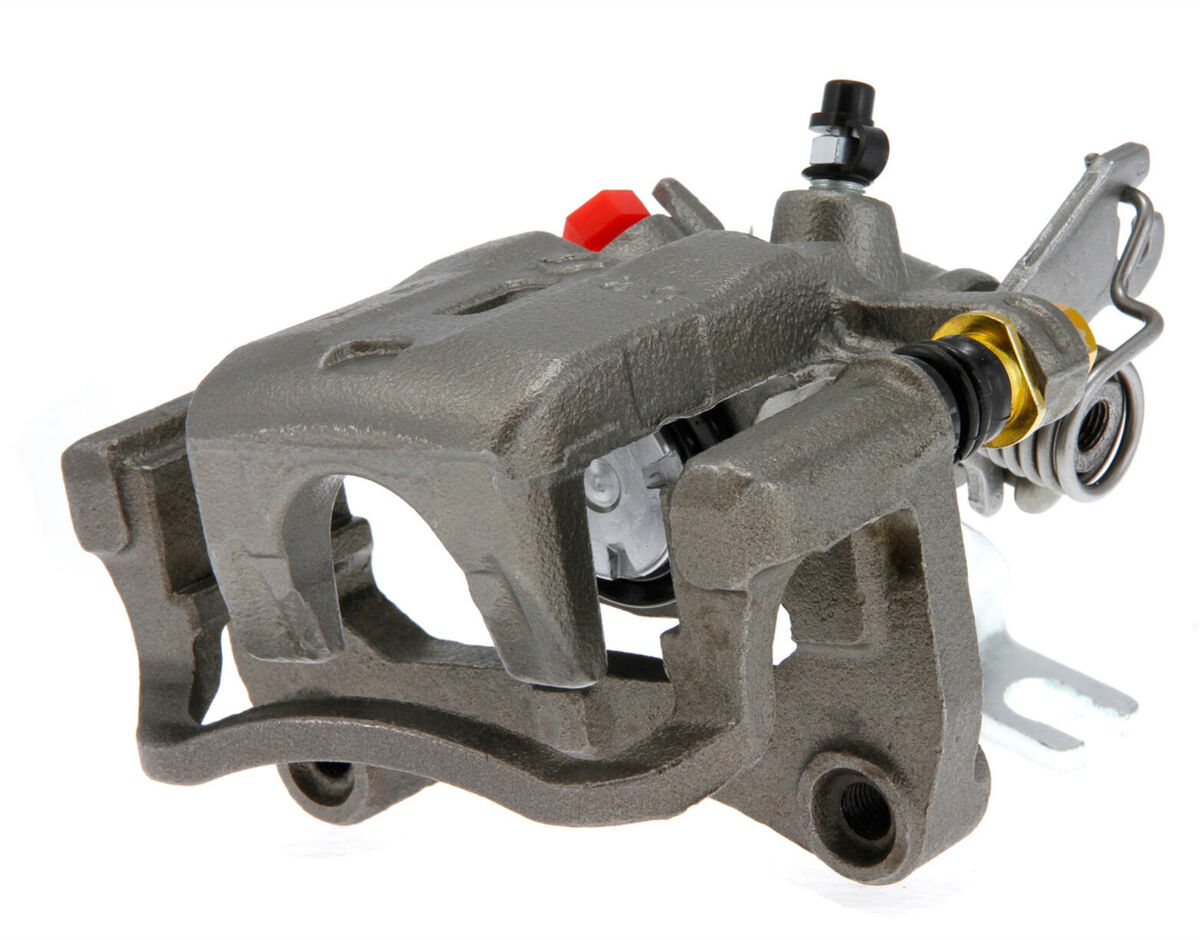

How to Read a Caliper

Reading a caliper may seem intimidating at first, but it’s actually straightforward once you understand the basic steps. Here’s a step-by-step guide on how to read a caliper:

- Zero the caliper: Start by closing the jaws of the caliper so that they are touching, then adjust the sliding scale or dial so that the zero mark aligns with the reference line or zero point on the main scale. This ensures that the caliper is properly calibrated.

- Place the object in the caliper: Open the jaws of the caliper and place the object between them. Gently close the jaws until they make light contact with the object.

- Read the main scale: Look at the main scale on the fixed jaw of the caliper. Each increment on the scale represents a unit of measurement (millimeters or inches), and the numbers indicate the whole numbers.

- Read the sliding scale or dial: If your caliper has a sliding scale or a dial, observe its position relative to the main scale. This sliding scale or dial represents a fraction of a unit of measurement and provides the fractional measurement.

- Add the main scale and sliding scale or dial: Combine the reading from the main scale and the sliding scale or dial to determine the final measurement. For example, if the main scale reading is 3 cm and the sliding scale or dial reading is on the 0.5 mark, the final measurement would be 3.5 cm.

It’s important to handle the caliper with care and ensure that the jaws make proper contact with the object being measured without exerting excessive pressure. This will help ensure accurate and consistent measurements.

With practice, you will become more proficient in reading calipers, allowing you to take precise measurements for your specific application.

Choosing the Right Measuring Tool

When it comes to choosing the right measuring tool for your needs, there are a few factors to consider. Selecting the appropriate tool will ensure accurate and reliable measurements. Here are some considerations to keep in mind:

- Type of measurement: Consider the type of measurement you need to make. If you’re measuring external dimensions, an outside micrometer or outside caliper would be suitable. For internal dimensions, an inside micrometer or inside caliper would be the right choice. Understanding the specific measurement requirements will help you narrow down your options.

- Measurement range: Determine the range of measurements you will be working with. Micrometers and calipers come in various sizes and have different measurement ranges. Ensure that the tool you choose can accommodate the dimensions you need to measure.

- Accuracy and precision: Consider the level of accuracy and precision required for your measurements. Micrometers are generally more accurate than calipers, offering measurements to the nearest thousandth of an inch or hundredth of a millimeter. Calipers, while less precise, are still suitable for many applications that don’t require extremely precise measurements.

- Materials and build quality: Look for tools made from high-quality materials, such as hardened steel, that can withstand regular use and provide reliable measurements. Consider factors like durability, ergonomics, and ease of use when choosing a measuring tool.

- Budget: Finally, consider your budget. Micrometers tend to be more expensive than calipers due to their higher precision and specialized design. However, there is a wide range of options available at various price points, so you can find a tool that meets your needs and budget.

By considering these factors, you can choose the right measuring tool that will provide accurate and reliable measurements for your specific tasks and applications.

Best Practices for Using Micrometers and Calipers

To ensure accurate measurements and prolong the lifespan of your micrometers and calipers, it’s important to follow some best practices when using these precision measuring tools. Here are some key tips to keep in mind:

- Handle with care: Micrometers and calipers are delicate instruments, so handle them with care. Avoid dropping or mishandling them, as this can compromise their accuracy and cause damage.

- Ensure clean surfaces: Before taking measurements, ensure that both the object being measured and the measuring surfaces of the tool are clean. Dust, dirt, or debris can affect the accuracy of the measurement.

- Make light contact: When using micrometers and calipers, make light contact with the object being measured. Applying excessive force can distort the measurement and damage the tool.

- Secure the object: For stable measurements, secure the object being measured to prevent any movement. This will help ensure consistent and reliable readings.

- Take multiple measurements: To verify accuracy and consistency, it’s good practice to take multiple measurements of the same dimension. Repeat the measurement a few times and compare the results to identify any variations.

- Use appropriate units: Use the appropriate units of measurement when recording and communicating your measurements. Ensure consistency between metric and imperial units if you are working with both systems.

- Regularly calibrate and maintain: Calibrate your micrometers and calipers regularly to ensure accuracy. Consult the manufacturer’s guidelines or use calibration equipment to verify and correct any deviations. Additionally, keep the tools clean and lubricated as recommended by the manufacturer.

- Store properly: When not in use, store your micrometers and calipers in a clean, dry, and secure location. Use protective cases or covers to prevent dust, moisture, or accidental damage.

By following these best practices, you can ensure that your micrometers and calipers provide accurate and reliable measurements for years to come.

Read more: How To Change Calipers

Common Mistakes to Avoid

When using micrometers and calipers, it’s important to be aware of common mistakes that can lead to inaccurate measurements. By avoiding these mistakes, you can ensure more reliable and precise results. Here are some common mistakes to watch out for:

- Incorrect zeroing: Failing to properly zero the micrometer or caliper can lead to significant measurement errors. Always ensure that the tool is properly zeroed before taking measurements by aligning the reference marks or scales.

- Misalignment of jaws or anvils: Improper alignment of the jaws or anvils can compromise the accuracy of the measurement. Make sure the object being measured is positioned properly and that the jaws or anvils are parallel and making even contact.

- Excessive force: Applying excessive force when taking measurements can distort the objects being measured and lead to inaccurate readings. Use light and consistent pressure to obtain reliable measurements.

- Inconsistent measurement technique: Inconsistent measurement techniques, such as varying the pressure, angle, or point of contact, can result in inconsistent and inaccurate measurements. Practice maintaining a consistent technique to ensure reliable results.

- Using worn or damaged tools: Using micrometers and calipers that are worn out or damaged can compromise the accuracy of the measurements. Regularly inspect your tools for any signs of wear, rust, or damage and replace or repair them as necessary.

- Not using the appropriate tool: Using the wrong tool for the specific measurement task can lead to inaccurate results. Ensure you are using the appropriate micrometer or caliper for the type of measurement you need to make (e.g., outside micrometer for external dimensions).

- Ignoring temperature effects: Temperature variations can affect the dimensions of objects and, consequently, the measurements obtained. Take into account any significant temperature changes that may affect the accuracy of your measurements.

- Not verifying calibration: Neglecting to calibrate your micrometers and calipers at regular intervals can lead to inaccurate measurements. It’s important to verify and adjust the calibration periodically to maintain precision.

By avoiding these common mistakes, you can improve the accuracy and reliability of your measurements using micrometers and calipers.

Proper Care and Maintenance of Micrometers and Calipers

To ensure the longevity and accurate performance of your micrometers and calipers, proper care and maintenance are essential. By following these guidelines, you can keep your measuring tools in optimal condition:

- Keep them clean: Regularly clean the measuring surfaces and moving parts of your micrometers and calipers. Use a soft, lint-free cloth to remove any dirt, oil, or debris. Avoid using abrasive materials or solvents that could damage the tools.

- Lubricate as needed: Apply a small amount of lubricant to the moving parts of your micrometers and calipers to ensure smooth operation. Use a lubricant recommended by the manufacturer and avoid over-lubricating.

- Handle with care: Always handle your measuring tools with care and avoid dropping or mishandling them. Rough handling can lead to misalignment, damage, or loss of calibration.

- Store in a protective case: When not in use, store your micrometers and calipers in a protective case or pouch. This will protect them from dust, moisture, and accidental damage.

- Avoid extreme temperatures: Exposure to extreme temperatures can affect the accuracy and performance of your measuring tools. Avoid storing them in areas with high heat, direct sunlight, or extreme cold.

- Regularly calibrate: Periodically calibrate your micrometers and calipers to ensure accuracy. Use calibration equipment or consult a professional calibration service for proper verification and adjustment of your tools.

- Inspect for wear and damage: Regularly inspect your micrometers and calipers for any signs of wear, damage, or rust. Pay attention to the jaws, anvils, and scales. Replace any worn or damaged parts to maintain the accuracy of your measurements.

- Follow manufacturer’s instructions: Read and follow the care and maintenance instructions provided by the manufacturer. These instructions may include specific guidelines for cleaning, lubrication, and storage of your specific micrometers and calipers.

By following these practices, you can preserve the accuracy and reliability of your micrometers and calipers, ensuring precise measurements for years to come.

Conclusion

Micrometers and calipers are indispensable tools for professionals and hobbyists who require precise measurements in their work. Whether you’re a machinist, engineer, woodworker, or jewelry maker, understanding how to use these measuring instruments correctly is crucial for producing accurate and high-quality results.

In this article, we explored the world of micrometers and calipers, learning about their types and applications. We discussed the importance of understanding measurement units and provided a comprehensive guide on how to read micrometers and calipers.

Furthermore, we emphasized the significance of choosing the right measuring tool for the job, considering factors like the type of measurement, measurement range, accuracy, and build quality. We also highlighted the best practices for using micrometers and calipers, such as handling them with care, making light contact, and taking multiple measurements for consistency.

Additionally, we discussed common mistakes to avoid, such as incorrect zeroing, excessive force, and using worn-out tools. We also stressed the importance of proper care and maintenance, including keeping the tools clean, lubricating them as needed, and storing them in protective cases.

By following these guidelines, you can ensure accurate measurements and prolong the lifespan of your micrometers and calipers, enabling you to work with precision and confidence.

In conclusion, micrometers and calipers are essential tools for anyone who values accuracy and quality in their work. With the knowledge and practices outlined in this article, you can master the art of measurement and unlock a world of precision in your craft.

Frequently Asked Questions about How To Use Micrometers And Calipers

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Use Micrometers And Calipers”