Home>Renovation & DIY>Tools & Equipment>What Grit Sandpaper To Use Before Staining

Tools & Equipment

What Grit Sandpaper To Use Before Staining

Published: December 20, 2023

Find the right grit sandpaper for pre-staining preparation with our comprehensive guide. Choose the best tools and equipment for a flawless finish.

(Many of the links in this article redirect to a specific reviewed product. Your purchase of these products through affiliate links helps to generate commission for Storables.com, at no extra cost. Learn more)

Introduction

When it comes to staining wood, achieving a smooth and flawless finish is a top priority. One crucial step in this process is sanding the wood before applying the stain. Sanding not only smoothens the surface but also opens up the wood pores, allowing the stain to penetrate evenly. However, choosing the right grit sandpaper and employing the correct sanding technique are essential for optimal results.

In this comprehensive guide, we will delve into the world of grit sandpaper and its pivotal role in the pre-staining process. Whether you are a seasoned woodworker or a passionate DIY enthusiast, understanding the nuances of grit sandpaper and its application will elevate your staining endeavors to new heights. So, let's embark on this journey to unravel the mysteries of grit sandpaper and unveil the secrets to achieving a flawless wood staining finish.

Key Takeaways:

- Choose the right grit sandpaper based on wood condition and species for a flawless finish. Start with a coarser grit for imperfections and transition to finer grits for smoothness.

- Employ consistent pressure, work with the wood grain, and use sanding blocks for effective sanding technique. Patience and precision are key for a professional-quality finish.

Read more: What Grit Sandpaper To Use Before Painting

Understanding Grit Sandpaper

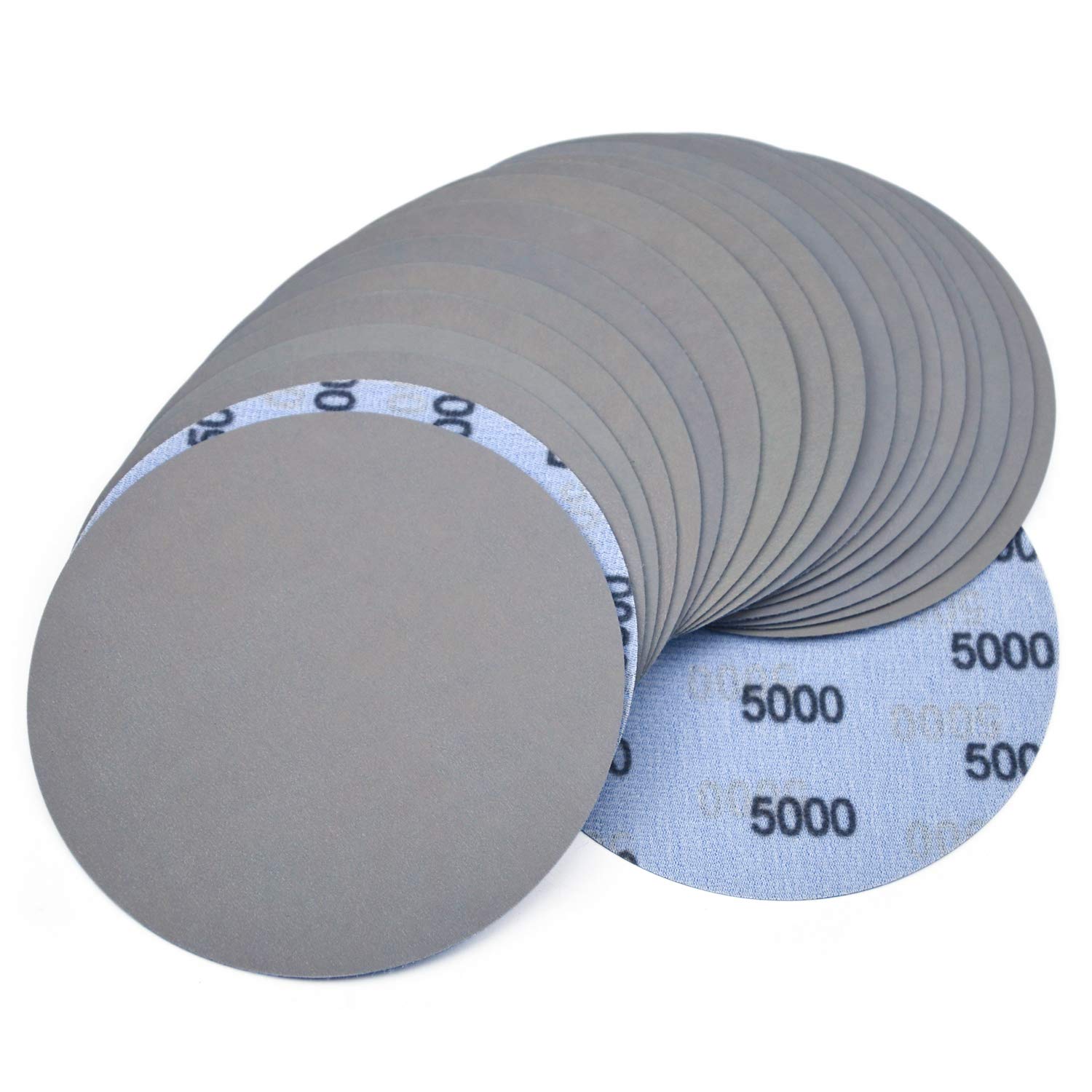

Before delving into the specifics of sanding for staining, it’s essential to comprehend the concept of grit sandpaper. Grit refers to the number of abrasive particles per square inch of the sandpaper. The higher the grit number, the finer the sandpaper. For example, 80-grit sandpaper is coarser and more abrasive than 220-grit sandpaper.

Common grit ranges include coarse (40-60 grit), medium (80-120 grit), fine (150-180 grit), and very fine (220-240 grit). Each type serves a distinct purpose in the sanding process. Coarse grit is ideal for removing rough surfaces and imperfections, while fine grit is used for smoothing and preparing the wood for staining.

Understanding the characteristics of different grit sandpapers is crucial for achieving the desired finish. Coarse grit sandpaper can leave deep scratches, which may not be visible after staining, but can affect the overall smoothness of the surface. On the other hand, using fine grit sandpaper directly after coarse grit may not effectively remove the scratches left by the coarser grit.

Moreover, the type of wood being sanded also influences the choice of grit. Softer woods, such as pine, require a different sanding approach compared to hardwoods like oak or maple. This is due to the varying densities and grain patterns of different wood species.

By grasping the nuances of grit sandpaper and its impact on different wood surfaces, you can make informed decisions when preparing wood for staining. This knowledge forms the foundation for achieving a professional-quality finish that enhances the natural beauty of the wood.

Pre-Stain Sanding Tips

Before diving into the sanding process, it’s important to prepare the wood for optimal results. Here are some essential pre-stain sanding tips to consider:

- Inspect the Wood: Before sanding, carefully inspect the wood surface for any imperfections, rough patches, or existing finishes. Address any issues that may affect the staining process.

- Clean the Surface: Remove any dust, dirt, or debris from the wood using a tack cloth or a damp cloth. A clean surface ensures that the sanding process is effective and prevents particles from becoming trapped in the wood pores.

- Choose the Right Grit: Select the appropriate grit sandpaper based on the condition of the wood. Coarse grit is suitable for rough surfaces, while fine grit is ideal for smoothing and preparing the wood for staining.

- Work with the Grain: Always sand in the direction of the wood grain to avoid creating visible scratches that may be accentuated after staining.

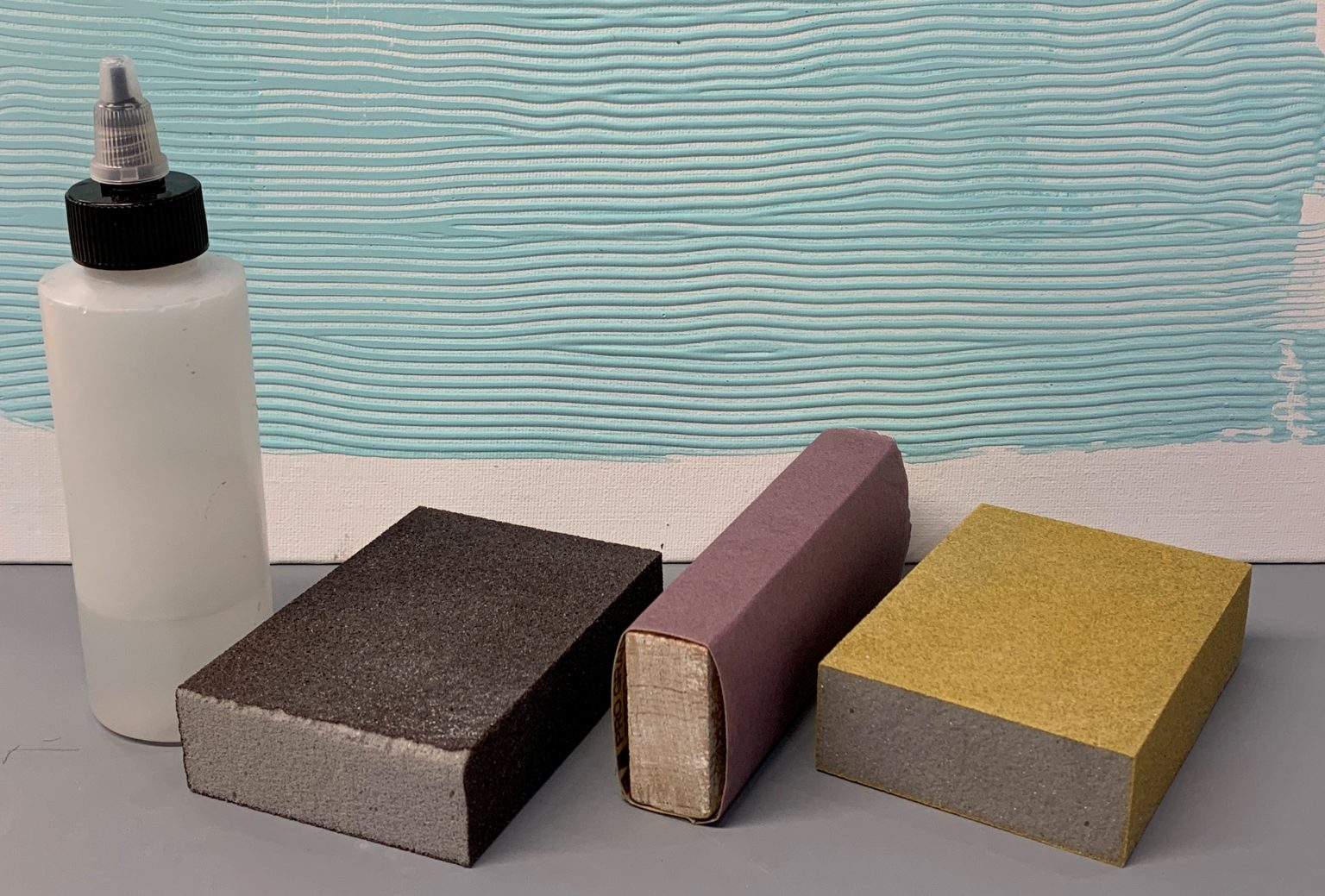

- Use a Sanding Block: Employing a sanding block or a sanding sponge helps maintain a consistent pressure and prevents uneven sanding, resulting in a more uniform surface.

- Progressive Sanding: Begin with a coarser grit to address any imperfections or rough areas, and gradually move to finer grits for smoothing. This progressive approach ensures a seamless transition to the staining phase.

- Inspect and Feel the Surface: After sanding, visually inspect and run your hand over the wood surface to ensure it is smooth and free of any blemishes. Address any remaining imperfections before proceeding to the staining stage.

By adhering to these pre-stain sanding tips, you can lay the groundwork for a successful staining process. Effective preparation and attention to detail during the sanding phase significantly contribute to the overall quality of the final stained wood finish.

Use 120-150 grit sandpaper to sand wood before staining. This will smooth the surface and allow the stain to penetrate evenly. Sand in the direction of the wood grain for best results.

Choosing the Right Grit Sandpaper

When it comes to selecting the appropriate grit sandpaper for pre-staining wood, understanding the characteristics of different grits and their applications is paramount. The choice of grit directly impacts the smoothness and readiness of the wood surface for staining. Here’s a guide to help you choose the right grit sandpaper:

- Assess the Wood Condition: Evaluate the condition of the wood to determine the level of sanding required. Rough or uneven surfaces may necessitate starting with a coarser grit, while smoother surfaces may only require fine grit sanding.

- Consider the Wood Species: Different wood species have varying hardness and grain patterns. Softwoods like pine may require a different sanding approach compared to hardwoods such as oak or maple. Adjust the grit selection based on the specific characteristics of the wood.

- Address Imperfections: For surfaces with visible imperfections, start with a coarser grit, such as 80 or 100, to remove rough spots, scratches, or existing finishes. This initial sanding stage prepares the wood for subsequent finer grits.

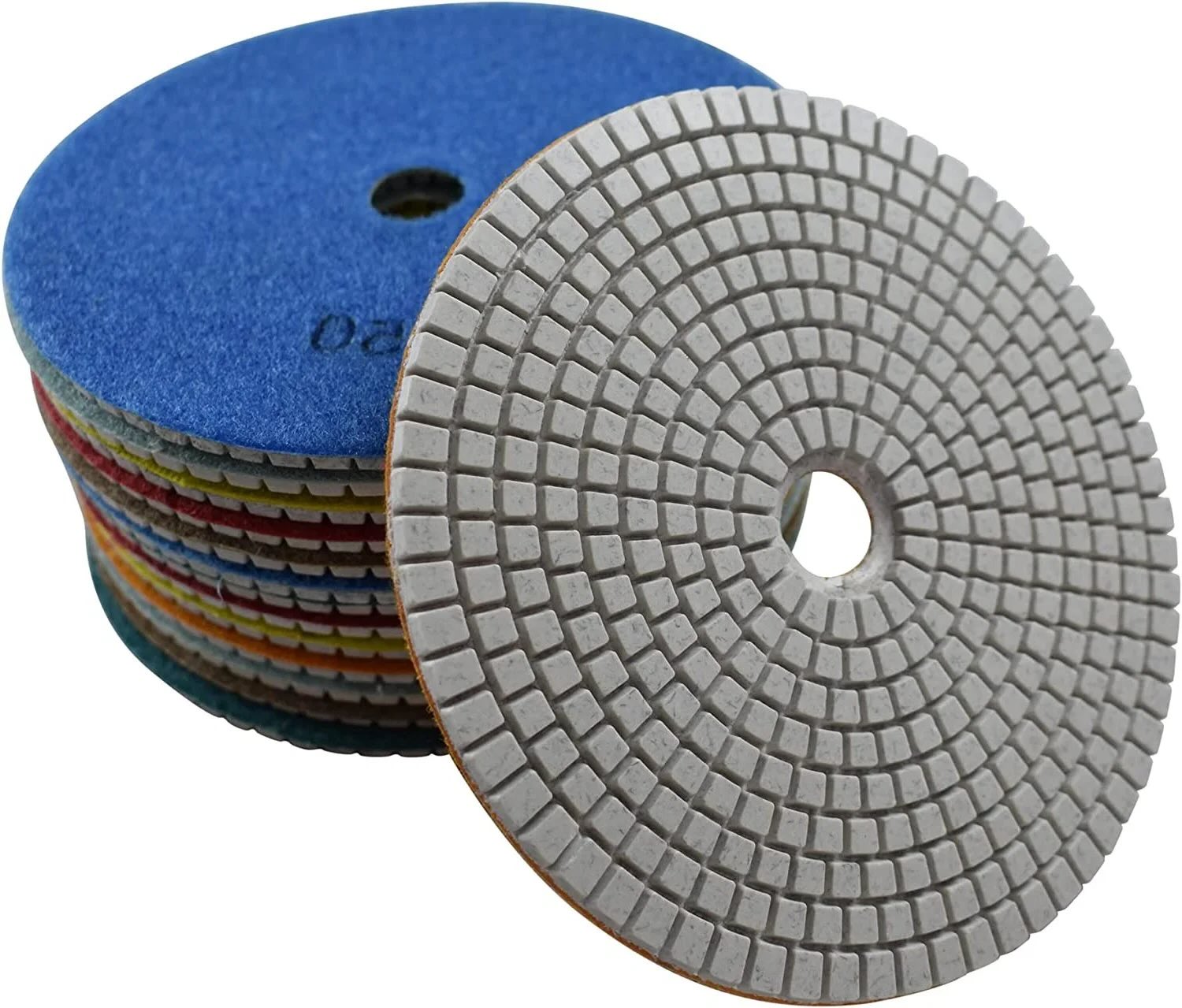

- Progressive Sanding: Gradually transition from coarser to finer grits to achieve a smooth and uniform surface. After the initial sanding with coarse grit, move on to medium grit (120-150) and then to fine grit (180-220) for the final preparation before staining.

- Test on Scrap Wood: If unsure about the appropriate grit, conduct a test on a scrap piece of the same wood to determine the most effective grit for achieving the desired smoothness without causing damage.

- Adapt to the Project: The scale and intricacy of the project may influence the grit selection. Larger surfaces may benefit from starting with a slightly coarser grit to expedite the initial sanding, while smaller, detailed areas may require a finer grit for precision.

By considering these factors and tailoring the grit selection to the specific characteristics of the wood and the project at hand, you can ensure that the sanding process effectively prepares the wood for a flawless staining application. Choosing the right grit sandpaper is a critical step towards achieving professional-quality results.

Sanding Technique

Mastering the art of sanding is essential for preparing wood surfaces before staining. The technique employed during the sanding process greatly influences the final outcome. Here are key elements to consider for a successful sanding technique:

- Work with the Grain: Always sand in the direction of the wood grain to prevent visible scratches and ensure a smooth, uniform surface. Sanding against the grain can result in unsightly marks that become accentuated after staining.

- Consistent Pressure: Apply consistent pressure when sanding to achieve an even surface. Avoid exerting excessive force, as it may lead to uneven sanding and create low spots on the wood.

- Varying Grits: Transition smoothly from coarser to finer grits, ensuring that each grit effectively addresses the imperfections left by the previous grit. This progressive approach results in a seamlessly sanded surface ready for staining.

- Use Sanding Blocks or Sponges: Employing a sanding block or a sanding sponge helps maintain a consistent sanding pressure and prevents the formation of uneven surfaces. These tools also facilitate precise control over the sanding process.

- Inspect and Feel: Periodically inspect and run your hand over the sanded surface to detect any remaining imperfections. Address any rough patches or blemishes before proceeding to the staining phase.

- Remove Dust: After sanding with each grit, use a tack cloth or a vacuum to remove dust and debris from the wood surface. This ensures a clean, particle-free surface ready for staining.

- Patience and Precision: Take your time during the sanding process to achieve a flawlessly smooth surface. Rushing through the sanding phase may result in overlooked imperfections that become apparent after staining.

By incorporating these elements into your sanding technique, you can elevate the quality of the wood preparation process, setting the stage for a successful and visually appealing staining application. Attention to detail and precision during sanding significantly contribute to the overall professional finish of the stained wood.

Conclusion

As we conclude our exploration of grit sandpaper’s role in the pre-staining process, it is evident that the selection and application of the right grit are crucial for achieving a flawless wood finish. Understanding the nuances of grit sandpaper, from its abrasive characteristics to its impact on different wood surfaces, empowers craftsmen and DIY enthusiasts to embark on their staining endeavors with confidence and precision.

By comprehending the significance of grit selection, embracing effective sanding techniques, and adhering to pre-stain sanding tips, individuals can elevate their woodworking projects to new heights. The careful consideration of wood condition, species, and project scale in the grit selection process ensures that the sanding phase effectively prepares the wood for the transformative staining application.

Furthermore, the mastery of sanding techniques, including working with the wood grain, employing consistent pressure, and transitioning smoothly between grits, contributes to the creation of a smooth and uniform wood surface ready for the staining process. Patience, precision, and attention to detail during sanding lay the groundwork for a professional-quality finish that enhances the natural beauty of the wood.

As you embark on your next wood staining project, remember that the journey to a flawless finish begins with the careful consideration of grit sandpaper and the meticulous execution of the sanding process. Embrace the artistry of wood preparation, and let each stroke of the sandpaper bring you closer to unveiling the innate splendor of the wood through the transformative power of staining.

With the knowledge and insights gained from this guide, may your future staining endeavors be marked by precision, artistry, and the timeless allure of beautifully stained wood.

Frequently Asked Questions about What Grit Sandpaper To Use Before Staining

Was this page helpful?

At Storables.com, we guarantee accurate and reliable information. Our content, validated by Expert Board Contributors, is crafted following stringent Editorial Policies. We're committed to providing you with well-researched, expert-backed insights for all your informational needs.

0 thoughts on “What Grit Sandpaper To Use Before Staining”