Articles

What Is An IMC Electrical Conduit

Modified: March 1, 2024

Learn all about the importance and benefits of IMC electrical conduit in this informative article. Discover how it ensures safe and reliable electrical installations.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

What Is IMC Electrical Conduit?

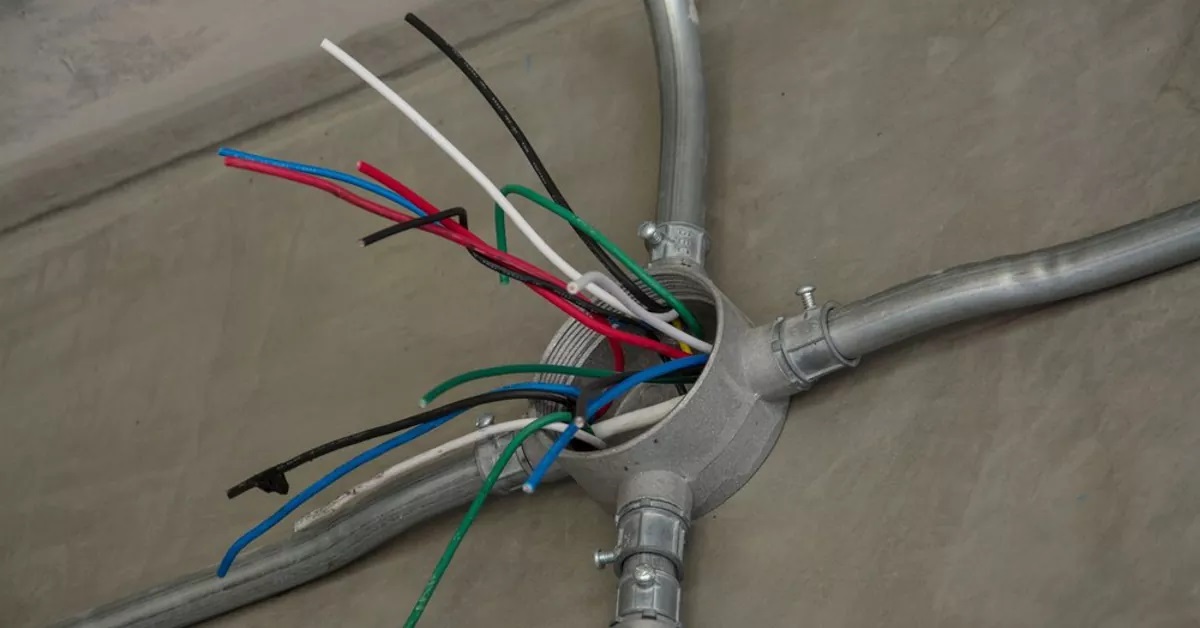

IMC, which stands for Intermediate Metal Conduit, is a type of electrical conduit used for protecting and routing electrical wiring in commercial and industrial buildings. It is a durable and reliable option that provides mechanical and electrical protection to the enclosed wiring system.

The IMC electrical conduit is made of galvanized steel, which offers excellent strength and corrosion resistance. It is designed to withstand tough environmental conditions, making it suitable for both indoor and outdoor installations.

IMC electrical conduit is widely used in various applications, including commercial buildings, factories, warehouses, and infrastructure projects. Its versatility and reliability make it an ideal choice for professionals in the electrical industry.

Let us explore the features, benefits, applications, installation process, and maintenance of IMC electrical conduit in detail.

Definition of IMC Electrical Conduit

Key Takeaways:

- IMC Electrical Conduit: A Versatile and Durable Wiring Solution

IMC conduit, made of galvanized steel, strikes a balance between flexibility and strength, providing excellent mechanical and electrical protection for commercial and industrial electrical wiring systems. - Enhancing Safety and Efficiency with IMC Conduit

IMC conduit offers superior protection, durability, and ease of installation, making it a cost-effective and versatile choice for safeguarding electrical systems in diverse applications.

Read more: What Is Electrical Conduit

IMC Electrical Conduit: A Versatile Wiring Solution

IMC electrical conduit is a type of rigid steel tubing that is used to protect and route electrical wiring in a variety of applications. It is specifically designed to provide both mechanical and electrical protection to the enclosed wiring system.

IMC electrical conduit is manufactured from galvanized steel, which makes it resistant to corrosion and provides durability and strength. The galvanized coating also helps to protect the conduit against moisture, chemicals, and other environmental factors that may otherwise damage the wiring.

The inner surface of the IMC conduit is smooth, allowing for easy pulling and installation of wires. Its threaded ends make it compatible with a range of electrical fittings, such as couplings, connectors, and conduit bodies.

One of the distinguishing features of IMC electrical conduit is its intermediate thickness. It is thicker than thin-wall conduit but thinner than rigid metal conduit (RMC). This intermediate thickness strikes a perfect balance between flexibility and strength, making it suitable for various applications.

IMC electrical conduit is available in standard lengths and can be easily cut to size using a pipe cutter or saw. It is also compatible with standard bending tools, allowing for easy customization and installation in complex routing scenarios.

Overall, the IMC electrical conduit provides a versatile and reliable wiring solution that meets the requirements of modern electrical installations.

Features of IMC Electrical Conduit

Durable and Reliable Protection for Electrical Wiring

IMC electrical conduit offers several key features that make it a popular choice for protecting and routing electrical wiring. Here are some of its notable features:

- Galvanized Steel Construction: IMC conduit is made of galvanized steel, which provides excellent strength, durability, and corrosion resistance. The galvanized coating protects the conduit from moisture, chemicals, and other environmental factors, ensuring long-lasting performance.

- Intermediate Thickness: IMC conduit strikes a perfect balance between flexibility and strength with its intermediate thickness. It is thicker compared to thin-wall conduit, providing better protection for the enclosed wiring, yet thinner than rigid metal conduit (RMC), making it easier to bend and install in tight spaces.

- Smooth Interior Surface: The inner surface of IMC conduit is smooth, allowing for easy pulling and installation of electrical wires. The smooth interior reduces friction, preventing damage to the insulation of the wires during installation or maintenance.

- Threaded Ends: IMC conduit features threaded ends, which allow for easy connection to electrical fittings such as couplings, connectors, and conduit bodies. The threaded connections provide a secure and reliable attachment, ensuring the integrity of the electrical wiring system.

- Compatibility: IMC conduit is compatible with a wide range of electrical fittings and accessories, making it easy to integrate into existing electrical systems. It can be used with standard couplings, connectors, straps, and hangers, simplifying the installation process.

- Excellent Mechanical Protection: The sturdy construction of IMC conduit provides superior mechanical protection for the enclosed wiring system. It can withstand impact, vibration, and other external forces, safeguarding the electrical conductors from physical damage.

- Wide Temperature Range: IMC conduit has a wide operating temperature range, allowing it to be used effectively in both extreme hot and cold environments. This makes it suitable for various applications, including outdoor installations.

These features make IMC electrical conduit an excellent choice for professionals in the electrical industry who require a durable and reliable solution for protecting and routing electrical wiring in commercial and industrial settings.

Benefits of Using IMC Electrical Conduit

Enhancing Safety and Efficiency in Electrical Installations

IMC electrical conduit offers several benefits that contribute to the safety, efficiency, and longevity of electrical installations. Here are some of the key benefits of using IMC electrical conduit:

- Superior Protection: IMC conduit provides excellent protection for electrical wiring against physical damage, moisture, chemicals, and other environmental factors. It helps ensure the integrity of the wiring system, reducing the risk of potential hazards and electrical malfunctions.

- Durability and Longevity: The galvanized steel construction of IMC conduit enhances its durability and longevity. It can withstand harsh environmental conditions, making it suitable for both indoor and outdoor applications. The corrosion-resistant coating ensures that the conduit maintains its performance over time.

- Flexibility: IMC conduit strikes a balance between flexibility and strength. Its intermediate thickness allows for easier bending and installation compared to rigid metal conduit (RMC), providing more flexibility in routing electrical wiring in complex layouts.

- Easy Installation: IMC conduit is compatible with standard bending tools and electrical fittings, making installation quick and convenient. The threaded ends enable easy connection to fittings, while the smooth interior surface reduces friction during wire pulling, simplifying the overall installation process.

- Cost-effective: IMC conduit offers a cost-effective solution for electrical installations. Its durable construction and long lifespan result in reduced maintenance and replacement costs over time. Additionally, the ease of installation reduces labor expenses, making it an economical choice for electrical projects.

- Versatility: IMC conduit is suitable for a wide range of applications. It can be used in commercial buildings, factories, warehouses, infrastructure projects, and more. Its compatibility with various electrical fittings and accessories allows for seamless integration into different electrical systems.

- Compliance with Codes and Standards: IMC conduit meets the requirements of various electrical codes and standards, ensuring that installations are compliant and safe. It is recognized and approved by regulatory bodies, providing peace of mind for professionals and clients.

By utilizing IMC electrical conduit, professionals in the electrical industry can benefit from enhanced safety, efficiency, and longevity in their electrical installations. Its protective properties and ease of installation make it a reliable choice for safeguarding electrical systems and ensuring smooth operation.

Applications of IMC Electrical Conduit

Flexible and Reliable Solution for Various Industries

IMC electrical conduit is widely used in a variety of applications across different industries. Its durability, versatility, and mechanical protection make it well-suited for various electrical wiring needs. Here are some of the common applications of IMC electrical conduit:

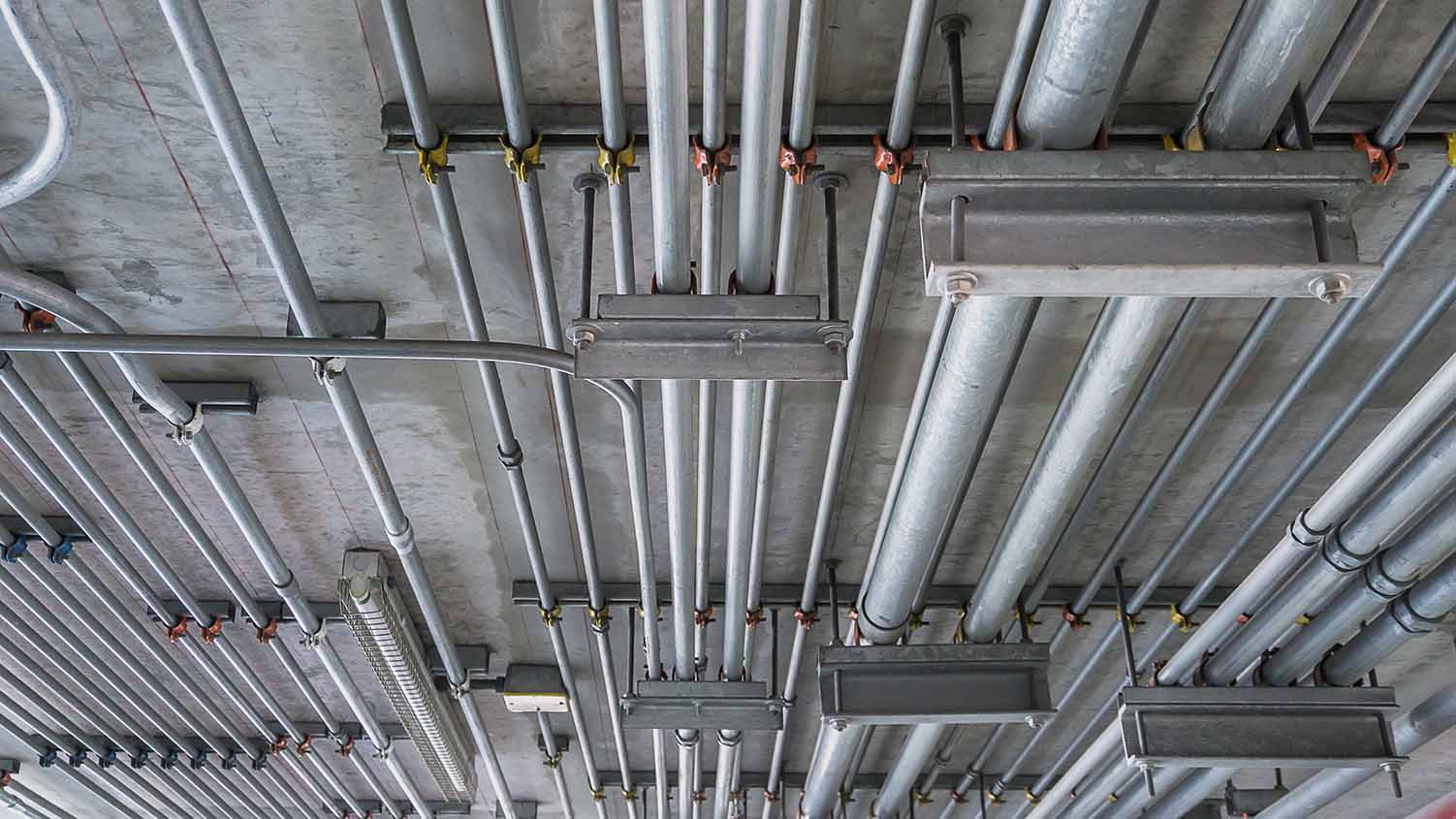

- Commercial Buildings: IMC conduit is frequently used in commercial buildings, such as offices, retail spaces, and restaurants. It provides a reliable solution for routing electrical wiring, ensuring the safety and efficiency of the building’s electrical system.

- Industrial Facilities: The robust construction of IMC conduit makes it ideal for industrial settings, including factories, manufacturing plants, and warehouses. It offers excellent mechanical protection, safeguarding the electrical wiring from heavy machinery, vibrations, and other potential hazards.

- Infrastructure Projects: IMC conduit is commonly utilized in infrastructure projects, such as bridges, tunnels, and highways. Its durability and resistance to environmental factors make it suitable for outdoor installations, ensuring the longevity of the electrical system in these critical infrastructure projects.

- Data Centers: Data centers require a reliable and stable electrical infrastructure. IMC conduit is often employed to protect the electrical wiring in data centers, ensuring uninterrupted power supply and reducing the risk of electrical failures that could lead to data loss or system downtime.

- Hospitals and Healthcare Facilities: IMC conduit provides a safe and secure wiring solution for hospitals and healthcare facilities. It helps protect critical electrical systems, such as patient monitoring equipment, emergency systems, and electrical panels, ensuring uninterrupted healthcare services.

- Schools and Educational Institutions: IMC conduit is used in schools and educational institutions to protect electrical wiring in classrooms, laboratories, and administrative areas. Its robust construction ensures the safety of students, teachers, and staff by guarding against potential electrical hazards.

- Retail and Commercial Spaces: IMC conduit is commonly employed in retail spaces, shopping malls, and commercial complexes. It helps route electrical wiring for lighting systems, HVAC controls, and power outlets, ensuring reliable and safe electrical distribution throughout these spaces.

These are just a few examples of the diverse applications of IMC electrical conduit. Its versatility, durability, and ease of installation make it a preferred choice for electrical professionals across various industries.

Installation Process of IMC Electrical Conduit

Read more: What Is A Conduit

Step-by-Step Guide for a Successful Installation

The installation process of IMC electrical conduit involves several steps to ensure a safe and efficient wiring system. Here is a step-by-step guide to help you with the installation:

- Plan and Prepare: Begin by planning the routing of the conduit and determining the quantity of conduit and fittings needed for the installation. Take into consideration any obstacles, such as walls and beams, that may require precise measurements or modifications.

- Tools and Materials: Gather the necessary tools and materials for the installation, including the IMC conduit, connectors, couplings, straps, hangers, and a conduit bender. Ensure that you have the appropriate safety equipment, such as gloves and safety glasses.

- Marking and Measurement: Use a tape measure and a level to mark the locations for the conduit runs. Measure and mark where the conduit will enter and exit walls or other enclosures. Take into account the required bends and offset measurements for navigating around corners and obstacles.

- Cutting the Conduit: Use a pipe cutter or a hacksaw to cut the IMC conduit to the desired lengths, based on the marked measurements. Ensure that the cuts are clean and free from burrs, which could impede the insertion of wires or cause damage to the insulation.

- Threading: If needed, thread the ends of the IMC conduit using a pipe threading tool. This will allow for a secure connection with the electrical fittings, such as couplings and connectors. Make sure the threads are clean and free from debris.

- Bending the Conduit: Utilize a conduit bender to create the necessary bends in the conduit for corners and offsets. Follow the manufacturer’s instructions and the planned measurements to achieve the desired bend radius without damaging the conduit. Use a level to ensure the bends are straight and aligned.

- Connecting and Securing: Connect the sections of IMC conduit using appropriate connectors and couplings. Ensure that the connections are tight and secure to maintain the integrity of the conduit system. Use straps and hangers to secure the conduit to walls, ceilings, or other structural components.

- Pulling Wires: Once the conduit is installed and secured, pull the electrical wires through the conduit. Ensure that the wires are properly sized for the conduit and comply with electrical codes and standards. Take care to prevent any damage to the wires during the pulling process.

- Grounding: Install the necessary grounding components, such as grounding bushings and grounding wire, according to electrical codes and safety requirements. Proper grounding is essential for electrical safety and to protect against electrical faults or surges.

- Final Inspection: Once the installation is complete, conduct a thorough inspection of the entire conduit system to ensure proper alignment, secure connections, and compliance with electrical codes. Check for any potential issues or deficiencies that may require adjustment or correction.

It is essential to adhere to proper safety protocols and consult electrical codes and regulations during the installation process. If you are unsure or inexperienced, it is recommended to seek the assistance of a qualified electrician or professional electrical contractor to ensure a successful and safe installation of the IMC electrical conduit.

Maintenance and Troubleshooting of IMC Electrical Conduit

Keeping your Wiring System in Optimal Condition

Maintaining and troubleshooting IMC electrical conduit is essential for ensuring the longevity and efficiency of the wiring system. Here are some maintenance and troubleshooting tips for IMC electrical conduit:

- Regular Inspections: Conduct regular inspections of the IMC conduit system to check for any signs of physical damage, corrosion, or loose connections. Inspect the conduit for dents, bends, or other abnormalities that may affect its performance or compromise the integrity of the wiring.

- Clean the Conduit: Periodically clean the interior of the IMC conduit to remove any debris, dirt, or dust that may accumulate over time. This will ensure smooth wire pulling and reduce the risk of friction damage to the wires during installation or maintenance.

- Check for Corrosion: Inspect the exterior of the IMC conduit for any signs of corrosion or rust. If you notice any areas of corrosion, use a wire brush or sandpaper to remove the rust and apply a corrosion-resistant paint or coating to protect it from further damage.

- Tighten Connections: Check the connections, such as couplings and connectors, along the conduit system to ensure they are tight and secure. Loose connections can lead to electrical failures or unsafe conditions. Properly tighten any loose connections or consider replacing damaged fittings.

- Repair or Replace Damaged Conduit: If you identify any damaged sections of the IMC conduit, such as dents, cracks, or breaks, it is important to repair or replace them promptly. Damaged conduit compromises the protection and integrity of the wiring system and should not be ignored.

- Verify Grounding: Regularly check the grounding components of the IMC conduit system to ensure they are in good condition and properly connected. Grounding is crucial for electrical safety and mitigating the risk of electrical faults or surges.

- Address Moisture Issues: Moisture can be detrimental to the performance and longevity of the wiring system. If you notice any water intrusion or excessive moisture around the IMC conduit, investigate and address the source of the moisture to prevent corrosion or damage to the wiring.

- Consult a Professional: If you encounter any complex issues or are unsure about troubleshooting steps, it is best to consult a qualified electrician or professional electrical contractor. They have the expertise to diagnose and resolve any problems with the IMC conduit system.

Proper maintenance and timely troubleshooting of IMC electrical conduit can help prevent potential electrical failures, ensure safety, and extend the lifespan of the wiring system. Regular inspections, cleaning, and addressing any issues promptly are key to maintaining an efficient and reliable electrical conduit system.

Comparison between IMC and Other Types of Conduits

Choosing the Right Conduit for Your Wiring Needs

When it comes to protecting and routing electrical wiring, there are several types of conduits available, each with its own advantages and considerations. Here’s a comparison between IMC and other common types of conduits:

Rigid Metal Conduit (RMC):

- RMC is the thickest and heaviest type of conduit, providing maximum protection for electrical wiring.

- It is suitable for heavy-duty applications where additional strength and durability are required.

- However, the rigid nature of RMC makes it more challenging to install, especially in tight spaces or when implementing complex wiring layouts.

- Overall, RMC is commonly used in industrial settings and high-risk areas where robust protection is essential.

Read more: How To Bend An Electrical Conduit

Electrical Metallic Tubing (EMT):

- EMT is a lightweight and cost-effective conduit option, made of thin-walled steel or aluminum.

- It is easy to bend, making it suitable for applications that require flexibility and maneuverability.

- EMT provides moderate protection for electrical wiring and is often used for residential and commercial installations.

- However, it may not be suitable for environments where high levels of physical protection are required.

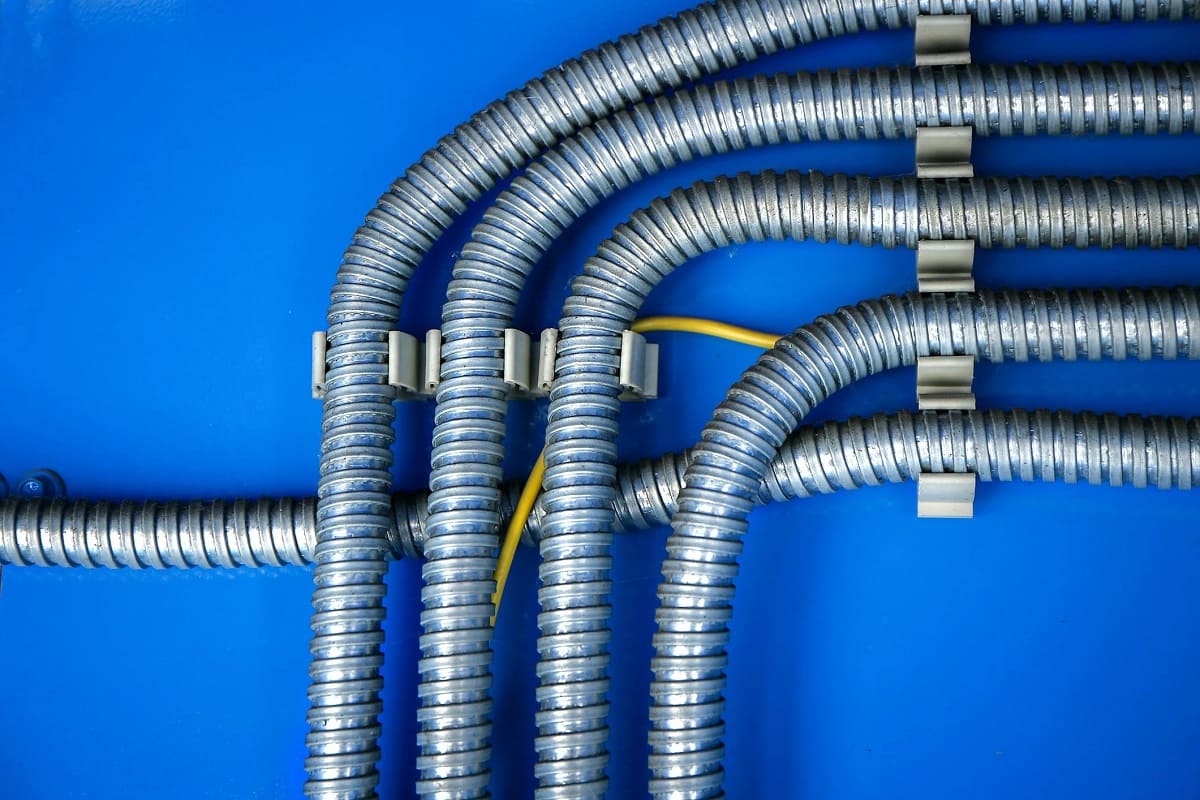

Flexible Metal Conduit (FMC):

- FMC is a flexible conduit made of spiral-wound metal strips, typically coated with a thermoplastic or liquid-tight jacket.

- It is highly flexible and easily adaptable to complex wiring layouts or areas with curves and bends.

- FMC offers moderate protection for electrical cables but may not be as durable as rigid conduits.

- It is commonly used in applications that require flexibility and where physical protection is not a primary concern.

IMC Electrical Conduit:

- IMC is an intermediate option in terms of thickness and flexibility, providing a balance between the durability of RMC and the maneuverability of EMT.

- It offers excellent mechanical and electrical protection for wiring systems in commercial and industrial settings.

- IMC is resistant to corrosion, making it suitable for both indoor and outdoor installations.

- It is compatible with various electrical fittings and accessories, allowing for easy customization and integration into existing systems.

- IMC is commonly used in applications that require a reliable and versatile conduit for protecting and routing electrical wiring safely.

Ultimately, the choice between IMC and other types of conduits depends on the specific requirements of the wiring project. Factors such as the level of physical protection needed, flexibility requirements, and installation constraints should be taken into account.

It is advisable to consult with electrical professionals or code officials to ensure compliance with regulations and to determine the most suitable conduit option for your specific application.

Frequently Asked Questions (FAQs)

Answers to Common Queries about IMC Electrical Conduit

Here are some frequently asked questions regarding IMC electrical conduit:

Read more: How To Run An Electrical Conduit

1. What does IMC stand for?

IMC stands for Intermediate Metal Conduit. It is a type of electrical conduit used for protecting and routing electrical wiring in commercial and industrial buildings.

2. What is IMC electrical conduit made of?

IMC electrical conduit is made of galvanized steel. The steel is coated with a layer of zinc, providing excellent corrosion resistance and durability.

3. Where is IMC electrical conduit commonly used?

IMC electrical conduit is commonly used in various applications, including commercial buildings, industrial facilities, infrastructure projects, data centers, hospitals, educational institutions, and retail spaces.

4. How does IMC conduit differ from other types of conduits?

IMC conduit differs from other types of conduits in terms of thickness and flexibility. It is thicker and more robust than Electrical Metallic Tubing (EMT) but more flexible than Rigid Metal Conduit (RMC).

Read more: How To Glue Electrical Conduit

5. Can IMC conduit be used for outdoor installations?

Yes, IMC conduit is suitable for both indoor and outdoor installations. Its galvanized steel construction provides excellent durability and corrosion resistance, making it suitable for various environmental conditions.

6. Can IMC conduit be bent?

Yes, IMC conduit can be bent using a conduit bender to accommodate corners and offsets. However, it is less flexible than Electrical Metallic Tubing (EMT), so care should be taken to prevent excessive bending or kinking.

7. How is IMC conduit installed?

IMC conduit is installed by cutting it to the desired lengths, threading the ends if necessary, and connecting the sections using appropriate connectors and couplings. The conduit is then secured using straps and hangers to ensure stability.

8. Is grounding necessary for IMC conduit?

Yes, grounding is necessary for IMC conduit. Proper grounding helps to ensure electrical safety by allowing for the safe dissipation of electrical charges and protecting against electrical faults or surges.

If you have any further questions or inquiries about IMC electrical conduit, it is recommended to consult with a qualified electrician or professional electrical contractor.

Conclusion

Choosing IMC Electrical Conduit for Optimal Wiring Protection

In conclusion, IMC electrical conduit stands as a reliable and versatile solution for protecting and routing electrical wiring in various applications. Its galvanized steel construction offers exceptional durability and corrosion resistance, ensuring the longevity and efficiency of the wiring system.

The intermediate thickness of IMC conduit strikes a balance between strength and flexibility, making it easier to install compared to rigid metal conduit (RMC) while providing better protection than Electrical Metallic Tubing (EMT). This makes IMC conduit suitable for a wide range of projects in commercial buildings, industrial facilities, infrastructure sites, data centers, healthcare facilities, and more.

The smooth interior surface of IMC conduit allows for easy wire pulling, and its threaded ends facilitate secure connections with electrical fittings. IMC conduit is compatible with various accessories, enabling seamless integration into existing electrical systems.

Regular maintenance, including inspections, cleaning, and addressing any issues promptly, ensures optimal performance and safety. It is important to adhere to electrical codes and consult professionals when needed, especially during troubleshooting or complex installations.

When it comes to selecting the right conduit for your wiring needs, consider the specific requirements of your project, including the level of physical protection, flexibility, and installation constraints. Consulting with electrical professionals or code officials can help you make an informed decision.

In summary, IMC electrical conduit offers an effective and reliable solution for protecting and routing electrical wiring in various applications. Its durability, versatility, and ease of installation make it a popular choice for professionals in the electrical industry.

Frequently Asked Questions about What Is An IMC Electrical Conduit

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Is An IMC Electrical Conduit”