Articles

What Are The Different Pipes Used In Plumbing

Modified: September 2, 2024

Discover the various types of pipes commonly used in plumbing systems. Read our informative articles to learn more about different pipe materials and their applications.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

##

Introduction

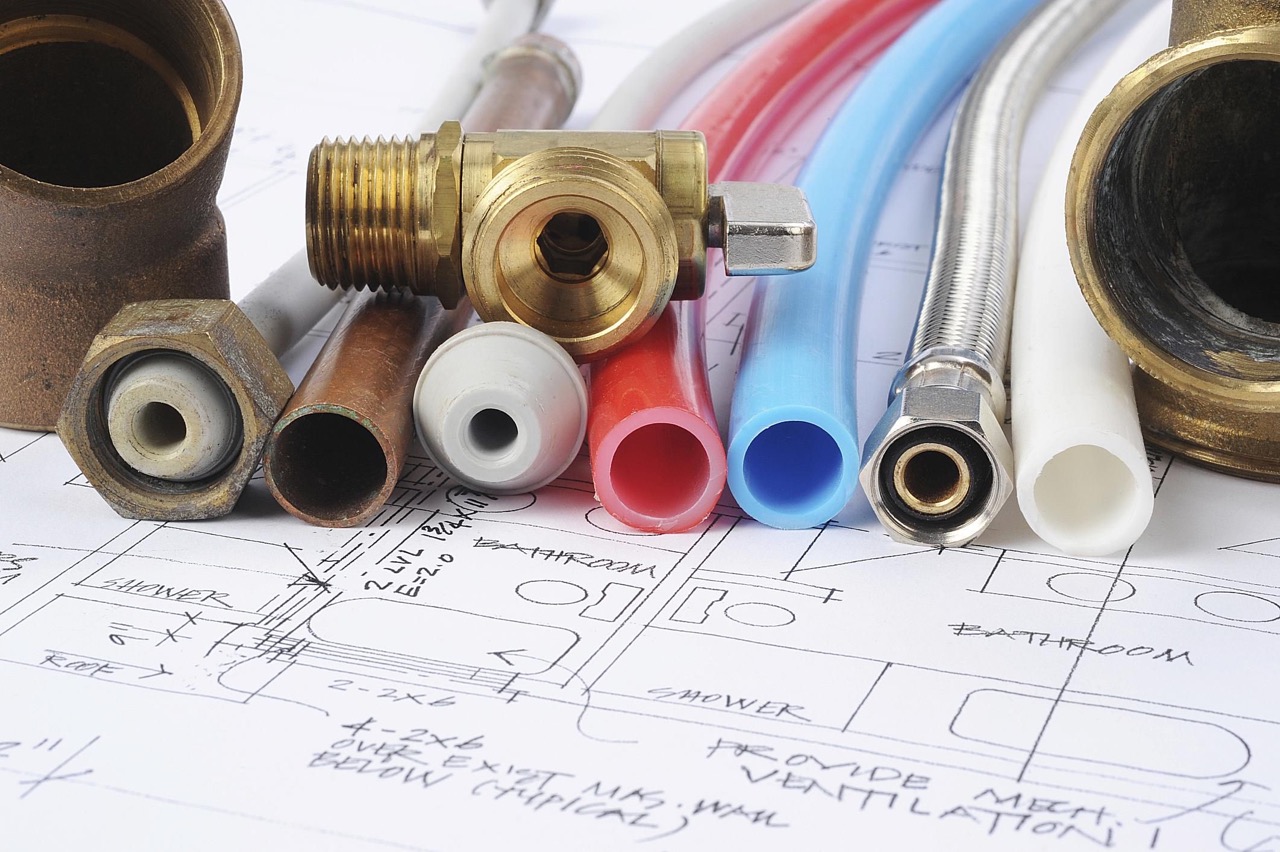

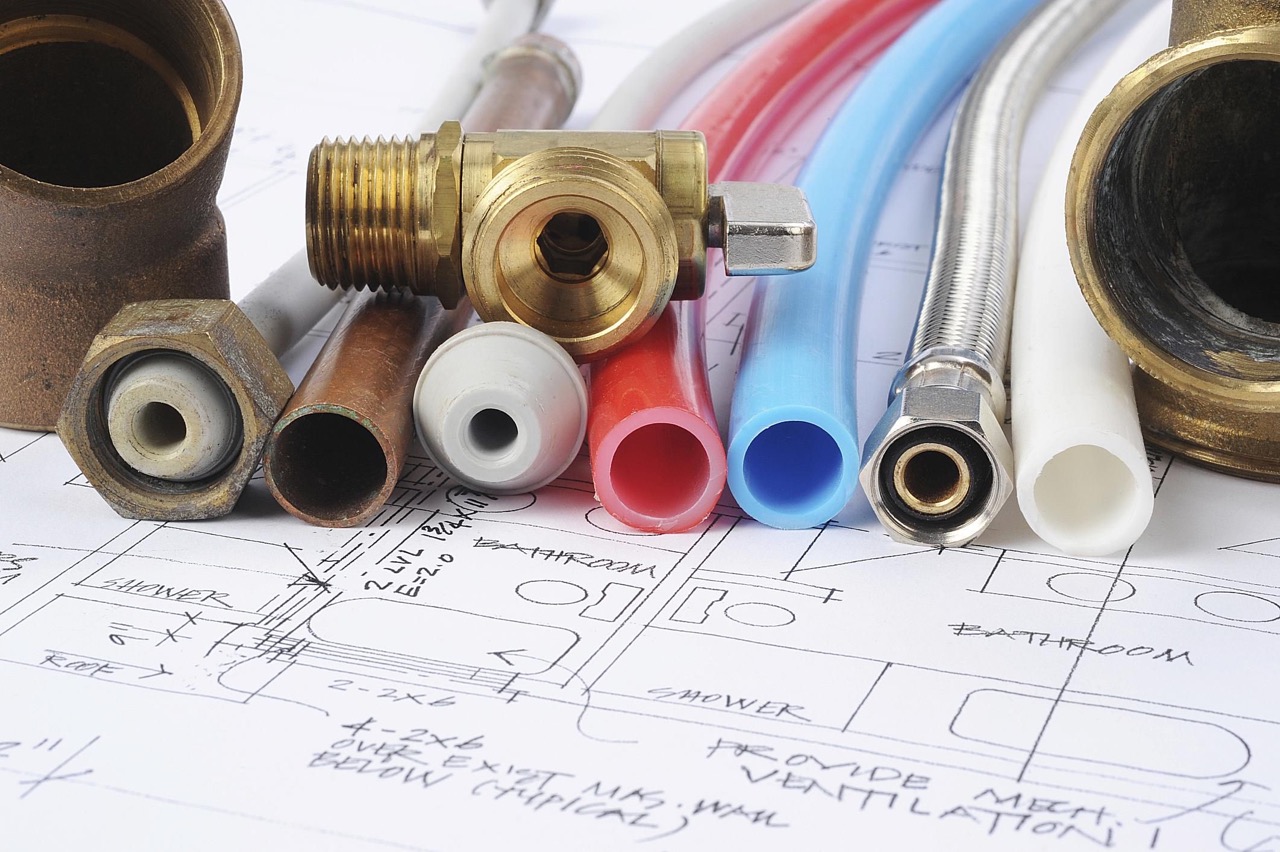

When it comes to plumbing systems, having the right pipes is crucial. The pipes used in plumbing play a key role in delivering water supply and removing waste from our homes and buildings. There are various types of pipes available, each with their own unique characteristics and applications. In this article, we will explore the different types of pipes commonly used in plumbing systems.

Choosing the right pipe material is essential to ensure the durability, efficiency, and longevity of the plumbing system. Factors such as cost, water pressure, corrosiveness, and the type of plumbing application all influence the selection of pipe material. Understanding the different types of pipes used in plumbing can help homeowners, contractors, and plumbers make informed decisions when it comes to pipe installations or repairs.

In the following sections, we will delve into the various types of pipes used in plumbing, highlighting their features, benefits, and common applications. Whether you’re a homeowner looking to renovate your bathroom, a contractor working on a new construction project, or a plumber troubleshooting plumbing issues, this article will provide you with valuable insights to help you make the right pipe choices for your specific needs.

Let’s dive into the world of plumbing pipes and explore the different materials that make up our plumbing systems. From traditional copper pipes to modern plastic options, we will examine their characteristics, advantages, and limitations.

Note: It is always advisable to consult with a licensed plumber or plumbing professional for expert advice and assistance when it comes to making decisions regarding plumbing pipe installations or repairs.##

Key Takeaways:

- Choose the Right Pipes for Your Plumbing Needs

Understanding the characteristics and applications of different pipes, such as copper, PVC, PEX, galvanized steel, cast iron, ABS, and HDPE, is crucial for ensuring a durable, efficient, and long-lasting plumbing system. Consider factors like cost, water quality, and intended application to make informed decisions. - Consult with a Professional Plumber for Expert Guidance

When it comes to selecting, installing, and maintaining plumbing pipes, consulting with a licensed plumber or plumbing professional is essential. Their expertise can provide valuable insights and ensure compliance with regulations, leading to a reliable and efficient plumbing infrastructure for your home or building.

Read more: What Is A Drain Pipe In Plumbing

Copper Pipes

Copper pipes have been a staple in plumbing systems for many years. This type of pipe is known for its durability, reliability, and long lifespan. Copper pipes are made from copper, a naturally occurring element known for its excellent thermal and electrical conductivity.

One of the primary advantages of copper pipes is their resistance to corrosion. Copper is highly resistant to corrosion caused by water, making it an ideal choice for plumbing systems. This resistance ensures that copper pipes maintain their structural integrity over time.

Copper pipes also have excellent heat resistance properties. They can withstand high temperatures without deforming or melting. This is particularly important in hot water systems where pipes are exposed to elevated temperatures.

In addition to their corrosion resistance and heat tolerance, copper pipes are also known for their ease of installation. Copper is a malleable material, which means it can be shaped and bent to fit various plumbing configurations. This flexibility makes copper pipes highly versatile and suitable for both residential and commercial plumbing applications.

Another benefit of copper pipes is their antimicrobial properties. Copper has been found to have natural antimicrobial effects, inhibiting the growth of bacteria and preventing the formation of biofilms inside the pipes. This makes copper pipes a hygienic choice for potable water systems.

However, it’s important to note that copper pipes can be more expensive than alternative materials such as plastic pipes. The cost of copper and the skilled labor required for installation contribute to its higher price point. Additionally, copper pipes can be susceptible to damage from freezing temperatures, so proper insulation is necessary in colder climates.

Overall, copper pipes are an excellent choice for plumbing systems due to their durability, resistance to corrosion, and antimicrobial properties. They provide peace of mind and longevity, making them a popular option for a wide range of plumbing applications.

Important considerations when using copper pipes include adhering to local building codes and regulations, ensuring proper insulation in cold climates, and consulting with a professional plumber for installation and maintenance guidance. By doing so, you can maximize the benefits of copper pipes and ensure a reliable and efficient plumbing system for your home or building.##

PVC Pipes

PVC (polyvinyl chloride) pipes are widely used in plumbing systems for their versatility, affordability, and ease of installation. These pipes are made from a synthetic plastic polymer called PVC, which is known for its durability, resistance to corrosion, and low maintenance requirements.

One of the biggest advantages of PVC pipes is their cost-effectiveness. PVC pipes are relatively inexpensive compared to other pipe materials, making them a popular choice for both residential and commercial plumbing projects. The affordability of PVC pipes extends beyond the initial purchase cost, as they also require minimal maintenance and have a long lifespan.

PVC pipes are also lightweight, making them easy to handle and install. This characteristic is particularly beneficial for installation in tight spaces or overhead applications. The lightweight nature of PVC pipes reduces the need for heavy machinery or equipment during the installation process, resulting in lower labor costs.

Another notable advantage of PVC pipes is their resistance to chemicals and corrosion. PVC is highly resistant to various chemicals commonly found in soil and water, ensuring the longevity of the pipe even in corrosive environments. This makes PVC pipes suitable for a wide range of plumbing applications, including drainage systems and underground installations.

In addition to their chemical resistance, PVC pipes are also non-conductive. This means they do not conduct electricity, making them a safe option for plumbing systems. PVC pipes are widely used for electrical conduit applications, where they provide protection and insulation for electrical wiring.

Furthermore, PVC pipes are known for their smooth interior surface, which results in minimal flow resistance. This smoothness reduces friction within the pipes, allowing for efficient water flow and reduced energy consumption. PVC pipes are also resistant to scaling and build-up, ensuring a consistent flow of water over time.

However, it’s important to note that PVC pipes have a lower heat tolerance compared to other pipe materials. They may warp or deform when exposed to high temperatures, so they are not suitable for hot water applications. PVC pipes are primarily used for cold water supply lines, drainage systems, and vent pipes.

Overall, PVC pipes provide an affordable, versatile, and low-maintenance solution for plumbing systems. Their resistance to corrosion and chemicals, as well as their ease of installation, make them a popular choice for a wide range of plumbing applications. It’s essential to follow local building codes and guidelines when using PVC pipes to ensure proper installation and compliance. Consulting with a professional plumber can provide valuable insights and guidance for utilizing PVC pipes effectively in your plumbing projects.##

PEX Pipes

PEX (cross-linked polyethylene) pipes have gained popularity in recent years due to their flexibility, durability, and ease of installation. These pipes are made from a high-density polyethylene material that is cross-linked, resulting in enhanced strength and flexibility.

One of the significant advantages of PEX pipes is their flexibility. PEX pipes can be bent and maneuvered without the need for additional fittings, making them highly adaptable for complex plumbing systems. The flexibility of PEX pipes allows for easier installation in tight spaces and around corners, reducing the need for excessive joints and fittings.

PEX pipes also have excellent resistance to freeze damage. They are able to expand and contract without cracking or bursting, making them a reliable option for plumbing systems in cold climates. This freeze-resistant property makes PEX pipes a favorable choice for both residential and commercial applications.

In addition to their flexibility and freeze resistance, PEX pipes are known for their resistance to corrosion and scaling. Unlike metal pipes, PEX pipes do not corrode when exposed to certain chemicals or minerals in water, ensuring a longer lifespan and improved water quality. The smooth interior surface of PEX pipes also resists scaling and build-up, promoting consistent water flow and minimizing pressure loss.

Another advantage of PEX pipes is their ability to withstand high temperatures and pressure. PEX pipes are suitable for both hot and cold water supply lines, making them versatile for a range of plumbing applications. The high-temperature resistance of PEX pipes allows for efficient hot water distribution throughout a building.

Furthermore, PEX pipes are known for their superior insulation properties. The material used in PEX pipes has excellent thermal efficiency, reducing heat loss during hot water distribution and preventing water from freezing in cold environments. This insulation property contributes to energy savings and improved overall efficiency of the plumbing system.

It’s important to note that PEX pipes are not recommended for outdoor or exposed applications, as they are susceptible to UV radiation damage. Proper insulation or covering should be used to protect PEX pipes when installed outdoors.

In summary, PEX pipes offer flexibility, freeze resistance, corrosion resistance, and excellent thermal efficiency. These factors make them a reliable choice for various plumbing applications. However, it’s crucial to follow industry standards and recommendations for PEX pipe installations to ensure proper connections, fittings, and insulation. Consulting with a professional plumber can provide valuable guidance and ensure the optimal use of PEX pipes in your plumbing system.##

Galvanized Steel Pipes

Galvanized steel pipes have been used in plumbing systems for many years due to their strength, durability, and corrosion resistance. These pipes are made from steel that has been coated with a layer of zinc to protect against corrosion and extend their lifespan.

One of the primary advantages of galvanized steel pipes is their exceptional strength. Steel is a robust and resilient material, making galvanized steel pipes suitable for high-pressure applications and underground installations. These pipes are commonly used in commercial and industrial plumbing systems where strength and durability are paramount.

Galvanized steel pipes also have excellent corrosion resistance. The zinc coating applied to the steel acts as a protective barrier, preventing rust and corrosion from developing on the pipe’s surface. This corrosion resistance makes galvanized steel pipes ideal for plumbing systems that come into contact with harsh or corrosive substances, such as industrial settings or areas with aggressive water conditions.

Another advantage of galvanized steel pipes is their fire resistance properties. Steel is naturally resistant to fire and can withstand high temperatures, making galvanized steel pipes a safe option for plumbing systems in fire-prone areas. The fire resistance of galvanized steel pipes adds an extra layer of protection and peace of mind.

In addition to their strength and corrosion resistance, galvanized steel pipes have a long lifespan. When properly installed and maintained, galvanized steel pipes can last for several decades. This longevity reduces the need for frequent replacements, saving both time and money in the long run.

Despite their numerous advantages, there are a few considerations to keep in mind when using galvanized steel pipes. Firstly, the zinc coating on galvanized steel pipes can gradually deteriorate over time, especially in aggressive water conditions. This can lead to decreased water quality and reduced flow rates. Regular inspections and maintenance are necessary to identify and address any signs of corrosion or damage.

Secondly, galvanized steel pipes can be challenging to work with due to their weight and rigidity. They require skilled professionals and specialized tools for installation and repairs. It’s essential to hire a qualified plumber with experience in handling galvanized steel pipes to ensure proper installation and minimize the risk of leaks or other issues.

In summary, galvanized steel pipes provide excellent strength, corrosion resistance, and fire resistance properties. They are commonly used in commercial and industrial plumbing systems due to their durability and long lifespan. However, regular maintenance and inspections are necessary to ensure the integrity of the zinc coating and prevent corrosion-related issues. Consulting with a professional plumber is recommended for the proper installation and maintenance of galvanized steel pipes in your plumbing system.##

When choosing pipes for plumbing, consider factors such as material, size, and intended use. Common options include copper, PVC, PEX, and galvanized steel. Each has its own advantages and limitations, so it’s important to select the right type for your specific needs.

Read more: How To Use Flex Pipe For Plumbing

Cast Iron Pipes

Cast iron pipes have a long history of use in plumbing systems and are known for their durability, strength, and soundproofing capabilities. These pipes are made from cast iron, a material known for its high resistance to corrosion and impact.

One of the primary advantages of cast iron pipes is their exceptional longevity. When properly installed and maintained, cast iron pipes can last for more than 100 years. This long lifespan reduces the need for frequent replacements, making cast iron pipes a cost-effective option for plumbing systems.

Another advantage of cast iron pipes is their superior soundproofing capabilities. The density of cast iron significantly reduces the transmission of noise and vibrations, making them ideal for multi-story buildings or areas where noise control is important. This soundproofing property helps to create a quieter and more comfortable living or working environment.

Cast iron pipes are also highly resistant to fire. Their non-combustible properties make them a safe choice for plumbing systems in fire-prone areas. In the event of a fire, cast iron pipes will not contribute to its spread, providing an extra level of security and protection.

Furthermore, cast iron pipes have a smooth interior surface, which allows for efficient water flow. The smoothness of the pipes reduces friction and minimizes the buildup of sediment or debris that can cause clogs or blockages. This feature contributes to a reliable plumbing system with consistent water flow rates.

Despite their numerous advantages, there are a few considerations to keep in mind when using cast iron pipes. Firstly, cast iron pipes are heavy and can be challenging to handle and install. They require additional support and careful planning during the installation process to ensure their stability and longevity.

Secondly, cast iron pipes are susceptible to corrosion over time. Although cast iron is naturally resistant to corrosion, exposure to certain chemicals or aggressive water conditions can still lead to rust and deterioration. Regular inspections and maintenance are necessary to identify and address any signs of corrosion or damage promptly.

Lastly, cast iron pipes may require special tools and expertise for repairs or replacements. It’s crucial to work with a qualified plumber who has experience working with cast iron pipes to ensure proper maintenance and prevent any issues that may arise.

In summary, cast iron pipes offer durability, strength, soundproofing capabilities, and fire resistance. Their long lifespan and resistance to corrosion make them a reliable choice for plumbing systems. However, proper installation, maintenance, and regular inspections are essential to ensure the longevity and performance of cast iron pipes. Consulting with a professional plumber is recommended for the proper handling and maintenance of cast iron pipes in your plumbing system.##

ABS Pipes

ABS (acrylonitrile butadiene styrene) pipes are a type of plastic pipe commonly used in plumbing systems. These pipes are known for their strength, durability, and resistance to chemicals. ABS pipes are made from a thermoplastic polymer composite that offers a range of advantages for plumbing applications.

One of the primary benefits of ABS pipes is their excellent resistance to chemicals, including corrosive substances found in plumbing systems. ABS pipes can withstand exposure to a variety of chemicals without deteriorating or corroding, making them suitable for both residential and commercial plumbing applications.

ABS pipes are also lightweight and easy to handle, making installation a breeze. The lightweight nature of ABS pipes reduces labor costs and simplifies the overall installation process. Additionally, ABS pipes can be cut and joined using solvent cement, which eliminates the need for complex and time-consuming welding or soldering.

Another advantage of ABS pipes is their soundproofing capabilities. The composition of ABS pipes helps dampen noise transmission, making them ideal for plumbing systems in apartments, multi-story buildings, or areas where noise control is important. The soundproofing properties of ABS pipes contribute to a quieter and more comfortable living or working environment.

Furthermore, ABS pipes are known for their low thermal conductivity. This means that they retain heat and cold, helping to maintain the temperature of the water inside the pipes. This property can be particularly useful in hot water supply lines, as it reduces heat loss and improves energy efficiency.

ABS pipes are also resistant to impact and abrasion. They can withstand physical stress and are less likely to crack or break compared to other pipe materials. This durability makes ABS pipes a reliable choice for plumbing systems, especially in areas with high traffic or where accidental impacts occur frequently.

It’s important to note that ABS pipes are not suitable for hot water temperatures above 176°F (80°C). They are primarily used for cold water supply lines, drain, waste, and vent systems. It’s crucial to follow local building codes and guidelines when installing ABS pipes and to consult with a professional plumber to ensure proper connections and compliance.

In summary, ABS pipes offer excellent chemical resistance, lightweight construction, soundproofing capabilities, and durability. Their ease of installation and low maintenance requirements make them a popular choice for plumbing applications. However, it’s essential to adhere to the recommended usage guidelines and consult with a professional plumber for the proper installation and maintenance of ABS pipes in your plumbing system.##

HDPE Pipes

HDPE (high-density polyethylene) pipes are versatile and durable pipes used in a wide range of plumbing applications. These pipes are made from a thermoplastic polymer known for its strength, flexibility, and resistance to chemicals. HDPE pipes offer several benefits that make them a popular choice for both residential and commercial plumbing systems.

One of the primary advantages of HDPE pipes is their high strength-to-density ratio. HDPE pipes are incredibly strong and have a high tensile strength, allowing them to withstand high-pressure applications. This strength makes HDPE pipes suitable for underground installations and other plumbing systems where durability is required.

HDPE pipes are also known for their flexibility. They can be easily bent and maneuvered without the need for additional fittings, making installation more efficient and cost-effective. The flexibility of HDPE pipes also allows for easier navigation around obstacles and reduces the risk of leaks or pipe failures due to stress.

Another key benefit of HDPE pipes is their resistance to chemicals and corrosion. HDPE is highly resistant to a wide range of chemicals, including acids, alkalis, and other corrosive substances. This resistance makes HDPE pipes suitable for a variety of plumbing applications, including industrial and agricultural settings where exposure to chemicals is common.

HDPE pipes are lightweight and easy to handle, simplifying the installation process. The lightweight nature of HDPE pipes reduces labor costs and makes them more manageable to transport and maneuver on-site. Additionally, HDPE pipes can be joined using heat fusion, eliminating the need for additional fittings and reducing the risk of leaks.

Furthermore, HDPE pipes have excellent UV resistance. They can withstand prolonged exposure to sunlight without degradation or discoloration, making them suitable for both indoor and outdoor plumbing applications. This UV resistance ensures the longevity and aesthetics of HDPE pipes, even in harsh environmental conditions.

It’s important to note that HDPE pipes have a limited temperature range. They are typically used for cold water supply lines and can handle temperatures up to 140°F (60°C). For hot water applications, it’s important to choose a different pipe material that can withstand higher temperatures.

In summary, HDPE pipes offer high strength, flexibility, chemical resistance, and UV resistance. Their durability, ease of installation, and low maintenance requirements make them a popular choice for a variety of plumbing applications. However, it’s crucial to follow local building codes and guidelines when installing HDPE pipes and to consult with a professional plumber for the proper connections and usage recommendations.##

Conclusion

Choosing the right pipes for your plumbing system is essential to ensure its durability, efficiency, and longevity. In this article, we explored the different types of pipes commonly used in plumbing systems, including copper pipes, PVC pipes, PEX pipes, galvanized steel pipes, cast iron pipes, ABS pipes, and HDPE pipes.

Copper pipes are renowned for their durability, resistance to corrosion, and natural antimicrobial properties. They are a popular choice for their reliability and longevity, although they can be more expensive than other materials.

PVC pipes are known for their affordability, versatility, and ease of installation. They offer excellent resistance to chemicals, corrosion, and scaling, making them suitable for a wide range of plumbing applications. However, they have a lower heat tolerance and are primarily used for cold water supply lines and drainage systems.

PEX pipes are valued for their flexibility, freeze resistance, and resistance to corrosion. They offer excellent versatility, making installation easier in tight spaces. PEX pipes are suitable for both hot and cold water supply lines and provide efficient water distribution.

Galvanized steel pipes are prized for their strength, durability, and corrosion resistance. They are commonly used in commercial and industrial plumbing systems and offer fire resistance properties. However, regular maintenance is required to prevent corrosion and deterioration.

Cast iron pipes are known for their longevity, soundproofing capabilities, and resistance to fire. They provide a reliable solution for plumbing systems and can last for more than a century when properly maintained.

ABS pipes offer excellent resistance to chemicals, lightweight construction, and soundproofing capabilities. They are a cost-effective choice for plumbing systems, although they are not suitable for hot water applications.

HDPE pipes are highly versatile, durable, and resistant to chemicals and UV radiation. Their high strength-to-density ratio and flexibility make them ideal for a wide range of plumbing applications, but they have a limited temperature range for hot water usage.

In conclusion, the choice of pipes for your plumbing system depends on factors such as cost, intended application, water quality, and local building codes. It is crucial to make informed decisions and consult with a professional plumber or plumbing expert to ensure proper installation, maintenance, and compliance with regulations. By selecting the right pipes for your plumbing system, you can enjoy a reliable, efficient, and long-lasting plumbing infrastructure for your home or building.

Frequently Asked Questions about What Are The Different Pipes Used In Plumbing

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Are The Different Pipes Used In Plumbing”