Home>Furniture & Design>Interior Design Trends>How To Bend Glass

Interior Design Trends

How To Bend Glass

Modified: October 18, 2024

Discover the latest interior design trends with our guide on how to bend glass, adding a modern touch to any space. Explore innovative techniques and ideas for incorporating this trend into your home.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

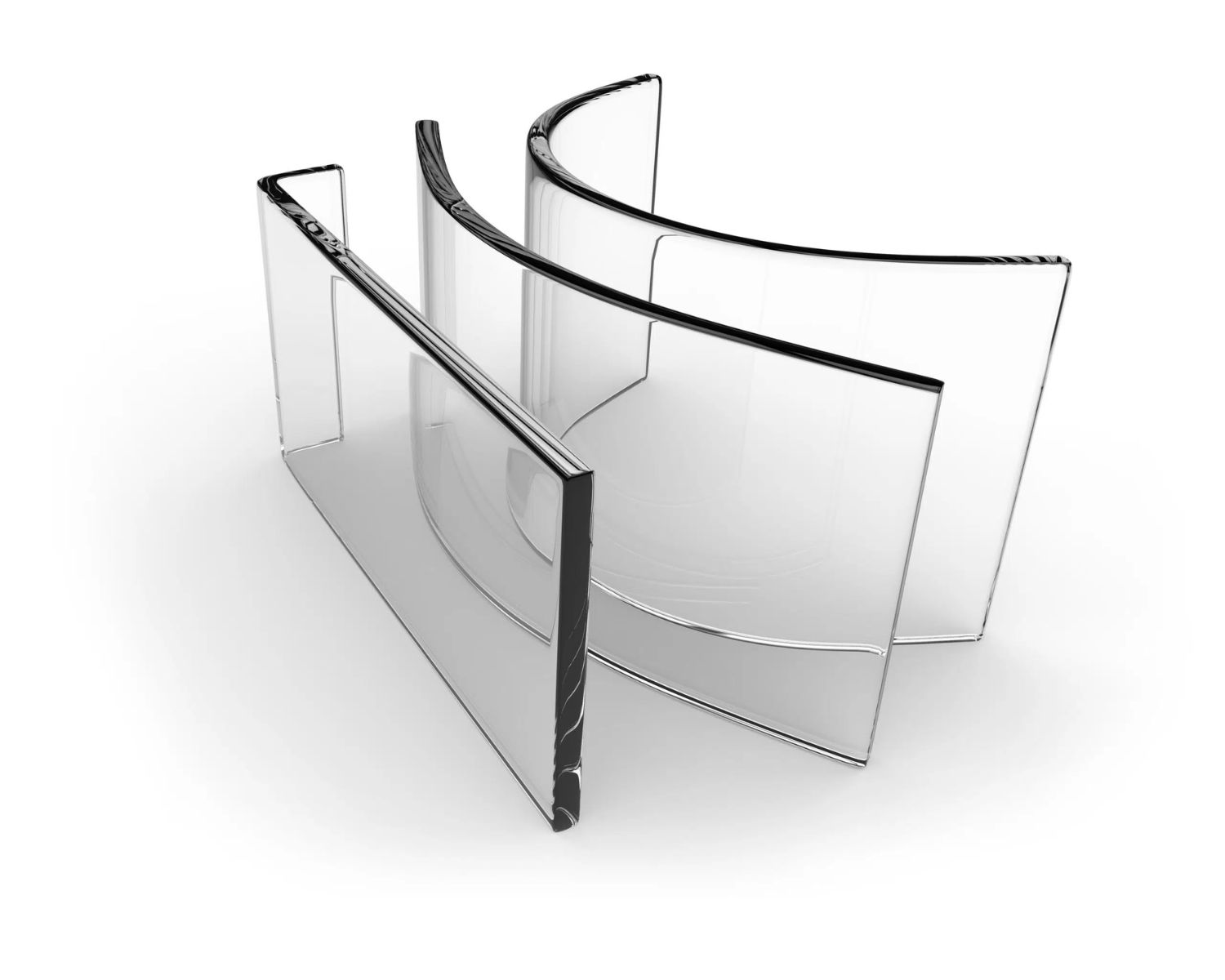

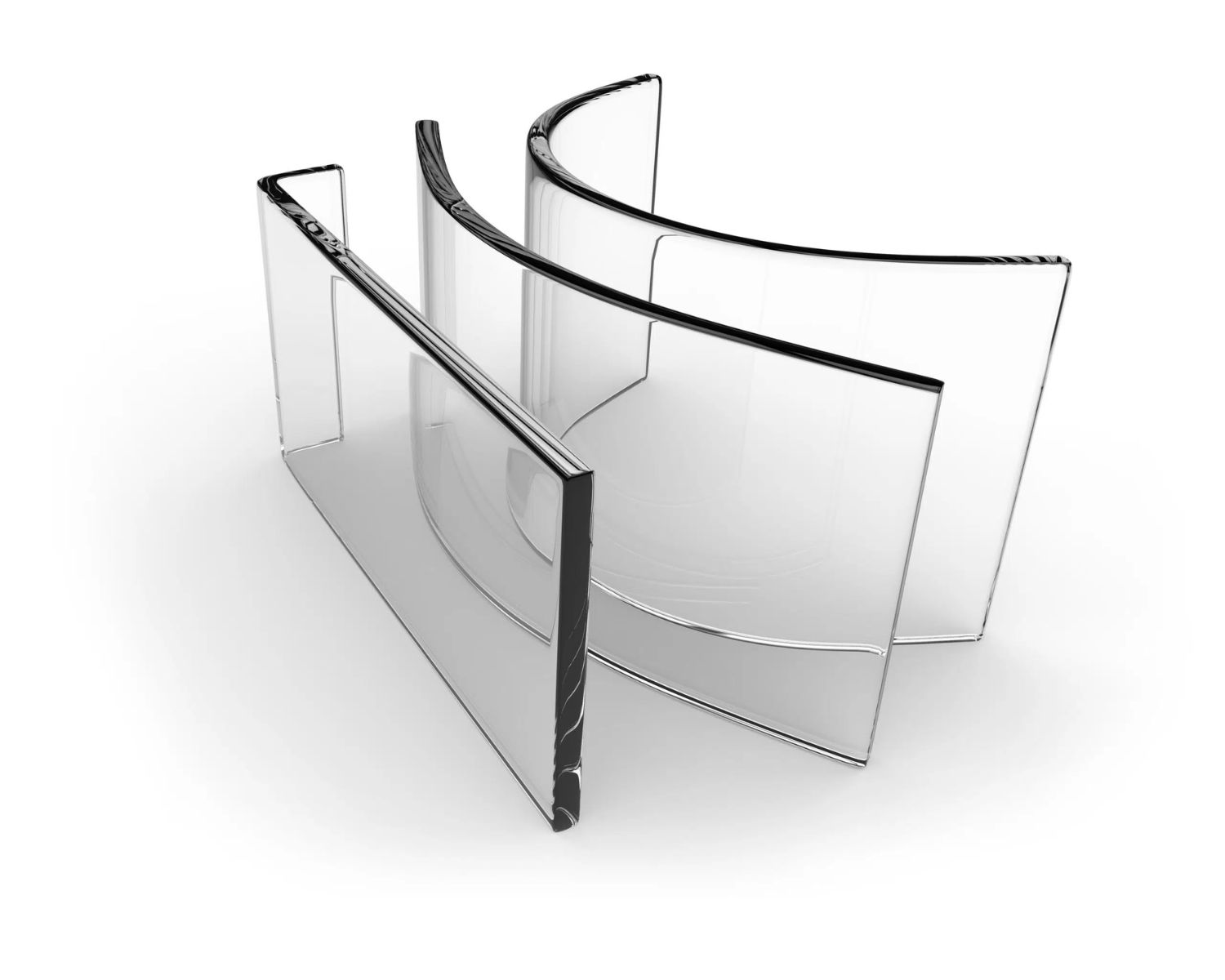

Bending glass is a fascinating and intricate process that allows for the creation of stunning and unique glass pieces. Whether you are a professional glass artist or a DIY enthusiast, mastering the art of bending glass can open up a world of creative possibilities. From crafting custom glass furniture to designing one-of-a-kind architectural elements, the ability to bend glass empowers individuals to bring their artistic visions to life.

The process of bending glass requires a deep understanding of the material's properties and behavior under heat, as well as the utilization of specialized tools and techniques. By harnessing the transformative power of heat, glass can be molded and shaped into graceful curves and intricate forms, adding a touch of elegance and sophistication to any space.

In this comprehensive guide, we will delve into the art and science of bending glass, exploring the fundamental principles, tools, and methods involved in this captivating craft. Whether you are a novice eager to embark on your first glass-bending project or an experienced artisan seeking to refine your skills, this guide will equip you with the knowledge and insights needed to navigate the mesmerizing world of glass bending.

Join us on this illuminating journey as we unravel the secrets of working with glass, from understanding its unique properties to mastering the techniques that enable the transformation of flat sheets into gracefully curved masterpieces. Let's embark on this captivating exploration of glass bending, where creativity and craftsmanship converge to shape the extraordinary.

Key Takeaways:

- Bending glass is a captivating blend of artistry and precision, where heat and technique converge to shape stunning curved creations, showcasing the boundless creativity and technical prowess inherent in the craft.

- Understanding glass properties and meticulous preparation are crucial for successful glass bending. The transformative journey unfolds with controlled heating, gentle manipulation, and meticulous finishing, yielding enduring works of art and design.

Read more: How To Bend Composite Decking

Understanding the Properties of Glass

Glass, a material renowned for its transparency, durability, and versatility, possesses unique properties that make it an ideal medium for artistic expression and functional design. To effectively bend glass, it is essential to comprehend its fundamental characteristics and behavior under specific conditions.

Transparency and Light Transmission

One of the defining features of glass is its exceptional transparency, allowing light to pass through with minimal distortion. This property makes it an ideal choice for creating visually striking, light-infused designs. When bent, the way light interacts with the curved surface of the glass can produce captivating visual effects, adding depth and dimension to the finished piece.

Thermal Conductivity

Glass exhibits relatively low thermal conductivity, meaning it does not conduct heat as readily as metals or other materials. This property is crucial when bending glass, as it necessitates a controlled and gradual application of heat to achieve the desired curvature without causing thermal shock or structural damage.

Tensile Strength and Flexibility

While glass is rigid and brittle in its solid state, it can be manipulated into curved shapes when subjected to controlled heating and cooling processes. Understanding the tensile strength and flexibility of glass is essential for determining the optimal temperature and duration for the bending process, ensuring that the material retains its structural integrity while undergoing transformation.

Read more: How To Measure Conduit Bending

Annealing and Stress Relief

When glass is bent, internal stresses are induced within the material. Proper annealing, a process of controlled cooling, is essential to relieve these internal stresses and enhance the overall strength and stability of the bent glass. Failing to adequately anneal the glass can lead to structural weaknesses and potential breakage over time.

Chemical Composition and Compatibility

The chemical composition of glass, including the presence of various additives and impurities, can influence its behavior during the bending process. Different types of glass, such as soda-lime glass or borosilicate glass, exhibit distinct properties and responses to heat, necessitating tailored approaches for successful bending.

By comprehensively understanding these properties of glass, artisans and enthusiasts can navigate the intricacies of the bending process with precision and confidence, unlocking the potential to create captivating and enduring works of art and design.

Tools and Materials Needed

Bending glass requires a precise combination of specialized tools and materials to facilitate the controlled application of heat and the manipulation of the glass into graceful curves. Whether embarking on a small-scale project or a larger endeavor, having the right equipment at your disposal is essential for achieving successful and visually stunning results.

Tools

-

Glass Cutter: A high-quality glass cutter is indispensable for scoring and cutting glass sheets to the desired dimensions before the bending process. Tungsten carbide wheel cutters are commonly preferred for their durability and precision.

-

Glass Grinding Equipment: Grinding and smoothing the edges of the glass pieces is crucial for ensuring a seamless and safe bending process. Diamond-coated grinding tools and polishing pads are essential for achieving precise and smooth edges.

-

Heat Source: A reliable heat source, such as a specialized glass kiln or a heat-resistant gas torch, is essential for applying controlled heat to the glass. Kilns equipped with programmable temperature controls offer precise heat management, while gas torches provide flexibility for smaller-scale projects.

-

Molds and Forms: Depending on the desired curvature and shape, molds and forms made of refractory materials, such as ceramic or fiberboard, are utilized to support the glass during the bending process. These molds help achieve consistent and accurate curves.

-

Safety Gear: Working with glass and heat necessitates the use of protective gear, including heat-resistant gloves, safety goggles, and aprons, to ensure personal safety and minimize the risk of accidents.

Read more: How To Bend Formica Backsplash

Materials

-

Glass Sheets: High-quality glass sheets suitable for bending, such as soda-lime glass or borosilicate glass, are fundamental to the bending process. The thickness and composition of the glass sheets should align with the intended application and design requirements.

-

Release Agents: To prevent the glass from sticking to the molds during the bending process, non-reactive release agents, such as ceramic fiber paper or kiln wash, are applied to the molds to facilitate easy removal of the bent glass.

-

Annealing Kiln: An annealing kiln is essential for the controlled cooling of the bent glass, relieving internal stresses and enhancing its strength and durability. The kiln should be capable of gradual temperature reduction to prevent thermal shock.

-

Measuring and Marking Tools: Accurate measurements and markings are crucial for precise glass cutting and bending. Tools such as rulers, markers, and T-squares aid in achieving the desired dimensions and angles.

By assembling the necessary tools and materials, artisans and enthusiasts can embark on their glass-bending journey with confidence, equipped to navigate the intricate process of transforming flat glass sheets into captivating curved creations.

Preparing the Glass for Bending

Before embarking on the mesmerizing process of bending glass, meticulous preparation of the glass sheets is essential to ensure a seamless and successful bending experience. This preparatory phase encompasses several critical steps that lay the foundation for achieving precise and visually striking curved glass creations.

Cleaning and Inspection

The journey of glass bending commences with the thorough cleaning and inspection of the glass sheets. Any dust, debris, or contaminants on the surface of the glass can interfere with the bending process and compromise the quality of the final result. Therefore, meticulously cleaning the glass with a gentle glass cleaner and lint-free cloth is imperative. Subsequently, a meticulous inspection of the glass sheets is conducted to identify any imperfections, such as scratches, chips, or irregularities, that could impact the bending process. Ensuring that the glass sheets are pristine and free from defects is crucial for achieving flawless curved designs.

Measurement and Marking

Accurate measurement and marking of the glass sheets are pivotal for determining the precise dimensions and angles for cutting and bending. Utilizing measuring tools such as rulers, markers, and T-squares, artisans meticulously mark the glass sheets according to the desired curvature and design specifications. Whether creating gentle arcs or intricate bends, the precision of the measurements and markings directly influences the quality and integrity of the final bent glass pieces.

Read more: How To Bend An Electrical Conduit

Cutting and Edging

Once the glass sheets are meticulously measured and marked, the next step involves cutting the sheets to the intended dimensions. A high-quality glass cutter equipped with a tungsten carbide wheel is employed to score the glass along the marked lines, facilitating clean and precise cuts. Following the cutting process, the edges of the glass pieces are carefully ground and smoothed using diamond-coated grinding tools and polishing pads. This meticulous edging ensures that the glass is free from sharp edges and imperfections, preparing it for the subsequent bending process.

Application of Release Agents

To facilitate the smooth and effortless removal of the bent glass from the molds after the bending process, non-reactive release agents are applied to the molds. Common release agents include ceramic fiber paper and kiln wash, which prevent the glass from adhering to the molds during the application of heat. This crucial step ensures that the bent glass retains its shape and integrity when removed from the molds, contributing to the overall success of the glass-bending endeavor.

By meticulously preparing the glass for bending through thorough cleaning, precise measurement and marking, meticulous cutting and edging, and the application of release agents, artisans and enthusiasts set the stage for a seamless and rewarding glass-bending experience. This preparatory phase lays the groundwork for the transformative process of shaping flat glass sheets into captivating and gracefully curved masterpieces.

Bending the Glass

With the meticulously prepared glass sheets and the essential tools and materials at hand, the transformative process of bending glass unfolds, offering a captivating blend of artistry and precision. The art of bending glass involves the controlled application of heat to gradually soften the glass, allowing it to be shaped into graceful curves and intricate forms. This pivotal phase of the glass-bending journey requires a nuanced understanding of the material's behavior under heat and the utilization of specialized techniques to achieve the desired curvature.

The heat source, whether a specialized glass kiln or a heat-resistant gas torch, is carefully employed to apply controlled heat to the glass sheets. The temperature and duration of heating are meticulously regulated to ensure that the glass reaches the optimal softening point without encountering thermal shock or structural compromise. As the glass gradually heats up, its rigidity gives way to a malleable state, enabling artisans to carefully manipulate the glass into the desired curvature.

Depending on the complexity of the desired bend, molds and forms made of refractory materials come into play, providing essential support and shaping the glass as it undergoes the bending process. The glass sheets, carefully positioned on the molds, begin to yield to the gentle pressure applied, gracefully conforming to the contours of the molds. Whether crafting subtle arcs or bold bends, the process demands a delicate balance of patience and precision, as artisans monitor the glass's response to the heat and carefully guide it into the desired form.

Throughout the bending process, the interplay of heat, timing, and skilled manipulation converges to bring forth the captivating transformation of flat glass sheets into elegantly curved masterpieces. The visual spectacle of witnessing the glass yield to the shaping forces of heat and craftsmanship is a testament to the artistry and technical finesse inherent in the glass-bending process.

As the glass assumes its new curved form, the culmination of the bending process marks a pivotal juncture in the glass-bending journey, setting the stage for the subsequent cooling and finishing phases. The successful execution of the bending process hinges on the harmonious orchestration of heat, technique, and creative vision, laying the foundation for the realization of captivating and enduring bent glass creations.

In the next phase, the cooling and finishing of the bent glass, the transformative journey continues, culminating in the emergence of impeccably curved glass pieces that embody the fusion of artistry and technical mastery.

Cooling and Finishing the Bent Glass

The culmination of the glass-bending process heralds the transition to the critical phase of cooling and finishing the bent glass. This pivotal stage is characterized by meticulous attention to detail and the application of precise techniques to ensure the structural integrity, visual appeal, and enduring quality of the curved glass creations.

Upon completion of the bending process, the bent glass is carefully transferred to an annealing kiln, where controlled cooling is initiated. This gradual cooling process is essential for relieving internal stresses within the glass, enhancing its strength and durability. The annealing kiln, equipped with programmable temperature controls, facilitates a carefully orchestrated reduction in temperature, safeguarding the glass against thermal shock and ensuring uniform cooling. Proper annealing is paramount for mitigating the risk of structural weaknesses and potential breakage, ultimately contributing to the longevity of the bent glass pieces.

As the glass undergoes the annealing process, the transformation from a malleable state to a resilient and stable form takes place. The controlled cooling period allows the glass to acclimate to its new curved shape, consolidating its structural integrity and fortifying its resistance to external forces. This phase of gradual cooling is a testament to the meticulous craftsmanship and technical finesse involved in the glass-bending journey, underscoring the dedication to precision and quality.

Following the completion of the annealing process, the bent glass undergoes a comprehensive inspection to ensure that it meets the exacting standards of quality and visual appeal. Any imperfections or irregularities are meticulously addressed, and the edges of the glass are refined to achieve a flawless finish. Diamond-coated grinding tools and polishing pads are employed to meticulously smooth and refine the edges, enhancing the tactile and visual allure of the curved glass pieces.

The finishing touches, including the removal of any residual release agents and the application of protective coatings if desired, further elevate the aesthetic and functional attributes of the bent glass. The meticulous attention to detail and the pursuit of excellence in finishing contribute to the creation of captivating and enduring glass pieces that embody the seamless fusion of artistry and technical mastery.

In essence, the cooling and finishing phase represents the culmination of the glass-bending journey, where the transformative potential of heat and craftsmanship converges to yield impeccably curved glass creations. This phase epitomizes the harmonious interplay of artistry and precision, culminating in the emergence of captivating and enduring bent glass pieces that stand as testaments to the boundless creativity and technical prowess inherent in the art of glass bending.

Read more: How To Bend Plastic Electrical Conduit

Conclusion

The art of bending glass is a captivating fusion of creativity, technical finesse, and a profound understanding of the material's properties. From the initial stages of meticulous preparation to the transformative process of shaping flat glass sheets into gracefully curved masterpieces, the glass-bending journey embodies a harmonious interplay of artistry and precision.

As artisans and enthusiasts embark on this mesmerizing exploration of glass bending, they are propelled into a realm where the transformative potential of heat converges with the meticulous application of technique, yielding captivating and enduring curved glass creations. The journey unfolds with the meticulous cleaning, measurement, and cutting of the glass sheets, laying the foundation for the subsequent bending process. The controlled application of heat, the gentle manipulation of the glass, and the essential support provided by molds and forms culminate in the emergence of elegantly curved glass pieces that bear testament to the artistry and technical mastery inherent in the glass-bending craft.

The cooling and finishing phase represents the culmination of the glass-bending journey, where the meticulous orchestration of controlled cooling and the pursuit of excellence in finishing yield impeccably curved glass creations. The transformative potential of heat is harnessed to enhance the structural integrity and visual allure of the bent glass, resulting in enduring works of art and design that captivate the senses and inspire awe.

As the bent glass pieces emerge from the cooling and finishing phase, they stand as tangible expressions of the boundless creativity and technical prowess inherent in the art of glass bending. Each curved creation embodies the seamless fusion of artistry and precision, serving as a testament to the enduring allure and versatility of glass as a medium for artistic expression and functional design.

In conclusion, the art of bending glass transcends the boundaries of craftsmanship, inviting individuals to embark on a captivating journey where creativity and technical finesse converge to shape the extraordinary. Whether crafting custom glass furniture, designing architectural elements, or creating captivating art installations, the ability to bend glass empowers artisans and enthusiasts to bring their artistic visions to life, leaving an indelible mark on the world of art and design.

Frequently Asked Questions about How To Bend Glass

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Bend Glass”