Home>Furniture & Design>Interior Design Trends>How To Make Dichroic Glass

Interior Design Trends

How To Make Dichroic Glass

Modified: April 22, 2024

Learn how to make stunning dichroic glass for your interior design projects. Discover the latest interior design trends and create unique pieces for your space. Explore the art of dichroic glass today!

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

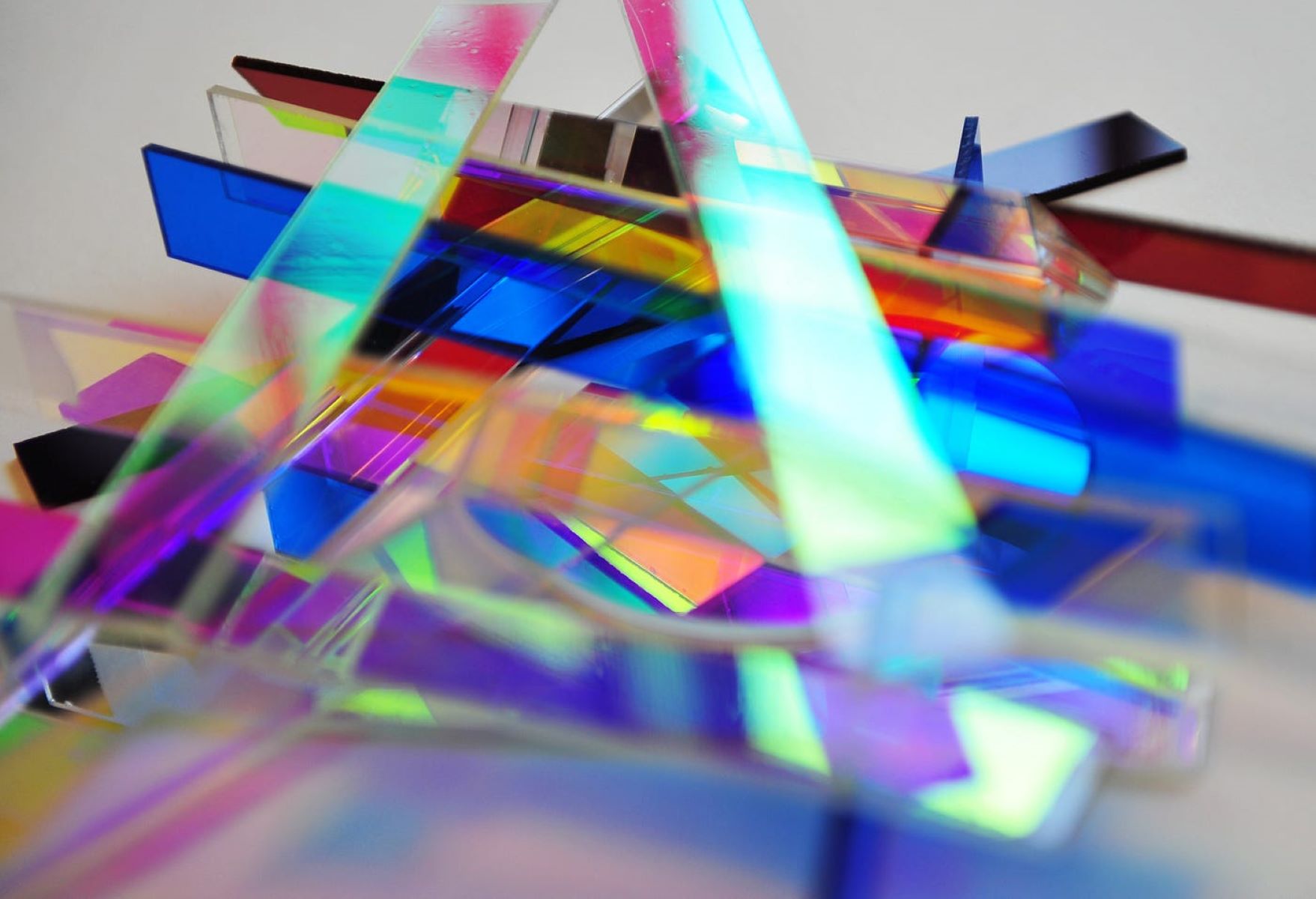

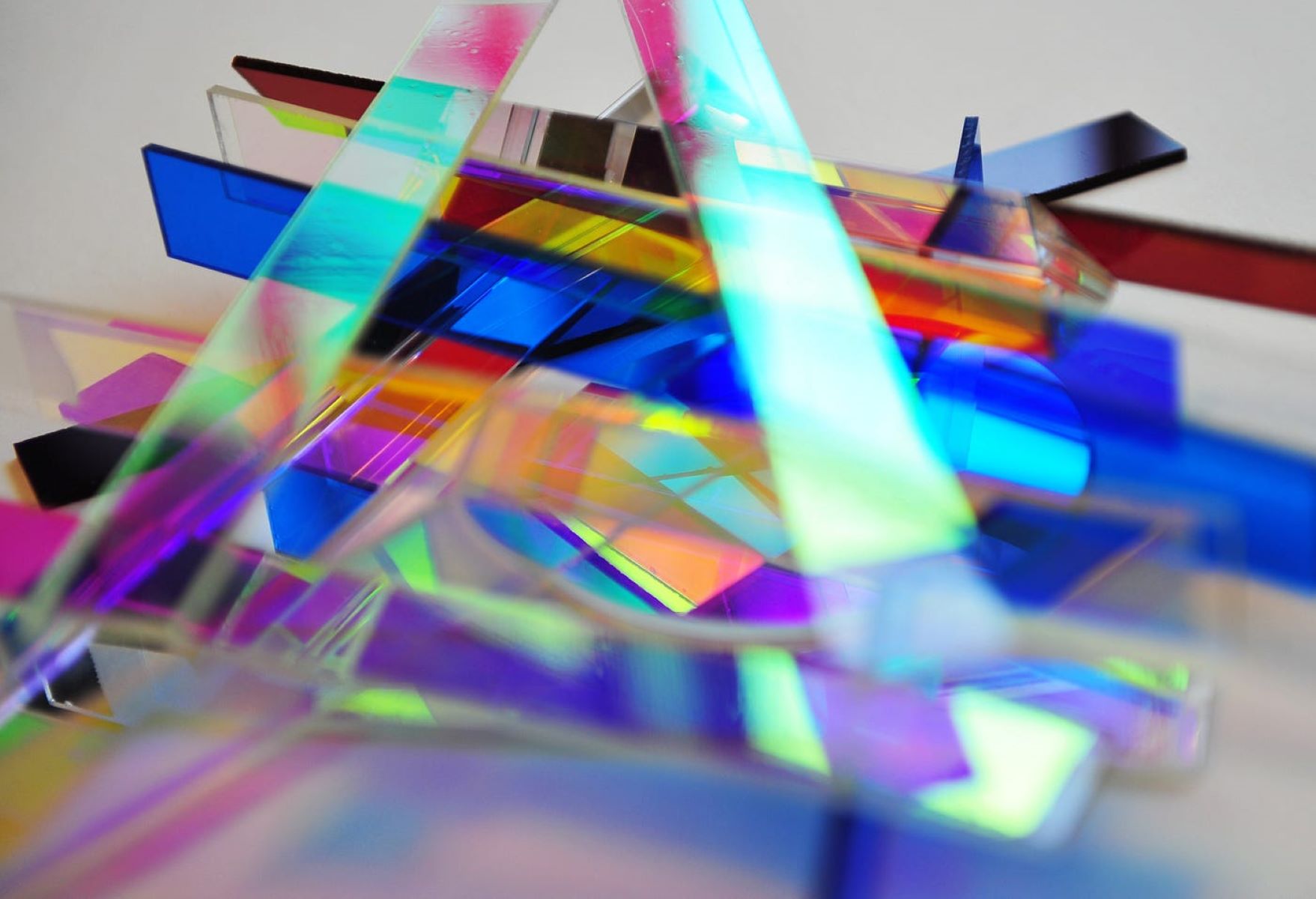

Dichroic glass has captivated artists and enthusiasts alike with its mesmerizing, iridescent beauty. This unique material, with its stunning array of colors and reflective properties, has become increasingly popular in the world of art and design. Whether you're a seasoned glass artist or a curious beginner, learning how to make dichroic glass can open up a world of creative possibilities.

The process of creating dichroic glass involves a delicate balance of artistry and precision. From selecting the right materials to mastering the intricate techniques, every step plays a crucial role in achieving the desired result. As you embark on this creative journey, you'll discover the magic of transforming ordinary glass into a dazzling display of color and light.

In this comprehensive guide, we'll delve into the fascinating world of dichroic glass and explore the materials and tools needed for this craft. We'll then walk through the step-by-step process of creating dichroic glass, from preparing the glass to firing and finishing the final piece. By the end of this guide, you'll have gained valuable insights into the art of making dichroic glass and be well-equipped to embark on your own creative endeavors.

Whether you're drawn to the radiant hues of dichroic glass jewelry, the shimmering accents in fused glass art, or the intricate details of dichroic glass sculptures, mastering the art of creating dichroic glass opens up a world of artistic expression. So, let's embark on this enchanting journey into the realm of dichroic glass and unlock the secrets to crafting these mesmerizing works of art.

Key Takeaways:

- Dive into the captivating world of dichroic glass, where art and science intertwine to create mesmerizing, color-shifting masterpieces that shimmer with iridescence and allure.

- Unleash your creativity and embark on a magical journey of crafting dichroic glass, from selecting materials to mastering the firing process, and witness the transformative power of light and color in your own radiant creations.

Read more: What Is Dichroic Glass

What is Dichroic Glass?

Dichroic glass, derived from the Greek word "dichroos" meaning "two-colored," is a mesmerizing and captivating material that exhibits a remarkable display of colors and light. This unique type of glass is renowned for its iridescent and reflective properties, making it a popular choice among artists, designers, and enthusiasts in the world of glass art.

At its core, dichroic glass is a type of art glass that contains multiple micro-layers of metal oxides, such as titanium, silicon, and magnesium, vaporized onto the surface of the glass in a vacuum chamber. These thin layers interact with light, causing a stunning array of colors to emerge as the angle of view or illumination changes. The result is a visually striking display of vibrant hues, metallic sheens, and captivating reflections that seem to shift and dance with the surrounding environment.

Dichroic glass is renowned for its versatility and can be used in a wide range of artistic applications, including jewelry making, fused glass art, sculpture, and architectural installations. Its ability to refract and reflect light in a dynamic manner makes it a popular choice for creating eye-catching pieces that exude a sense of depth, movement, and luminosity.

One of the most intriguing aspects of dichroic glass is its chameleon-like nature, as it can appear to change color depending on the angle of view and the surrounding lighting conditions. This dynamic quality adds an element of surprise and wonder to dichroic glass creations, captivating the viewer with its ever-shifting hues and luminous effects.

In essence, dichroic glass represents a harmonious fusion of art and science, where the interplay of light and materials gives rise to a visual symphony of colors and reflections. Its unique properties and captivating allure have made it a sought-after medium for artists and designers seeking to imbue their creations with a sense of enchantment and wonder.

As we delve deeper into the world of dichroic glass, we'll explore the materials and techniques involved in creating these mesmerizing works of art, unlocking the secrets to harnessing the beauty and magic of dichroic glass in our creative endeavors.

Materials and Tools Needed

Creating dichroic glass requires a careful selection of materials and specialized tools to ensure the successful realization of vibrant and reflective glass pieces. Here's a detailed look at the essential components and equipment needed for this captivating craft:

Glass Sheets:

The foundation of dichroic glass art begins with high-quality glass sheets. It's essential to choose compatible glass that is specifically designed for fusing and can withstand the thermal stresses of the firing process. Clear and colored glass sheets serve as the canvas for the dichroic coatings, allowing the interplay of light and color to come to life.

Dichroic Coatings:

Dichroic coatings, consisting of ultra-thin layers of metal oxides, are the key to achieving the mesmerizing color-shifting effects characteristic of dichroic glass. These coatings are available in a diverse range of hues and textures, allowing artists to unleash their creativity and experiment with different combinations to achieve stunning visual effects.

Read more: What Does Dichroic Glass Mean

Kiln:

A kiln serves as the heart of the dichroic glass creation process, providing the controlled heat necessary for fusing the glass layers and dichroic coatings together. It's crucial to use a kiln equipped with precise temperature control and programmable firing schedules to ensure consistent and reliable results.

Glass Cutter:

A glass cutter is an indispensable tool for shaping and cutting glass sheets to the desired dimensions. Precision cutting is essential for creating intricate designs and ensuring a seamless fit between the glass layers during the fusing process.

Safety Gear:

Working with glass and kiln-fired materials requires the use of appropriate safety gear, including safety glasses, heat-resistant gloves, and a well-ventilated workspace. Prioritizing safety measures is essential to prevent accidents and ensure a secure working environment.

Firing Tools:

Various firing tools, such as kiln shelves, kiln wash, and fiber paper, are essential for preparing the kiln and creating a suitable firing environment for the glass and dichroic coatings. These tools help prevent glass from sticking to the kiln shelves and ensure smooth firing processes.

Read more: How To Make Glass Ornament

Cleaning Supplies:

After the firing process, cleaning supplies such as glass cleaner, lint-free cloths, and polishing materials are necessary for removing any residue and achieving a pristine finish on the dichroic glass pieces.

By assembling these materials and tools, artists and enthusiasts can embark on the captivating journey of creating dichroic glass art, unlocking the potential to craft stunning pieces that shimmer with iridescence and allure.

Steps to Make Dichroic Glass

-

Prepare the Glass Sheets: Begin by selecting and cutting the glass sheets to the desired dimensions using a glass cutter. Ensure that the glass pieces are clean and free from any debris or contaminants that could affect the fusing process.

-

Apply Dichroic Coatings: Carefully select the desired dichroic coatings and apply them to the surface of the glass sheets. This process involves arranging and layering the dichroic materials to create captivating patterns and color combinations. Precision and attention to detail are crucial for achieving stunning visual effects.

-

Assemble the Glass Layers: Arrange the dichroic-coated glass layers to create the desired design or composition. Pay close attention to the alignment and placement of the glass pieces to ensure a seamless fusion of colors and textures during the firing process.

-

Load the Kiln: Place the assembled glass layers onto kiln shelves, ensuring that they are properly supported and positioned for the firing process. It's essential to follow recommended kiln loading practices to prevent glass pieces from shifting or fusing together unintentionally.

-

Program the Firing Schedule: Utilize the kiln's programmable features to set a precise firing schedule tailored to the specific requirements of the dichroic glass pieces. This includes gradually ramping up the temperature, holding at critical stages for heat absorption, and carefully controlling the cooling process to avoid thermal shock.

-

Monitor the Firing Process: During the firing cycle, closely monitor the kiln to ensure that the glass reaches the desired temperature and undergoes the fusing process as intended. Maintaining a consistent firing environment is essential for achieving optimal results and preserving the integrity of the dichroic coatings.

-

Cooling and Annealing: Once the firing cycle is complete, allow the kiln to gradually cool to room temperature to anneal the glass. This controlled cooling process helps relieve internal stresses and strengthens the glass, reducing the risk of cracking or breakage.

-

Inspect and Clean the Glass: Carefully inspect the finished dichroic glass pieces for any imperfections or irregularities. Use glass cleaner and lint-free cloths to remove any residue and achieve a pristine, reflective surface that showcases the vibrant colors and shimmering effects of the dichroic coatings.

By following these meticulous steps, artists and enthusiasts can unlock the transformative process of creating dichroic glass, harnessing the interplay of light and materials to craft captivating works of art that radiate with iridescence and allure.

Firing and Finishing

The culmination of the dichroic glass creation process lies in the pivotal stages of firing and finishing, where the transformative magic unfolds, bringing the vibrant hues and reflective properties of dichroic glass to life. This critical phase requires precision, patience, and a keen eye for detail to ensure that the dichroic coatings fuse seamlessly with the glass layers, resulting in stunning, iridescent masterpieces.

Firing Process

As the assembled glass layers adorned with dichroic coatings are carefully positioned within the kiln, the firing process commences, setting the stage for the intricate dance of heat and materials. The kiln, a vessel of controlled transformation, gradually elevates the temperature, allowing the glass and dichroic coatings to meld together in a symphony of color and light. The precise firing schedule, meticulously programmed to accommodate the unique characteristics of dichroic glass, plays a pivotal role in dictating the outcome of the fusion process. The gradual ramping up of temperature, strategic holds at critical stages, and the controlled cooling phase are all orchestrated to coax out the full potential of the dichroic materials, ensuring that the resulting glass pieces shimmer with captivating iridescence.

Read more: How To Make Sugar Glass

Annealing and Cooling

Following the completion of the firing cycle, the glass undergoes a crucial phase of annealing, where it is allowed to gradually cool within the kiln. This controlled cooling process is essential for relieving internal stresses within the glass, fortifying its structural integrity, and mitigating the risk of potential fractures or breakage. The meticulous balance of heat and time during the annealing process bestows resilience upon the dichroic glass, ensuring that it emerges from the kiln with strength and durability, ready to captivate and endure.

Finishing Touches

Once the dichroic glass pieces have undergone the transformative journey within the kiln, they emerge as radiant, iridescent creations awaiting the final touches. Careful inspection reveals the mesmerizing interplay of colors and reflections, as artists and enthusiasts meticulously examine each piece for perfection. Any residual traces are delicately removed, and the glass is polished to a lustrous sheen, allowing the vibrant hues and shimmering effects of the dichroic coatings to take center stage. The finishing touches serve to elevate the dichroic glass to its full potential, ensuring that each piece embodies the captivating allure and enchanting beauty that defines this extraordinary art form.

In the realm of dichroic glass, the firing and finishing stages represent the culmination of meticulous craftsmanship and artistic vision, where the alchemy of heat and materials converges to create works of art that mesmerize and inspire. Through the careful orchestration of these transformative processes, artists and enthusiasts breathe life into dichroic glass, unveiling its radiant splendor and timeless allure.

Conclusion

In conclusion, the art of creating dichroic glass is a captivating journey that intertwines artistic expression with scientific precision. From the selection of high-quality glass sheets to the meticulous application of dichroic coatings, each step in the process contributes to the mesmerizing allure and iridescent beauty of dichroic glass creations.

As artists and enthusiasts embark on this enchanting endeavor, they delve into a world where light and color converge to form a symphony of visual delight. The transformative power of the kiln, carefully orchestrated firing schedules, and the delicate balance of annealing and cooling all play a pivotal role in shaping dichroic glass into radiant, iridescent masterpieces.

The allure of dichroic glass lies in its chameleon-like nature, where colors shift and dance with the surrounding environment, captivating the viewer with their ever-changing hues and luminous effects. Whether adorning jewelry, enhancing fused glass art, or sculpted into intricate forms, dichroic glass stands as a testament to the harmonious fusion of artistry and scientific ingenuity.

As the final polishing touches reveal the vibrant hues and shimmering reflections of the dichroic coatings, each piece of dichroic glass emerges as a testament to the transformative power of creativity and craftsmanship. The finished creations serve as beacons of enchantment, inviting viewers to immerse themselves in the captivating world of dichroic glass, where every angle reveals a new facet of its iridescent splendor.

In the realm of art and design, dichroic glass stands as a testament to the boundless possibilities that arise when creativity and innovation converge. Its ability to captivate and inspire serves as a testament to the enduring allure of this extraordinary medium, inviting artists and enthusiasts to continue exploring the depths of its luminous beauty.

As we conclude this exploration into the art of making dichroic glass, we are reminded of the transformative power of creativity and the enduring allure of materials that captivate the imagination. With each radiant creation, dichroic glass invites us to embrace the enchanting dance of light and color, unlocking a world of artistic expression that shimmers with iridescence and timeless allure.

Frequently Asked Questions about How To Make Dichroic Glass

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “How To Make Dichroic Glass”